Abstract

The effectiveness of a novel and low-cost adsorbent, iron-modified bamboo charcoal (BC-Fe), for arsenic removal from aqueous systems was evaluated in this study. The BC-Fe was synthesized by loading iron onto bamboo charcoal via soaking in a ferric salt solution. The BC-Fe possessed a porous structure with a surface area of 277.895 m2/g. The adsorption characteristics of arsenic onto BC-Fe were further investigated at various pHs, contact times, arsenic concentrations, and adsorbent doses in batch tests. The corresponding optimum equilibrium pH ranges for As(III) and As(V) removal were 4–5 and 3–4, respectively. The equilibrium times for As(III) and As(V) adsorption were 30 and 35.5 h, respectively. The arsenic removal was strongly dependent on the initial adsorbate concentration and adsorbent dosage. The maximum arsenic removal capacities of BC-Fe under the experimental conditions were 7.237 and 19.771 mg/g for As(III) and As(V), respectively. The pseudo-second-order kinetic model and Freundlich isotherm explained the kinetic and equilibrium of both the As(III) and As(V) adsorbent processes, respectively. Based on these results, the BC-Fe developed in this study is a promising material for the treatment of arsenic-contaminated water.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Arsenic is a cancer causing element that is widely distributed in water systems due to natural processes and anthropogenic activities (Mandal and Suzuki 2002; Paige et al. 1996). In recent years, arsenic contamination in natural water resources has been reported in many countries worldwide (Nordstrom 2002; Mandal and Suzuki 2002). Consumption of arsenic-contaminated drinking water can cause damage to skin as well as the organs of the respiratory, digestive, circulatory, neural, and renal systems (Choong et al. 2007). Worldwide awareness of the arsenic crisis has motivated regulatory agencies to propose more stringent standards for arsenic in drinking water. For example, the WHO and USEPA have revised the standard for arsenic in drinking water from 0.05 to 0.01 mg/L (WHO 2004; EPA 2001). In addition, the government of China decided to reduce its permissible limit for As in drinking water from 0.05 to 0.01 mg/L in 2007 (China National Ministry of Health 1985, 2006) For these reasons, it is of great importance to remove arsenic from wastewater and contaminated drinking water effectively.

Among methods developed to remove the arsenic from contaminated water such as coagulation and flocculation, precipitation, ion exchange, and membrane filtration, adsorption is the most widely used because it is simple, cost-effective, and sludge-free. The effectiveness of adsorption primarily depends on the characteristics of the adsorbent; therefore, there has been considerable interest in identifying the proper adsorbents for arsenic removal. A wide range of materials including commercial materials and by-products from agriculture and industry have been employed in arsenic adsorption processes (Mohan and Pittman 2007). Iron oxides have a strong affinity to arsenic, but are mostly found in fine powdery forms, and it is difficult to separate them from water after adsorption. While, iron-loaded granular materials, which have a high arsenic adsorption capacity and enable easy water/solid separation, have been the focus of many recent studies. When compared to other substances used to support iron such as sand (Thirunavukkarasu et al. 2002), zeolite (Payne and Abdel-Fattah 2005), cement(Kundu and Gupta 2007), cellulose, and sponge (Nguyen et al. 2010; Guo and Chen 2005), activated carbon is preferred because its high surface area supplies more reactive sites for iron loading. Indeed, a number of studies have shown that iron-modified activated carbon has good arsenic adsorption properties (Mondal et al. 2008; Chen et al. 2007), but the relatively high cost of activated carbon may restrict its widespread use. Therefore, it is important to develop low-cost adsorbents with high adsorption capacity for arsenic removal from aqueous systems.

Bamboo charcoal is manufactured by the thermal decomposition of bamboo. Bamboo is a grass-like plant with high carbon content (44%; Chan et al. 2008) and is widely cultured in large amounts in the Asia-Pacific region. In China, the bamboo forest area is 4.84 million hm2 and is increasing at an average of 126,000 hm2 annually according to the statistics of the Sixth National Forest Resources Survey (Wang et al. 2009). The growth of bamboo is rapid (20–100 cm in 24 h; Liese 1987) and consumes little energy (0.5 MJ/kg compared to 0.8 MJ/kg for timber; Janssen 1981). Therefore, bamboo charcoal is about two to four times less expensive than activated carbon in China (Wang et al. 2009). Owing to its high surface area, large pore volume and low cost, bamboo charcoal has become a popular adsorbent for air and water purification in recent years (Horikawa et al. 2010; Asada et al. 2002). Indeed, bamboo charcoal has excellent adsorption properties for nitrate-nitrogen (Mizuta et al. 2004), heavy metals (Lalhruaitluanga et al. 2010; Wang et al. 2009), dyes (Chan et al. 2008), and some other organic pollutants (Zhang et al. 2009). However, research on this novel, low-cost adsorbent is still limited. Additionally, few studies have been conducted to evaluate the use of raw or modified bamboo charcoal for arsenic uptake from aqueous solutions.

A preliminary study revealed that the arsenic adsorption capacity of raw bamboo charcoal is minimal, indicating that it is not useful for arsenic treatment. However, previous studies have shown that the arsenic adsorption ability of activated carbon can be increased significantly when it is pretreated with various iron compounds (Hung and Vane 1989; Mondal et al. 2008). Because bamboo charcoal has a large surface area similar to that of activated carbon, it may be a good agent for loading and supporting iron, which could enhance its arsenic adsorption capacity.

This study was conducted to develop a novel and low-cost adsorbent, iron-modified bamboo charcoal (BC-Fe) and assess the arsenic adsorption potential of this new adsorbent via batch tests.

2 Experimental

2.1 Materials

All chemicals were analytical grade and used as received. Stock solutions of arsenic containing 1,000 mg/L As(III) or As(V) were prepared by dissolving NaAsO2 or Na2HAsO4·7H2O in double distilled water. Working solutions of the desired concentrations were prepared by diluting the stock solution. The pH was adjusted using acid and base solutions (1 M HCl and 1 M NaOH). Bamboo charcoal was purchased from a bamboo manufacturer in Zhejiang, China. Prior to use, the bamboo charcoal was ground and sieved to a size of 63–125 μm. The powder of the bamboo charcoal was then boiled in double distilled water for 1 h to remove ash and any impurities from the pores. After boiling, the charcoal was dried at 100 ± 5°C for 24 h and then stored in desiccators.

2.2 Synthesis

The modifying process was conducted based on the method described by Huang (Hung and Vane 1989) and the method proposed by Yang (Yang et al. 2009). Briefly, the bamboo charcoal was added to NaOH solution with a concentration of 0.01 M, after which the mixture was shaken for 24 h. The bamboo charcoal was then washed with distilled water and filtered to remove residual OH– ions before being dried at 100 ± 5°C for 24 h. Next, 125 ml 0.1 M FeCl3 solution, adjusted to pH 2.5, was mixed with 10 g of the base washed bamboo charcoal. Finally, the mixtures were shaken for 24 h, washed and dried.

2.3 Analysis

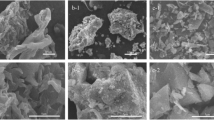

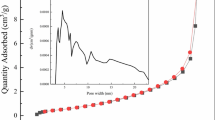

To examine the surface morphology of the adsorbent, scanning electron microscopy (SEM) imaging was conducted using a FEI Quanta 200 SEM (Oregon, USA). The surface area, micro pore volume and pore size of virgin bamboo charcoal and BC-Fe were determined by BET method using a Micrometrics ASAP 2000 system (Georgia, USA). The pH of the point of zero charge (pHpzc) was determined using the method described by Muñiz et al. (2009). The total iron loaded onto the bamboo charcoal was extracted using 50% (V/V) HCl according to the procedure proposed by Gu et al. (2005) and analyzed by the ferrozine spectrophotometric method (Stookey 1970). Quantitative determination of total arsenic was conducted using an AFS820 hydride generation atomic fluorescence spectrophotometer (Beijing Titan Instruments, China; Gu et al. 2005).

2.4 Batch Experiments

Batch experiments were conducted to investigate the effects of solution pH, arsenic concentration, BC-Fe dose and contact time on arsenic removal as well as to obtain data for isotherm and kinetic studies. All batch tests were conducted on a mechanical shaker in a room with a controlled temperature of 25 ± 2°C. Specifically, 10 ml of pH-adjusted arsenic solution with a concentration ranging from 2–38 mg/L and 0.01–0.15 g modified bamboo charcoal were added to a series of 50 ml capped polyethylene tubes. Those tubes were then placed on a shaker for 48 h, which was found to be sufficient to reach equilibrium in a preliminary study. At the desired time, samples were collected and filtered through a 0.45 μm filter membrane, after which the filtrate was collected to analyze the residual arsenic.

The removal percentage of arsenic (R%) and the amount of arsenic adsorbed per unit weight of adsorbent (mg/g) at time t(q t ) and at equilibrium (q e) were calculated from the following equations:

where C 0, C e, and C t (mg/L) are the arsenic concentrations in solution before adsorption, at equilibrium and at time t, respectively, and m (g/L) is the mass concentration of BC-Fe. Each experiment was conducted in duplicate and the results were reported using the mean value.

3 Results and Discussion

3.1 Characteristics of Adsorbent

3.1.1 Chemical and Physical Properties of the Adsorbent

The SEM images showing the surface morphology are shown in Fig. 1. The surface of both the raw bamboo charcoal and BC-Fe were highly porous, which provided a large surface area for iron loading and arsenic adsorption. The results of BET as well as the iron contents and pHpzc of raw bamboo charcoal and BC-Fe are presented in Table 1. When compared with raw bamboo charcoal, the iron content of BC-Fe increased to 7.76% and the specific surface area dropped by 4%. These changes were apparently due to iron impregnation. The pore volume and pore surface area of BC-Fe are lower than that of virgin bamboo charcoal. These findings indicate that iron occupies some internal pores of bamboo charcoal.

3.1.2 Iron Efficiency

Iron efficiency indicates the intrinsic efficiency of iron for arsenic removal and is an important parameter for evaluation of the method of iron preloading. The iron efficiency of BC-Fe for As(III) and As(V) at optimized pH ranged from 10.000 to 93.175 and from 25.209 to 254.548 mg(As)/g(Fe), respectively, depending on the initial arsenic concentration and adsorbent dose. Our results are comparable with the results of some other arsenic adsorption studies that were conducted using iron containing adsorbents, such as iron-modified activated carbon (Chen et al. 2007; Gu et al. 2005) and granular ferric hydroxide (Driehaus et al. 1998). These findings imply that bamboo charcoal is a good iron bearing material for arsenic adsorption. The iron efficiency is also an indicator of the availability of preloaded iron to arsenic ions in aqueous solution. According to previous studies (Chen et al. 2007; Muñiz et al. 2009), small and highly dispersed iron oxide-based particles lead to high iron efficiency, while large iron (hydr)oxides particles are not available to arsenic and can even prevent arsenic ions from diffusing toward the inner surface of the adsorbent, leading to low iron efficiency. The relatively high iron efficiency obtained in our experiments probably indicates that a fairly good dispersion of iron inside the bamboo charcoal was achieved via our iron preloading method.

3.2 Batch Tests

3.2.1 Effect of pH

The pH of the solution is an important parameter in the adsorption process. Since the arsenic solution was not buffered, the pH of the solution is expected to change during the adsorption process. The pH of the solution at equilibrium (pHfin) was also measured and summarized in Fig. 2. Generally, the change in pH was not significant for pHini < 5 or pHini > 12. However, pHfin was lower than pHini for 5 < pHini < 12. In order to investigate the reason for the pH change, experiments were conducted with BC-Fe in distilled water in pH range of 2.0–12.0 for 48 h contact. And the results are also presented in Fig. 2 and show the same trend as solutions containing arsenic. Clearly, the change in solution pH was mainly caused by release of H+ ions by the adsorbent. However, at relatively low and high pH, the released H+ ions may not be enough to affect the finial pH.

The arsenic adsorption capacity (q e) vs. pHfin is plotted in Fig. 3. As shown in it, pH influenced arsenite and arsenate adsorption differently, which has also been observed in other experiments (Lenoble et al. 2002; Hristovski et al. 2009). The effect of pH on As(III) removal was insignificant at pHfin values ranging from 2 to 9, with maximum removal being observed at pHfin 4–5 (pHini 7–8). However, a decrease in arsenic adsorption was observed when the pHfin was greater than 9. This is because the unchanged H3AsO3 was predominant at pH values below 9. Thus, the weak electrostatic effects between arsenite and the adsorbent resulted in favored arsenic adsorption. When the solution pH increased to 9, the negatively charged arsenite species (i.e. H2AsO −3 and HAsO 2−3 ) were predominate, whereas the adsorbent surface became negative according to the value of pHpzc. Thus, the decrease in As(III) uptake above pH 9 was due to electrostatic repulsion between the adsorbent and negatively charged arsenite species. Similar results were also obtained from arsenite adsorption by carbon-based adsorbents (Pattanayak et al. 2000), iron oxides (Lenoble et al. 2002), and iron-impregnated materials (Kundu and Gupta 2007).

As shown in Fig. 3, the pH had a stronger effect on As(V) adsorption than on As(III). It is clear that the As(V) adsorption capacity of BC-Fe decreased as pHfin increased from 4 to 13, with the maximum removal occurring at pHfin 3–4 (pHini 3–4). This is somewhat consistent with other reported results (Hristovski et al. 2009; Gu et al. 2005). Negatively charged arsenate species are dominant in a pH range of 2–12. As the pH increases, the surface potential of the adsorbent becomes less positive (pH below pHpzc) or more negative (pH above pHpzc). Thus, the weakening electrostatic attraction and increasing repulsion contribute to decreased As(V) adsorption.

It should be noted that under strong acid conditions (pHfin below 2), adsorption of both arsenic species was relatively low. This was attributed to the dissolution of impregnated iron under acidic conditions, which was confirmed by the finding that iron was detected in the solution after shaking for 24 h. Approximately 17.3% of the iron desorbed into the solution at pH 1.95; nevertheless, iron desorption was negligible at pHfin values greater than 2.

All further experiments for As(III) and As(V) adsorption were conducted at their corresponding optimum pHini (7–8 and 3–4, respectively).

3.2.2 Effect of Contact Time

The amount of arsenic adsorbed with different agitation times is plotted in Fig. 4. The results revealed that both As(V) and As(III) uptake could be divided into three phases. Specifically, the arsenic uptake was rapid in the first few hours (6.5 and 6 h for As(III) and As(V), respectively), with approximately 79.8% of the total As(V) and 44.5% of the total As(III) being removed. Conversely, the arsenic removal was slow in the following 23.5 and 29.5 h periods for As(III) and As(V), respectively, during which time only 9.0% of As(III) and 24.5% of As(V) were further removed. No significant change in the percentage of adsorbed arsenic was observed up to 30 and 35.5 h for As(III) and As(V), respectively, indicating that an equilibrium condition had been achieved. Thus, the corresponding equilibrium time for As(III) and As(V) were considered to be 30 and 35.5 h. This equilibrium time is comparable with previously reported results. For example, iron-modified activated carbon was found to require 20–72 h to show significant arsenic removal (Hristovski et al. 2009; Payne and Abdel-Fattah 2005; Hung and Vane 1989; Chen et al. 2007) and iron oxide-coated sponges were found to require 24 h for removal (Nguyen et al. 2010).

The change in adsorption rate during adsorption could be explained as follows. In the beginning of the reaction, a large number of free adsorption sites were available on the surface of the adsorbent. Arsenic irons instantly bonded with adsorption sites on the outer surface of BC-Fe. Therefore, a high adsorption rate was initially observed. After that, the active sites at the outer surface could readily bind with arsenic ions during the initial stage. Therefore, the arsenic ions must diffuse into inner active sites to be adsorbed, leading to a lower adsorption rate during the second phase.

3.3 Modeling Study

3.3.1 Kinetic Studies

Four kinetic models including the pseudo-first-order, pseudo-second-order, Elovich model, and intraparticle model were applied to the kinetic data of arsenic absorption onto BC-Fe to investigate the mechanism of the adsorption process and determine the rate controlling step in the overall adsorption process.

The linear form of the pseudo-first-order kinetic model (Lagergren 1898), pseudo-second-order kinetics (Ho and McKay 1999), and Elovich model (Chien and Clayton 1980)can be expressed as follows:

where k 1 (h-1) is the rate constant of the pseudo-first-order adsorption, k 2 (g/mg/h) is the pseudo-second-order rate constant, α (mg/g/h) is the initial adsorption rate and β (g/mg) is related to the extent of surface coverage and activation energy for chemisorptions.

The intraparticle diffusion model (Weber and Morris 1963) describes the intraparticle uptake of the adsorbate during the adsorption process varies proportionally with the half power of time, t 1/2:

where k ip (mg/g/h1/2) is the intraparticle diffusion rate constant and I is a constant that indicates the thickness of the bounding layer.

The kinetic parameters and correlation coefficients (R 2) for all four kinetic models were calculated from the linear plots of log(q e – q t ) vs. t, t/q t vs. t, q t vs. lnt and q t vs. t 1/2, respectively, and are listed in Table 2.

Based on correlation coefficients, the pseudo-second-order kinetic model represented the arsenic uptake best. The plots of q t /t vs. t showed good linearity with high correlation coefficients (1 for As(III) and 0.989 for As(V); Fig. 5). In addition, the equilibrium uptake calculated from the kinetic plots (q e,cal) agreed well with the experimental values (q e,exp, 3.473 and 10.079 mg/g for As(III) and As(V), respectively). Therefore, the sorption kinetics was well described by the pseudo-second-order kinetics, which implied that the arsenic uptake by BC-Fe was due to chemisorption. The pseudo-second-order kinetic model has been used to describe arsenic uptake by other iron containing adsorbents (Gu and Deng 2007; Guo and Chen 2005; Fierro et al. 2009).

The high R 2 values for the Elovich model inferred that the sorption data were well represented by this model and further confirmed that chemisorption contributed to arsenic removal. For pseudo-first-order kinetics model, the large differences between q e,cal and q e,exp indicates that the adsorption of arsenic by BC-Fe does not follow pseudo-first-order kinetics.

The kinetic data in this study were applied to the intraparticle diffusion model to identify the mechanism of adsorption. A plot of q t vs. the square root of time, t 1/2, shown in Fig. 6, contained three linear parts. Similar results have also been obtained in arsenic adsorption studies using iron-modified granular activated carbon (Mondal et al. 2009) and some other adsorption experiments (Lazaridis and Asouhidou 2003; Senthilkumaar et al. 2006). The first linear portions of the plots depict the instantaneous adsorption on the outer surface; while the second portions represent macropore diffusion, with intraparticle diffusion controlling the rate; and the third parts represent microspore/mesopore diffusion (Mondal et al. 2009). The multiple nature of the relationship implies that the adsorption processes for both arsenic species were complex and controlled by intraparticle diffusion and film diffusion.

3.3.2 Adsorption Equilibrium Isotherm

In this section, three isotherm models, the Langmuir, Freundlich, and Temkin models, were applied to the data obtained by varying the initial arsenic concentration to identify the best fitting isotherm and investigate the mechanism of arsenic adsorption by BC-Fe. The linear form of the Langmuir, Freundlich, and Temkin isotherm models can be expressed as follows:

where q max (mg/g) is the amount of adsorbate that can be adsorbed by a unit weight of adsorbent when a complete monolayer is formed; K L is the adsorption constant related to the energy of adsorption; K F (mg/g)/(mg/L)1/n, and n are the Freundlich constants, which are the adsorption capacity and intensity of adsorption, respectively; B is related to the heat of adsorption and K T (L/mg) is the equilibrium binding constant.

The parameters and correlation coefficients calculated by correlating the sorption data using these three isotherm models are listed in Table 3. Based on the value of R 2, the Freundlich model fitted the sorption data best with the highest correlation coefficients for both arsenic species (0.983 for As(III) and 0.987 for As(V)), followed by the Langmuir and Temkin models for As(III) adsorption and the Temkin and Langmuir models for As(V) adsorption.

For the Freundlich isotherm model, the numerical value of n can be used to indicate the favorable nature of adsorption. A high value of n implies that the adsorption is good over the entire investigated concentration (Kundu and Gupta 2007). The value of n for both As(III) and As(V) was higher than 2, implying a good adsorption process over the entire range of concentrations. The value of k F can be taken as a relative measure of sorption capacity. The higher k F value of As(V) indicates that As(V) is more easily adsorbed onto BC-Fe, which is in accordance with the results obtained from other experiments conducted to evaluate the effects of pH and adsorbent dose. Recently, the Freundlich isotherm was reported to be suitable to represent arsenic adsorption processes by a wide range of iron containing adsorbents, including iron-pretreated activated carbon (Mondal et al. 2009), FeCl3 modified tea fungal biomass (Murugesan et al. 2006), granular ferric hydroxide (Badruzzaman et al. 2004), and iron oxide-coated sand (Thirunavukkarasu et al. 2002).

The correlation coefficients of the Langmuir model were relatively high (0.921 for As(III) and 0.953 for As(V)). However, the calculated q max were lower than those obtained from experiments (4.753 mg/L and 11.608 mg/g for As(III) and As(V), respectively). These findings indicate that the Langmuir isotherm poorly represented the arsenic adsorption on BC-Fe in this study. This may have been due to the heterogeneity of the adsorbent. Previous studies have shown that multisites are provided for arsenic adsorption onto iron-impregnated granular activated carbon (Mondal et al. 2009). Similar processes may have occurred in the system evaluated herein. The aforementioned reasons may also explain why the Freundlich isotherm fitted our data better than the Langmuir isotherm. However, the separation factor R L, which can be calculated using the value of the constant K L and the initial arsenic concentration C 0, indicates the favorability of arsenic adsorption onto BC-Fe (R L > 1, unfavorable; R L = 1, linear; 0 < R L < 1, favorable; and R L > 0, irreversible). R L is defined by the following formula:

where the terms have the same meanings as stated above. The values of R L were calculated for the entire concentration range studied was between 0 and 1, confirming favorable adsorption.

Although the present isotherm sorption data fit was found to be poor when the Temkin model was used, the chemisorptions, at least partially, are indicated.

3.3.3 Effects of Initial Arsenic Concentration and Adsorbent Dose

According to the Freundlich isotherm model (Eq. 9) and Eq. 2, the relationship between R% and C 0 could be expressed as:

And the relationship between q e and C 0 also can be determined from the following equation which is derived from Eqs. 9, 2 and 3:

The effect of the initial arsenic concentration on arsenic adsorption predicted using Eqs. 12 and 13 as well as the experimental data are illustrated in Fig. 7 (the adsorbent dose were 3 g/L for As(III) and 2 g/L for As(V)). There was a continuous increase in arsenic uptake capacity and a decrease in the percentage of arsenic adsorbed due to the increase in initial arsenic concentration at fixed adsorbent dosage levels. The increase in arsenic adsorption capacity with the increase in initial concentration was due to the availability of more arsenic ions in solution for adsorption and higher probability of collision between arsenic ions and BC-Fe at higher initial arsenic concentration (Baral et al. 2006). However, as the initial arsenic concentration increases, the ratio of the number of arsenic ions to the available active sites on the adsorbent becomes high and the arsenic ions are difficult to get adsorbed, leading to a decrease in the removal percentage.

When the initial As(III) concentration was 2.343 mg/L, the residual arsenic concentration in the solution (9.72 μg/L) was lower than the WHO guideline for arsenic in drinking water. And BC-Fe had a greater adsorption capacity for As(V) than As(III). Thus 3 g of BC-Fe is sufficient to remove 2.343 mg inorganic arsenic from 1 L water to meet the WHO guideline and it is approved in additional experiment.

The effects of adsorbent dose on arsenic adsorption capacity and removal efficiency could also be predicted using the Freundlich isotherm:

The predicted results (the values of C 0 for As(III) and As(V) were 13.038 and 37.284 mg/L, respectively) is illustrated in Fig. 8. The effect of BC-Fe dose on arsenic removal was also investigated via experiment and the results are presented in Fig. 8. As shown in it, the isotherm predicted the experimental results well obtained at adsorbent dose higher than 2 g/L. And the data at lower adsorbent dose deviated from the predicted results. This deviation may come from error of weighing low dose of adsorbent. However, the maximum arsenic removal capacity of BC-Fe was 7.237 and 19.771 mg/g for As(III) and As(V), respectively, when the adsorbent dosage was 1 g/L.

Both predicted and experimental results showed that the increased adsorbent dose led to an increase in arsenic removal and a decrease in arsenic adsorption capacity. This trend is in good agreement with the results of previous studies (Mondal et al. 2008; Kundu and Gupta 2007). The increase in R% with adsorbent dosage can be attributed to the increased adsorbent surface and active sites. The decrease in q e with increased adsorbent dose is primarily due to the lower surface coverage of the adsorbent (number of occupied active sites to number of available sites) at higher adsorbent concentration (Mondal et al. 2008). Another reason may be the decrease in total surface area of the adsorbent because of the particle interactions at high adsorbent dose (Rao et al. 2008).

4 Conclusion

In this study, a low-cost adsorbent for arsenic removal from an aqueous system, BC-Fe, was synthesized by loading iron onto bamboo charcoal. The BC-Fe formed a porous structure with a surface of 277.895 m2/g and showed potential for use as an adsorbent for As(III) and As(V) removal from aqueous solutions. The adsorption characteristics of arsenic were investigated under batch experiments at different pH values, adsorbent dosage levels, initial arsenic concentrations, and contact time. The following results were obtained:

-

1

The solution pH influenced arsenic adsorption differently. Generally, As(III) was fairly well removed at a wide pHfin range (2–9), while the removal of As(V) decreased as the pH increased. The optimum pHfin for As(III) and As(V) removal was 4–5 and 3–4, respectively.

-

2

The arsenic removal increased sharply in the first several hours, after which the removal rate become slow, eventually reaching equilibrium after a contact time of 30 h for As(III) and 35.5 h for As(V).

-

3

The adsorption processes for both arsenic species were found to follow the pseudo-second-order kinetic model. Adsorption rates were controlled by both intraparticle diffusion and film diffusion. Equilibrium data of arsenic adsorption onto BC-Fe were better described by the Freundlich isotherm model.

-

4

According to Freundlich isotherm model, an increase in the initial concentration of arsenic decreased the percentage of arsenic adsorbed, but increased the adsorption capacity; whereas, an increase in adsorbent dosage led to an increase in the arsenic removal percentage, but a decrease in adsorption capacity. The maximum arsenic removal capacities of BC-Fe were 7.237 and 19.771 mg/g for As(III) and As(V), respectively.

The high arsenic adsorption capacity and low-cost characteristics of the BC-Fe synthesized in this study indicate that it is a promising treatment option for the removal of arsenic from contaminated water.

References

Asada, T., Ishihara, S., Yamane, T., Toba, A., Yamada, A., & Oikawa, K. (2002). Science of bamboo charcoal: study on carbonizing temperature of bamboo charcoal and removal capability of harmful gases. Journal of Health Science, 48(6), 473–479.

Badruzzaman, M., Westerhoff, P., & Knappe, D. (2004). Intraparticle diffusion and adsorption of arsenate onto granular ferric hydroxide (GFH). Water Research, 38(18), 4002–4012.

Baral, S. S., Das, S. N., & Rath, P. (2006). Hexavalent chromium removal from aqueous solution by adsorption on treated sawdust. Biochemical Engineering Journal, 31(3), 216–222.

Chan, L., Cheung, W., & McKay, G. (2008). Adsorption of acid dyes by bamboo derived activated carbon. Desalination, 218(1–3), 304–312.

Chen, W., Parette, R., Zou, J., Cannon, F., & Dempsey, B. (2007). Arsenic removal by iron-modified activated carbon. Water Research, 41(9), 1851–1858.

Chien, S., & Clayton, W. (1980). Application of Elovich equation to the kinetics of phosphate release and sorption in soils. Soil Science Society of America Journal, 44(2), 265.

China National Ministry of Health (1985). National Standards of Peoples Republic of China: sanitary standards for drinking water. GB-5749-85 (pp. 1–5). China P.R.

China National Ministry of Health. (2006). National Standards of Peoples Republic of China: sanitary standards for drinking water. GB-5749-2006 (pp. 1–12). Beijing: Standards Press of China.

Choong, T., Chuah, T., Robiah, Y., Gregory Koay, F., & Azni, I. (2007). Arsenic toxicity, health hazards and removal techniques from water: an overview. Desalination, 217(1–3), 139–166.

Driehaus, W., Jekel, M., & Hildebrandt, U. (1998). Granular ferric hydroxide—a new adsorbent for the removal of arsenic from natural water. Journal of Water SRTAqua, 47, 30–35.

EPA (2001). Arsenic and Clarifications to Compliance and New Source Monitoring Rule: A Quick Reference Guide In USEPA (Ed.). Washington, DC.

Fierro, V., Mu iz, G., Gonzalez-Sánchez, G., Ballinas, M., & Celzard, A. (2009). Arsenic removal by iron-doped activated carbons prepared by ferric chloride forced hydrolysis. Journal of Hazardous Materials, 168(1), 430–437.

Gu, Z., & Deng, B. (2007). Use of iron-containing mesoporous carbon (IMC) for arsenic removal from drinking water. Environmental Engineering Science, 24(1), 113–121.

Gu, Z., Fang, J., & Deng, B. (2005). Preparation and evaluation of GAC-based iron-containing adsorbents for arsenic removal. Environmental Science and Technology, 39(10), 3833–3843.

Guo, X., & Chen, F. (2005). Removal of arsenic by bead cellulose loaded with iron oxyhydroxide from groundwater. Environmental Science and Technology, 39(17), 6808–6818.

Ho, Y., & McKay, G. (1999). Pseudo-second order model for sorption processes. Process Biochemistry, 34(5), 451–465.

Horikawa, T., Kitakaze, Y., Sekida, T., Hayashi, J., & Katoh, M. (2010). Characteristics and humidity control capacity of activated carbon from bamboo. Bioresource Technology, 101(11), 3964–3969.

Hristovski, K., Westerhoff, P., Möller, T., & Sylvester, P. (2009). Effect of synthesis conditions on nano-iron (hydr) oxide impregnated granulated activated carbon. Chemical Engineering Journal, 146(2), 237–243.

Hung, C., & Vane, L. (1989). Enhancing As5+ removal by a Fe2+-treated activated carbon. Journal of the Water Pollution Control Federation, 61(9), 1596–1603.

Janssen, J. (1981). Bamboo in building structures. Ph. D. thesis, Eindhoven University of Technology,

Kundu, S., & Gupta, A. (2007). Adsorption characteristics of As (III) from aqueous solution on iron oxide coated cement (IOCC). Journal of Hazardous Materials, 142(1–2), 97–104.

Lagergren, S. (1898). About the theory of so-called adsorption of soluble substances. Kungliga Svenska Vetenskapsakademiens Handlingar, 24(4), 1–39.

Lalhruaitluanga, H., Jayaram, K., Prasad, M., & Kumar, K. (2010). Lead (II) adsorption from aqueous solutions by raw and activated charcoals of Melocanna baccifera Roxburgh (bamboo)—a comparative study. Journal of Hazardous Materials, 175(1–3), 311–318.

Lazaridis, N., & Asouhidou, D. (2003). Kinetics of sorptive removal of chromium (VI) from aqueous solutions by calcined Mg-Al-CO3 hydrotalcite. Water Research, 37(12), 2875–2882.

Lenoble, V., Bouras, O., Deluchat, V., Serpaud, B., & Bollinger, J. (2002). Arsenic adsorption onto pillared clays and iron oxides. Journal of Colloid and Interface Science, 255(1), 52–58.

Liese, W. (1987). Research on bamboo. Wood Science and Technology, 21(3), 189–209.

Mandal, B., & Suzuki, K. (2002). Arsenic round the world: a review. Talanta, 58(1), 201–235.

Mizuta, K., Matsumoto, T., Hatate, Y., Nishihara, K., & Nakanishi, T. (2004). Removal of nitrate-nitrogen from drinking water using bamboo powder charcoal. Bioresource Technology, 95(3), 255–257.

Mohan, D., & Pittman, C. (2007). Arsenic removal from water/wastewater using adsorbents—a critical review. Journal of Hazardous Materials, 142(1–2), 1–53.

Mondal, P., Majumder, C., & Mohanty, B. (2008). Effects of adsorbent dose, its particle size and initial arsenic concentration on the removal of arsenic, iron and manganese from simulated ground water by Fe3+ impregnated activated carbon. Journal of Hazardous Materials, 150(3), 695–702.

Mondal, P., Mohanty, B., Majumder, C., & Bhandari, N. (2009). Removal of arsenic from simulated groundwater by GAC-Fe: a modeling approach. AICHE Journal, 55(7), 1860–1871.

Muñiz, G., Fierro, V., Celzard, A., Furdin, G., Gonzalez-Sánchez, G., & Ballinas, M. (2009). Synthesis, characterization and performance in arsenic removal of iron-doped activated carbons prepared by impregnation with Fe (III) and Fe (II). Journal of Hazardous Materials, 165(1–3), 893–902.

Murugesan, G., Sathishkumar, M., & Swaminathan, K. (2006). Arsenic removal from groundwater by pretreated waste tea fungal biomass. Bioresource Technology, 97(3), 483–487.

Nguyen, T., Vigneswaran, S., Ngo, H., & Kandasamy, J. (2010). Arsenic removal by iron oxide coated sponge: experimental performance and mathematical models. Journal of Hazardous Materials, 182(1–3), 723–729.

Nordstrom, D. (2002). PUBLIC HEALTH: enhanced: worldwide occurrences of arsenic in ground water. Science, 296(5576), 2143.

Paige, C., Snodgrass, W., Nicholson, R., & Scharer, J. (1996). The crystallization of arsenate-contaminated iron hydroxide solids at high pH. Water Environment Research, 68(6), 981–987.

Pattanayak, J., Mondal, K., Mathew, S., & Lalvani, S. (2000). A parametric evaluation of the removal of As (V) and As (III) by carbon-based adsorbents. Carbon, 38(4), 589–596.

Payne, K., & Abdel-Fattah, T. (2005). Adsorption of arsenate and arsenite by iron-treated activated carbon and zeolites: effects of pH, temperature, and ionic strength. Journal of Environmental Science and Health, Part A, 40(4), 723–749.

Rao, M., Rao, G., Seshaiah, K., Choudary, N., & Wang, M. (2008). Activated carbon from Ceiba pentandra hulls, an agricultural waste, as an adsorbent in the removal of lead and zinc from aqueous solutions. Waste Management, 28(5), 849–858.

Senthilkumaar, S., Kalaamani, P., Porkodi, K., Varadarajan, P., & Subburaam, C. (2006). Adsorption of dissolved reactive red dye from aqueous phase onto activated carbon prepared from agricultural waste. Bioresource Technology, 97(14), 1618–1625.

Stookey, L. (1970). Ferrozine—a new spectrophotometric reagent for iron. Analytical Chemistry, 42(7), 779–781.

Thirunavukkarasu, O., Viraraghavan, T., Subramanian, K., & Tanjore, S. (2002). Organic arsenic removal from drinking water. Urban water, 4(4), 415–421.

Wang, F., Wang, H., & Ma, J. (2009). Adsorption of cadmium (II) ions from aqueous solution by a new low-cost adsorbent—bamboo charcoal. Journal of Hazardous Materials, 177(1–3), 300–306.

Weber, W., & Morris, J. (1963). Kinetics of adsorption on carbon from solution. Journal of the Sanitary Engineering Division, 89(17), 31–60.

WHO. (2004). Guidelines for drinking-water quality. Geneva, Switzerland: World Health Organization.

Yang, J., Park, H., Lee, H., & Lee, S. (2009). Removal of Cu (II) by activated carbon impregnated with iron (III). Colloids and Surfaces A: Physicochemical and Engineering Aspects, 337(1–3), 154–158.

Zhang, J., Zhao, D., Wang, J., & Yang, L. (2009). Photocatalytic oxidation of dibenzothiophene using TiO2/bamboo charcoal. Journal of Materials Science, 44(12), 3112–3117.

Acknowledgment

This work was supported by grants from the State Key Laboratory of Freshwater Ecology and Biotechnology (No.2009FBZ09) and the Water Pollution Control and Management Project of China (2009ZX07102-003 and 2009ZX07104-005-03).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, X., Ao, H., Xiong, X. et al. Arsenic Removal from Water by Iron-Modified Bamboo Charcoal. Water Air Soil Pollut 223, 1033–1044 (2012). https://doi.org/10.1007/s11270-011-0921-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11270-011-0921-7