Abstract

Photocatalytic oxidation of dibenzothiophene (DBT) using TiO2-loaded bamboo charcoals (BC) prepared by wet impregnation was studied. Results obtained here can be used as the reference for evaluating reactions in hydrocarbons, which aims at the development of an oxidative desulfurization process for fuel oils. Technological conditions (the amount of photocatalysts, hydrogen peroxide, and TiO2 loading) were also investigated in detail. The results show that TiO2/BC improves the dispersed degree of TiO2 catalyst, which shows a better photocatalytic performance than pure TiO2. We also found a special characterization of TiO2/BC, it can locate just at the oil–water phase boundary. The oxidation proceeds in the oil phase and most of the oxidation products transfer to water phase, resulting in the successive removal of DBT from the n-octane phase without additional extraction by solvent. In addition, kinetics parameters of the photocatalytic oxidation of DBT were measured and calculated. The result shows the kinetics of photocatalytic oxidation of DBT is first order.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In order to protect against environmental contamination, the sulfur level in diesel fuels is presently limited to 15 ppm in Japan, Europe, and US [1]. The presence of sulfur in fuels is considered a major source of atmospheric pollution because sulfur atmospheric discharge from combustion is a precursor of acid rain due to the formation of sulfur oxides [2]. Hydrodesulfurization (HDS) at high temperatures (320–380 °C) and high pressures (3–7 MPa) over CoMo or NiMo catalysts is currently a major process in petroleum refineries, performed in order to reduce the sulfur in diesel fuel. The major sulfur compounds existing in current commercial diesel are the alkyl dibenzothiophenes (DBTs) with one or two alkyl groups at the positions 4 or 6. These have been considered to be the most refractory sulfur compounds in HDS, due to the steric hindrance of the alkyl groups [3]. A new approach is needed, which is not limited to the conventional HDS method for the development of an energy-saving desulfurization process. The oxidative desulfurization (ODS) is considered to be one of the promising new methods for super deep desulfurization of fuel oil [4–6]. As one of the processes, photochemical reaction with sunlight as an energy source is also promising. As reported by Matsuzawa et al. [7], DBT and 4, 6-dimethyldibenzothiophene (4, 6-DMDBT) in acetonitrile are photooxidized to 5-oxide (sulfoxide) and 5,5-dioxide (sulfone) using dioxide (TiO2). The application of this photochemical oxidation to desulfurization has been realized in some literatures [8–10], using oil–water and oil–polar solvent two-phase systems. The desulfurization of light oil to a sulfur content of less than 0.05 wt% has been achieved successfully. However, ultraviolet (UV) irradiation was found to be essential to oxidize DBTs, and the desulfurization hardly progressed at wavelength of λ > 400 nm.

TiO2 can absorb light throughout the UV range and has been demonstrated to be an effective photocatalyst for a number of reactions. However, TiO2 is agglomerated easily in reaction system, which will reduce photocatalysis of TiO2, and is difficult to recover. Thus, many researcher loaded TiO2 on some support (such as activated carbon [11, 12], glass substrates [13, 14], silica gels [15, 16], poly-divinylbenzene [17]), in order to overcome above-mentioned demerit of TiO2. Photocatalytic oxidation applied on water treatment was studied more using TiO2 loading [11–19]. The report about desulfurization of fuel oil is seldom.

Here, we report a photocatalytic oxidation system of DBT using TiO2-loaded bamboo charcoal (BC) as photocatalyst, H2O2 as an oxidant, and water as solvent. The effect of the amount of photocatalysts, hydrogen peroxide, and TiO2 loading on removal ratio of DBT was also investigated in detail. Kinetics parameters of the photocatalytic oxidation of DBT were measured and calculated.

Experimental sections

Chemicals

The model diesel (sulfur content is 1,000 μg/g) was made up by DBT (analytic reagents, Alfa Aesar company, Beijing, China) was dissolved into n-octane (analytic reagents, Tianjin Kemiou company, China). H2O2 solution (30%) (Dongfang reagent company, shijizhuang, China) is chemically pure reagent. Bamboo charcoal (Suichang bamboo charcoal company, Zhejiang, China) was boiled in distilled water for 1 h to remove some ash and impurities. They were then dried at 100 °C in an oven for 24 h and stored in desiccators. BC was crushed and sieved with 40–60 meshes.

Apparatus

The model diesel solution was photoirradiated in a quartz tube with a ground glass stopper in a closed cell. A magnetic stirrer (Pasolina TR-100) under the reactor was used to stir the solution. During photoirradiation, the inwall of closed cell was wrapped with aluminum foil to reflect and shield against other laboratory light sources. Light source is UV bactericidal lamp whose wave length is 200–400 nm.

Concentrations of sulfur compound and the oxidation products were determined by microcolometric detector (WK-2D, Jiangsu, China), mass spectrometer (MS-2010EV, Shimazu, Japan), and gas phase chromatogram (GC-7890-II, ShangHai, China).

Preparation of TiO2-loaded BC

Pure TiO2 powder was prepared by the method called acid-catalyzed sol–gel formation. Solution A was mixed using tetrabutyl titanate (4 mL) [Ti(OBu)4] and ethanol absolute (20 mL); solution B was mixed using ethanol (95%, 78 mL), nitric acid (2 mL), and distilled water (32 mL). Solution B was dropped into solution A with stirring acutely to give a Ti-containing sol. Then, this sol was dried by vacuum at 120 °C for 48 h, and calcined at 400 °C for 6 h. We obtained pure TiO2 particle. TiO2/BC was prepared by impregnating BC in TiO2 emulsion for four times, then was dried in drying oven at 120 °C for 24 h. TiO2 loading on BC are 5%, 9%, 15%, and 18%.

Tetrabutyl titanate [Ti(OBu)4], ethanol absolute, ethanol (95%), and nitric acid analytic reagents are analytic reagents and purchased from Tianjin Kemiou company of China.

Photoirradiation

Photooxidation experiments were carried out as follows: An n-octane solution of DBT (10 mL), given volume 30% H2O2, and H2O were placed in a quartz tube and given amount TiO2/BC was added into the solution. The solution was photoirradiated for 0–10 h with magnetic stirring. Reactant samples were collected and analyzed to determine substrate concentration and reaction products at intervals of 1 h. H2O2 of different volumes (1, 3, 5, 8, and 10 mL) were diluted to 10 mL with distilled water in each experiment. Given amount TiO2/ BC are 0.01, 0.02, 0.03, 0.04 and 0.05 g.

Results and discussion

XRD and SEM images of TiO2/ BC

From XRD spectrogram (Fig. 1) of TiO2/ BC, we can see that the characteristic peak of TiO2 is seen obviously, which indicated TiO2 was loaded onto BC successfully. From SEM images (Fig. 2) of TiO2/BC, we can see that few TiO2 was loaded onto skirt and surface of pore well, which has not only maintained the original pore structure, and it does not plug the pores (Fig. 2a). However, excessive TiO2 blocked seriously in pore canal of BC (Fig. 2b).

Effect of the presence of photocatalyst (pure TiO2 and TiO2/BC) on photooxidation of DBT

In this experiment, 0.1 g photocatalyst and 15 wt% H2O2 (30%) were added in 10 mL model diesel, the mixture was stirred and irradiation time is 2.5 h. The effect of TiO2/BC, H2O2, and pure TiO2 on the removal ratio of DBT in n-octane by UV lamp irradiation is shown in Fig. 1. We can see that little decrease in the concentration of DBT was observed if model diesel was irradiated in the absence of any photocatalyst. Apparently, the removal ratio of DBT was differential in the order of TiO2/BC > pure TiO2 > H2O2. The addition of photocatalyst promoted the oxidations of DBT, since the rate of •OH formation and charge transfer can be accelerated by the addition of photocatalyst. TiO2/BC shows a photocatalytic capability better than pure TiO2 powder, because TiO2/BC improves the dispersed degree of TiO2 catalyst, which shows a better photocatalytic performance than pure TiO2 (Fig. 3).

Optimization of reaction condition

In order to screen optimal reaction condition, amount of TiO2/BC and concentration of H2O2 were investigated in detail. In this experiment, one of the conditions was changed, while two other conditions were immovable, irradiation time is 2.5 h. Two major reaction conditions were selected to investigate. The results were shown in Table 1. A swift increase of removal ratio of DBT occurred as photocatalyst amount was increased. However, with the more photocatalyst added into the reaction mixture, the removal ratio of DBT did not increase obviously, even decreased a little. The reason is that photocatalyst is one of the important roles in photocatalysis reaction, increasing photocatalyst amount accelerated charge transfer and generation of hydroxyl free radical (•OH), consequently accelerated photocatalytic oxidation of DBT. However, excessive photocatalysts would shield part UV light source, which influences reaction rate, in addition, too much photocatalysts would be wasted. An increase of removal ratio of DBT occurred as H2O2 concentration was increased. However, the rate of reaction decreased when more than 24% (vol.%) of H2O2 was added. The reason is that H2O2 is the source of hydroxyl free radical (•OH), which has strong oxidizing property; increasing H2O2 concentration accelerated generation of hydroxyl free radical (•OH), consequently accelerated photocatalytic oxidation of DBT, while excessive amount of H2O2 would poison surface Ti [7]; and also, too much H2O2 would consume some hydroxyl free radical (•OH). So, optimization of reaction condition is that amount of photocatalysts is 0.04 g/10 mL model diesel and H2O2 (30%) concentration is 24% (vol.%). We can also find that the overall removal efficiency of the TiO2-attached charcoal on DBT increases with TiO2 loading. But, the removal ratio of DBT decreases when TiO2 loading is greater than 15% (wt%). Excessive TiO2 loading blocked seriously in pore canal of BC (Fig. 2b), which reduced adsorptive capacity to DBT. The above results can be attributed to a fact that well-dispersed TiO2 onto BC would behave a greater photocatalytic activity than TiO2 aggregation in liquid phase.

Kinetics of photocatalytic oxidation of DBT

Reaction kinetics is of great importance in explaining the reaction mechanism. Experiments to obtain kinetics parameters of the oxidation of DBT were carried out under optimal reaction condition.

The rate constant of the apparent consumption of DBT was obtained from the pseudo first-order equation:

where C0 and Ct are the concentrations of substrate at time zero and time t (s), and kp is the first-order rate constant (s−1). Half-lives (t1/2 (s)) were calculated using Eq. 2, which was derived from Eq. 1 by replacing Ct with C0/2,

Values obtained in seconds were converted to hours.

When –ln (Ct /C0) was plotted against t, a straight line with slope kp was obtained (Fig. 4), indicating that photocatalytic oxidation of DBT by TiO2/BC, H2O2, and UV light irradiation follows first-order kinetics. The rate constant (1.162 × 10−4) for this system in this study increased by a factor of 11.92, and half-life (1.657 h) decreased by a factor of 11.95, compared with the P25 (kp = 9.74 × 10−6 s−1, t1/2 = 19.8 h), a commercial photocatalyst showed the highest photooxidation rate in literature [7].

Products formed by photocatalytic oxidation of DBT

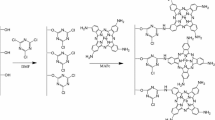

We did not detect other oxidized products by gas phase chromatogram (GC-7890-II, ShangHai) in oil layer. But we detected fragmention peaks at m/z 200 of DBT 5-oxide and those at m/z 216 of DBT 5,5-dioxide by Mass Spectrum (MS-2010EV, Shimazu, Japan) in water phase (Fig. 5). When Ba(NO3)2 solution was dropped into water phase, no white deposit appeared. So we confirm that photocatalytic oxidized products of DBT are DBT 5-oxide and DBT 5,5-dioxide.

Reaction Modes of photooxidation DBT on photocatalysts

In our previous study [20], we found BC has a large capability of collection of the target substrate (DBT) from the oil phase onto the support, providing the substrate-rich environment at the TiO2/BC interface; thereby, this concentration effect results in an enhanced rate of mass transport of DBT from oil phase to support, while oxidized products, which have higher polarity, were transferred to water phase, as schematically illustrated in Fig. 6b. We also found TiO2/BC located just at the liquid–liquid phase boundary, because BC is macropore material leading to density of BC lower (Fig. 7).

The enhancement of the reaction rate by using the adsorbent supports might imply that the supply of the adsorbed DBT to the TiO2/BC interface occurs very faster as compared with the collision of a diluted DBT concentration to the suspended photocatalyst surfaces.

Conclusion

We studied the photocatalytic oxidations of DBT in n-octane using TiO2/BC. We found that that the TiO2-loaded charcoals exhibit better photodegradation efficiency, comparing with pure TiO2 aggregation. Products from DBT were tentatively identified. Oxidized products of DBT transfer to water phase fleetly for their higher polar property. The kinetics of photocatalytic oxidation of DBT is fist order regardless of other factors. This photocatalytic oxidation system was found to be useful for the ODS of diesel oil. The pecularity of TiO2/BC is that it could locat just at the oil–water phase boundary, which can decrease amount of photocatalyst and increase mass transport. These findings demonstrated that the existence of bamboo charcoal acts as a critical role for improving catalyst dispersion and transport of DBT. Therefore, TiO2/BC is a promising photocatalyst at oil–water system especially.

References

Dumont V, Oliviero L, Mauge F, Houalla M (2008) Catal Today 130:195

Villasen F, Loera O, Campero A, Viniegra-González G (2004) Fuel Process Technol 86:49

Wang DE, Qian WH, Amano H, Okata K, Ishihara A, Kabe T (2003) Appl Catal A Gen 253:91

Shiraishi Y, Taki Y, Hirai T, Komasawa I (1998) Chem Commun 5:2601

Vasily H, Fajula F, Bousquet J (2001) J Catal 198:179

Lina Y, Jian L, Xingdong Y, Sh Jian, Yutai Q (2007) J Mol Catal A Chem 262:114

Matsuzawa S, Tanaka J, Sato S, Ibusuki T (2002) J Photochem Photobiol A Chem 149:183

Hirai T, Ogawa K, Komasawa I (1996) Ind Eng Chem Res 35:586

Hirai T, Shiraishi Y, Ogawa K, Komasawa I (1997) Ind Eng Chem Res 36:530

Shiraishi Y, Hirai T, Komasawa I (1999) J Chem Eng Jpn 32:158

Hiroyuki U, Shigeyoshi I, Hiroshi Y (1993) Chem Lett 12:1995

Tsukasa T, Shigeyoshi I, Susumu K, Hiroshi Y (1996) Environ Sci Technol 30:1275

Chen SF (1997) J Environ Sci 9:278

Hiroaki T, Akihiko H (2000) J Phys Chem B 104:4585

Zhe O, Jin H (2000) Langmuir 16:6216

Zhe Y (2000) Appl Surf Sci 158:3237

Zh Liuxue, Peng L, Zhixing S (2006) J Mater Sci 41:7218. doi:https://doi.org/10.1007/s10853-006-0917-7

Wu C-H, Shr J-F, Wu C-F, Hsieh C-T (2008) J Mater Process Technol 203:326

Chuang CS, Wang M-K, Ko C-H, Ou C-C, Wu C-H (2008) Bioresour Technol 99:954

Dishun Zh, Juan Zh, Erhong D, Jinlong W (2008) Appl Surf Sci 254:3242

Acknowledgements

This research was supported by Grant 20276015 from National Natural Science Foundation of China and Grant 203364 from National Natural Science Foundation of HeBei province.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, J., Zhao, D., Wang, J. et al. Photocatalytic oxidation of dibenzothiophene using TiO2/bamboo charcoal. J Mater Sci 44, 3112–3117 (2009). https://doi.org/10.1007/s10853-009-3413-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3413-z