Abstract

Water Distribution Systems (WDSs) are indispensable infrastructures for urban societies. Due to vitality of continuous supply of drinking water in urban areas, it is necessary to have a performance evaluation and monitoring system to provide the expected level of security in water distribution systems. A main weakness point of these systems is the physical break of pipes which results in high level of water loss, pollution risk and public unsatisfactory. In this study, a framework is developed to increase physical water supply security in urban areas. For this purpose, a physical vulnerability index (PVI) is developed for evaluation of physical statues of water mains. In quantifying PVI, pipe characteristics and bedding soil specifications are considered. The importance of these factors on PVI is determined using Analytical Hierarchy Process (AHP). In system performance evaluation, the pipe role in system performance is incorporated regarding pipe location in WDS, distance of pipe from reservoir and average pressure of pipe. Then, System Physical Performance Index (SPVI) is evaluated. An optimization algorithm is employed to determine ways to improve the system performance through enhancing the physical condition of the pipe in the system at a minimum cost. The genetic algorithm is employed for solving the optimization model. A global sensitivity analysis method named FAST, is used for sensitivity analysis to incorporate the correlation between different parameters in analysis. The proposed framework is applied to a case study located in Tehran metropolitan area. The results of this study show the significant value of the proposed algorithm in supporting decision makers to better choose vulnerable pipes for rehabilitation practices in order to decrease system vulnerability against physical failures.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Water Distribution Systems (WDSs) are one of the most important infrastructures in cities. Increasing water demand associated with water losses because of aging of the available water mains is one of the biggest problems in urban areas followed by increasing vulnerability of WDSs. The frequency of failure of pipes in water distribution networks increases over the time mainly due to system aging and deterioration. Therefore, it is important to investigate the vulnerability of WDSs and plan to improve them in order to provide more secure water supply. The purpose of this study is to assess physical vulnerability of a WDS in dealing with physical and environmental factors which cause system failure.

The concept of vulnerability has been a powerful analytical approach for achieving states of failure probability in physical systems, and for guiding normative analysis of actions to enhance well-being of the system as expressed by Adge (2006). Pinto et al. (2010) introduced the theory of vulnerability of water pipe network. This theory analyses the connectivity and the quality of the pipelines in the network. The potential of this theory lies in the identification of weaknesses in a real water pipe network which requires accounting for different types of damages and consequences.

Increasing physical water supply security in urban areas can be achieved by developing physical vulnerability index in order to evaluate the physical statues of water mains in WDSs. Baoyu et al. (2009) presented a vulnerability assessment model for regional water distribution system in northern China. The model takes into account the impact of residual chlorine and water age, uncertainty and probabilistic characteristic of the distribution systems to calculate the vulnerability index of each junction and the entire system.

Investigation of the literature on evaluation and analysis of failures in water distribution networks, shows there is a large number of factors which are used in analysis of pipe vulnerability including physical factors (pipe material, wall thickness, pipe age, pipe vintage, diameter, joint types, thrust restraint, pipe lining and coating and manufacture processes), factors representing the surrounding media condition (soil type, soil moisture, groundwater presence, climate, pipe location, traffic type, road type, serviced area type, pipe bedding, underground disturbances, stray electrical currents, seismic activity, and installation practices) and operational factors (internal water pressure, leakage, breakage, pipe roughness, water quality, flow velocity, backflow potential, and operational and maintenance practices). Table 1 provides a summary of studies considering the most studied factors in pipe failure analysis. Based on this table the common factors in pipe vulnerability analysis are physical factors such as age, material, diameter and length.

The goal of this study is to rank the pipes of a network form their physical vulnerability aspect. The importance of different factors in assessing vulnerability of a water distribution system can be determined using AHP (Analytical Hierarchy Process) proposed by Saaty (1991). Dey (2003, 2004) developed an AHP model to identify the factors influencing failure on specific portions of petroleum pipelines. Tran et al. (2003) incorporated the AHP technique with the expected maximum utility to evaluate renewal priorities of irrigation assets grouped by types and location within its hydraulics system. Al-Barqawi and Zayed (2008) developed condition assessment and performance models for water mains using AHP and artificial neural network (ANN). Eleven sub factors within three main factors (physical, environmental, and operational) are considered in water mains performance evaluation. The AHP model is structured to determine weights of factors and subfactors, which contribute to water main deterioration.

Following determining the pipe vulnerability, an optimization algorithm is developed to improve the system performance and decrease its vulnerability. Since the pioneering work of Simpson et al. (1994), Genetic Algorithms (GAs) have been extensively applied to optimize WDSs for hydraulic criteria. Different studies have demonstrated the effectiveness of GAs in operational optimization of water distribution systems such as Goldberg and Kuo (1987); Mackle et al. (1995); Engelbrecht and Haarhoff (1996); Schwab et al. (1996); De Schaetzen et al. (1998) and Nazif et al. (2010). Dandy and Engelhardt (2001; 2006) used the GA to find an optimal schedule for replacement of water supply pipes. The goal was to minimize the present value of capital, repair, and damage costs.

Due to high uncertainty in the data gathered from field analyses and to determine the main factors in the system vulnerability, sensitivity analysis is necessary. Fu et al. (2012) investigated the use of global sensitivity analysis (GSA) as a tool to reduce the computational demands associated with multi-objective design and rehabilitation of WDSs. Two case studies of increasing complexity, the New York Tunnels network and the Anytown network, are used to demonstrate the proposed methodology.

One of the most popular GSA techniques is FAST (Fourier Amplitude Sensitivity Test) which is able to consider the parameters correlation in sensitivity analysis. FAST is computationally efficient and can be used for nonlinear models. It has been widely applied in sensitivity analysis of different models, such as chemical reaction models (Haaker and Verheijen 2004); atmospheric models (Kioutsioukis et al. 2004); nuclear waste disposal models (Lu and Mohanty 2001); soil erosion models (Wang et al. 2001); and hydrological models (Francos et al. 2003).

In the present study a methodology is proposed to evaluate the pipe and total WDS physical vulnerability and find the optimal scheme for its improvement. In pipe vulnerability evaluation different physical and environmental factors are considered and prioritized using the AHP method. A GA based optimization model is developed to improve the system operation while reducing its vulnerability with the minimum cost. The modified FAST method is used for sensitivity analysis of the effective factors in pipe and system vulnerability. The proposed methodology is employed in a real water distribution network located at Tehran, the capital city of Iran.

The characteristics of the considered water distribution network are given in the following section. Methodology is described in section 3 and the results are presented and discussed in section 4. Finally a summary and conclusion is given.

2 Case Study

In recent years, Tehran, the capital of Iran, has become one of the Mega cities of the world. Because of aging of water distribution infrastructure, pipe break is a common problem in this city. Since there is no rehabilitation program for aging pipes in Tehran, this problem is getting more severe through the time. Therefore, evaluation of system vulnerability and developing strategies for decreasing the system vulnerability are essential for Tehran WDS. To show and test the application of the proposed methodology, a part of Tehran WDS located at the north western part of Tehran is selected as the case study. This part of Tehran water distribution supplies water for 120,000 residents in an area of about 450 ha. The schematic of this part of WDS is shown in Fig. 1. There are 35 main demand nodes with the total demand of 0.51 m3/s and 78 water mains. The characteristics of the network are given in Table 2.

3 Methodology

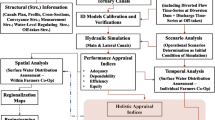

The methodology of this study is presented in Fig. 2. The general attitude of the methodology is to determine the effective parameters on physical vulnerability of a WDS as well as quantifying it. Among different system components, the effect of pipe physical failure is considered in evaluating vulnerability of WDS. For this aim, two different sets of factors are defined including physical characteristics of pipe and bedding soil conditions. AHP method is used to determine the priority of each item in each set. Engineering judgment and experts’ experiences are used to weight the items. Based on the resulted weights, the pipe vulnerability index (PVI) is quantified. Using PVI and the importance of each pipe in the WDS, System Physical Vulnerability Index (SPVI) is developed for the entire WDS. An optimization model is proposed to improve the system performance and reduce its vulnerability with the objective function of minimizing costs. Sensitivity of the effective factors in pipe and system vulnerability is analyzed using FAST. Considering Fig. 2, methodology is composed of 6 steps, which are described in the following.

-

1-

Data collection

To quantify pipe and system vulnerability, different data sets are needed, including pipe and water distribution system characteristics. It is tried to incorporate the major factors affecting pipe and system failure based on the literature. The selected factors for quantifying pipe vulnerability are classified into two groups of pipe physical characteristics and environmental factors. To evaluate the vulnerability of the WDS, factors such as pipe location in network, pipe distance from reservoir and hydraulic pressure of pipe are utilized.

-

2-

Selection of effective factors in pipe and system vulnerability

Based on Røstum (1997), there are a number of possible factors which cause pipe failures. These variables are categorized into four main groups of physical, external/environmental, internal (hydraulics) and maintenance. The factors in the physical category affecting the pipe failure include diameter, material, length, age, etc. Investigation on different WDSs have demonstrated the close relationship of these factors with water main failures (Røstum 1997). Therefore, referring to the headings in Table 1, diameter, material, length and age, are considered as physical factors in order to evaluate the vulnerability of pipes. By increasing the diameter, thickness of the pipes increases which results in less pipe failure probability. The longer pipes are more vulnerable to excess loadings, with higher failure probability. The aging pipes are subject to erosion and corrosion that decreases their strength against external loadings and make them more vulnerable from physical aspects.

The second group of factors affecting pipe vulnerability is related to bedding soil condition that falls into environmental factors category. As shown in Table 1, the most common factors in this category are corrosion and land use. Corrosion is evaluated by groundwater depth and soil type. Wet soil (rate of moisture) increases the probability of corrosion in pipe, therefore by increasing the groundwater depth, the corrosion feature of bedding soil decreases. Three soil’s types in the study area are clay loams, sands and gravels. Land use is another factor which determines the external pipe loading that affects pipe failure probability.

There are several important factors that determine how a pipe failure would impact the WDS performance. The main cause of pipe failure is water shortage in demand nodes. To determine the resulting shortage from each pipe failure, WDS is simulated considering a failed pipe and the percentage of water shortage is determined. Using Eq. 1 the amount of supplied water can be determined in each node, and then the shortage in water supply based on the base demand is calculated.

where A d is the actual water delivery of a certain node in WDS, R is the based demanded water to a given point, P is the pressure in that point and P min is the pressure head in the WDS and is equal to 20 m.

The next factor affecting WDS performance is the length of shortest path to the reservoir (LSPR). By increasing the LSPR, because of dependency of a pipe performance on the other pipes in between, the probability of pipe failure would be increased. In WDSs, particularly in looped networks, it is likely that the number of routes to reach the reservoir from a pipe is more than one path, so in this study the shortest path is considered and determined. The lesser the distance the more important is the pipe’s role in WDS, and more pipes will be affected by its possible failure.

Pipe average pressure is the last factor in determining the effect of pipes on WDS performance. Normally, a pipe with high pressure is more likely to fail than a pipe with low pressure. The pressure in nodes is simulated using EPANET 2.0 and, then the average pressure in a pipe is calculated by \( {P_{ave }}={{{\left( {{P_1}+{P_2}} \right)}} \left/ {2} \right.} \), where P 1 and P 2 are pressures at the ends of a pipe.

-

3-

Weighting the selected factors in pipe and system vulnerability

To evaluate pipe vulnerability as well as determining the importance of pipe in the WDS performance, the range of variation of each factor should be classified. Pipes are classified based on the local expert judgments, considering the fact that pipes with similar characteristics and behavior fall in the same class. Different categories of factors related to pipe physical and environmental characteristics and pipe importance in the WDS are shown in Figs. 3 and 4, respectively.

To determine the priority of factors and subfactors in each category, AHP method is utilized. The results of applying AHP for weighting the factors and subfactors and the corresponding weights and scores are presented in Figs. 3 and 4.

-

4-

Pipes Vulnerability Index (PVI) Evaluation

Following determining weights and scores by the AHP analysis, physical vulnerability of pipe can be quantified as follows:

where PVI P is the physical vulnerability index of pipe P in the WDS, n is the total number of factors (or sub-factors), ω i is the weight of the factor i and S i,P is the given score to the pipe p for factor i. The physical vulnerability of a pipe varies between zero and one where the higher values show the higher level of vulnerability.

-

5-

System vulnerability evaluation

-

5-1-

Determining the importance (weight) of pipe in the WDS

-

5-1-

For SPVI evaluation, a weighted average of pipes PVI is used. In a WDS, due to role of each pipe in total system performance, the failure impacts of different pipes are not the same. Therefore a weight is assigned to each pipe regarding its importance in the overall system performance. Equation (3) is used to quantify the relative weight of pipe (RW i ) in WDS.

in which \( \sum\limits_{i=1}^n {R{W_i} = 1.0} \)

-

5-2-

Quantifying System Physical Vulnerability Index (SPVI)

By using the results of AHP method for evaluating PVI and weighing the importance of pipe on the WDS performance, SPVI can be estimated:

where PVI i is the physical vulnerability index of pipe i, RW i is the relative weight of pipe i and n is the total number of pipes. In order to improve system performance, it is important to define different classes of SPVI to engage proper rehabilitation practices. Considering the SPVI range of (0, 1), four different classes, ranging from low to critical, are defined in Table 3 for this purpose.

-

6-

Improvement of system

In improvement of system two issues are considered, the cost based optimization for improvement of SPVI and sensitivity analysis on pipe vulnerability. Based on the results, strategies are proposed for system improvement. These issues are further discussed in the following.

-

6-1-

Minimum cost optimization

In this study an optimization model is proposed to improve the system vulnerability (SPVI) with the least cost. These objectives are weighted to change the problem into a single objective optimization. The developed model structure is as follows:

subject to:

In Eq. 5, the normalized costs based on the maximum available budget for system improvement, Cost max (which is here $105), are used. w 1 and w 2 are determined based on the consideration of the relative importance of the system vulnerability and the costs of system improvement. In this study, w 1 and w 2 are considered to be 5 and 1, respectively due to strategic importance of water distribution network in Tehran residents’ daily life and the experts’ judgment placing significantly more weight on the first objective. P i is the pressure at node i and P min and P max are the minimum and maximum desired pressure at the nodes, respectively. Equation 8 indicates that D j, the pipe j diameter, is chosen from the available commercial pipe diameters designated as AD. In case of real implementation of the proposed methodology, a sensitivity analysis on the weights should be done.

The considered options for system improvements are considered as:

-

1.

Replacing the current pipes with new pipes with different diameter and/or material

-

2.

Duplicating the current pipes with the appropriate diameter and material

GA is used to solve the optimization model. Each chromosome in developed GA model includes 4np genes where np is the number of pipes in the network (Fig. 5). Each 4 genes in a chromosome are decision variables of a pipe in network. The first gene determines whether the material of current pipes changes or not. The second gene determines the diameter of replacement pipe which varies between 1 and 10, each number indicating an available pipe diameter (Table 4). The third gene determines the material of the new duplicate pipe. The 4th gene determines if a new pipe is duplicated or no and the diameter of the new added pipe to the network. The value of the 4th gene varies between 0 and 10 where zero shows not duplicating.

-

6-2-

Sensitivity analysis of the WDS vulnerability

Sensitivity analysis is used to determine how a model output changes in response to changes in model inputs. Modified FAST method is used for sensitivity analysis to incorporate the correlation between different parameters affecting pipe and system vulnerability.

The main idea of FAST is to introduce for all parameters a search function with a characteristic integer frequency. Through the search functions, the model output becomes a periodic function. Fourier analysis is performed on the model outputs to derive the Fourier spectrum. Finally, the first-order sensitivity index of each parameter is derived from the Fourier spectrum based on the characteristic frequency (Xu and Gertner 2007).

If Y=f(x 1 ,x 2 ,…,x n ) is considered as a computer model where n is the number of independent parameters, the domain of independent parameters is the hypercube

where \( x_i^{{\left( {\min } \right)}} \) and \( x_i^{{\left( {\max } \right)}} \) are the minimum and maximum values for x i . A search function is introduced for each parameter to explore the space Ω n :

where ω i is the characteristic frequency for x i and \( F_i^{-1 } \) is the inverse cumulative distribution function (ICDF) for x i (Lu and Mohanty 2001). s is the common variable for all parameters. The search function aims to sample the parameter space according to an expected probability density function and lets the parameter x i to oscillate periodically at the corresponding frequency ω i . Consequently the model output is a periodic function of s. If the ω i ’s are positive integers, the period T is 2π (Cukier et al. 1973). Thus, the model output can be expanded with a Fourier series

where A 0, A k and B k are the Fourier coefficients. Discrete sampling is used to get the Fourier coefficients. The sample for s is denoted as

where \( {s_j} = {{{-\pi +\pi }} \left/ {N} \right.}+\left( {{{{2\pi }} \left/ {N} \right.}} \right)\left( {j-1} \right),\,\,\forall j = 1,2,\ldots,N \). The search function of Eq. (11) is then applied to each sample element from S to get the sampled values for each parameter.

Using the discrete sample, the variance of the model output can be decomposed as follows:

The spectrum of the Fourier series is defined as \( {\varLambda_k}=\frac{1}{2}\left( {A_k^2+B_k^2} \right)\left( {k\in Z} \right) \). By summing the spectrum values for the characteristic frequency ω i and its higher order harmonics pω i (p is a positive integer), the partial variance in model output arising from the uncertainty of parameter x i , V i , can be estimated by

where \( p=\left\{ {1,2,\ldots } \right\} \) and \( {{{p{\omega_i}\leq \left( {N-1} \right)}} \left/ {2} \right.} \). By summing all the values of the spectrum, the total variance can be derived

The ratio of V i /V measures the contribution of parameter x i to the total variance of response variable Y. This ratio is also termed the first-order sensitivity index based on the Sobol’s definition of variance-based sensitivity indices (Chun et al. 2000). Using FAST method, it is possible to get the higher order sensitivity indices and the interaction effects among parameters (Saltelli et al. 1999).

Since \( {{{p{\omega_1}\leq \left( {N-1} \right)}} \left/ {2} \right.} \), in order to calculate V i from its characteristic frequency ω i and its Mth harmonics Mω i , the minimum sample size N should be (Saltelli et al. 1999):

where M is the maximum value for the p in calculating V i in Eq. (15) and ω max is the largest frequency among the frequency set for all parameters. For more descriptions and details of FAST see Xu and Gertner (2007).

4 Results

-

1-

PVI evaluation using AHP

Result of using AHP and pairwise comparison is shown in Fig. 3. In this figure the values of weights and scores for different factors and sub factors are presented. Following weighting factors and sub factors, pipe PVI can be calculated using Eq. 1. Results show that PVI of the most and the least vulnerable pipes is 0.877 and 0.400, respectively and the average of PVI is 0.6.

The results indicate in the study region, 6 pipes (pipes number 54, 69, 40, 30, 58 and 78) out of total WDS pipes (78 pipes) have PVI more than 0.8. This shows a high level of vulnerability due to the high age, long length and weak material.

-

2-

Output of AHP for pipe importance in WDS

The AHP structure for determining weights of pipes in the system hydraulic performance and the corresponding classes, weights and scores are shown in Fig. 4. The weights of majority of system’s pipes are close to each other which show the same role of pipes in WDS, the exceptions are pipes number 39, 37, 31, 32, 40, 54, 33 and 11 which are located near reservoir and play a major role in water delivery of the system. The failure of each of these pipes will separate a large number of demand nodes from the reservoir and cause considerable water shortage.

-

3-

SPVI evaluation

By determining pipe weight and PVI, SPVI can be qualified. Using Eq. 3, the value of SPVI is estimated as 0.63 which, considering Table 3, represents the moderate vulnerability state of the WDS. This index can be used to compare different WDSs in terms of physical vulnerability of pipes. It is necessary to keep in mind that to compare different WDSs’ performance using the proposed SPVI, the same factors should be used to evaluate system vulnerability.

-

4-

Optimization results

The GA algorithm is run considering the crossover probability of 0.8, mutation probability of 0.08 and the population size of 100. The tournament method is used for chromosomes selection and one point method is selected for crossover. P min and P max are considered to be 20 and 60 m, respectively, based on local standards of system performance. The pipes are considered to be made of cast iron or concrete. The unit length cost of pipes with different materials and diameters (that are available to be used) in the study area are shown in Table 4. Since there are 78 pipes in the network, the chromosome length is 312 (78 × 4).

After 6500 generations, the optimization model has converged to the optimal solution. The variations of cost of system improvement and the objective function (Z) are given in Fig. 6. The best solution decreases the system SPVI to 0.488 with a cost of $26.3 M. This shows a 15 % improvement in system vulnerability which is an indicative of higher performance. In the best solution, the pipes with higher importance in the network are usually replaced and/or duplicated to provide redundancy which is often advisable to prevent total system failure. The optimization has resulted in changing the type and increasing the diameter of pipes with higher PVI (PVI more than 0.55) due to their high role in the SPVI evaluation.

The results of optimization for duplicated pipes in the network are tabulated in Table 5. In this table, material and diameter of pipes after optimization as well as the physical characteristics of doubled pipes are presented. As it is shown 19 pipes are doubled and because of this redundancy the diameter of replaced pipes are decreased by one or two sizes. The diameter of other pipes is increased commonly by one or two sizes to meet the current objectives to reduce the vulnerability.

-

5-

PVI Sensitivity analysis

In order to analyze uncertainty associated with the parameters affecting PVI and weight of pipes in the system performance, it is needed to determine the most effective factors in results. In determining PVI, age of the pipe and its length can have uncertainty. The level of water table is considered to be constant.

To apply FAST method, probability density function (PDF) of factors are determined. For age parameter, normal distribution function with variance 50.79 and mean 12.45 and for length parameter, rayleigh distribution function with mean 0.323, mode parameter 0.258 and variance 0.029 are selected as the best distribution functions. Characteristic frequencies (ω) of 3 and 7 are assigned for age and length of pipes. Considering M as 3, the sample size is determined to be 43 and the sample s is generated (Eq. 6). Using Eqs. 3–14, the values of age and length are calculated.

Correlation between parameters of age and length is calculated as 98 %. Based on Iman and Conover (1982) the values of age and length are reordered. In order to determine the sensitivity of a parameter, values are rearranged based on the order of the considered parameter. Then coefficient values of Fourier series are determined. The variance contribution (or sensitivity index) is estimated to be 40.79 % and the partial variances contributed by length and age are determined to be 13.6 % and 14.1 %, respectively (Eqs. 8 and 9). Based on the estimated parameters using selected distribution functions, pipe vulnerability index is calculated.

-

6-

Sensitivity analysis of weights for each pipe

The parameters which their uncertainty in this part is analyzed are average pressure and pipe location in WDS. The best probability distribution functions for average pressure and location of pipe are selected as log-normal density function with mean 32.48, and variance 63.23 and, exponential density function with lambda of 5.05, respectively.

Characteristic frequencies (ω) of 3 and 7 are assigned for the selected parameters and value of M is considered as 4. Sample size is determined to be 57 and the sample s is generated. Based on the FAST application results, in SPVI evaluation, the pipe length and age correspond to 13.6 % and 14.1 % of the output variance, respectively. Also in pipe importance evaluation, the pipe role in system performance and pipe average pressure contribute to 17.34 % and 13.02 % of output variance results. It can be concluded that the pipe role in system performance is the most effective factor in system physical vulnerability.

-

7-

Improvement of system performance

In the optimization model in this study, only the pipes and how they should be modified are considered, however it is impossible to include all of these changes at the same time due to budget limitations. To address the temporal scheme of the system improvement, an algorithm is proposed to decrease the system vulnerability based on pipe importance in system performance as well as PVI.

Pipe physical vulnerability index and weight (importance) can be used to develop strategies for rehabilitation practices of WDS. The pipes with high importance and PVI are prioritized for rehabilitation as a preventive strategy to reduce SPVI and the resulting costs of pipe failure in WDS. Considering the values of PVI and pipe weights, Fig. 7 is developed in which the most important and vulnerable pipes are depicted. Considering the variations of pipe importance and PVI, the area between vertical and horizontal axis which are correspond to pipe PVI and importance, respectively, is classified into 16 groups. Based on the status of each pipe in Fig. 7, pipes are prioritized for applying rehabilitation strategies. Regarding the classification of Fig. 7, the pipes which are closer to region 1 are more vulnerable to failure and have higher priority for rehabilitation while pipes with more favorable conditions are closer to the region 7. Based on the different regions, pipes are treated in four classes as follow:

-

Class one: Network Modification

The pipes which fall into two regions 1 and 2 are placed in this class. As it is shown in Fig. 7, none of the pipes are located in region 1. However there are 3 pipes in region 2: pipe #39 which is directly connected to the reservoir and pipes #37 and #40 which are connected to pipe #39. The last two pipes supply water for the western and eastern halves of WDS. These pipes have high values of vulnerability and weight, the most important role in system hydraulics performance and their failure induce a significant cost to system. In this class construction of pipelines or parallel structures can be considered in order to reduce dependency of the system over these pipes.

-

Class two: Urgent Rehabilitation

In this class, modification and rehabilitation are considered for pipes which are located in the region 3. Figure 7 shows that 6 pipes are located in this region. In order to apply long term strategies, modification of the system should be considered on these pipes with the aim of reducing weight of pipes (make the role of pipes less significant in WDS performance), however short term strategies deal with rehabilitation practices of reducing PVI.

-

Class three: Rehabilitation

Pipes #13 and #47 which are located in regions 4 and 5, respectively, are considered in this class for rehabilitation practices. Comparing the pipes which are treated in the previous class, rehabilitation practices in this class must be scheduled in order to reach lower PVI values of pipes. The rehabilitation is first implemented on the pipes which have higher PVI and importance.

-

Class four: Long term improvements

In a system life time horizon, the improvement of WDS pipes which are less prone to vulnerability is considered to improve the system’s performance. For improvement of these pipes, the characteristics of pipes located in regions 6 and 7 can be used as an option of improvement because the system operation shows that pipes in region 6 and 7 well match with the requirements of the network. This helps to determine characteristics of pipes with better condition in the system in order to decrease the SPVI, without wasting considerable money.

Since pipe minimum PVI is equal to 0.42, there is no pipe located in region 7, however, there exist 9 pipes in region 6 which can be considered in the long term improvement strategies. These pipes almost have the same characteristics, such as large diameter, concrete material, low age and small length. By considering these common characteristics it is practically possible to apply rehabilitation strategies and replace old pipes with new ones having desirable characteristics. These characteristics can also be considered and used in the future expansion and development of the system.

5 Summary and Conclusion

Physical failure of the system components especially pipes is the main factor resulting in system vulnerability. Different factors are important in pipe physical vulnerability such as physical characteristics of pipes and pipes bedding soil conditions, which are considered in this study. Each of these factors includes several sub-factors with different importance in pipe vulnerability assessment. In order to determine and assign factors and sub factors’ weights, AHP is used. PVI and SPVI vulnerability indices are proposed for pipe and WDS, respectively. An optimization model is developed to decrease the system vulnerability with the least cost. A global sensitivity analysis method named FAST, is used for sensitivity analysis of effective factors in PVI and SPVI and to incorporate the correlation between different factors in vulnerability analysis. The methodology is applied to part of a WDS at Tehran province to investigate its performance in real life situation.

The results indicate that the case study’s WDS is moderately vulnerable to physical failure as reflected in SPVI of 0.54 which corresponds to the mean of its variation range. Also the most vulnerable pipes in WDS are determined and proposed as candidate pipes for rehabilitation due to their relatively high PVI and importance in the WDS. Using the suggested optimization algorithm, the system vulnerability is significantly reduced through replacement and/or duplication of pipes with higher importance in system performance. This decreases the PVI of pipes with higher importance in system performance and results in less SPVI. Furthermore by doubling important pipes, their weight in system performance and system dependency to them is decreased. For example pipes 39 and 31 which have the large diameters in current system have been doubled and their diameter is reduced to half or less. The results of this study show that the proposed scheme can be used for prioritizing the system’s improvement practices regarding the pipe PVI and importance. For instance weight of pipe 39 in system performance and its PVI were 1 and 0.85, which after optimization reduced to 0.6 and increased to 0.9, respectively. This scheme also helps to determine the most vulnerable parts (pipes) of the system. By making improvements in the pipes, the system performance can be significantly improved with the least cost. Therefore, the results of the proposed model can help decision makers to better allocate the budgets for improvement of the system’s performance.

References

Al-Barqawi H, Zayed T (2008) Infrastructure management: integrated AHP/ANN model to evaluate municipal water mains’ performance. J Infrastruct Syst 14(4):305–318

Adge WN (2006) Vulnerability. Glob Environ Chang 16(3):268–281

Andreou S (1986) Predictive models for pipe break failures and their implications on maintenance planning strategies for deteriorating water distribution systems. Dissertation, MIT, Cambridge

Andreou SA, Marks DH (1987) Maintenance decisions for deteriorating water pipes. J Pipelines 7:21–31

Baoyu Z, Xinhua Z, Yuan Z (2009) Vulnerability assessment of regional water distribution systems. Environ Scie Info Appl Technol 2:473–477

Brémond B (1997) Statistical modeling as help in network renewal decision. European Commission Co-operation on Science and Technology (COST), Committee C3 – Diagnostics of Urban Infrastructure, Paris, France

Chun MH, Han SJ, Tak NI (2000) An uncertainty importance measure using a distance metric for the change in a cumulative distribution function. Reliab Eng Syst Saf 70(3):313–321

Clark RM, Stafford CL, Goodrich JA (1982) Water distribution systems: a spatial and cost evaluation. J Water Res Plan Manag 108(3):243–256

Constantine AG, Darroch JN (1993) Pipeline reliability: Stochastic models in engineering technology and management. In: Osaki S, Murthy DNP (eds.), World Scientific Publishing Co, Singapore

Cukier RI, Fortuin CM, Shuler KE, Petschek AG, Schaibly JH (1973) Study of the sensitivity of coupled reaction systems to uncertainties in rate coefficients. I. Theory. J Chem Phys 59(8):3873–3878

Dandy GC, Engelhardt M (2001) Optimal scheduling of water pipe replacement using genetic algorithms. J Water Res Plan Manag 127(4):214–223

Dandy GC, Engelhardt M (2006) Multi-objective trade-offs between cost and reliability in the replacement of water mains. J Water Res Plan Manag 132(2):79–88

Dey K (2003) Analytic hierarchy process analyzes risk of operating cross-country petroleum pipelines in India. Nat Hazards Rev 4(4):213–221

Dey K (2004) Decision support system for inspection and maintenance: a case study of oil pipelines. IEEE Trans Eng Manag 51(1):47–56

De Schaetzen W, Savic DA, Walters GA (1998) A genetic algorithm approach to pump scheduling in water supply systems. Proceedings of Hydroinformatics 98, Rotterdam, Netherlands: 897–899

Eisenbeis P, Rostum J, Le Gat Y (1999) Statistical models for assessing the technical state of water networks—Some European experiences. Proceedings of AWWA Annual Conference, Chicago

Engelbrecht R, Haarhoff J (1996) Optimization of variable speed centrifugal pump operation with a genetic algorithm, Computer methods and water resources III. In: Abousleiman Y, Brebbia C, Chend A-D, and Ouazar D (eds) Computational mechanics. UK pp. 497–504

Francos A, Elorza FJ, Bouraoui F, Bidoglio G, Galbiati L (2003) Sensitivity analysis of distributed environmental simulation models: understanding the model behavior in hydrological studies at the catchment scale. Reliab Eng Syst Saf 79(2):205–218

Fu G, Kapelan Z, Reed P (2012) Reducing the complexity of multi-objective water distribution system optimization through global sensitivity analysis. J Water Res Plan Manag 138(3):196–207

Goldberg DE, Kuo CH (1987) Genetic algorithms in pipeline optimization. J Comput Civ Eng 1(2):128–141

Goulter IC, Kazemi A (1988) Spatial and temporal groupings of water main pipe breakage in Winnipeg. Can J Civ Eng 15(1):91–97

Haaker MPR, Verheijen PJT (2004) Local and global sensitivity analysis for a reactor design with parameter uncertainty. Chem Eng Res Des 82(A5):591–598

Iman RL, Conover WJ (1982) A distribution-free approach to inducing rank correlation among input variables. Commun Stat - Simul Comput 11(3):311–334

Jacobs P, Karney B (1994) GIS development with application to cast iron water main breakage rate. Proceedings of 2nd international conference on water pipeline systems. BHR Group Ltd, Edinburgh, Scotland

Jeffery (1985) Predicting urban water distribution maintenance strategies: A case study of New Haven Connecticut, Thesis (M.S.)--Massachusetts Institute of Technology, Dept. of Civil Engineering

Kettler AJ, Goulter LC (1985) An analysis of pipe breakage in urban water distribution networks. Can J Civ Eng 12(2):286–293

Kioutsioukis I, Tarantola S, Saltelli A, Gatelli D (2004) Uncertainty and global sensitivity analysis of road transport emission estimates. Atmos Environ 38(38):6609–6620

Kleiner Y, Rajani B (2001) Comprehensive review of structural deterioration of water mains: statistical models. Urban Water 3:131–150

Lu Y, Mohanty S (2001) Sensitivity analysis of a complex, proposed geologic waste disposal system using the Fourier Amplitude Sensitivity Test method. Reliab Eng Syst Saf 72(3):275–291

Mackle G, Savic DA, Walters GA (1995) Application of genetic algorithms to pump scheduling for water supply. In: Genetic Algorithms in Engineering Systems: Innovations and applications, 400–405, GALESIA’95, IEE Conf. no. 414

McMullen ID (1982) Advanced concepts in soil evaluation for exterior pipeline corrosion. Proceedings of the AWWA Annual. Conference, Miami

Nazif S, Karamouz M, Tabesh M, Moridi A (2010) Pressure management model for urban water distribution networks. Water Res Manag 24:437–458

Pinto J, Varum H, Bentes I, Agarwal J (2010) A Theory of Vulnerability of Water Pipe Network (TVWPN). Water Res Manag 24:4237–4254

Røstum J (1997) The concept of business risk used for rehabilitation of water networks. In: Proceedings of the 10th EJSW at Tautra. Deterioration of Built Environment: Buildings, Roads and Water Systems, J. Røstum, L. Dören and W. Schilling (ed) Norwegian University of Science and Technology, IVB-report B2-1997-2, ISBN 82-7598-040-2 67–75

Saaty TL (1991) Decision-making with dependence and feedback: The analytic network process. RWS Publications, Pittsburgh

Saltelli A, Tarantola S, Chan KPS (1999) A quantitative model-independent method for global sensitivity analysis of model output. Technometrics 41(1):39–56

Schwab M, Savic DA, Walters GA (1996) Multiobjective genetic algorithm for pump scheduling in water supply systems. Rep No 96/02, University of Exeter, Exeter, UK

Shamir U, Howard CDD (1979) An analytic approach scheduling pipe replacement. J AWWA 71(5):248–258

Simpson AR, Dandy GC, Murphy L (1994) Genetic algorithms compared to other techniques for pipe optimization. J Water Res Plan Manag 120(4):423–443

Tran T, Malano H, Thompson R (2003) Application of the analytical hierarchy process to prioritize irrigation asset renewal: the case of the La Khe irrigation scheme, Vietnam. Eng Constr Archit Manag 10(6):382–390

Walaski TM, Pelliccia A (1982) Economic analysis of water main breaks. J AWWA 74(3):140–147

Wang G, Fang S, Shinkareva S, Gertner GZ, Anderson A (2001) Uncertainty propagation and error budgets in spatial prediction of topographical factor for revised universal soil loss equation (RUSLE). Trans Am Soc Agric Eng 45(1):109–118

Xu C, Gertner GZ (2007) Uncertainty and sensitivity analysis for models with correlated parameters. Reliab Eng Syst Saf 93(10):1563–1573

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nazif, S., Karamouz, M., Yousefi, M. et al. Increasing Water Security: An Algorithm to Improve Water Distribution Performance. Water Resour Manage 27, 2903–2921 (2013). https://doi.org/10.1007/s11269-013-0323-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11269-013-0323-2