Abstract

Water distribution systems (WDSs) are one of the vital infrastructures in urban areas. The common objective considered in WDSs design is providing required water with the minimum construction cost. Less attention is paid to “water quality” as an objective in optimal design of WDSs. The aim of this paper is to include a water quality based objective in WDS design alongside other common objectives. For this purpose, the water quality reliability index developed based on “chlorine residual” and “water age”, is used. EPANET2.0 is applied for WDS simulation and ACO (Ant-Colony-Optimization) has been used as the optimization algorithm. Head-Driven-Simulation-Method (HDSM) is also considered. The proposed model is applied to Jahrom (a city in the south of Iran) WDS. The outputs show that the proposed model would result in less construction costs in comparison to the original design and 4–10 % of construction cost can be reduced depending on the considered objectives and selected optimal solution by managers and decision makers while the resulted solutions include high water quality reliability (ranging from 93 to 99 %). Also using HDSM method for hydraulic analysis of WDS instead of DDSM can lead to solutions with less construction cost (U$10,000 in average) and acceptable water quality reliability.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Water distribution systems are one of the most critical urban facilities and always must have proper functionality to satisfy all customer’s demands within sufficient pressure and standard quality. Optimal design of these systems should be taken into account due to great investment needed for their development as well as securing above purposes. Optimal design of WDSs can be categorized into single-objective and multi-objective optimization.

There are varieties of studies on single/multi objectives optimization of WDSs. Ostfeld (2005) minimized the total cost of design and operation of the WDSs under unsteady system performance considering pressure and chlorine residual constraints.

Zabihi (2008) optimized the construction cost of WDS while residual chlorine was considered as constraint alongside with nodal pressure and flow velocity. He concluded that satisfying water quality constraint cannot be guaranteed by applying minimum velocity constraint and water quality must be considered in optimization process as an objective.

Tabesh et al. (2011) optimized the chlorine dosage and location of chlorine injection in a WDS using GA algorithm.

Gupta et al. (2012) offered a two-phase optimization model to minimize design cost of WDS and maximize hydraulic-quality reliability.

Islam et al. (2013) proposed a water quality index (WQI) in order to achieve optimal chlorine dosage and number of booster pumps. This model was claimed to be useful for small networks that chlorine residual is often selected as water quality parameter.

Tabesh et al. (2011) and Islam et al. (2013) considered quality constraints in optimization process but they didn’t consider total cost of WDS as it is an important issue in WDS design. Ostfeld (2005) and Zabihi (2008) tried to overcome this shortage but they didn’t consider both quality parameters and construction cost as two-objective optimization as they are in contrast with each other. Gupta et al. (2012) tried a two-phase optimazation and just a single solution could be achieved in their porposed approach and unlike two-obective optimization, managers and decision don’t have several solutions to choose a proper solution according to situations.

Liu et al. (2010) used hybrid genetic algorithm to optimize reconstruction and extension of WDS. Maximizing water quality as well as minimizing costs were objectives of the optimization model. Kanta et al. (2012) developed a multi-objective optimization model for rehabilitation of WDS with three objectives of 1-minimizing water quality deficiencies 2-minimizing potential fire damages and 3-minimizing the mitigation cost.

Afshar and Mariño (2012) investigated a multi-objective optimization to monitor water quality of large scale WDSs. Using two-colony ant algorithm(ACO), they optimized a real WDS nodes in order to minimize total number of stations while maximizing total water quality assessed in WDS.

Fu et al. (2013) proposed a many-objective optimization model for WDS design or rehabilitation. Six objectives of 1-minimizing operating cost, 2-minimizing capital cost, 3-minimizing leakage, 4-minimizing hydraulic failure, 5-maximizing firefighting capacity, 6-minimizing water age were used. Complicated visual analytics were used to interpret complex trade-off between mentioned objectives. Kurek and Ostfeld (2013) introduced multi-objective optimization of WDS operation. The proposed model was employed for minimizing the energy cost, water quality objective (chlorine disinfected concentration and water age) and tank cost.

Mulholland et al. (2013) focused on multi-objective optimization of a WDS operation by minimizing the energy cost alongside with minimizing the loss of chlorine and also minimizing tank volume. Li et al. (2014) developed a multi-objective optimization model in order to maximize water quality and minimize re-chlorination cost. Water quality was maximized in a way that disinfection was applied in whole network and at the same time Disinfected-By-Products(DBPs) could be lowered. Babaei et al. (2015) applied a model for minimization of operation cost and maximization of WDS reliability. Operation cost included energy and chlorine cost while reliability included both hydraulic and quality reliability.

Siew et al. (2016) developed a new optimization approach which was penalty-free as they deployed pressure-driven analysis method. Objective functions were total cost and performance of system. The obtained solutions were cheaper as compared to previous studies. Water quality (i.e. chlorine residual, DBPs and water age) was assessed and results shown that they were improved as well as hydraulic criteria.

By reviewing recent papers in multi-objective, it can be understood that the main shortage of studies like Liu et al. (2010) and Kanta et al. (2012) is that they didn’t consider chlorine residual as water quality parameter which is an important parameter in assessing water quality in WDSs. Afshar and Mariño (2012); Fu et al. (2013); Kurek and Ostfeld (2013); Babaei et al. (2015); Mulholland et al. (2013) and Li et al. (2014) investigated optimization of WDSs with different assumptions and objective functions but none of them considered construction cost as an objective in optimization process. Although Siew et al. (2016) considered total cost of WDS, but water quality was not assessed as an objective function. Therefore, none of mentioned papers have considered water quality parameters in WDSs design.

It can be concluded that common optimal designs of WDSs are just based on minimizing the construction costs and in some cases, maximizing the hydraulic reliability. Although water quality based optimization of WDS during its operation, has been widely investigated in the recent studies, still less attention is paid to water quality based reliability in WDS design. Neglecting water quality parameters in designing WDSs can lead to several problems in their operational functionality. In some cases, it would be difficult or sometimes impossible to offer a proper operation program in order to satisfy water quality based constraints. It is also remarkable that in most studies chlorine residual has been the only water quality parameter considered in WDS optimization process and water age is rarely investigated. Therefore, in this study the main objective is to overcome these shortages.

This study investigates multi-objective optimal design of WDS considering the satisfaction of water quality necessities as an objective. The proposed model is applied to Jahrom (a city in south of Iran) WDS and is investigated in four different scenarios. Chlorine residual and water age are considered as representatives of water quality. Water quality objective is quantified based on penalty curves of “chlorine residual” and “water age”. While using available penalty curves for chlorine residual, a new water age penalty curve is developed in this study regarding the weaknesses of available ones. The effect of considering different sets of objective functions in WDS optimal design is explored through examining different scenarios. Furthermore, HDSM (Head-Driven-Simulation-Method) is used in design stage for hydraulic analysis of WDS which would provide some advantages over DDSM(Demand-Driven-Simulation-Method).

2 Methodology

2.1 HDSM Analysis

In HDSM nodal outflow is related to available pressure and is obtained using a head-outflow relationship (e.g. Wagner et al. 1988; Shirzad et al. 2013). A code was developed using EPANET2.0 (Rossman 2000) toolkit to calculate HDSM in MATLAB. The written code calls pressure results in MATLAB and then modifies demands in all nodes according to Wagner et al. (1988) relationship. The network is again simulated using the modified demands and this process is repeated until demands converge to a constant value.

2.2 Water Age Penalty Curve

Some water age penalty curves have been proposed in literature. Coelho (1996) suggested a penalty curve for water age which is formulated as:

where PI: is performance index and WA: is water age(hour). In this penalty curve, there are upper and lower limits for water age. If the water age is less than the lower limit, then performance of the system is very well and value of “one” will be dedicated to excellent performance index. If water age is higher than the upper limit, performance index will be “zero” and it means, poor water age service. Performance index between upper and lower limits, would be dedicated by a number between “zero” and “one”. Coelho (1996) considered 6 and 10 h for lower and upper limits, respectively.

Tamminen et al. (2008) suggested a three-part water age penalty curves for evaluation of water age in a WDS. They considered 10 and 30 h as the lower and upper limits in one of the penalty curves and 20, 80 and 50,350 h for the other two penalty curves. All of these numbers were assumed and no specific basis was found for these penalty curves. In this research, it is tried to find a reasonable basis for the lower and upper limits. For this purpose, the results of Srinivasan et al. (2008) and Wang (2013) are deployed.

Srinivasan et al. (2008) investigated the effects of chlorine and residence time on total bacteria in drinking WDSs. The ratio of bacteria in bulk water to the total bacteria in WDS was considered as an index to study the effects of residence time on the WDSs water quality. The results of this research showed a meaningful increase in the mean of index with residence time increase. At a residence time of 8.2 h the proposed index was very low indicating that the system situation is acceptable. By increasing the residence time to 48 h, the index became very high indicating that the water quality deteriorated and the system performance is unacceptable.

Wang (2013) investigated the effects of water age and pipe materials on some bacteria species and physic-chemical water parameters. The results showed that there is not a specific correlation between bacteria species and water age in different WDSs. Furthermore, Wang (2013) investigated physiochemical parameters in WDSs. There were sensible changes in physiochemical parameters like “Disinfected-Concentration” and “Dissolved-Oxygen” by increasing the water age. The results also showed that TOC (Total-Organic-Carbon) decreases as water age increases. In addition, PH had not a huge change as water age increased except in WDS with cement pipes. It can be concluded that there is not a specific correlation between bacteria species and water age in these three WDSs. The effect of water age on different parameters is complicated and an explicit conclusion from the Wang (2013) results is almost impossible without further investigations. Note that the results of Wang (2013) were retrieved of studies on very simple lab-scale networks with identical pipe materials and pipe age. It is obvious that in real scale networks like WDSs found in every city with so many different pipe materials and pipe age, the correlation between water age and bacteria species or physicochemical parameters would be more complicated.

In the proposed penalty curve, if the water age is below 8 h the number dedicated to its performance will be 1 and if the water age is above 48 h, its performance will be zero. If water age is between 8 and 48 h, a number between zero and one will be dedicated for its performance considering a linear behaviour of system. Eight and 48 h are specified based on the results of Srinivasan et al. (2008) as discussed earlier. The proposed penalty curve can be formulated as:

where PI: is performance index and WA: is water age(hour).

2.3 Optimization Model Formulation

2.3.1 Decision Variables

Decision variables in the proposed model are pipes diameter, tank’s head and chlorine injection dosage in tank. All the decision variables are discrete. The decision area of different decision variables is formulated as follows:

where Dj PE: is the decision variable set for PE(Poly-Ethylene) pipes diameter, Dj AC: is the decision variable set for Asbestos Cement (AC) pipes, H: is the decision variable set for tank’s head and C: is the decision variable set for chlorine dosage injection in tank. As the proposed model is going to be deployed in a real case study, two different pipe materials are used the same in the original design of the considered WDS.

2.3.2 Objectives

Construction and chlorine costs are considered as the cost objective and combined together as the first objective. The second objective is water quality reliability. Chlorine residual and water age are considered for water quality reliability evaluation.

Cost Evaluation

Construction cost includes pipe cost, excavation (based on width and depth of trenches which are dependent on pipe diameter) and demolition of asphalt concrete and materials in trench and etc.

The cost of one-year chlorine usage through the last year of service WDS design is also included in the cost objective. Chlorine cost is computed considering the inflation rate through 22 years of project life time. The unit length piping cost can be formulated as (Shirzad 2013):

where RTD: is the coefficient for exchanging Rials (Iranian currency) to Dollars.

Construction and chlorine costs are formulated as:

where Di: is the pipe diameter of section “i” (mm), Li: is the pipe length in section “i” (m), NP: is the number of pipes and ULPC: is the unit length piping cost ($/m). Q: is the outgoing discharge of tank during one-day operation (l/day), C: is the chlorine injection in tank (mg/l), CV: is the unit cost of chlorine ($/mg).

Water Quality

Water quality reliability is considered as the second objective in the proposed optimization model. Two different water quality variables are studied in this paper. The first one is chlorine residual and the other one is water age. Combination of water age and chlorine residual is also considered and assessed in this research.

At each consumer node, chlorine residual is assessed by a penalty curve, and then the water quality reliability of network is evaluated using a weighted mean of nodal reliability, proposed by Gupta et al. (2009). The formulation of network water quality can be represented as:

where, Qnik req: is the required demand of each node, Qnik avl: is the available discharge at each node, N: is number of nodes, T: is number simulation steps, Rq,t: is the total water quality reliability of network based on chlorine residual, i: is the counter of nodes,k: is the counter of tanks and bi: is a coefficient for each node based on chlorine residual and is derived from chlorine residual penalty curve proposed by Coelho (1996) which is formulated as:

where Cl: is chlorine residual(mg/l). Note that, there was a time factor in the above equation for failure of pipes, pumps and etc. which is not applicable in this research.

The formulation of network water quality reliability based on water age is like Eq. (9) with a minor change:

in which bi: is a coefficient for each node based on water age and is derived from water age penalty curve formulated as Eq. (2), RWA,t: is the total water quality reliability of network based on water age.

Water age and chlorine residual are combined into one water quality reliability index to consider both of these parameters in design of WDS. Combined water quality reliability can be formulated as:

in which Rcombined: is the combined reliability.

2.3.3 Constraints

Surplus pressure in WDSs can increase pipe breaks and leakages and undesired water consumption. Based on WDS design codes, the maximum water pressure in demand nodes is limited to 60 m-H2O. In case of minimum pressure constraint, the standard code suggests the range of 14–26 m-H2O depending on the height of building in the region. The maximum water velocity in pipes is limited to 2 m/s in order to minimize the risk of pipe failure. These constraints are considered in the optimization model as follows:

2.3.4 Scenarios

In this section, the proposed optimization model for WDS design is introduced by four scenarios to investigate the effects of water quality consideration in WDS design.

In all scenarios, extended period simulation is considered. In scenario one hydraulic analysis is based on DDSM method whiles in scenario two, HDSM method is deployed and minimum pressure is released in order to investigate the optimal design of WDS under the desired pressures. In scenario three, water age is considered as the quality parameter and scenario four investigates the effect of both water age and chlorine residual as the water quality parameters. Chlorine residual is considered as the decision variable except in scenario three. Also in scenario 4, both of chlorine and water age are considered.

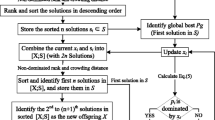

Finally, Ant Colony Optimization (ACO) (Dorigo 1992) is deployed due to its simplicity and consistency in utilizing discrete decision variables. More information about the optimization algorithm and ACO can be seen in Afshar et al. (2009).

3 Case Study: Jahrom WDS

As a real case study, Jahrom WDS is deployed and Extended Period Simulation (EPS) is applied and variation of tank level and detention time in tank is considered in model. Jahrom WDS consists three isolated zones. Zone three is chosen to examine the proposed algorithm. The population of the Jahrom City is about 124,000 and the population covered by the zone three of WDS is about 5000 people. More information about Jahrom and its WDS can be found in appendix 1.

As Jahrom WDS has been designed for 22 years of service life (after 22 years, rehabilitation program is going to be implemented), chlorine wall decay constant (Kw) in PE pipes is considered to be equal to 0.25 m/day based on the results of Al-Jasser (2007). Also Kw = 12 m/day is assumed for AC pipes regarding results of Al-Jasser (2007).

The bulk decay constant (Kb) can be determined by examining water sources. As there was no data available for this constant, there is no other way unless making an assumption for Kb according to suggested values in literature. Ghimire et al. (2005) suggested Kb = 2.5 day−1, in a case when there is no information in Kb and therefore, in this research Kb is assumed as 2.5 day−1 (for dealing with this deficiency sensitivity analysis on Kb values is implemented and the results are presented in appendix 2). Roughness coefficient of pipes in different ages of service has been applied using offered relationships.

For better performance of ACO, sensitivity analysis of ACO parameters is advised. Zecchin et al. (2005) studied ACO parameters in optimizing of WDSs problems. They concluded that, ACO has a better performance when parameters of α and β are selected within the values of 1 ≤ α ≤ 2 and 0 ≤ β ≤ 1. Shirzad (2013) has opted similar values after sensitivity analysis. α = 1 and β = 0 is opted as Shirzad (2013) used. To avoid sensitivity analysis for ρ (pheromone evaporation rate), Zecchin et al. (2005) suggested values of 0.97 ≤ ρ ≤ 0.99. So ρ = 0.98 is used here. Sensitivity analysis has been made for the rest of parameters and “initial pheromone (τ0)” = 100, “inside cycle” = 1500, “overall iteration” = 20 and “number of ants” = 25 was opted.

3.1 Scenario One: Minimizing Cost and Maximizing Reliability Based on Chlorine Residual Using DDSM Method

The formulation of this scenario is:

Subject to

As discussed earlier, Zabihi (2008) showed that, considering minimum velocity constraint in optimization problems, cannot guarantee proper performance of WDS from water quality point of view. So other decision variables such as chlorine dosage which directly influences water quality, should be taken into account. So chlorine dosage injection is going to be applied in all scenarios and its functionality in water quality is going to be investigated. In the optimization process, chlorine dosage is selected from discrete values ranging from 0.5 to 0.8 mg/l as chlorine dosage below 0.5 mg/l causes chlorine deficit in the farthest nodes of WDS and chlorine dosage above 0.8 mg/l is also prohibited by standard codes.

Standard pipe diameters for PE and AC are different and ACO selects corresponding pipe diameter according to pipe material at each section. It should be noted that tank head is also variable and ACO can choose different head ranging from 1134 to 1139 m, in order to tune network pressure between maximum and minimum pressure constraint.

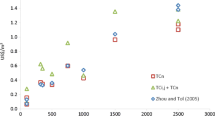

The obtained results of this scenario are illustrated in Fig. 1. For better illustration of the results, water quality risk is used instead of water quality reliability as follow:

The optimization model has found solutions with water quality risk of 1 %. Another remarkable point is that the cost difference of the least cost solution (S3-4) and the most reliable solution (S3-1) is just U$20,000. It means that with increasing 5.8 % of cost, the water quality risk is decreased about 6 %.

Chlorine dosage decision variable contains various amount ranging from 0.50 to 0.80 mg/l but the obtained results contains chlorine dosage of 0.50 and 0.55 mg/l and it means that chlorine dosage of 0.55 mg/l is enough to achieve low levels of water quality risk up to 1 % and further increase in chlorine dosage is not needed. In the actual network of Jahrom, booster pumps are used in order to inject chlorine into the network, and the obtained results in this scenario proves that, actually there is no need to any booster pump in network and choosing proper pipes for each section and injecting chlorine in tank is enough to lower the water quality risk.

Pumps and energy cost considerations are not involved in this study. The reason is that pumps are used before the tank in this WDS and based on the obtained results, almost in all optimal solutions the tank heads are the same and therefore, the pumping cost that is related to the pumping head would be the same in all solutions and does not make any difference in their evaluation. Furthermore, decision variables (which are pipe diameters, chorine dosage and etc.) are not affected by performance of pumps. So the performance of pumps in almost all results as well as the energy cost are the same. In the other word, considering energy cost will increase a constant value to first objective of all points in Pareto optimal solutions.

For better evaluation of the proposed model, the obtained results are compared with original design (i.e. already constructed in Jahrom). In the WDS of Jahrom, booster pumps are used in order to inject chlorine into the network. Unfortunately, for some security reasons, there is no access to chlorine dosage injection data in Jahrom WDS. Therefore, just to provide a basis for comparison of the obtained solutions and actual design of Jahrom WDS, chlorine dosages of 0.50 and 0.55 mg/l are assumed (that is the common chlorine dosage among the obtained solution). Comparing the obtained results with the original design of Jahrom WDS is also shown in Fig. 1.

Solution O-1 is the original design of WDS with assumption of 0.50 mg/l chlorine dosage. This design is U$52,200 more expensive than solution “S3-4” (in Fig. 1) that is the least cost solution and U$22,000 more expensive than solution “S3-1” (in Fig. 1) which is the most expensive one. O-2 is the original design of Jahorm WDS with assumption of 0.55 mg/l chlorine dosage. This result is also U$64,000 more expensive than the solution “S3-4” and U$34,000 more expensive than solution “S3-1”. It is worth to say that in original design, tank head is 1134 m which causes pressure deficit in some nodes. Actually original design is placed in non-feasible area according to the formulation of this scenario.

Pareto optimal solution in this scenario could be divided into two groups. One group includes solutions with chlorine dosage of 0.50 mg/l and the other group contains solutions with chlorine dosage of 0.55 mg/l. In Fig. 1 these two groups are illustrated. For better comparison of solutions in construction cost point of view, one solution in each group is selected which have small difference in both objectives. In the first group (i.e. solution with chlorine dosage of 0.50 mg/l) the best solution from water quality risk aspect is solution “S3-3” which has risk of 1.6 %. This result can be an acceptable solution that decision makers can opt as final scheme, but construction cost of this result is relatively high and should be considered by managers and decision makers.

On the other hand, solution “S3-2” (in the second group with 0.55 mg/l chlorine dosage) has the risk similar to the solution “S3-3” but it has less construction cost. For better comparison of construction cost of the obtained results, the results of second group are redesigned with chlorine of 0.50 mg/l. This makes the chlorine cost of all results equivalent and so the difference of obtained solution in construction cost point of view can be compared easily. Figure 2 shows compared solution of group one and redesigned results of group two.

Figure 2 shows that solution “S3-2” is a very cheap solution in construction cost as compared to solution “S3-3” (about U$10,000). Decision makers can opt solution “S3-2” if financial resources are limited and they can opt solution “S3-3” which has lower injected chlorine dosage and the risk of producing DBPs decreases.

3.2 Scenario Two: Minimizing Cost and Water Quality Risk, Based on Chlorine Residual Using HDSM Method

The formulation of this scenario is like scenario one. The only difference is that the minimum pressure constraint is not applied, and it is necessary in HDSM analysis to consider WDS design in undesirable situation such as pressure deficit. A constraint is also applied to secure at least 95 % supply of water demand in WDS as follows:

Figure 3 shows the results of scenario two as well as scenario one, so a comparison can be made easily. Releasing minimum pressure constraint has resulted in solutions with lower costs. Results has been processed and minimum water supply in HDSM based designs is 97 % (as compared to DDSM based design) and 3 result has 100 % water supply. This means that three of the obtained solutions are exactly equal to the obtained solutions in scenario one. This can be justified that in WDS with high nodal pressure and thus full water supply might lead to higher water velocity in WDS and then lower chlorine decay in WDS.

The results are also evaluated from the minimum percentage of water supply aspect. The results show that in some solutions the minimum percentage of water supply is 40 % which might be unacceptable as final solution. Only three solutions have 100 % nodal supply. Releasing minimum pressure constraint and applying HDSM analysis would offer cheaper WDS designs but specific care should be taken into account due to unsatisfactory of nodal pressure in some regions.

The results also checked for firefighting discharge and 19 results were facing pressure deficit. In 12 results, just one node had pressure deficit less than 0.1 m and in the 7 results, three nodes had maximum pressure deficit of 0.6 m.

3.3 Comparing Scenarios One and Two

Figure 3 also compares the obtained results of scenarios one and two. Some results of scenario two have in average, U$10,000 less cost in comparison with scenario three. There are 3 common solutions (C-1,C-2 and C-3) in these scenarios. Scenario two leads to cheaper solution but as discussed in scenario two, obtained solutions have various range of nodal consumption, which is needed to be considered by decision makers. Scenario two needs a very high computational effort. So achieving cheaper cost in scenario two needs higher computational cost.

3.4 Scenario Three: Minimizing Cost and Minimizing Water Quality Risk Based on Water Age Using DDSM Method

The formulation of scenario three is:

Subject to:

In this scenario, instead of chlorine residual, water age is considered as water quality parameter and optimization model tries to obtain solutions with lower risk from “water age” point of view. As explained earlier, the water quality objective (based on water age) is similar to water quality objective based on chlorine residual with a minor change, bi is calculated based on penalty curve of water age (Eq. (2)). Note that, in order to put this scenario in the same criteria to be compared to other scenarios (in cost objective), chlorine cost is added to the objective function. Figure 4 shows the results of this scenario.

The most remarkable point in Fig. 4 is that the maximum difference of obtained solutions in the second objective (water quality risk based on water age) is just 0.2 %. It shows that the proposed penalty curve in water age (Eq. (2)) is not suitable or is not well defined, but the results show that 55 % of nodes have water age above 8 h and performance dedicated to those nodes are completely different. A reason could be selection of non-suitable decision variables in this scenario. Changing decision variable would improve water quality (based on water age) results in this scenario. The suitable decision variables which directly influence water age are: 1-tank sizing 2-tank siting 3-pumping schedule (and using variable-speed or fix-speed).

3.5 Comparing Scenarios One and Three

Results of scenario three are redesigned with chlorine dosage of 0.50 mg/l and compared with results of scenario one (only results with chlorine dosage of 0.50 mg/l are used for comparison) (Fig. 5).

Although some cheaper results are found in scenario three but these results are not good choices for WDS design because water quality risk is relatively high. So considering both residual chlorine and water age in optimization is necessary and as a result combined water quality risk of these parameters is deployed in scenario four.

3.6 Scenario Four: Minimizing Cost and Minimizing Water Quality Risk Based on Both Water Age and Chlorine Residual, Using DDSM Method

The formulation of this scenario is:

Subject to

In this scenario, mixed reliability is applied and Fig. 6 shows the Pareto optimal solutions of this scenario. Although there are solutions with acceptable quality risk, note that, all the differences between solutions are in chlorine reliability and water age reliability does not have any significant effect in solution.

As discussed earlier, proper decision variables should apply to achieve solution with very low risk in water quality like the solution in scenario one.

4 Conclusion

Water quality reliability is an important issue in designing WDSs but less attention is paid to it in WDS design literature. In this paper a two-objective optimization model of WDSs considering residual chlorine and water age as “water quality objective” along with construction cost and chlorine cost as “cost objective” was proposed. Coelho (1996) penalty curve of chlorine residual was used as representative of water quality reliability based on chlorine residual and in this research a water age penalty curve was represented due to ambiguous basis of previous water age penalty curves. ACO used as optimization algorithm and EPANET2.0 was deployed as hydraulic-quality simulator.

The proposed model was applied to a real case study. It was studied in four scenarios with different assumptions, analysis methods, constraints and objectives. The results of scenario one showed the effect of considering chlorine dosage as decision variable. In scenario one, functioning of the proposed model was proved, as the obtained results had over performed the original design (U$22,000 to U$64,000 less construction cost in comparison with the original design). The results also demonstrated acceptable performance of optimization model in finding solutions with low quality risk (ranging from 7 to 1 %). Effect of releasing minimum pressure constraint was evaluated in scenario two and for more realization of WDS situation, HDSM method was deployed and a code was written in MATLAB. Scenario two offered cheaper results in comparison with scenario one (an average of U$10,000 less cost) but fitness of results must be assessed by decision makers due to pressure deficit risk in some nodes. The newly developed water age penalty curve was assessed in scenario three. The results offered little improvement in reliability objective (just 0.2 %) with relatively great construction cost (U$9000) which was not economically a logical choice. Combined water quality reliability was assessed in scenario four and because of a small effect of water age reliability (due to improper decision variables), solutions with low water quality was not achieved.

References

Afshar A, Mariño MA (2012) Multi-objective coverage-based ACO model for quality monitoring in large water networks. Water Resour Manag 26(8):2159–2176

Afshar A, Sharifi F, Jalali MR (2009) Non-dominated archiving multi-colony ant algorithm for multi-objective optimization: application to multi-purpose reservoir operation. Eng Optim 41(4):313–325

Al-Jasser AO (2007) Chlorine decay in drinking-water transmission and distribution systems: pipe service age effect. Water Res 41(2):387–396

Babaei N, Tabesh M, Nazif S (2015) Optimum Reliable operation of water distribution networks by minimizing energy cost and chlorine dosage. Water SA 41(1):149–156

Coelho ST (1996) Performance assessment in water supply and distribution. Ph.D. Thesis, Civil & Offshore Engineering Department, Heriot-Watt University, Edinburg

Dorigo M (1992) Optimization, learning and natural algorithm. Ph.D. Thesis, Politecnico di Milano, Milan

Fu G, Kapelan Z, Kasprzyk J, Reed P (2013) Optimal design of water distribution systems using many-objective visual analytics. J Water Resour Plan Manag 139(6):624–633

Ghimire S, Barkdoll B, Bergstrom P (2005) Network modeling to demonstrate efficacy of improved water quality monitoring. World Water Congress, ASCE, R Walton, Anchorage, Alaska, USA

Gupta R, Dhapade S, Bhave PR (2009) Water quality reliability analysis of water distribution networks. International Conference on Water Engineering for Sustainable Environment organized by IAHR, Vancouver, Canada, 5607–5613

Gupta R, Hussain A, Bhave PR (2012) Water quality reliability based design of water distribution networks. World Environmental and Water Resources Congress 2012, Albuquerque, 3320–3330

Islam N, Sadiq R, Rodriguez MJ (2013) Optimizing booster chlorination in water distribution networks: a water quality index approach. Environ Monit Assess 185(10):8035–8050

Kanta L, Zechman E, Brumbelow K (2012) Multiobjective evolutionary computation approach for redesigning water distribution systems to provide fire flows. J Water Resour Plan Manag 138(2):144–152

Kurek W, Ostfeld A (2013) Multi-objective optimization of water quality, pumps operation, and storage sizing of water distribution systems. J Environ Manag 115(1):189–197

Li C, Yu J Z, Zhang TQ, Mao XW, Hu YJ (2014) Multiobjective optimization of water quality and rechlorination cost in water distribution systems. Urban Water J (ahead-of-print) 1–7

Liu H, Yuan Y, Zhao M, Fang H, Zhao H (2010) Hybrid multi-objective genetic algorithm for optimal design of water supply network. Water Distribution Systems Analysis 2010, Tucson, 899–908

Mulholland M, Latifi MA, Purdon A, Buckley CA, Brouckaert CJ (2013) Multi-objective optimisation of the operation of a water distribution network. In A.K. and I.T.B.T.-C.A.C. Engineering, (ed.), 23rd European Symposium on Computer Aided Process Engineering. Lappeenranta, 709–714

Ostfeld A (2005) Optimal design and operation of multiquality networks under unsteady conditions. J Water Resour Plan Manag 131(2):116–124

Rossman LA (2000) EPANET User’s manual. Risk Reduction Engineering Laboratory, U.S. Environmental Protection Agency, Cincinnati

Shirzad A (2013) Multiobjective optimization of water distribution networks and presenting a comprehensive model for dynamic design of these networks. Ph.D. Thesis, School of Civil Engineering, College of Engineering, University of Tehran, Tehran

Shirzad A, Tabesh M, Farmani R, Mohammadi M (2013) Pressure-discharge relations with application to Head-Driven Simulation of water distribution networks. J Water Resour Plan Manag 139(6):660–670

Siew C, Tanyimboh TT, Seyoum AG (2016) Penalty-free multi-objective evolutionary approach to optimization of Anytown water distribution Network. Water Resources Management 1–18

Srinivasan S, Harrington GW, Xagoraraki I, Goel R (2008) Factors affecting bulk to total bacteria ratio in drinking water distribution systems. Water Res 42(13):3393–3404

Tabesh M, Azadi B, Roozbahani A (2011) Quality management of water distribution networks by optimizing dosage and location of chlorine injection. Int J Environ Res 5(2):321–332

Tamminen S, Ramos H, Covas D (2008) Water supply system performance for different pipe materials part I: water quality analysis. Water Resour Manag 22(11):1579–1607

Wagner JM, Shamir U, Markes DH (1988) Water distribution reliability: simulation methods. J Water Resour Plan Manag 114(3):276–294

Wang H (2013) Critical factors controlling regrowth of opportunistic pathogens in premise plumbing. PhD Thesis, Virginia Polytechnic Institute and State University, Virginia Tech, Blacksburg, US

Zabihi M (2008) Optimal design of water distribution systems considering quality constraints. M.Sc. Thesis, School of Civil Engineering, College of Engineering, University of Tehran, Tehran

Zecchin A, Simpson AR, Maeir HR, Nixon JB (2005) Parametric study for an ant algorithm applied to water distribution system optimization. IEEE Trans Evol Comput 9(2):175–191

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendix 1

(DOCX 39 kb)

Appendix 2

(DOCX 21 kb)

Rights and permissions

About this article

Cite this article

Shokoohi, M., Tabesh, M., Nazif, S. et al. Water Quality Based Multi-objective Optimal Design of Water Distribution Systems. Water Resour Manage 31, 93–108 (2017). https://doi.org/10.1007/s11269-016-1512-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11269-016-1512-6