Abstract

Bair, accompanied by some of his past co-authors, has commented on our paper “History, Origins and Prediction of Elastohydrodynamic Friction”. We believe that our paper presents a balanced summary of current understanding of EHD friction, its origins and prediction. However, Bair et al. appear to have chosen to interpret our paper as an assault on the high-stress viscometric approach that Bair has championed for some years and also as an espousal of the Eyring model of rheology which he has consistently denigrated over the same period. To combat this perceived assault, they suggest that our paper somehow misrepresents the literature and indeed contains numerous misstatements of fact and misrepresentations by omission. Our reply refutes this.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Bair, accompanied by some of his past co-authors, has commented on our paper “History, Origins and Prediction of Elastohydrodynamic Friction” [1]. For convenience in our response, we shall use the singular “Bair” as shorthand for “Bair, Vergne, Kumar, Poll, Krupka, Hartl, Habchi, Larson”.

Bair’s comment is lengthy, and we shall try to address its various points as concisely as possible. However, we shall start by noting in its Abstract and Introduction two statements that we believe are manifestly false and that lie at the heart of the debate.

Bair writes: Progress in EHL has been paralyzed by the assumption that shear thinning should be indistinguishable from the shear dependence of a liquid heated by viscous dissipation. Although the statement is somewhat unclear, we believe that in essence he is saying that we cannot distinguish the effects on shear stress of isothermal shear thinning and shear heating. This is incorrect. As our paper discusses in Sect. 7.1, so long as temperature rise is kept to a reasonably low level, it is possible to calculate and account for its effect on mean shear stress when studying non-Newtonian behaviour. This is, however, much more practicable in an EHD contact, where contact times are very short and film thicknesses very thin, than it is in existing high-stress viscometers. In EHD contacts, it allows us to extend exploration of the relationship between mean shear stress and strain rate from combined values of shear stress × strain rate of 1012 W/m3 up to levels in excess of 1013 W/m3.

Bair also writes that by employing real viscosity measured with viscometers there has been revolutionary progress in predicting film thickness and friction. In terms of friction, which is the topic of our paper, we contest this. We show in our paper that thermal limitations mean that measurements from high-stress viscometer of the type developed to date by Bair are currently irrelevant with respect to the levels of shear stress and strain rate present in rolling–sliding EHD contacts and thus yield no useful information about fluid response within such contacts. It is noteworthy that Bair does not rebut this fact in his comment. We agree that some progress has been made in determination of EHD film thickness by measuring shear thinning in viscometers, but we leave it to the reader to judge the extent to which this can be classed as revolutionary.

We do think that revolutionary progress may be possible in future but not from current high-stress viscometers, nor indeed EHD friction measurements. It will require techniques able to study fluid behaviour at realistic EHD contact conditions. This is why we devoted the last sections of our paper to describe two such techniques.

Now we shall comment on the various issues raised by Bair in his section entitled Misrepresentations. We note that what Bair regards as misrepresentations might be considered by less partial eyes to be simply differences of opinion. We retain the subheadings 2.1–2.9 used by Bair.

2 Differences of Opinion

2.1 Pressure and Temperature Dependence of Viscosity

We are confused about Bair’s comments on pressure–viscosity since we took great care in Sect. 6 of our paper to stress the importance of using appropriate pressure–viscosity data to analyse EHD, something that he has long advocated. We also believe that we explained quite clearly the existence of a point of inflection at high viscosity/pressure and we provided the main equations used to describe this. Instead of acknowledging this, Bair chooses to take issue with our statement that most of the fluid data in the ASME report do not show a point of inflection; writing that the liquids would surely have crossed an inflection had ASME been able to measure high enough viscosity. We stand by our wording.

Bair states that Eqs. (9) and (45) of our paper assume that viscosity has no temperature dependence. In fact viscosity does not appear in these equations. However, mean shear stress does, and the equations allow mean shear stress to be temperature dependent. A more precise definition of β in the Nahme-Griffiths number is that it is the temperature coefficient of shear stress. As pointed out by Bair [2], this is actually only proportional to the temperature coefficient of viscosity for a Newtonian fluid, which the fluid in an EHD contact most certainly is not. The values measured for the temperature coefficient of mean shear stress in our paper were generally in the range −0.01 to −0.06.

2.2 Mechanics of Eyring Theory

Bair cites a well-known figure by Mooney to suggest that diffusive motion cannot be driven by a shear stress [3]. The sketch shows shear stresses acting in equal and opposite directions on a group of molecules and deduces that the molecule of interest will not move. This can be criticised at several levels. Firstly, researchers contemporary to Mooney noted that Mooney’s criticism would affect the pre-exponential term of Eyring’s model, but not the latter’s basic principle [4]. Secondly, of course, liquid molecules between two surfaces in relative motion do move, not just due to diffusion, and especially in a non-equilibrium dynamic configuration; thus, they must experience forces which, far from being simply self-balanced at individual molecule level, are in equilibrium with (often inhomogeneous) fluxes. Ultimately, the confusion may arise from differences between a molecular and a continuum approach and, as Goldstein suggested in 1969; the absence of any explanation of how stresses applied to the surfaces of the medium are transmitted through it to act on the individual molecules [5]. With the advent of molecular dynamic simulation, we now understand this issue and have become much more familiar with the concept of forces acting on individual molecules than was the case in the days of Mooney. What we have learnt supports the concept of interatomic applied forces proposed by Eyring.

Bair cites our sentence; Polymer shear thinning is also generally considered to involve polymer molecule alignment, while in EHD contacts, shear thinning with characteristic linear/log shear stress versus strain rate response is seen even for simple, spherical type molecules, such as cyclohexane. He then states that cyclohexane is not spherical. We agree that it is not a perfect sphere—hence the use of the term spherical type. However, cyclohexane is often cited and studied as a quasi-spherical molecule in the literature [e.g. 6, 7]. Bair then says that simple molecules such as nonane show birefringence and must thus align under shear, referring to Champion and Meeten’s excellent paper on this subject [8]. This is irrelevant; we know that linear molecules above a certain length align and thus exhibit birefringence under shear. But we know of no work that suggests that cyclohexane does so. Indeed it is used as a non-aligning solvent to study solute birefringence, and molecular dynamics simulation (MDS) has shown that while it does shear thin at very high shear rates, this is accompanied by little if any molecular alignment [9].

Bair has written; Today, aside from the EHD community, it is widely accepted that shear-thinning results from molecular alignment [10]. Is this true? This is an important question since it provides a means of testing the various rheological models because some are based on molecular alignment and some (such as Eyring) are not. The fact that we see shear thinning with cyclohexane in EHD where MDS indicates cyclohexane does not align, and indeed the fact that numerous MDS have shown that shear thinning can be obtained with Lennard-Jones fluids (we cannot think of anything more spherical) [e.g. 11, 12] suggests that alignment is not a necessary precursor of shear thinning for simple molecular liquids.

As an aside, it is interesting to note that Eyring’s shear-thinning model was adapted by Bondi to incorporate the effects of molecular alignment [13].

We are familiar with the Cox-Merz rule, which suggests an identity between viscosities measured in high-strain viscometers and those measured in oscillatory ones [14]. We did not discuss this in our paper for space reasons. While this rule may be valid for moderate strain conditions, we question whether it is likely to be so in the context of EHD rheology. The strain in an EHD contact is of O(1,000), which means that on average each molecule in a layer passes approximately 1,000 molecules in a neighbouring layer during its own fleeting passage through a contact. The strain in a crystal-based oscillatory viscometer is usually less than unity, i.e. no molecule fully passes its neighbour. We note that Bair has used a similar argument in the past to dismiss the relevance of the Cox-Merz rule in the context of high-stress viscometry, writing; The oscillatory shear approach is inherently a small strain, low shear stress process markedly different from continuous shear at high shear stress. [15]. Since publication of our paper, Bair et al. [16] have reviewed the applicability of the Cox-Merz rule for simple molecular liquids. They found poor agreement between oscillatory and high-stress viscometry even at the limited combination of (shear stress × strain rate) conditions attainable using such viscometry. In all cases, high-stress viscometry showed markedly more shear thinning than oscillatory measurements.

2.3 The Thermal Origin of the Sinh Law

We have already addressed this issue in the opening section of our comment. It is simply incorrect to suggest that the observed sinh law response relating strain rate to shear stress seen in our EHD friction measurements derives from shear heating. As already mentioned in the Introduction of this comment and clearly set out in our paper, it is straightforward to estimate the temperature rise due to shear and so its effect on shear stress. We can thus both identify the operating range of an EHD contact where thermal effects are negligible and apply a correction in cases where they are not negligible. In the region where thermal effects can be shown to be negligible, the sinh law fits the data closely. At higher shear stresses and strain rates when shear heating does occur, thermal correction collapses the data back on to a sinh plot.

2.4 Viscosity of DEHP

In our paper, we use actual measured pressure–viscosity data of DEHP to test the fits of both the Carreau-Yasuda and Eyring models. However, Bair ignores this fact and instead diverts the reader by misrepresenting an earlier paper in which Spikes presented a simplified procedure to enable engineers to estimate EHD friction coefficients by interpolation of measured traction data [17]. This involved extracting a single, average value of effective pressure–viscosity coefficient. As Ref. [17] makes clear, this is an averaged value based on assuming an exponential viscosity–pressure relationship and the approach is proposed solely to allow engineers to estimate EHD friction values very straightforwardly, without recourse to integration or iteration. It is most certainly nothing else, and in the paper, the author always precedes the term “viscosity–pressure coefficient” with the word “average” to emphasise this.

2.5 Thermally Corrected Friction Curves

As stated in our paper, we intend to describe our thermal correction method in more detail in a future publication. However, we provide more detail here for clarity. We assume a mean temperature rise across the contact as indicated by Eq. 45. Johnson and Greenwood have demonstrated the validity of the mean temperature approach [18]. We start with a set of mean shear stress versus strain rate curves made at a series of different bulk temperatures between 30 and 110 °C, as shown in Fig. 16 of our paper. (In this figure, the 110 °C data are not shown since we do not determine a thermal correction at this temperature as this would involve extrapolation). Our correction involves two stages.

In the first stage, we use Eq. 45 to estimate the mean temperature rise for every single measurement, based on the mean shear stress and strain rate of this measurement (Eq. 45); thus, for each measured data point, we now have a corrected mean film temperature which is equal to or higher than the bulk test temperature.

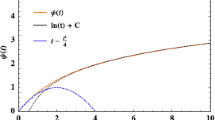

In the second stage, for every single data point, we identify its strain rate and extract, from the data measured at other temperatures, measurements made at this identical strain rate, with interpolation when necessary. We thus obtain a plot of mean shear stress versus corrected mean temperature at this fixed strain rate, as shown in Fig. 1. We fit a smooth curve to this and use interpolation to determine, for our data point, how much the mean shear stress will have been reduced by the calculated rise in temperature. We add this value to the measured mean shear stress. When carried out on all points in a shear stress/strain rate curve, this gives us an isothermal mean shear stress/strain rate curve at the bulk test temperature. We only do this for mean temperature rises of <5 °C, since we recognise that the procedure becomes less exact as temperature rise increases.

It is important to note that this procedure makes no assumptions about the rheology of the film nor how mean shear stress varies with temperature. The latter is extracted directly from our measurements made at a series of different temperatures.

2.6 EHD Friction Curves as Logarithmic

This section notes that linear/log behaviour is observed in many types of sliding contact including some unlubricated ones as well as in EHD contacts. Bair concludes, one hopes in jest, that this implies that empty space or nothing obeys the Eyring equation. It is a jest that Bair has made before [19]. Eyring’s model and the related one of Prandtl [20], are thermally activated flow models in which adjacent molecules slide past one another at a rate that is controlled by the influence of applied force on thermal diffusion. In recent years, this thermally activated flow concept, which predicts a characteristic linear/log speed–force relationship, has become the predominant model to explain the origins of dry and boundary friction [e.g. 21–23], as well as being employed to describe the flow of liquids at high pressure [24]. The fact that this flow model has applicability to describe these other types of friction does not, of course, detract from its suitability to model EHD friction as implied by Bair; indeed it reinforces it. If, under the extreme conditions in an EHD contact, liquid shear becomes localised to the sliding of neighbouring molecular layers one over another, as seems quite probable, then one would expect the flow processes that determine EHD, boundary and dry friction to be intrinsically related.

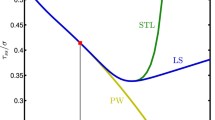

The final paragraph of this section of Bair is difficult to follow, intertwining reference to pressure fragility, which was not discussed in our paper at all, with the suggestion that our statement that Clifton identified a flaw in one of his papers [25] is somehow misleading. In their paper, Bair and Winer suggest that an EHD model in which the central, high-pressure region experiences a limiting shear stress while the periphery remains piezo-viscous Newtonian will yield a linear/log mean shear stress versus strain rate relationship [26]. They provide an approximate equation to demonstrate this and claim that this is the origin of the linear/log response seen in EHD friction. In the Discussion of this paper, Clifton provides a full analytical solution and notes Eq. (22) differs considerably from the corresponding equation by the authors. It appears that these differences should be examined before the conclusion is drawn that the apparent Sinh Law behavior in EHD measurements can be interpreted as limiting shear stress behavior by accounting fully for the pressure variation in the contact region [25]. In other words, he thinks that Bair and Winer’s equation and conclusion are incorrect. In Fig. 2, we compare Clifton’s accurate prediction of the relationship between mean shear stress and log(strain rate) with Bair and Winer’s approximation. It is clear that the latter is unrealistic for large strain rates.

Comparison of mean shear stress versus strain rate predicted by Bair and Winer’s approximate and Clifton’s exact solutions of a combination of Newtonian and limiting shear stress behaviour in a point EHD contact [25]. Conditions assumed; maximum Hertz pressure = 1 GPa, viscosity at zero pressure = 0.05 Pas, pressure–viscosity coefficient = 20 GPa−1, limiting friction coefficient = 0.1

2.7 EHL Film Thickness

As its title suggests and as made clear in its Introduction, our paper focussed entirely on EHD friction and did not discuss the much more tractable issue of EHD film thickness. So it is difficult to see how we can be charged with misrepresentation in this context. We shall ignore this section of Bair’s comment.

2.8 Fitting Rheological Equations of State to Friction Curves

We do not fit rheological equations to friction curves. We test the ability of rheological equations to predict measured friction curves. Surely this is valid test of rheological equations?

Of course another and arguably better way might be to test whether rheological equations can predict high-stress viscometer data. But, as we point out in our Introduction, such viscometers are still incapable of approaching the shear stress/strain rate conditions prevalent within EHD contacts. In fact the product of (shear stress x strain rate) attainable in high-stress viscometry is still two orders of magnitude below EHD rolling/sliding contact conditions, not as Bair suggests very close.

2.9 Molecular Dynamics Simulations

Bair states that our statement that published molecular dynamics simulations have provided support to many different models of shear thinning, including both Eyring and Carreau equations, e.g. [109–114] is misleading. We consider it perfectly correct and not at all misleading. There have been very many MDS of liquids under high strain rate conditions, and the results of these have been compared with many different models of shear thinning. Since our paper was not a review of MDS, we did not attempt to list all of these—hence we used the term e.g. above and cited a representative sample to illustrate the spread of comparisons attempted.

3 Conclusions

When writing our review paper, we strived hard to present a balanced summary of current understanding of EHD friction, its origins and prediction.

Bair and his co-authors appear to have chosen to interpret our paper as an assault on the high-stress viscometric approach that Bair has championed for some years and also as an espousal of the Eyring model of rheology which he has consistently denigrated over the same period. They appear to regard our paper as undermining the great progress, indeed the revolutionary progress that they claim to have made over the last seven years.

To combat this perceived assault, they suggest that our paper somehow misrepresents the literature and indeed contains numerous misstatements of fact and misrepresentations by omission. In reality, most of these misstatements are simply inconvenient truths.

It is true that existing high-stress viscometers cannot reach the combination of stress/strain rate conditions relevant to rolling–sliding EHD contacts. This means that they are not able to reveal the prevailing rheology of lubricants in such contacts.

It is true that mean shear stress/strain rate curves can be obtained from EHD friction measurements at conditions that are clearly relevant to EHD, both under conditions where there is negligible shear heating and, by applying a thermal correction, when there is a modest temperature rise due to shear heating.

It is true that the Carreau-Yasuda and the Eyring shear-thinning models are equally effective at fitting both high-stress viscometry measurements (up to the limit they can be measured) and EHD friction-derived mean shear stress/strain rate measurements. Thus, we cannot at present determine a preference for either model based on such measurements alone.

Overall and in summary, we believe that our paper provides a fair and accurate account of research and current understanding of EHD friction and hope that it will be of value to researchers.

References

Spikes, H.A., Zhang, J.: History, origins and prediction of elastohydrodynamic friction. Tribol. Lett. 56, 1–25 (2014)

Bair, S., Winer, W.O.: A new high pressure, high shear stress viscometer and results for lubricants. Tribol. Trans. 36, 721–725 (1993)

Mooney, M.: A theory of the viscosity of a Maxwellian elastic liquid. Trans. Soc. Rheol. 1, 63–94 (1957)

Macedo, P.B., Litovitz, T.A.: On the relative roles of volume and activation energy in the viscosity of liquids. J. Chem. Phys. 42, 245–256 (1965)

Goldstein, M.: Viscous liquids and the glass transition: a potential energy barrier picture. J. Chem. Phys. 51, 3728–3739 (1969)

Hicks, C.P., Young, C.L.: Critical temperatures of mixtures of quasi-spherical molecules. Application of the “van der Waals treatment to some organo-silicon compounds + hydrocarbon systems”. Trans. Faraday Soc. 67, 1598–1604 (1971)

Bordarier, P., Rousseau, B., Fuchs, A.H.: Rheology of model confined ultrathin fluid films. I. Statistical mechanics of the surface force apparatus experiments. J. Chem. Phys. 106, 7295–7302 (1997)

Champion, J.V., Meeten, G.H.: Flow birefringence in simple liquids. Trans. Faraday Soc. 64, 238–247 (1968)

Rowley, R.L., Ely, J.F.: Non-equilibrium molecular dynamics simulations of structured molecules: II. Isomeric effects on the viscosity of models for n-hexane, cyclohexane and benzene. Mol. Phys. 75, 713–730 (1992)

Bair, S.: Actual Eyring models for thixotropy and shear-thinning: experimental validation and application to EHD. Trans. ASME J. Tribol. 126, 728–732 (2004)

Farhat, H., Eu, B.C.: Monte Carlo method and the nonequilibrium structure and non-Newtonian viscosity of a sheared simple liquid. J. Chem. Phys. 110, 97–108 (1999)

Gattinoni, C., Heyes, D.M., Lorenz, C.D., Dini, D.: Traction and nonequilibrium phase behavior of confined sheared liquids at high pressure. Phys. Rev. E 88, 052406-1–052406-10 (2013)

Bondi, A.: Flow orientation in isotropic fluids. J. Appl. Phys. 16, 539–544 (1945)

Cox, W.P., Merz, E.H.: Correlation of dynamic and steady flow viscosities. J. Polym. Sci. 28, 619–622 (1958)

Bair, S., Winer, W.O.: The high pressure high shear stress rheology of liquid lubricants. Trans. ASME J. Tribol. 112, 1–9 (1992)

Bair, S., Yamaguchi, T., Brouwer, L., Schwarze, H., Vergne, P., Poll, G.: Oscillatory and steady shear viscosity: the Cox-Merz rule, superposition, and application to EHL friction. Tribol. Int. 79, 126–131 (2014)

Spikes, H.A.: Basics of EHL for practical application. Lubr. Sci. 27, 45–67 (2015)

Johnson, K.L., Greenwood, J.A.: Thermal analysis of an Eyring fluid in elastohydrodynamic traction. Wear 61, 353–374 (1980)

Bair, S.: The nature of the logarithmic traction gradient. Tribol. Int. 35, 591–597 (2002)

Prandtl, L.: Ein Gedankenmodell zur kinetischen Theorie der festen Körper. Z. für Angew. Math. und Mech. 8, 85–106 (1928)

Gnecco, E., Bennewitz, R., Socoliuc, A., Meyer, E.: Friction and wear on the atomic scale. Wear 254, 859–862 (2003)

Bouhacina, T., Aime, J.P., Gauthier, S., Michel, D., Heroguez, V.: Tribological behavior of a polymer grafted on silanized silica probed with a nanotip. Phys. Rev. B 56, 769–7703 (1997)

Hölscher, H., Schirmeisen, A., Schwarz, U.D.: Principles of atomic friction: from sticking atoms to superlubric sliding. Philos. Trans. Roy. Soc. A 366, 1383–1404 (2008)

Muser, M.H.: Lubricants under high local pressure: liquids act like solids. Mat.-wiss. u. Werkstofftech. 35, 603–609 (2004)

Clifton, R.J.: Discussion to paper Bair, S., Winer, W.O.: The high shear stress rheology of liquid lubricants at pressures of 2 to 200 MPa. Trans. ASME J. Tribol. 112, 253–256 (1990)

Bair, S., Winer, W.O.: The high shear stress rheology of liquid lubricants at pressures of 2 to 200 MPa. Trans. ASME J. Tribol. 112, 253–256 (1990)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Spikes, H., Zhang, J. Reply to the Comment by Scott Bair, Philippe Vergne, Punit Kumar, Gerhard Poll, Ivan Krupka, Martin Hartl, Wassim Habchi, Roland Larson on “History, Origins and Prediction of Elastohydrodynamic Friction” by Spikes and Jie in Tribology Letters. Tribol Lett 58, 17 (2015). https://doi.org/10.1007/s11249-015-0483-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-015-0483-8