Abstract

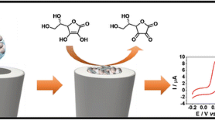

Composite materials made of multiwalled carbon nanotubes and silver (Ag-MWCNT) or gold particles (Au-MWCNT) were synthesized and characterized by XRD and SEM/EDS techniques. The composites and the MWCNTs were applied as surface modifiers of carbon paste electrodes (CPEs). The mediator based electrocatalytic activity of the modified electrodes was investigated for H2O2 oxidation/reduction by electrochemical measurements. All voltammetric working electrodes (Ag-MWCNT/CPE, Au-MWCNT/CPE, MWCNT/CPE and the bare CPE) were characterized by cyclic voltammetry (CV) in acetate and phosphate supporting electrolytes (0.1 mol L−1, pH 4.50 and 7.50, respectively) in the absence and presence of the H2O2 analyte. Amperometric experiments were performed in stirred solutions at selected constant working potentials, in accordance with the CV responses, for developing new analytical methods for the determination of H2O2. In the case of the Ag-MWCNT/CPE the most promising working potentials in the acetate buffer solution were − 0.40 V and + 0.80 versus SCE; in phosphate buffer solution these values were between − 0.20 and − 0.30 V and from + 0.60 to + 1.0 V. The Au-MWCNT/CPE is applicable in acetate buffer supporting electrolyte in the working potential close to − 0.30 V versus SCE and from + 0.70 to + 1.0 V; in the phosphate buffer solution only from + 0.60 V versus SCE and higher values. Due to the presence of the signal enhancement effect of Au and Ag nanoparticles, the sensitivity of the obtained methods is significantly higher in comparison to the results obtained by the MWCNT/CPE and bare CPE. The relative standard deviation of the measurements was lower than 10%. The practical application using the Ag-MWCNT/CPE was shown for the determination of H2O2 in real nursing product sample. It was proven that the developed mediator based (electro)catalytic platform exhibits low detection limit, high selectivity, reproducibility and stability.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Hydrogen-peroxide (H2O2) is an analyte of great importance because of its large involvement in different fields of application such as environmental protection/analysis, pharmaceutical research, textile industry, medical diagnostics, etc. [1,2,3]. It is a powerful oxidant and found applications in many organic compound synthesis and for removal of pollutants from wastewater by advanced oxidation processes [4,5,6,7]. Moreover, H2O2 is an active ingredient of different disinfection and nursing products, with 3% of H2O2. Therefore, there is a need for development of sensitive and reliable analytical methods for determination of this target analyte in different complex matrices.

Electroanalytical measurements compared to other ones enable low-cost, selective, sensitive, simply and fast detection/determination of H2O2 [8]. In analytical voltammetry carbon paste presents a convenient electrode material (CPE) for the amperometric determination of H2O2 due its direct oxidation or reduction which occurs at highly positive or negative working potentials. In order to reduce the overpotential of H2O2 redox processes on such simpler carbonaceous electrodes different modifiers/mediators/catalysts are incorporated into the electrode bulk or at electrode surface [9, 10] with aim to improve the selectivity and in some cases the sensitivity of the working electrode and on this way the sensitivity of the related analytical method as well. The modification of carbon paste electrodes with mono- or bimetallic micro- and nanoparticles (Pt, Pd, Cu, Ag) or other nanostructures (carbon nanotubes) for the determination of H2O2 has received considerable attention [11,12,13]. The benefited properties of CNTs such as chemical stability, high surface area, excellent electrical conductivity and electrocatalytic activity makes them suitable for preparation/modification of electrochemical working electrodes/sensors. They can be functionalized with organic molecules, polymers, enzymes, proteins, DNA and with different metal (nano)particles which expand their application [12]. Combination of CNTs and metal (nano)particles produce the hybrid materials which are often important for catalysis (including electrocatalysis) and nanotechnology [14]. Such materials can be incorporated in/on working electrodes upgrading their catalytic activity towards H2O2 sensing and improving the selectivity and/or sensitivity of its determination. Beside Pt and Pd nanoparticles deposited onto the CNTs surface for determination of H2O2 [10, 15,16,17,18,19,20], the Ag and Au (nano)particles are also found application for similar purposes. Different substrate electrodes (such as glassy carbon or gold) were surface modified with multiwalled carbon nanotubes (MWCNTs) or ionic liquid functionalized MWCNTs decorated with Ag nanoparticles for determination of H2O2 [21,22,23,24]. The gold electrode surface modified with composite of polyaniline, MWCNTs and Au nanoparticles and functionalized CNTs with Au nanoparticles have proven to be suitable as electrochemical sensors for determination of H2O2 [13, 25]. Furthermore, fluorine-doped tin oxide electrode modified with ZnO nanorods and Ag nanoparticles [26] and Pt electrode modified with Ag nanoparticles [27] were used as well for amperometric sensing of H2O2. Another one, the ceramic electrode modified with a nanohybrid composite made from singlewalled carbon nanotubes and Ag nanoparticles was successfully applied for determination of H2O2 in a complex sample as honey [28]. Also, the composite material Ag-CNTs was used as a building element during the preparation of nanocomposites with polypropylene and polystyrene improving the electrical conductivity and mechanical properties of polymers compared to non-functionalized CNTs [29].

The aim of this work was to prepare silver or gold nanoparticle modified MWCNTs based nanocomposite materials (Ag-MWCNT and Au-MWCNT), their incorporation into the simply paraffin oil and graphite powder containing carbon paste working electrode sensor surface, and the investigation/comparison of the voltammetric behavior and applicability of these electrodes in the determination of H2O2 with special attention to a real sample/nursing product.

2 Experimental

2.1 Chemicals and Solutions

All chemicals used were of analytical reagent grade. As supporting electrolytes two 0.1 mol L−1 buffers, acetate pH 4.50 and phosphate pH 7.50 were applied. The acetate buffer solution was made from required volumes of 0.1 mol L−1 sodium acetate (tri-hydrate) (13.6 g L−1) (p.a., Sigma-Aldrich) and 0.1 mol L−1 acetic acid (p.a., Sigma-Aldrich) solutions. The phosphate buffer solution (0.1 mol L−1, pH 7.50) was prepared by appropriate mixing of aqueous solutions of 0.1 mol L−1 sodium dihydrogenphosphate (p.a., Sigma-Aldrich), and 0.1 mol L−1 disodium hydrogenphosphate (p.a., Sigma-Aldrich). The pH values of the prepared buffer solutions were measured by pH-meter. Standard solutions of H2O2 were daily prepared from the 30% H2O2 (INK, Inzenjering, Beograd) by appropriate dilutions, while the concentration of the stock was controlled by permanganometric titration. All solutions were prepared with doubly distilled water.

2.2 Apparatus

Cyclic voltammetric (CV) and amperometric measurements at constant potential were performed at an electrochemical analyzer AUTOLAB PGSTAT12 operated via GPES 4.9 software. The voltammetric vessel with reduced bottom included a three-electrode system with reference saturated calomel (SCE) and auxiliary platinum (Amel) electrodes and the following working electrodes: native CPE, MWCNT/CPE, Au-MWCNT/CPE, and Ag-MWCNT/CPE. All potentials are quoted to the SCE.

pH measurements were performed on a digital pH-meter (Radiometer) using a glass electrode in combination with SCE.

Surface morphology characterization and semi-quantitative chemical analysis of the Au-MWCNT and Ag-MWCNT composites was performed with a HITACHI S-4700 Type II cold field emission scanning electron microscope (SEM) by using an integrated Röntec QX2 EDS detector. Spectra were analyzed by the factory standard software after automatic background subtraction and peak fitting.

Powder X-ray diffraction (XRD) patterns for the synthesized materials were obtained by a Rigaku Miniflex II instrument using Cu Kα radiation.

2.3 Procedures

2.3.1 Preparation of MWCNT, Ag-MWCNT and Au-MWCNT

MWCNTs in their native and functionalized forms were used as surface modifier of the CPE. MWCNTs were prepared in our laboratory by catalytic chemical vapor deposition described elsewhere [30]. The as-grown MWCNTs were subjected to acid treatment for purification and functionalization (since acid treatment results in attachment of mainly—COOH groups at defect sites). The Ag-MWCNT and Au-MWCNT (nano)hybrid materials were prepared by a sonication assisted reduction method [31, 32]. Briefly, the required amount of AgNO3 (or in case of Au-MWCNT sodium tetrachloroaurate(III) salt) was dissolved in water and 100 mg MWCNT was added to the solution. After 15 min sonication the reduction was carried out using NaBH4 resulting in formation of Ag-MWCNT (or in case of gold Au-MWCNT) (nano)hybrid material. After this treatment the resulting substances were washed 3 times with ethanol and dried for overnight at 90 °C.

2.3.2 Preparation of Working Electrodes

The carbon paste was prepared by hand-mixing of 0.5 g graphite powder (< 20 µm, synthetic, Sigma Aldrich) with 0.2 mL paraffin oil (Kemika, Croatia) in agate mortar. The paste was packed into piston-driven Teflon holders with a diameter of 2 mm [33] and left for 24 h at room temperature. The CPE surface was formed/cleaned mechanically by squeezing out a small amount of paste from the holder by the micrometer screw of the electrode and wiping the surface with a piece of clean Teflon to obtain the appropriate shape of the renewed native/substrate CPE. The suspensions for the CPE modifications were prepared by dispersing 1.5 mg MWCNT, Au-MWCNT or Ag-MWCNTs in 1.0 mL of ethanol and sonicated in sonication bath (Bandelin) for cc. 20 min at room temperature. 3.0 µL of the resulting suspensions was dropped on a freshly generated CPE surfaces and the modified working electrodes (MWCNT/CPE, Au-MWCNT/CPE and Ag-MWCNT/CPE) were dried at room temperature cc. 15 min in accordance with our similar earlier procedure [10].

2.3.3 SEM–EDS Study of MWCNT, Au-MWCNT and Ag-MWCNT

The surface modifiers were analyzed by the accelerating voltage of 10.00 or 20.00 kV at different magnifications. The EDS measurements were performed at different representative locations of the investigated materials.

2.3.4 X-Ray Diffraction Measurements

Four different samples: native MWCNT, oxidized MWCNT, Ag-MWCNT and Au-MWCNT were characterized in the range from 0° to 90° 2θ.

2.3.5 Cyclic Voltammetric Measurements in Model Solutions

CVs were recorded in phosphate and acetate buffer solutions (0.1 mol L−1, 10.0 mL, pH 7.50, and 4.50, respectively) with all investigated electrodes in the absence and presence of H2O2 in a potential range from 1.00 to − 1.00 V with a scan rate of 50 mV s−1 starting in cathodic direction.

2.3.6 Amperometry in Model Solutions

Into the both buffer supporting electrolytes (0.1 mol L−1, pH 7.50 and 4.50) equal aliquots of H2O2 standard solution were added by micropipette in the concentration range from 0.86 to 5.81 mmol L−1 in appropriate time intervals and constant potential of the working electrode versus SCE under permanent stirring of the solution (300 rpm). The widest investigated potential range for the selection of appropriate working potential(s) was from 1.00 to − 1.00 V. Such measurements were recorded by Au-MWCNT/CPE, Ag-MWCNT/CPE, MWCNT/CPE and bare CPE. Detailed analysis was performed at pH 7.50 at the operation potentials from − 0.20 to − 0.30 V in the lower concentration range of H2O2 with the Ag-MWCNT/CPE. As the optimal working potential − 0.25 V was chosen under mentioned circumstances, which later served for real sample analysis as well. In all cases the limit of detection (LOD) and quantitation (LOQ) values were evaluated as signal/noise 3 and 10, respectively.

2.3.7 Analysis of H2O2 Active Ingredient Content in the Selected Nursing Product

The 2.50 mL aliquot of the sample Oto aqua clean (spray solution) was directly added into volumetric flask of 25.0 mL which was flipped to the mark with doubly distilled water. Aliquot of 15.0 µL of such diluted sample was added by micropipette into the voltammetric vessel with 10.0 mL of phosphate buffer supporting electrolyte pH 7.50 (0.1 mol L−1) during the amperometric measurement under constant potential and stirring. In the same run in the next steps three times the equal volumes of H2O2 standard solution were added into the system. On such way the sample was analyzed by standard addition method. The applied working potential was − 0.25 V. The experiments were repeated in triplicates by three times renewed Ag-MWCNT/CPE surface.

3 Results and Discussion

3.1 Physical Characterization of the MWCNT, Ag-MWCNT and Au-MWCNT

The SEM micrographs (Fig. 1) obtained for the MWCNT (a) and composites Ag-MWCNT (b, c) and Au-MWCNT (d) confirmed a very similar carbon nanomaterial based frameworks where the MWCNTs are densely and randomly oriented. It can be stated that the structure was not affected during the nanoparticle decoration process. For both nanocomposites the Ag and Au nanoparticles, recognized as bright and mainly spherical unites, are surrounded by the carbon nanotubes. The average diameter of the metal particles was between 50 and 200 nm, the metal content was around 5 wt% for both composites.

The X-ray diffractograms at Fig. 2a, b showed the characteristic diffraction patterns of the synthesized materials: MWCNT (curve 1), Ag-MWCNT (curve 2) and Au-MWCNT (curve 3) in their full diffractograms (a) and in a section plot with characteristic signals (b), respectively. The aim of the XRD measurements was to characterize the Au and Ag-rich phase and to determine the possible impact of this phase on the composites by means of identifying the types of the metal-based particles. As it is well known, the XRD patterns for all MWCNT based materials revealed the presence of a broad peak at 25.8° corresponding to the interlayer spacing (0.34 nm) of the nanotubes (d002) which is in good agreement with the literature [34] for the native MWCNT (not shown) and oxidized form of MWCNTs (grey line marked as CNT). The XRD patterns of the (nano)hybrid material confirmed the presence of face-centered cubic (fcc) structured Au (JCPDS 4-784) and Ag (JCPDS 4-783) nanoparticles beyond the graphitic carbon structure. The section plot (b) showed the received information with more details concerning the peak positions of Ag and Au particles in the angle range between 35° and 50°.

3.2 Electrochemical Characterization of Au-MWCNT and Ag-MWCNT Modified Carbon Paste Electrodes

As first, cyclic voltammetric (Fig. 3) and amperometric (Figs. 4, 5) responses of the H2O2 analyte were investigated on native CPE (not shown), and by nanomaterials modified ones (MWCNT/CPE (not shown), Au-MWCNT/CPE (Figs. 3a, 4) and Ag-MWCNT/CPE (Figs. 3b, 5) in slightly alkaline (0.1 mol L−1 phosphate buffer, pH 7.50) and acidic (0.1 mol L−1 acetate buffer, pH 4.50) supporting electrolytes. Figure 3 illustrates the CV signals of the composite nanomaterials modified working electrodes in the absence (dashed lines) and presence (full lines) of H2O2 in the polarization range from 1.00 to − 1.00 V in both buffer solutions (red lines pH 7.50, black lines pH 4.50). The native CPE has poor electrocatalytic properties toward the target analyte which is in accordance with our recent work where it was found that the H2O2 responses at the CPE belong to its direct electrochemical oxidation and reduction [10]. For the MWCNT/CPE in the slightly alkaline media the improvement of the H2O2 reduction signal intensity was obtained at potentials lower than − 0.40 V. The effect is much significant in the case of the composite modified electrodes due to the presence of noble metal mediator (nano)particles into the MWCNT framework at the sensor surfaces. Namely, based on the recorded CVs, the Ag-MWCNT/CPE (Fig. 3b) showed pronounced reduction signal from − 0.10 V and at lower potentials. Moreover, the electrode showed significant H2O2 response at 0.10 V and higher values. Concerning the Au-MWCNT/CPE (Fig. 3a), in the negative polarization mode from − 0.30 V significant H2O2 reduction signal was observed, but the electrode is promising for H2O2 detection at positive polarizations at 0.40 V and higher potential values as well. Differences were observed for the composite nanomaterial-modified electrodes in acetate buffer supporting electrolyte (black lines) in the presence (full lines) and absence (dashed lines) of the H2O2. In the acidic media the Ag-MWCNT/CPE and Au-MWCNT/CPE showed sharp reduction signals which started close to − 0.25 and − 0.65 V, respectively.

It should be noted that the MWCNTs on the CPE enhanced the H2O2 signal intensity mainly because of the increased sensor surface, and due to the changed/reduced overpotential of H2O2 redox processes which indicates the mediator based behavior of the working electrode. The two noble metal (nano)particles in combination with MWCNTs additionally changed/enhanced the H2O2 signal intensities and reduced the overpotentials because of their pronounced mediator/catalytic effects on the electrode surface concerning the reduction or oxidation of the target analyte. The tested supporting electrolytes influence the H2O2 signal generation in the case of all four electrodes, but particularly in the case of the composite modified ones.

It is important to emphasize that the simple graphite powder and paraffin oil containing carbon past electrode showed appropriate affinity to the MWCNTs, Ag-MWCNTs and Au-MWCNTs modifiers. These electrodes are stable during few days, except in the case of mechanical damaging of their surfaces. The electrochemical activation/conditioning of the working electrodes was required before each set of measurements by recording 10 CVs in the appropriate supporting electrolytes in the potential span from 1.00 to − 1.00 V versus SCE. Additionally, the total renewing of the surface is possible by simply mechanical cleaning of the electrode by squeezing out a small amount of paste from the holder and wiping the surface with a piece of clean Teflon to obtain the appropriate shape of the renewed substrate CPE as it is elaborated with details in “Procedures”.

The first screening by amperometric measurements performed in wider working potential range and at higher concentrations of the target analyte (e.g. from 0.86 to 5.81 mmol L−1) in both supporting electrolytes can offer more detailed information to compare the behavior of the Au-MWCNT/CPE and Ag-MWCNT/CPE with the MWCNT/CPE and bare CPE. Some illustrative staircase shaped current–time response curves of H2O2 recorded on Au-MWCNT/CPE and Ag-MWCNT/CPE are presented on Figs. 4 and 5, respectively. As for the Au-MWCNT/CPE, it is applicable for the development of the analytical methods for H2O2 determination in both investigated media but mainly at positive working potentials starting from 0.70 V in the case of acetate (Fig. 4a) and 0.60 V in phosphate (Fig. 4b) buffer solutions. Some outlines of the parameters for the methods based on the Au-MWCNT/CPE are elaborated in the Table 1. Concerning the Ag-MWCNT/CPE based H2O2 amperometric responses in the acetate buffer supporting electrolyte (pH 4.50) in the positive potential range they are poor (Fig. 5a), so the development of the analytical method under all described experimental conditions is possible still at 0.80 V and higher potential values. Concerning the negative working potentials (Fig. 5b) an applicable working condition was found at − 0.40 V. It can be noted that the signal to noise ratio is not favored for the both polarization mode at such conditions. As for the slightly alkaline media the Ag-MWCNT/CPE showed acceptable analytical behavior from the working potential 0.60 V and higher values (Fig. 5c), and between − 0.20 and − 0.30 V in the negative working potential range (Fig. 5d). However the CV signals prognoses excellent H2O2 reduction responses in negative potential range, the amperometric measurements showed that the signal to noise ratio is unfavorable in many cases of investigated negative working potentials. Therefore such potential values are not suitable for analytical purposes. The analytical parameters of the amperometric methods at selected usable working potentials are presented in the Table 2 for the Ag-MWCNT/CPE.

The RSD of the methods did not exceed 10% in all investigated cases based on the three times repeated measurements considering all investigated staircase steps on amperometric curves.

As for the MWCNT/CPE, and especially the native CPE, in the investigated electrolytes the H2O2 signals are with significantly lower intensities, so the Ag-MWCNT/CPE and the Au-MWCNT/CPE are the favored ones. Based on the obtained responses, both composite modified electrodes are with excellent mediator supported electrocatalytic behavior under defined experimental conditions. Because of the lower price of the Ag-MWCNT/CPE, this electrode was selected for the further measurements and optimization.

3.3 Optimization of the Analytical Method Based on the Ag-MWCNT/CPE

To get deeper insight into the possibilities and limits of the analytical method based on the Ag-MWCNT/CPE and amperometry in phosphate buffer pH 7.50 (0.1 mol L−1) different working potentials as − 0.20, − 0.25 and − 0.30 V were investigated while the H2O2 concentration range was nearly three times lower (0.29–1.99 mmol L−1, Fig. 6) in comparison to those applied for the first screening measurements. The working potential of − 0.20 V (Fig. 6a) is suitable analytical condition, but in the case of the − 0.25 V (Fig. 6b) the H2O2 signal intensity is enhanced. Further working potential changes till − 0.30 V (Fig. 6c) lead to the significant noise enhancement receiving the lower, unfavorable, signal to noise ratio. This reflects on the analytical parameters of the developed methods which are elaborated in the Table 3.

Optimization of the amperometric working potentials by Ag-MWCNT/CPE in phosphate buffer supporting electrolyte pH 7.50 (0.1 mol L−1) for H2O2 measurements in the concentration range from 0.29 to 1.99 mmol L−1: a − 0.20 V, b − 0.25 V and c − 0.30 V. d The amperogram recorded by MWCNT/CPE at analogues measurement conditions at working potential of − 0.25 V

Additionally, it can be mentioned that as it is illustrated on the Fig. 6d, the MWCNT/CPE is not applicable under the same conditions for the H2O2 measurements.

The − 0.25 V was selected for next experiments when an additional investigation was performed to define with more details the analytical parameters of the Ag-MWCNT/CPE based method concerning the working electrode sensitivity. The lowest investigated concentration range was 0.07–0.49 mmol L−1 and a representative amperometric response is presented at the Fig. 7a together with the belonging liner calibration curve in the inset with the following equation: y = 0.002 − 0.564x, r = 0.999. The LOD of the method is 0.02 mmol L−1 and the LOQ is 0.07 mmol L−1.

Amperograms of the H2O2 recorded by Ag-MWCNT/CPE in phosphate buffer pH 7.50 at working potential of − 0.25 V versus SCE: a target analyte concentration range of 0.07–0.49 mmol L−1 (inset with the appropriate calibration curve) and b interference study of glucose at 0.07 mmol L−1 of target analyte and 0.07 mmol L−1 of added glucose (arrow showed the introduced chemicals)

The measurements were repeated six times with same Ag-MWCNT/CPE surface, and the H2O2 signals at the amperometric staircase steps has lower RSD than 6%, considering each staircase steps, which proved that the electrode is usable for higher number of measurements without significant changes of the Ag-MWCNT/CPE sensor surface. Additionally, the surface renewing by mechanical cleaning and drop coating was repeated three times and with such prepared Ag-MWCNT/CPEs all measurement procedures were repeated in triplicates. The results showed that the RSDs are lower than 8%.

Furthermore, beside the H2O2 determination, test experiments were performed for direct glucose sensing on the Ag-MWCNT/CPE. The tested 0.04 and 0.07 mmol L−1 of glucose did not give recognizable response at − 0.25 V in phosphate buffer solution pH 7.50. Furthermore, the both concentrations of glucose, 0.04 mmol L−1 (not shown) and 0.07 mmol L−1 (Fig. 7b) were introduced into the system after the first added aliquot of H2O2 (0.07 mmol L−1). Next addition of equal amount of H2O2 in the same run produces the expected current intensity increase in both investigated cases, which proved that the presence of the glucose at such concentration levels did not affect on the H2O2 sensing.

3.4 Amperometric Method in Combination with Ag-MWCNT/CPE for Determination of H2O2 Content in a Nursing Product

To investigate the applicability of the Ag-MWCNT/CPE for the determination of H2O2 in a nursing product concerning its active ingredient the commercially available products was selected with an expected content as 3% of H2O2. Figure 8 shows amperograms recorded with two Ag-MWCNT/CPE surfaces at − 0.25 V in phosphate buffer solution during the determination of the target analyte. The amperograms were recorded on the way that after 100 s of baseline recording firstly the defined volume of diluted sample was introduced into the supporting electrolyte by micropipette, and after that three times the equal volume of standard H2O2 solution was added. The steps of the staircase signals presented the full measurement run. On this way the standard addition method was used for analysis. The outlines of the experiments performed with three different Ag-MWCNT/CPE surfaces are summarized in the Table 4.

The found average amount of the H2O2 is 2.8%, and the highest RSD was 5.3%. It can be concluded that here is an easy to perform, and reliable analytical method, based on the mediator/catalyst signal enhancement of H2O2 on Ag-MWCNT modified CPE for determination of the H2O2 target analyte in a selected nursing product.

Concerning the design of ecologically and economically acceptable, reliable working electrodes, further detailed investigations are planned with composite nanomaterials. For this purpose, nanoparticles as contemporary building unites of chemical sensors or enzymatic layers as constituents of simple biosensors will be applied. In this way the determination of different target analytes of biological, physiological or environmental importance becomes possible by a sensitive bioelectrochemical detection.

4 Conclusions

In this study, the link between the preparation of Ag-MWCNT or Au-MWCNT modified carbon based electrodes, the consequent structure and the amperometric measurements of H2O2 determination are discussed. Carbon paste electrode (CPE) surfaces were modified with Ag-MWCNT and Au-MWCNT by simple drop coating method. The modifier components were characterized by XRD, SEM and the prepared working electrodes by electrochemical techniques. Cyclic voltammetric and amperometric experiments were performed at two different pHs (7.50 and 4.50) for the basic characterization of the H2O2 responses in order to compare the performance of the MWCNT/CPE, bare CPE and composite modified electrodes. The results showed that the composite based sensor surfaces exhibit remarkable improved electrochemical response towards H2O2 compared to unmodified CPE, and MWCNT/CPE under defined experimental conditions in the appropriate supporting electrolytes, and at the applied working potentials. This indicates a mediator based electrocatalytic effect of the Ag and Au particles in the composite materials. For practical application, the choice of adequate working potential and pH of the supporting electrolyte are very important experimental parameters for Ag-MWCNT/CPE which depends on the complexity and type of the sample. Optimized Ag-MWCNT/CPE based analytical method was applied for determination of H2O2 in a nursing product with the following experimental parameters: working potential − 0.25 V, phosphate buffer supporting electrolyte 0.1 mol L−1, pH 7.50.

The developed amperometric method is simple and reliable for receiving information in short response time about the H2O2 content in selected nursing product.

References

Sitnikova NA, Borisova AV, Komkova MA, Karyakin AA (2011) Superstable advanced hydrogen peroxide transducer based on transition metal hexacyanoferrates. Anal Chem 83:2359–2363

Karam P, Halaoui LI (2008) Sensing of H2O2 at low surface density assemblies of Pt nanoparticles in polyelectrolyte. Anal Chem 80:5441–5448

Sang Y, Zhang L, Li YF, Chen LQ, Xu JL, Huang CZ (2010) A visual detection of hydrogen peroxide on the basis of Fenton reaction with gold nanoparticles. Anal Chim Acta 659:224–228

Guwy AJ, Hawkes FR, Martin SR, Hawkes DL, Cunnah P (2000) A technique for monitoring hydrogen peroxide concentration off-line and on-line. Water Res 34:2191–2198

Park JH, Cho IH, Chang SW (2006) Comparison of Fenton and photo-Fenton processes for livestock wastewater treatment. J Environ Sci Health B 41:109–120

Raoof JB, Ojani R, Hasheminejad E, Rashid-Nadimi S (2012) Electrochemical synthesis of Ag nanoparticles supported on glassy carbon electrode by means of p-isopropyl calix[6]arene matrix and its application for electrocatalytic reduction of H2O2. Appl Surf Sci 258:2788–2795

Salimi A, Hallaj R, Soltanian S, Mamkhezri H (2007) Nanomolar detection of hydrogen peroxide on glassy carbon electrode modified with electrodeposited cobalt oxide nanoparticles. Anal Chim Acta 594:24–31

Liu Y, Wang DW, Xu L, Hou HQ, You TY (2011) A novel and simple route to prepare a Pt nanoparticle-loaded carbon nanofiber electrode for hydrogen peroxide sensing. Biosens Bioelectron 26:4585–4590

Kotzian P, Brázdilová P, Kalcher K, Vytřas K (2005) Determination of hydrogen peroxide, glucose and hypoxanthine using (bio)sensors based on ruthenium dioxide-modified screen-printed electrodes. Anal Lett 38:1099–1113

Anojčić J, Guzsvány V, Vajdle O, Madarász D, Rónavári A, Kónya Z, Kalcher K (2016) Hydrodynamic chronoamperometric determination of hydrogen peroxide using carbon paste electrodes coated by multiwalled carbon nanotubes decorated with MnO2 or Pt particles. Sens Actuators B 233:83–92

Chen S, Yuan R, Chai Y, Hu F (2013) Electrochemical sensing of hydrogen peroxide using metal nanoparticles: a review. Microchim Acta 180:15–32

Gao C, Guo Z, Liu J-H, Huang X-J (2012) The new age of carbon nanotubes: an updated review of functionalized carbon nanotubes in electrochemical sensors. Nanoscale 4:1948–1963

Rajabzade H, Daneshgar P, Tazikeh E, Mehrabian RZ (2012) Functionalized carbon nanotubes with gold nanoparticles to fabricate a sensor for hydrogen peroxide determination. J Chem 9:2540–2549

Wildgoose GG, Banks CE, Compton RG (2006) Metal nanoparticles and related materials supported on carbon nanotubes: methods and applications. Small 2:182–193

Han KN, Li CA, Ngoc Bui M-P, Pham X-H, Kim BS, Choa YH, Seong GH (2012) Development of Pt/TiO2 nanohybrids-modified SWCNT electrode for sensitive hydrogen peroxide detection. Sens Actuators B 174:406–413

Miao Z, Zhang D, Chen Q (2014) Non-enzymatic hydrogen peroxide sensors based on multi-wall carbon nanotube/Pt nanoparticle nanohybrids. Materials 7:2945–2955

Shi Q-C, Zeng W-F, Zhu Y-N (2009) Electrochemical detection of hydrogen peroxide at a waxed graphite electrode modified with platinum-decorated carbon nanotubes. J Shanghai Univ 13:63–66

Fang Y, Zhang D, Qin X, Miao Z, Takahashi S, Anzai J-I, Chen Q (2012) A non-enzymatic hydrogen peroxide sensor based on poly(vinyl alcohol)–multiwalled carbon nanotubes–platinum nanoparticles hybrids modified glassy carbon electrode. Electrochim Acta 70:266–271

Guzmán C, Orozco G, Verde Y, Jiménez S, Godínez LA, Juaristi E, Bustos E (2009) Hydrogen peroxide sensor based on modified vitreous carbon with multiwall carbon nanotubes and composites of Pt nanoparticles–dopamine. Electrochim Acta 54:1728–1732

Guzsvány V, Anojčić J, Radulović E, Vajdle O, Stanković I, Madarász D, Kónya Z, Kalcher K (2017) Screen-printed enzymatic glucose biosensor based on a composite made from multiwalled carbon nanotubes and palladium containing particles. Microchim Acta 184:1987–1996

Afraz A, Rafati AA, Hajian A (2013) Analytical sensing of hydrogen peroxide on Ag nanoparticles–multiwalled carbon nanotube-modified glassy carbon electrode. J Solid State Electrochem 17:2017–2025

Li X, Liu Y, Zheng L, Dong M, Xue Z, Lu X, Liu X (2013) A novel nonenzymatic hydrogen peroxide sensor based on silver nanoparticles and ionic liquid functionalized multiwalled carbon nanotube composite modified electrode. Electrochim Acta 113:170–175

Shi Y, Liu Z, Zhao B, Sun Y, Xu F, Zhang Y, Wena Z, Yang H, Li Z (2011) Carbon nanotube decorated with silver nanoparticles via noncovalent interaction for a novel nonenzymatic sensor towards hydrogen peroxide reduction. J Electroanal Chem 656:29–33

Zhao W, Wang H, Qin X, Wang X, Zhao Z, Miao Z, Chen L, Shan M, Fang Y, Chen Q (2009) A novel nonenzymatic hydrogen peroxide sensor based on multi-wall carbon nanotube/silver nanoparticle nanohybrids modified gold electrode. Talanta 80:1029–1033

Narang J, Chauhan N, Pundir CS (2011) A non-enzymatic sensor for hydrogen peroxide based on polyaniline, multiwalled carbon nanotubes and gold nanoparticles modified Au electrode. Analyst 136:4460–4466

Lin C-Y, Lai Y-H, Balamurugan A, Vittal R, Lin C-W, Ho K-C (2010) Electrode modified with a composite film of ZnO nanorods and Ag nanoparticles as a sensor for hydrogen peroxide. Talanta 82:340–347

Guascito MR, Filippo E, Malitesta C, Manno D, Serra A, Turco A (2008) A new amperometric nanostructured sensor for the analytical determination of hydrogen peroxide. Biosens Bioelectron 24:1057–1063

Habibi B, Jahanbakhshi M, Pournaghi-Azar MH (2012) Voltammetric and amperometric determination of hydrogen peroxide using a carbon-ceramic electrode modified with a nanohybrid composite made from single-walled carbon nanotubes and silver nanoparticles. Microchim Acta 177:185–193

Xin F, Li L (2011) Decoration of carbon nanotubes with silver nanoparticles for advanced CNT/polymer nanocomposites. Compos A 42:961–967

Niesz K, Siska A, Vesselényi I, Hernádi K, Méhn D, Galbács G, Kónya Z, Kiricsi I (2002) Mechanical and chemical breaking of multiwalled carbon nanotubes. Catal Today 76:3–10

Fási A, Pálinkó I, Seo JW, Kónya Z, Hernadi K, Kiricsi I (2003) Sonication assisted gold deposition on multiwall carbon nanotubes. Chem Phys Lett 372:848–852

Billing BK, Agnihotri PK, Singh N (2017) Fabrication of branched nanostructures for CNT@Ag nano-hybrids: application in CO2 gas detection. J Mater Chem C 5:4226–4235

Švancara I, Metelka R, Vytřas K (2005) Piston-driven carbon paste electrode holder for electrochemical measurements. In: Vytřas K, Kalcher K (eds) Sensing in electroanalysis, vol 1. University of Pardubice, Pardubice

Endo M, Takeuchi K, Hiraoka T, Furuta T, Kasai T, Sun X, Kiang HC, Dresselhaus SM (1997) Stacking nature of graphene layers in carbon nanotubes and nanofibers. J Phys Chem Solids 58:1707–1712

Acknowledgements

The authors acknowledge the financial support of the Ministry of Science and Technological Development of the Republic of Serbia (ON172059 and ON172012), the Hungarian GINOP-2.3.2-15-2016-00013 project, the CEEPUS CIII-CZ-0212-09-1516 network and the Hungarian Scientific Research Fund (OTKA K120115).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Guzsvány, V., Vajdle, O., Gurdeljević, M. et al. Ag or Au Nanoparticles Decorated Multiwalled Carbon Nanotubes Coated Carbon Paste Electrodes for Amperometric Determination of H2O2. Top Catal 61, 1350–1361 (2018). https://doi.org/10.1007/s11244-018-0986-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-018-0986-2