Abstract

A dual-site reaction mechanism is proposed for Pt based water–gas shift catalysts. The sorption equilibrium parameters are evaluated in detail to validate their physical significance. The values of the van ‘t Hoff parameters for CO and H2 correspond to those for chemisorption on platinum. The sorption parameters of H2O and CO2 on the supports have been quantitatively determined from temperature-programmed desorption experiments and have been compared to the values obtained from the kinetic study. Finally the proposed model is able to explain the different activities between the two catalysts.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Recently metal catalysts supported on reducible metal oxides have received interest for the water–gas shift (WGS) reaction in the context of fuel cells, as these catalysts are highly active in the temperature range of 250–400 °C and they are non-pyrophoric and do not require any pretreatment before use. The data reported in the literature strongly suggest an important role of the support in enhancing the rate of CO conversion, most likely through the activation of water on the support and/or the creation of a unique active site at the interface of the metal and the support.

Several different mechanisms are reported in the literature [1, 2] but only one quantitative model taking into account both the metal and the support has been published yet. Germani et al. [3] proposed a dual-site mechanism that describes the WGS over Pt/CeO2–Al2O3 catalyst:

where * is a metallic site and S–O is an adsorption site on the support. In this mechanism CO and H2 chemisorb on the metal whereas CO2 and H2O are adsorbed on the support. The reaction between “CO-derived” and “H2O-derived” adsorbed species takes place at the metal support interface (step 3 and 4).

In order to examine if the above reaction mechanism can describe the kinetics of the WGS reaction over different Pt supported catalysts we have studied in detail the WGS reaction over Pt/CeO2 and Pt/TiO2. To better validate this reaction mechanism, the sorption parameters for water and carbon dioxide have been determined by independent temperature programmed desorption (TPD) experiments in a fixed bed reactor.

2 Experimental

Platinum catalysts were prepared by incipient wetness impregnation of the support with a solution of the metal precursor (NH3)4Pt(NO3)2. The supports used were commercial CeO2 (from Rhodia) and anatase-TiO2 (from Engelhard) powders with surface areas of 119 and 80 m2/g, respectively, as determined by the BET method (Micromeritics ASAP 2020). The catalysts were dried overnight at 80 °C and calcined at 400 °C for 4 h with a ramp of 2 °C/min under a controlled airflow of 30 mL/min.

The theoretical metal loadings of the catalysts amounted to 1.2 wt%. The metal content of the catalysts was determined by elemental chemical analysis with a plasma atomic emission spectrometer (Spectroflame-ICP D-SPECTRO, Induced Coupled Plasma). Dispersion of platinum was determined by H2 chemisorption in a static volumetric apparatus (Belsorb max) at −78 °C for Pt/CeO2 and at 25 °C for Pt/TiO2. Catalysts were previously pretreated with hydrogen at 400 °C during 30 min. The method used was described in a previous study by Perrichon et al. [4]. To calculate the metal dispersion, it was supposed that the adsorption stoichiometry is one hydrogen atom per one surface platinum atom.

The kinetic study and the temperature-programmed desorption (TPD) experiments were conducted at ambient pressure in a tubular fixed bed reactor (4 mm) equipped with an online mass spectrometer. The sample was reduced with 10% H2/Ar (200 NmL/min) at 400 °C for 30 min with a ramp of 2 °C/min. After reduction, the catalysts were aged under a typical reformate mixture (10% CO, 20% H2O, 10% CO2, 40% H2, balanced Ar, 200 NmL/min) for 48 h. At this point the kinetic study was started or the TPD experiment after purging with 100 NmL/min Ar at 600 °C for 30 min and cooling down to room temperature.

The kinetic study was conducted in the temperature range of 150–400 °C with 0.2 g of catalyst diluted in 0.4 g of SiC, and by varying the gas composition over the range 1–20% CO, 1–20% CO2, 5–25% H2O and 5–40% H2, giving ~150 experiments per catalyst. For the TPD experiments of CO2 and H2O on Pt/CeO2, Pt/TiO2 and the corresponding supports, the reactor was filled with 0.2 g of the 100–200 μm sieve fraction of the sample. Before and after the catalyst sample quartz particles were packed (500 μm).

Adsorption was carried out at room temperature, with a mixture of CO2/H2O/Ar = 45/1.15/5 NmL/min during 1 h. Water vapour was obtained by bubbling CO2 through a saturator containing water at 19.5 ± 0.5 °C. The sample was purged with Ar (50 NmL/min) for 45 min. Temperature programmed desorptions experiments were realized with 50 NmL/min Ar, from 25 °C to 600 °C at a heating rate of 10 °C/min. The procedure was repeated on the same sample to record a second TPD spectrum with a heating rate of 20 °C/min in order to better decouple the kinetic parameters of the mathematical model.

2.1 Kinetic Modeling

The mass balance for a one-dimensional pseudo-homogeneous isothermal reactor is integrated numerically using the ODEPACK library [5] and is coupled to a non-linear regression analysis routine based on Marquardt’s algorithm [6]. After the optimization, the variance/covariance matrix is calculated and a statistical analysis is performed.

2.2 TPD Modeling

The TPD model is based on a one-dimensional pseudo-homogeneous fixed bed reactor, thus assuming no radial and no external and internal mass- and heat transfer limitations. The continuity equations are then given for the gas phase and adsorbed phase respectively as:

Together with the following initial and boundary conditions:

This set of partial differential equations is transformed into a set of ordinary differential equations by the methods of lines [7]. Note that this model takes re-adsorption in the catalyst bed into account.

3 Results and Discussion

The metal loading, the catalyst surface area and the metal dispersion for the two samples are reported in the Table 1.

The catalysts have slightly different surface areas, but quite similar metal loadings and platinum surface areas. Activity tests realized with a typical reformate mixture show that the TiO2 based catalyst presents an activity higher than the CeO2 based catalyst. To determine the apparent reaction orders and activation energies a regression analysis was performed with all the data based on a power law rate equation:

Both data sets are described adequately by the power law rate equation. Table 2 shows the obtained apparent activation energies and the reaction orders.

Both catalysts show rather similar reaction orders, except the order in CO that is significantly different over both catalysts. The apparent activation energies differ for both catalysts as well. The calculated turnover frequency (TOF) confirms the better activity of the Pt/TiO2 catalyst compared to Pt/CeO2.

Some information can be extracted from the values of the reaction orders. Low CO reaction orders indicate a strong adsorption of CO on Pt and the large negative order for hydrogen implies a strong inhibition for both catalysts. Water has a positive effect on the activity. CO2 causes a small but significant, inhibiting effect on the ceria-supported catalyst. Germani et al. [3] reported quite similar orders and a similar activation energy for a Pt/CeO2/Al2O3 catalyst. Panagiotopoulou and Kondarides [8] reported a value of the activation energy of 89 kJ/mol for a Pt/ceria catalyst and 50–71 kJ/mol for Pt/TiO2 catalyst depending on the particle size of the TiO2 crystallites [9].

The sequence of elementary steps, initially proposed over Pt supported catalysts by Germani et al. [3], described in the introduction is used here as a basis for the kinetic study on our catalysts.

The corresponding rate is equation is given by:

Microkinetic modeling gives more information on the mechanistic route than the power law model and can be used as a tool in catalyst development [10]. The idea is to verify if this model can be applied in a general way to Pt-based WGS catalysts. It is assumed that the sorption steps on the metal and support are independent. Standard adsorption enthalpies of CO and H2 over platinum were fixed from data in the literature at −90 and −110 kJ/mol, respectively [11, 12] (see Table 3). Standard adsorption enthalpies of CO2 and H2O over the two supports were initially estimated through regression analysis but could not be estimated statistically significant from the current data set. Therefore these parameters were also fixed at the values given in Table 3. All pre-exponential factors and the lumped activation energy for step 3 and 4 were estimated through regression analysis for the data over the two samples. The final values of the estimated parameters are reported in Table 3 with the pre-exponential factors for the sorption presented as the adsorption entropies. The kinetic model describes the data adequately over both samples thus capturing the variation in the reaction orders and activation energies. Figure 1 shows the parity curves for Pt/CeO2 and Pt/TiO2. The estimated values of the pre-exponential factors for CO and H2 adsorption on Pt are very close for the two samples. The values of the standard adsorption entropies also meet the criteria formulated by Boudart et al. [13]:

which hold for Langmuir adsorption, where \( {\text{S}}_{\text{gas}}^{0} \) is the standard entropy for each species in the gas phase. Thus chemisorption of CO and H2 takes place on platinum and the van ‘t Hoff sorption parameters are independent of the support. This is in line with the results reported by Vannice and coll. [11, 12]. The values of the standard adsorption entropies for H2O and CO2 depend on the support, with no significant adsorption of CO2 on titania. Again the standard adsorption entropies on the supports fulfill the above criteria. The values of the rate constant for the rate determining step (4) cannot be evaluated sensibly as this constant is lumped with the rate constant of step (3).

As already mentioned above the statistical analysis showed that the sorption parameters are strongly correlated and cannot be estimated from the data sets. To validate this model unambiguously for both catalysts the sorption parameters over both supports were determined independently from TPD experiments.

Therefore desorption spectra were recorded for CO2 and H2O, adsorbed simultaneously on the sample at room temperature, over the catalysts as well as over the supports. It was observed that the presence of the platinum particles did not change the TPD spectra significantly, thus only the spectra over the supports are considered here. Figures 2 show the experimental CO2 and H2O TPD spectra for Pt/CeO2 and Pt/TiO2. The spectra have been recorded with two different heating rates, 10 and 20 °C/min, but in the qualitative discussion that follows only the peak temperatures of the 20 °C/min spectra are mentioned as they show a better signal to noise ratio.

The spectra strongly depend on the operating conditions during the adsorption and pre-treatment of the samples, which modifies the state of the surface. Therefore, the comparison with TPD data from the literature is difficult. In addition, infrared studies report the presence of several different species adsorbed on the surface of metal oxides after contact with CO2 and H2O [14, 15].

Hardly any CO2 is retained over the TiO2 support, and as a result the CO2 TPD spectrum shows a very weak desorption peak with its maximum at approximately 90 °C. Wang et al. studied the basicity of a TiO2 support prepared by a sol–gel method and reported two CO2 desorption peak, one at 95 °C and a second much less intense at 215 °C [14].

In contrast to the titania sample CO2 adsorbs on the ceria support and the TPD spectrum shows a desorption peak of CO2 at 130 °C. The signal to noise ratio is too low to ascertain the presence of a second peak (shoulder) just before the main one. Some tailing of the peak above 175 °C cannot be excluded either. Luo et al. reported that the TPD spectrum obtained after CO2 adsorption on CeO2 were composed of CO2 desorption at 140 °C and 440 °C [16]. These peaks were assigned to monodendate and bidentate carbonate species in the adsorbed states. Jin [17] observed for a Pt/CeO2 catalyst two CO2 desorption peaks at −133 °C and around 427 °C. In this case the signal to noise ratio might be too low to detect the high temperature peak.

The H2O TPD spectrum over the TiO2 support shows two desorption peaks (120 °C and 175 °C) as well as a long tailing up to temperatures of 500 °C. H2O TPD reported in the literature for TiO2 anatase show two desorption peaks with maxima at 69–127 (I) and 191–256 °C(II) very similar as reported here [18]. The enthalpies of adsorption were evaluated to be 36 and 55–69 kJ/mol for peaks I and II, respectively. The authors assigned the first peak to physically adsorbed species on hydroxyl groups or chemisorbed water molecules, and the second peak to chemisorbed species on surface oxygen ions through hydrogen bonds.

The H2O TPD spectrum over the ceria support shows an almost symmetrical desorption peak centered around 120 °C with an important tailing at higher temperatures on which a second very weak desorption peak is located at around 260 °C.

TPD spectra have been simulated using the mathematical reactor model presented above for desorption of CO2 and H2O over ceria and titania (except CO2 over TiO2 which adsorption is assumed negligible). Figures 2 show the simulations as full lines with the kinetic parameters reported in Table 3. The simulation of the CO2 TPD over ceria fits the experimental data very well. CO2 sorption follows first order Langmuir kinetics. The values of the kinetic parameters used in the simulation are in very good agreement with the results of the kinetic study over Pt/CeO2 (see Table 3).

The adsorption of water on oxide surfaces has been studied in detail especially in the case of rutile TiO2, but mainly by qualitative methods [19]. There has been recently a consensus of both theoretical calculations and experimental methods that water adsorbs both molecularly and dissociatively on TiO2 surfaces. Oxygen vacancies act as the active site for the water dissociation [20, 21]. TPD experiments under vacuum conditions over TiO2 (100) show a large desorption peak above 17 °C that is assigned to a hydroxyl recombination [22]. Much less is known on the adsorption of water on ceria [19], but Herman et al. [23] reported a TPD of D2O over CeO2 (001) under vacuum conditions and they assigned the third desorption peak at 2 °C to a hydroxyl recombination. Therefore the simulations of the water desorption spectra over TiO2 and CeO2 are based on both molecular (low temperature peak) and dissociative (high temperature peak) adsorption. It should be noted here that the second broad desorption peak over both oxides could also be modeled by molecularly adsorbed water molecules that present strong lateral interaction through hydrogen bonding. More characterization is necessary to gather direct evidence to assign this peak to water dissociation. Whatever the assignment is it will not have much impact on the proposed kinetic model as water adsorption and dissociation are lumped into one step.

The comparison between the simulation and the TPD data of H2O over ceria shows that for both heating rates a reasonable good fit is obtained and both desorption peaks are well described, except the tailing above 350 °C for the 20 °C/min spectrum. The values of the adsorption enthalpies for molecular and dissociative adsorption amount to −44 and −90 kJ/mol, respectively.

The simulations for water desorption over TiO2 describe the two desorption peaks quite well. Again the model does not fit on the 20 °C/min spectrum the tailing at high temperatures properly. On both supports this might be due to hydroxyl species having a strong interaction and thus a higher desorption activation energy. The values of the adsorption enthalpies for molecular and dissociative adsorption over TiO2 amount to −45 and −70 kJ/mol, respectively. The similar values of the adsorption enthalpies for molecular adsorption over both supports agree with the value of −41 kJ/mol for the heat of vaporization of water at 100 °C. The value of the adsorption enthalpies for dissociative water adsorption over TiO2 are within the range of values of −69 to −79 kJ/mol for the formation of hydroxyls on anatase TiO2 on the dominant (101) plane based on DFT calculations by Arrouvel et al. [24].

Substitution of the adsorption enthalpies for the water dissociation on the supports does not change the model fit of the experimental data but it increases the estimated values of the activation energies.

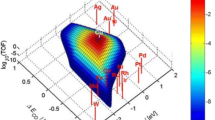

The analysis of the two water TPD spectra over ceria and titania shows that water adsorbs stronger on titania than on ceria and even more so at low surface coverages. The calculated sorption equilibrium constants given in Table 3 indicates that the water coverages under typical reformate conditions are well below 20% and they are higher on TiO2 than on CeO2. Thus the better activity of the TiO2 supported Pt catalyst compared to the Pt/CeO2 is due to at least two factors: negligible CO2 adsorption on TiO2 preventing blocking of the active sites and a higher water adspecies concentration leading to a higher reaction rate as this species is involved in the rate determining step.

4 Conclusion

A kinetic study of the water–gas shift reaction has been conducted over a Pt/CeO2 and a Pt/TiO2 catalyst. The data over both catalysts have been modeled by a rate equation based on a dual-site reaction mechanism where CO and H2 chemisorb on the platinum particles and H2O and CO2 on the support. The reaction takes place at the interface of the particles and the support. Regression analysis of the two data sets showed that the van ‘t Hoff equilibrium parameters correspond to physical realistic values for chemisorption of CO and H2 on platinum. The chemisorption of H2O and CO2 on the two supports have been studied by TPD experiments. Simulation of the TPD spectra have been carried out to facilitate their interpretation and to compare the sorption parameters with those from the kinetic modeling of the steady-state data. The results of both methods are in reasonable good agreement, although not all the features of the water chemisorption on the two supports have been clarified. The model is also able to explain the better activity of the Pt/TiO2 catalyst compared to Pt/CeO2 in terms of the difference in CO2 and H2O sorption on the two supports. These results confirm a dual-site reaction mechanism and give an idea of the complexity of the WGS reaction, in particular concerning the activation of water on the support.

Abbreviations

- εb :

-

Reactor void space \( \left( {{\text{m}}_{\text{gas}}^{3} {\text{ m}}_{\text{reactor}}^{ - 3} } \right) \)

- Ci :

-

Gas phase concentration of species i \( \left( {{\text{mol m}}_{\text{gas}}^{ - 3} } \right) \)

- θi :

-

Surface coverage of species i (−)

- Dax,i :

-

Axial diffusion coefficient \( \left( {{\text{m}}_{\text{gas}}^{3} {\text{ m}}_{\text{reactor}}^{ - 1} {\text{s}}^{ - 1} } \right) \)

- Lt :

-

Active site concentration mol m−3 catalyst

- t:

-

Time (s)

- z:

-

Axial reactor coordinate (m)

- νij :

-

Stoichiometric coefficient of species i in reaction j (−)

- kj :

-

Rate constant of reaction j (\( \left( {{\text{m}}_{\text{gas}}^{3} {\text{ mol}}^{ - 1} } \right)^{\text{nk}} \) s−1)

- n:

-

Number of reactions (−)

- T:

-

Temperature (K)

- β:

-

Heating rate (K/s)

- Γ:

-

Approach to equilibrium

- SBET :

-

Surface area (m2 g−1)

- Pi :

-

Partial pressure of species I (bar)

- A0 :

-

Pre-exponential factor (different dimensions)

- Keq :

-

Equilibrium constant (−)

- Eact :

-

Activation energy (kJ/mol)

- Ns :

-

Active site concentration (mol/kgcatalyst)

- \( \Updelta {\text{S}}_{\text{gas}}^{0} \) :

-

Standard adsorption entropie (J/mol K)

- \( {\text{S}}_{\text{gas}}^{0} \) :

-

Standard gas phase entropie (J/mol K)

- R:

-

Gas constant (J/mol/K)

- \( \Updelta {\text{H}}_{\text{ads}}^{0} \) :

-

Standard adsorption enthalpie (kJ/mol)

References

Grenoble DC, Estadt MM, Ollis DF (1981) J Catal 67:90

Burch R (2006) Phys Chem Chem Phys 8:5483

Germani G, Schuurman Y (2006) AIChE J 52:1806

Perrichon V, Retailleau L, Bazin P, Daturi M, Lavalley JC (2004) Appl Catal A: Gen 260:1

Hindmarsh AC (1983) In: Stepleman RS et al. (eds) Scientific computing, Amsterdam, North-Holland, pp 55–64

Marquardt DW (1963) J Soc Indust Appl Math 11:431

Schiesser WE (1991) The numerical method of lines. Academic Press, San Diego

Panagiotopoulou P, Kondarides DI (2006) Catal Today 112:49

Panagiotopoulou P, Christodoulakis A, Kondarides DI, Boghosian S (2006) J Catal 240:114

Hansen AG, Well WJM, Stoltze P (2007) Top Catal 45:219

Vannice MA, Hasselbring LC, Sen B (1985) J Catal 95:57

Vannice MA, Hasselbring LC, Sen B (1986) J Catal 97:66

Boudart M, Mears DE, Vannice MA (1967) Ind Chim Belge 32:281

Wang JA, Cuan A, Salmones J, Nava N, Castillo S, Moran-Pineda M, Rojas F (2004) Appl Surf Sci 230:94

Prin M, Pijolat M, Soustelle M, Touret O (1991) Thermochim Acta 186:273

Luo M-f, Zhong Y-j, Zhu B, Yuan X-x, Zheng X-m (1997) Appl Surf Sci 115:185

Jin T, Okuhara T, Mains GJ, White JM (1987) J Phys Chem 91:3310

Egashira M, Kawasumi S, Kagawa S, Seiyama T (1978) Bull Chem Soc Japan 51:3144

Henderson MA (2002) Surf Sci Report 46:1

Brookes IM, Muryn CA, Thornton G (2001) Phys Rev Lett 87:266103

Schaub R, Thostrup P, Lopez N, Lægsgaard E, Stensgaard I, Nørskov JK, Besenbacher F (2001) Phys Rev Lett 87:266104

Henderson MA (1996) Langmuir 12:5093

Herman GS, Kim YJ, Chambers SA, Peden CHF (1999) Langmuir 15:3993

Arrouvel C, Digne M, Breysse M, Toulhoat H, Raybaud P (2004) J Catal 222:152

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Thinon, O., Rachedi, K., Diehl, F. et al. Kinetics and Mechanism of the Water–Gas Shift Reaction Over Platinum Supported Catalysts. Top Catal 52, 1940 (2009). https://doi.org/10.1007/s11244-009-9377-z

Published:

DOI: https://doi.org/10.1007/s11244-009-9377-z