Abstract

A simple and efficient protocol for the ligand-free Mizoroki–Heck coupling reaction of various aryl bromides with different olefins has been reported by using in situ generated PdNPs of size 5–10 nm in aqueous solution of bio-surfactant. The bio-surfactant used in this study is a saponin extract of the seeds of pericarps (pods) of the Acacia concinna plant. The in situ generated PdNPs have been characterized by various techniques such as HRTEM, EDS and XPS. The influence of various parameters such as the nature and amount of bases, the nature of Pd precatalysts as well as the effect of temperature has been investigated on Mizoroki–Heck coupling reaction. The generated PdNPs significantly coupled the various aryl bromides with different olefins in aqueous extract of the seeds of pericarps (pods) of the Acacia concinna plant at 100 °C.

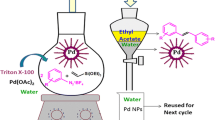

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Palladium-catalyzed cross-coupling reactions, especially, Mizoroki–Heck coupling reaction [1], have emerged as one of the most efficient catalytic tools in organic chemistry for the synthesis of a variety of important pharmaceutical intermediates [2,3,4,5,6]. This coupling reaction is also extensively used for the synthesis of organic polymers and compounds of theoretical interests [7,8,9,10,11].

Recently, a large number of efforts have been made to carry out the Mizoroki–Heck coupling reaction in aqueous media [12], because water offers many advantages such as the conservation of the environment and also development of an economically viable process. But the use of water as a reaction medium turns out to be the most challenging, due to the low solubility of substrates into the water that also affects the reaction kinetics. In view of the importance of Mizoroki–Heck coupling reaction in aqueous medium, much attention has been paid to develop milder and simpler procedures like the development of ligand-free Pd catalysis without additives, including TBAB, PEG, surfactants, etc. [13]. Efficient ligand-free Pd catalysis in the water offers an ecological and economical advantage. One of the main limitations of the ligand-free approach in Pd catalysis is the leaching of Pd into the solution in the form of Pd black. This limitation can be partially avoided by the use of various surfactants and some additives [14, 15]. Some naturally occurring biodegradable surfactants have also been used as efficient additives for stabilizing the substrates and are innocuous to the ecosystem or to the environment [16]. Thus, development of an eco-friendly and biodegradable materials for catalysis is, therefore, essential in the present context.

Nanomaterials can play a dynamic role in nanotechnology, due to their extraordinarily different properties as compared to their bulk counterparts. The PdNPs have been widely reported as active catalysts for the Mizoroki–Heck coupling reaction [17, 18]. From the environmental point of view, bio-inspired synthesis of metal nanoparticles using microorganisms, viruses, plant extracts, proteins and DNA molecules has been well applied in various fields of chemistry [19,20,21]. Recently, various biomaterials have been reported for different Pd-catalyzed cross-coupling reactions [22,23,24].

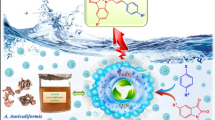

Recently, we have used different biomaterials as a solid support for Pd catalysts in various cross coupling reactions [25, 26]. In continuation of our special efforts, the use of natural materials in different coupling reactions [27,28,29,30,31]. In the present study, we have used the bio-extract of an Acacia concinna pods commonly named as ‘Shikakai’ in India as a green and environmentally benign reaction medium for ligand-free Pd-catalyzed Mizoroki–Heck coupling reaction in water at 100 °C.

Results and discussion

Preparation of aqueous extract of Acacia concinna pods

Pods of Acacia concinna fruit commonly known as ‘Shikakai’ have been used as detergents, expectorant, emetic and purgative in India [32]. The surface-active component saponins extracted from the pericarps and seeds of this plant are a complicated mixture of saccharin derivatives called triglycosides of acacia acid and act as nonionic surfactants. The pods of Acacia concinna have been found to contain the saponin of acacic acid (trihydroxymonocarboxylic acid) belonging to the tetracyclic triterpene group [33, 34]. Initially, we have prepared an aqueous extract of Acacia concinna pods, in which dry pods of Acacia concinna were soaked in distilled water for 12 h. Then, the resulting material was crushed and filtered through Whatman filter paper to obtain the aqueous extract of Acacia concinna pods (Fig. 1) called aqueous extract of bio-surfactant.

Optimizations of reaction conditions for Mizoroki–Heck coupling reaction in aqueous extract of bio-surfactant

Herein, we have adopted a simple procedure in which the PdNPs were prepared in situ using Pd(OAc)2 as a Pd source. In order to determine the best protocol for aqueous ligand-free Mizoroki–Heck coupling reaction, preliminary experiments were performed by coupling 4-methylbromobenzene with t-butyl acrylate and Et3N as a base in aqueous extract of bio-surfactant at 100 °C (Scheme 1).

After stirring the reaction mixture at 100 °C, it turned into a black-colored solution due to the formation of PdNPs as shown in Fig. 2.

To gain further insight into the consequence on the in situ formed PdNPs, HRTEM, EDS and XPS analyses of PdNPs were carried out. Figure 3 shows the HRTEM images of the PdNPs formed in the reaction mixture after 5 min and after completion of the reaction. The HRTEM analysis of reaction mixture confirmed the formation of PdNPs of a size ~ 5–10 nm with spherical morphology.

In order to confirm the presence of other elements present along with PdNPs, EDS analysis was carried out which as shown in Fig. 4. EDS analysis of reaction mixture indicated the presence of palladium along with carbon and oxygen.

XPS analysis of the reaction mixture after 5 min (Fig. 5a) and after completion of the reaction (Fig. 5b) provided useful information about the oxidation state of Pd. The characteristic binding energy peak observed at lower energy doublet was assigned to metallic Pd, whereas the higher binding energy could be related to Pd oxide. It also observed that initially, most of the Pd is in Pd(II) oxidation state, and as the reaction proceeds, almost all Pd(II) is reduced to Pd(0). After completion of the reaction, intensity of the peak due to Pd(0) is stronger than that of Pd(II), suggesting that the majority of Pd(OAc)2 was reduced to PdNPs during the course of a reaction.

Next, by using the above model reaction (Scheme 1), the effect of various reaction parameters such as nature and amount of the bases, nature and amount of the Pd catalysts employed, the reaction scale and reaction time was investigated.

The influence of nature of the bases (Table 1) has been investigated by performing the model reaction by varying organic and inorganic bases in an aqueous bio-surfactant solution at 100 °C. It was observed that NEt3 was found to be more effective (Table 1, entry 7) as that of other bases (Table 1, entries 1–6). The effect of varying the amount of NEt3 is also summarized in Table 1. When the amount of NEt3 was increased from 1.0 mmol to 2.0 mmol, the yield of the desired product was improved from 56 to 85% (Table 1, entries 7 and 8). It was also found that further increasing the amount of base from 2 mmol to 4 mmol does not improve the yield of the product (Table 1, entries 9 and 10).

Next, the influence of nature of catalyst precursors was studied for model reaction (Table 2). It was observed that except PdCl2, all the catalyst precursors were found to be less effective than Pd(OAc)2 in terms of reaction time as well as yield. In contrast, a heterogeneous catalyst Pd/C, did not show any catalytic activity (Table 2, entry 2).

The influence of catalyst concentration is very important, as it affects the cost of the process. It has been found that increasing the Pd(OAc)2 concentration of 2.0 mol. % to 3.0 mol. % and even increasing the reaction time to 24 h did not improve the yield of the product (Table 2, entries 8 and 12–13); it may be due to the formation Pd black by agglomeration of PdNPs [13]. In addition, the lower catalyst loading provided lower conversion for 24 h (Table 2, entries 9–11). Thus, 2 mol.% Pd(OAc)2 was found to be the most effective with a maximum yield of 85% in 12 h (Table 2, entry 6).

Furthermore, the effect of the amount (mmol) of aryl bromide on the yield of the product was investigated under optimized reaction conditions and the results are illustrated in Fig. 6. For this study, in each set of experiments, a ratio of 4-methylbromobenzene to t-butyl acrylate, NEt3 and Pd(OAc)2 was kept constant. The results showed that the good activity was reported for 1.5 mmol of 4-methylbromobenzene. It was also observed that initially, the 1 mmol of 4-methylbromobenzene worked less efficiently, but showed similar reactivity as 1.5 mmol of 4-methylbromobenzene. In addition, the half of the reaction was completed within 4 h.

Finally, we examined the effect of temperature on the yield of the coupling reaction and the results are graphically illustrated in Fig. 7. For this study, the model reaction was carried out in a temperature range of 25–120 °C for 12 h reaction time. As temperature increases, the yield of the desired coupling product increases continuously up to 80 °C. Though a drastic rise in rate was observed at 90 °C, further increase in temperature has no significant effect on the yield of the product.

We explored the scope and generality of the optimized protocol (aryl bromide 1.0 mmol), olefin (1.0 mmol), NEt3 (2.0 mmol), Pd(OAc)2 (2.0 mol %), aqueous extract of bio-surfactant (5.0 mL) at 100 °C under air) for various aryl bromides containing different functional groups. As shown in Table 3, in general, all reactions provided the desired coupling products in good to excellent yields (77–89%).

Gram-scale synthesis

From an industrial point of view, we studied the applicability of Mizoroki–Heck cross-coupling reaction on the gram scale in aqueous extract of bio-surfactant (Scheme 2). For this study, the reaction of 4-methylbromobenzene with t-butyl acrylate was carried out in 10 mmol scale. Thus, the desired coupling product was obtained with 85% yield at 100 °C in 12 h. Thus, this gram-scale synthesis can work as a practical method for industrial applications in aqueous extract of bio-surfactant.

Conclusion

In conclusion, an aqueous extract of the Acacia concinna pods was utilized for the Mizoroki–Heck coupling reaction. The in situ generated PdNPs was employed as a highly efficient catalyst for the Mizoroki–Heck coupling of various aryl bromides with different olefins with good to excellent yields at 100 °C in 12 h. Furthermore, this method could be performed on the gram-scale synthesis with excellent yield of the desired product. This reported protocol is superior with the added benefits of green chemistry, ligand-free conditions, use of aqueous medium as well as natural resources and a green and economical method for the synthesis of PdNPs.

References

Bräse S, Meijere AD (2008) In metal-catalyzed cross-coupling reactions. WileyVCH: Verlag GmbH, Berlin, p 217

Beletskaya IP, Cheprakov AV (2000) Chem Rev 100:3009

Heck RF, Nolley JP (1972) J Org Chem 37:2320

Mizoroki T, Mori K, Ozaki A (1971) Bull Chem Soc Jpn 44:581

Carin CC, Seechurn J, Kitching MO, Colacot TJ, Snieckus V (2012) Angew Chem Int Ed 51:5062

Biajoli AFP, Schwalm CS, Limberger J, Claudino TS, Monteiro AL (2014) J Braz Chem Soc 25:2186

Nicolaou KC, Bulger PG, Sarlah D (2005) Angew Chem Int Ed 44:4442

Prashad M (2004) Top Organomet Chem 6:181

Smith GB, Dezeny GC, Hughes DL, King AO, Verhoeven TR (1994) J Org Chem 59:815

Danishefsky SJ, Masters JJ, Young WB, Link JT, Snyder LB, Magee TV, Jung DK, Isaacs RCA, Bornmann WG, Alaimo CA, Coburn CA, Di Grandi MJ (1996) J Am Chem Soc 118:2843

Dounay AB, Overman LE (2003) Chem Rev 103:2945

Lee H-S, Pai S-H, Liao W-T, Yang X-J, Tsai F-Y (2017) RSC Adv 7:34293

Jadhav SN, Rode CV (2017) Green Chem 19:5958

Bhattacharya S, Srivastava A, Sengupta S (2005) Tetrahedron Lett 46:3557

Huang J, Lin L, Sun D, Chen H, Yang D, Li Q (2015) Chem Soc Rev 44:6330

La Sorella G, Strukul G, Scarso A (2015) Green Chem 17:644

Khazaei A, Rahmati S, Hekmatian Z, Saeednia S (2013) J Mol Catal A: Chem 372:160

Puthiaraja P, Pitchumani K (2014) Green Chem 16:4223

Gardea-Torresdey J, Tiemann K, Gamez G, Dokken K, Tehuacanero S, Jose-Yacaman M (1999) J Nanopart Res 1:397

Dujardin E, Peet C, Stubbs G, Culver JN, Mann S (2003) Nano Lett 3:413

Mertig M, Colombi Ciacchi L, Seidel R, Pompe W, De Vita A (2002) Nano Lett 2:841

Kumbhar A, Salunkhe R (2015) Curr Org Chem 19:2075

Majumdar R, Tantayanon S, Bag BG (2017) Int Nano Lett 7:267

Boruah PR, Ali AA, Saikia B, Sarma D (2015) Green Chem 17:1442

Pore S, Rashinkar G, Mote K, Salunkhe R (2010) Chem Biodiver 7:1796

Mote K, Pore S, Rashinkar G, Kamble S, Kumbhar A, Salunkhe R (2010) Arch Appl Sci Res 2:74

Jadhav SN, Kumbhar AS, Salunkhe R (2015) Appl Organometal Chem 29:339

Kumbhar AS, Jadhav SN, Kamble S, Rashinkar G, Salunkhe R (2013) Tetrahedron Lett 54:1331

Jadhav SN, Kumbhar AS, Kamble S, More P, Salunkhe R (2013) C R Chimie 16:957

Jadhav S, Jagdale A, Kamble S, Kumbhar AS, Salunkhe R (2016) RSC Adv 6:3406

Jadhav SN, Kumbhar AS, Mali SS, Hong CK, Salunkhe RS (2015) New J Chem 39:2333

Tezuka Y, Honda K, Banskota AH, Thet MM, Kadota S (2000) J Nat Prod 63:1658

Varshney IP, Handa G, Pal R (1973) J Ind Chem Soc 50:544

Varshney IP, Shamuddin KM (1970) Bull Chem Soc Jpn 43:3830

Acknowledgements

One of the authors, Seema Patil, is grateful to the Department of Science and Technology (DST), New Delhi, Government of India, for the award of the Women Scientist Scheme-A (WOS-A), File no. SR/WOS-A/CS-85/2018. We also partly acknowledge the University Grants Commission, Government of India, New Delhi, for supporting this work under the scheme of Major Research Project [F. No. 41-182/2014 (SR)].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

There are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Patil, S.P., Jadhav, S.N., Rode, C.V. et al. Bio-surfactant: a green and environmentally benign reaction medium for ligand-free Pd-catalyzed Mizoroki–Heck cross-coupling reaction in water. Transit Met Chem 45, 403–411 (2020). https://doi.org/10.1007/s11243-020-00392-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11243-020-00392-x