Abstract

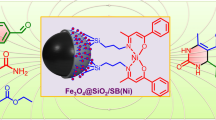

In this study, a novel amino acid-based Ni complex was immobilized on SiO2-modified Hercynite magnetic nanoparticles as the support to prepare the heterogenized guanidino-nickel catalyst (Hercynite@SiO2-l-Arginine-Ni). The uniform surface morphologies of these nanoparticles were characterized using SEM. Thermogravimetric analyses indicated that the [Hercynite@SiO2-l-Arginine-Ni] nanocomposite possessed reliable thermal stability. The homogeneous dispersion of nickel species on the surface of the amino acid-modified Hercynite was characterized using X-ray mapping and XRD. The catalysis studies showed that this heterogenized l-Arginine-Ni magnetic complex was highly active for the asymmetric Hantzsch synthesis of polyhydroquinolines and cyclocondensation of anthranilamide with aromatic aldehydes to generate 2,3-dihydroquinazolin-4(1H)-ones. In addition, the magnetic and heterogeneous nature of Hercynite core allows the easy separation of the catalyst by magnetic decantation. Besides, the [Hercynite@SiO2-l-Arginine-Ni] can be reused for at least 5 catalytic cycles for both of the mentioned reactions without an obvious drop in its activity.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The art of synthesizing the targets molecules via multicomponent reactions, including the sequentially named reactions, has attracted great interest due to the fact that these procedures would enable the organic chemistry researchers to synthesize novel organic complex products using simple starting materials in fewer steps and shorter time in a single reaction vessel [1,2,3,4,5]. In this regard, Knoevenagel condensation–Michael addition–cyclization is one of the most popular sequences which was utilized to synthesize a wide variety of functionalized organic molecules [6,7,8,9].

N-heterocycles are a series of the most important organic intermediates and drug compounds with industrial, biological, and medicinal properties [10,11,12]. Polyhydroquinolines, which are a class of dihydropyridine-containing compounds, can be regarded as important series of N-containing heterocycles and are widely used in synthetic organic and bio-organic chemistry [13,14,15,16]. We have previously reviewed the available synthetic methods for the synthesis of polyhydroquinolines [17]. Despite the numerous reported synthetic procedures in the literature, the most useful synthetic method to generate polyhydroquinolines is a one-pot and multicomponent synthesis using the condensation of an aldehyde, two equivalents of β-keto esters and a nitrogen source, which is named as the Hantzsch reaction [15, 17, 18]. This strategy helps circumvent the isolation of unstable intermediates (Michael donor and Michael acceptor compounds) that may not be easily separated [17, 19].

The benzene ring—which was fused to a 6-membered alicyclic moiety with two N atoms on positions 1 and 3—and its condensation with a phenyl ring and keto group on carbons 2 and 4, respectively, generated one of the most important heterocyclic ring systems, i.e., 2,3-dihydroquinazolin-4(1H)-one [19, 20]. The catalytic cyclocondensation method is still a widely used procedure to synthesize these heterocycles in which an aldehyde is heated with anthranilamide derivatives, a multi-step sequence ensues, a water molecule is lost and 2,3-dihydroquinazolin-4(1H)-one derivatives are formed, which have a chiral center at the phenyl-substituted carbon 2 [21, 22].

Due to the uses of polyhydroquinolines and 2,3-dihydroquinazolin-4(1H)-ones as synthons in synthetic organic chemistry and their fantastic biological applications, there has probably been more work carried out on the synthesis of these heterocyclic compounds [17, 23, 24]. Henceforth, the progress of green, toxic-free, efficient, and shorter recycling catalytic methods to access these compounds is of practical significance from both industrial and academic points of view.

Ni-based catalytic complexes have been one of the most used and accepted choices of catalyst for laboratory and commercial-scale synthesis; including, coupling reactions [25, 26], copolymerization of olefins [27], multicomponent reactions [28], hydrogenation and oxidation reactions [29], amination reactions and other organic functional group transformations [29,30,31]. The catalytic properties of Ni-based materials are highly dependent on their physicochemical parameters.

Nowadays, instead of a normal catalyst, nano-catalyst is said to be gaining a lot of importance due to its morphology and size difference from the normal catalyst [32]. Significantly, the synthesis of transition metal-based heterogeneous catalytic nanostructures by proper solid-state stabilizer has been widely utilized in the catalytic transformation of organic functional groups [17, 32]. Nano-magnetic-based solids are one of the most advantageous heterogeneous catalytic supports, which have been developed during recent decades [17, 33]. During our previous research to find novel advantageous heterogeneous catalytic supports, normal spinel Hercynite (FeAl2O4) NPs were found to be an efficient nanomagnetic material with fantastic properties in stabilizing different organic/inorganic materials [19, 34, 35]. Thus, Hercynite MNPs can be regarded as ideal solid support to encapsulate Ni-complexes as efficient and stable heterogeneous catalysts.

This work delignated an excellent recoverable nano-catalytic system for the synthesis of polyhydroquinolines and 2,3-dihydroquinazolin-4(1H)-ones under extremely green conditions, which can be considered as an industrially important aspect to develop a practical and cost-effective catalytic process with a broad scope of aldehydes.

Experimental

Preparation of arginine-Ni complex supported on the surface of Hercynite magnetic nanoparticles ([Hercynite@SiO2-l-Arginine-Ni])

During the first step, FeAl2O4 (Hercynite) MNPs were prepared by a chemical co-precipitation process according to our previously reported method [35]. The SiO2 shell was grafted on the surface of obtained Hercynite nanoparticles to generate Hercynite@SiO2 MNPs according to the previously reported method for Fe3O4 surface modification [6]. Afterward, in order to immobilize the amino acid containing Guanidino-based ligand, the obtained Hercynite@SiO2 nanoparticles (1 g) were dispersed in the 50 ml mixture of water and ethanol (1:1) by sonication for 30 min and then, 3 mmol of l-Arginine and 3 mmol K2CO3 were added to solution. Furthermore, it was stirred under reflux conditions for 48 h under a N2 atmosphere. Subsequently, the obtained NPs (Hercynite@SiO2-l-Arginine) were isolated by magnetic separation, washed with hot ethanol and water several times and then, dried at 60 °C. Finally, Ni(NO3)2\(\cdots\)6 H2O (2.5 mmol) salt was dissolved in a aqueous ethanol (15 mL), and then, it was added to a dispersed solution of ethanol (15 mL) containing 1 g of Hercynite@SiO2-l-Arginine. Subsequently, it was stirred under an N2 atmosphere at 80 °C for 24 h. Finally, the target [Hercynite@SiO2-l-Arginine-Ni] hybrid complex was collected by an external magnet. Afterward, the obtained black powder was transferred into an oven and then dried at 60 °C for 4 h (Scheme 1).

General procedure for the catalytic synthesis of polyhydroquinolines

A mixture of the substituted aromatic aldehyde (1.0 mmol) ethyl acetoacetate (1 mmol) and dimedone (1 mmol) was stirred with ammonium acetate as a green NH3 source (1.2 mmol) and [Hercynite@SiO2-l-Arginine-Ni] (10 mg) for 70–180 min at 80 °C under solvent-free conditions. Completion of the following reaction has been analyzed via TLC. Subsequently, the reaction mixture was diluted with hot ethanol to dissolve the organic products. Moreover, the catalyst was separated using magnetic decantation, and then, the resultant unrefined polyhydroquinoline products were further purified through recrystallization in ethanol.

General procedure for the catalytic synthesis of 2,3-dihydroquinazolin-4(1H)-ones

A mixture of the substituted aromatic aldehydes (1.0 mmol), anthranilamide (2-aminobenzamide) (1 mmol) and [Hercynite@SiO2-l-Arginine-Ni] (10 mg) was stirred for 35–250 min at 80 °C under solvent-free conditions. Completion of the following reaction has been analyzed via TLC. Subsequently, the reaction mixture was diluted with hot ethanol to dissolve the organic products, the catalyst was separated using magnetic decantation and the resultant unrefined 2,3-dihydroquinazolin-4(1H)-one products were further purified through recrystallization in ethanol.

Selected spectral data

Ethyl 2,7,7-trimethyl-5-oxo-4-(p-tolyl)-1,4,5,6,7,8-hexahydroquinoline-3- carboxylate

1H NMR (400 MHz, DMSO-d6) δ: 0.85 (s, 3H), 1.00 (s, 3H), 1.12–1.15 (t, J = 8 Hz, 3H), 2.14–2.20 (m, 4H), 2.27 (m, 3H), 2.40–2.45 (m, 2H), 3.94–4.00 (q, J = 8 Hz, 2H), 26.97–7.04 (m, 4H), 9.03 (s, 1H) ppm.

Ethyl 2,7,7-trimethyl-5-oxo-4-(p-anisol)-1,4,5,6,7,8-hexahydroquinoline-3- carboxylate

1H NMR (400 MHz, DMSO-d6) δ: 0.84 (s, 3H), 1.02 (s, 3H), 1.11- 1.15 (t, J = 8 Hz, 3H), 1.96- 2.00 (d,, J = 16 Hz, 1H), 2.16–2.20 (d,, J = 16 Hz, 1H), 2.30 (s, 3H), 2.41–2.45 (d, J = 16 Hz, 1H), 3.95–4.01 (q, J = 8 Hz, 2H), 4.40–4.48 (m, 3H), 4.84 (s, 1H), 7.15–7.17 (d, J = 8 Hz, 2H), 7.25–7.27 (d, J = 8 Hz, 2H), 9.13 (s, 1H) ppm.

Ethyl 2,7,7-trimethyl-5-oxo-4-(4-hydroxy)-1,4,5,6,7,8-hexahydroquinoline-3- carboxylate

1H NMR (400 MHz, DMSO-d6) δ: 0.85 (s, 3H), 1.01 (s, 3H), 1.12- 1.16 (t, J = 8 Hz, 3H), 1.95–1.99 (d,, J = 16 Hz, 1H), 2.20 (s, 1H), 2.26–2.30 (m, 4H), 2.39 (s, 1H), 2.40–2.44 (d, J = 16 Hz, 1H), 3.94–4.00 (q, J = 8 Hz, 2H), 4.81 (s, 1H), 6.97–7.04 (m, 4H), 9.03 (s, 1H) ppm.

2-Phenyl-2,3-dihydroquinazolin-4(1H)-one

1H NMR (400 MHz, DMSO-d6): δ = 5.76 (s, 1H), 6.66–6.70 (m, 1H), 6.75–6.77 (m, 1H), 7.13 (s, 1H), 7.23–7.27 (m, 1H), 7.34–7.42 (m, 3H), 7.49–7.52 (m, 2H), 7.61–7.63 (m, 1H) 8.31 (s, 1H).

2-(4-chlorophenyl)-2, 3-dihydroquinazolin-4(1H)-one

1H NMR (400 MHz, DMSO-d6): δ = 6.15 (s, 1 H), 6.71–6.78 (m, 2 H), 7.03 (s, 1 H), 7.25–7.29 (t, J = 8 Hz, 1 H), 7.40–7.42 (t, J = 4 Hz, 2 H), 7.50–7.52 (m, 1 H), 7.65–7.67 (m, 2 H), 8.24 (s, 1 H).

2-(thiophen-3-yl)-2,3-dihydroquinazolin-4(1H)-one

1H NMR (400 MHz, DMSO-d6): δ = 6.02 (s, 1 H), 6.69–6.73 (d, j = 8 Hz, 1 H), 6.75–6.77 (d, j = 8 Hz, 1 H), 6.98–7.00 (m, 1 H), 7.13–7.14 (m, 1 H), 7.25–7.29 (m, 2 H), 7.45–7.47 (m, 1 H), 7.61–7.63 (m, 1 H), 8.45 (s, 1 H).

2-(4-tolyl)-2, 3-dihydroquinazolin-4(1H)-one

1H NMR (400 MHz, DMSO-d6): δ = 2.30 (s, 3 H), 5.71–5.72 (t, J = 8 Hz, 4 H), 6.65–6.69 (m, 1 H), 6.73–6.75 (m, 1 H), 7.05 (s, 1 H), 7.19–7.26 (m, 3 H), 7.37–7.39 (m, 2 H), 7.60–7.62 (m, 1 H), 8.25 (s, 1 H).

Results and discussion

Catalyst synthesis

The nickel complex supported on the surface of silica-coated spinel normal magnetic Hercynite nanoparticles [Hercynite@SiO2-l-Arginine-Ni] was successfully constructed based on the experimental reaction, as shown in Scheme 1.

Catalyst characterization

The as-prepared [Hercynite@SiO2-l-Arginine-Ni] and its parent core-shells were then fully characterized using different physio-chemical techniques; including, FT-IR, XRD, TGA, VSM, EDX, ICP-ASE, X-ray-mapping and SEM analysis.

FT-IR analysis (Fig. 1) shows the FT-IR spectra of Hercynite, Hercynite@SiO2, Hercynite@SiO2-Arginine, and [Hercynite@SiO2-l-Arginine-Ni] MNPs. All FT-IR spectra in Fig. 1 are completely consistent with the previous analyses of Hercynite (FeAl2O4) MNPs [19, 35], indicating absorption bands at 580–600 cm−1 (Fe–O stretching vibrations). Moreover, peaks at around 3420–3450 cm−1 are formed by the stretching vibrations of the hydroxyl and interlayer water molecules. In Hercynite@SiO2 spectrum, the characteristic bonds at 1089 cm−1 (Si–O) and 800 cm−1 (Si–O–Si) confirm the successful coating of silica on the surface of the MNPs [36,37,38]. In the Hercynite@SiO2-l-Arginine spectrum, the peaks at 2852 cm−1 and 2923 cm−1 are caused by the aliphatic stretching vibrations C–H of methylene groups. Besides, the absorption bands at 1356, 1464, and 1631 cm−1 are related to the bending vibration of N–H [39]. The absorption peak observed at 1732 cm−1 is due to C=O stretching vibrations, confirming the successful immobilization of l-Arginine ligand on the surface of Hercynite@SiO2 [40]. As compared with the free Hercynite@SiO2-l-Arginine, the bending vibration of the N–H peak shifts to a lower wavenumber. This is because of the interaction between the electron-donor nitrogen group's head and the nickel species. Generally, these observations indicate the successful synthesis of [l-arginine-Ni] catalytic complex on the surface of Hercynite@SiO2 nanomagnetic core–shell.

The obtained normal angle powder X-ray diffraction (P-XRD) patterns for Hercynite (Black curve) and [Hercynite@SiO2-l-Arginine-Ni] (Red curve) are shown in Fig. 2. The P-XRD pattern of Hercynite exhibits several peaks, which are in good agreement with the XRD pattern of the spinel-type FeAl2O4 MNPs [35]. Regarding the XRD pattern of the [Hercynite@SiO2-l-Arginine-Ni], the phase of nanoparticles is identified by the peak position of 2θ = 18.39°, 30.20°, 35.74°, 37.34°, 43.32°, 46.62°, 53.67°, 57.27°, 62.76°, 71.21° and 74.47° which correspond to (111), (022), (131), (222), (040), (133), (242), (151), (044), (062) and (353) Miller indices, respectively. Moreover, it is worth mentioning that they matched well with the library patterns cubic spinel normal mineral Hercynite (JCPDS file, PDF No. 96-901-2447) [41], which is similar to the diffraction phase of the applied cubic structure Hercynite support for catalyst preparation. Moreover, the successful synthesis of Hercynite@SiO2 core–shell was confirmed by the presence of a broad peak at 2θ = 20–30° which is due to the amorphous silicon layer, demonstrating that the Hercynite structure was protected in the core where SiO2 cover did not alter the crystal structure of the magnetic Hercynite nanoparticles [25, 26]. In addition, after anchoring the [l-Arginine-Ni] complex, the peaks were found to be broader than that of the Hercynite nanostructures. But, the peak intensity of the catalyst significantly increased that confirming the growth of crystalline particles during. Moreover, the background became noisy due to the amorphous silica shell [42]. In addition, the diffraction peaks at 2θ = 33.92° and 43.26° are related to a separate phase of nickel species in [Hercynite@SiO2-l-Arginine-Ni], confirming the complexion of Ni and its strong attachment over Hercynite@SiO2-l-Arginine composite [43, 44]. Finally, based on the Williamson-Hall (βCosθ = Kλ/D + C.e.Sinθ) and Scherrer (D = Kλ/(β cos θ) equations, the average crystallite size of [Hercynite@SiO2-l-Arginine-Ni] nanoparticles was found to be about 16 nm (Fig. 3).

Figure 4 shows the TGA–DSC curve of [Hercynite@SiO2-l-Arginine-Ni] MNPs. The thermal decomposition process of [Hercynite@SiO2-l-Arginine-Ni] is roughly divided into three stages, with a total weight loss of 27.46%. The first stage occurs at below 200 °C, the weight loss is about 5%, and there is an endothermic peak near 74 °C (removal of water and other organic solvents). The next stage occurs from 210 to 350 °C, in which the weight loss is about 16% and there is an endothermic peak near 278 °C, which is related to endothermic l-Arginine-Ni complex decomposition; at this stage, the structure of the catalyst begins to collapse. As seen from the above analysis, the organic catalytic complex was successfully grafted on the surface of Hercynite@SiO2 support.

The magnetization curves of Hercynite and [Hercynite@SiO2-l-Arginine-Ni] MNPs catalyst are shown in Fig. 5. The magnetization of pure Hercynite is about 40 emug−1 and that of the catalyst is 25 emug−1. This finding indicates the paramagnetic nature of the catalyst, and this change is related to the coating of MNPs with silica shell and organic moieties.

The EDX analysis verified the composition of [Hercynite@SiO2-l-Arginine-Ni], showing the corresponding elements of the formed nanoparticles and confirming the synthetic route proposed in Scheme 1. As shown in Fig. 6, EDS analysis confirms the presence of three main elements of Hercynite support which are Fe (Lα = 0.705 and kα = 6.398 keV), Al (kα = 1.486 keV) and O (kα = 0.525 keV) species. Moreover, the successful synthesis of Hercynite@SiO2 core shell was confirmed by the presence of Si (kα = 1.739 keV) species. As shown in Fig. 6, the immobilization of l-Arginine ligand was confirmed by the presence of carbon (kα = 0.277 keV) and nitrogen (kα = 0.392 keV) elements. In addition, the corresponding peaks of Ni (Lα = 0.851 keV and kα = 7.471 keV) in the EDS spectrum clearly confirmed the complexation of Ni with the heterogenized l-Arginine Moieties. Moreover, the exact amount of Nickel (0.89 × 10–3 mol/g or 3.86 W%) in [Hercynite@SiO2-l-Arginine-Ni] has been determined using the ICP-OES analysis.

X-ray mapping analysis was applied to determine the element dispersion of [Hercynite@SiO2-l-Arginine-Ni] magnetic nanocatalyst. As shown in Fig. 6, elemental X-ray mapping results are in excellent agreement with EDX patterns. Besides, the elemental mapping images show a uniform distribution of Fe, Al, Si, O, C, N and Ni elements, indicating the coordination of l-Arginine moiety to the nickel species (Fig. 7) and that the final metal-based catalytic complex has been successfully synthesized. These observations support the high purity of the prepared samples and show the elements throughout the samples.

Figure 8 shows that smooth [Hercynite@SiO2-l-Arginine-Ni MNPs] were successfully prepared with nano- and smaller-sized magnetite particles. According to FE‐SEM images, the synthesized [Hercynite@SiO2-l-Arginine-Ni] MNPs are well dispersed and of quasi-spherical structure. Moreover, they have a homogeneous distribution and are uniform in size. In addition, the catalyst demonstrated the increment in the size of the particles, as compared to its Hercynite parent, which is mainly due to the functionalization of Hercynite MNPs upon modification with the SiO2 shell, organic compounds and further complexation with nickel(II) nitrate hexahydrate.

Catalytic performance

After coordination of magnetic l-Arginine to Ni, the formed materials ([Hercynite@SiO2-l-Arginine-Ni]) can be also used as the catalyst for the synthesis of 2,3-dihydroquinazolin-4(1H)-ones and asymmetric Hantzsch synthesis of Polyhydroquinolines via 4-Chlorobenzaldehyde as the model reaction under the green conditions.

Initially, the Hantzsch synthesis under green conditions was optimized. Unfortunately, the condensation process does not occur under catalyst-free conditions after 2 h, due to the stability of starting reagents in the absences of an activator. Thus, we tried to determine the best suitable amount of catalyst by optimizing the prototypical reaction with various catalyst loadings, solvents and temperatures. Six different catalytic amounts of [Hercynite@SiO2-l-Arginine-Ni] catalytic complex were tested. The trials showed that increasing the quantity of the catalyst from 2 to 10 mg can improve the reaction yield (Table 1, entries 2–6). Furthermore, when the amount of the catalyst increased to 12 mg, the yield was not changed and gave the same results as the 10 mg (Table 1, entries 6, 7). By all these study results, it can be concluded that 10 mg of [Hercynite@SiO2-l-Arginine-Ni] is sufficient to bring out the complete Hantzsch synthesis in 80 min at 80 °C. Afterward, different types of solvents were used to determine the optimal reaction media, as shown in Table 1. The results revealed that the product yield was found to be 95% under solvent-free conditions using 10 mg of [Hercynite@SiO2-l-Arginine-Ni] after 80 min, as compared to the solvent-containing conditions. The presence of various solvents reduces the targeted product at the same conditions. To our delight, when using water, EtOH, DMSO, DMF, and PEG-400, the condensation reaction gave the desired product in lower yields.

Entries 6, 16–18 displayed the effect of reaction temperature from room temperature to 80 °C. Interestingly, the reaction yield was decreased if the reaction temperature was decreased to room temperature. Besides, it was found out that 80 °C would be the best, providing 95% of the desired polyhydroquinoline derivative (Table 1, entries 6, 16–18).

After discovering the optimum reaction conditions, the scope and limitation of the catalytic system were investigated for a range of aromatic aldehydes (Table 2). It is noted that all of the substituted aromatic aldehydes with electron-withdrawing groups as well as electron-donating groups at different positions of the aromatic rings showed excellent reactivity in reaction and underwent the Hantzsch transformation to polyhydroquinoline products (Table 2). It is observed that the electronic effects of the substituents in the aryl aldehydes affect the rate of the reaction as well as yields of the products. In addition, it is more immense to reveal that the aldehydes with substituents in para positions provide better yields in comparison with meta substituent aldehydes, indicating that this method is responsive to the steric hindrances. Particularly, in all the cases, the formations of by-products were not observed.

A possible transformation mechanism that accounts for the [Hercynite@SiO2-Argenin-Ni] catalyzed construction of Hantzsch synthesis of polyhydroquinolines under solvent-free conditions is proposed in Scheme 2 [16]. Herein, we hypothesized that the starting substrates can be activated by [Hercynite@SiO2-l-Arginine-Ni], due to its high Lewis acid property. According to this mechanism, the coordinative covalent bond between the Ni complex and oxygen atom of the aldehyde and β-keto esters increased the electrophilicity of the carbonyl carbon moiety. The initial formation of intermediate (I) occurs via condensation of dimedone with aromatic aldehydes, followed by the removal of a H2O molecule during Knoevenagel reaction. The enamine intermediate (II) which was obtained from the combination of NH3 with ethyl acetoacetate as the active carbonyl compound, undergoes the 1.4-Michael addition, affording the imine intermediate (III). Afterward, the imine intermediate undergoes a cyclization reaction and affords the targeted polyhydroquinoline products [8].

Our next goal was to check the catalytic activity of [Hercynite@SiO2-l-Arginine-Ni] MNPs in the click chemistry synthesis of 2,3-Dihydroquinazolin-4(1H)-one derivatives under the obtained optimal condition for Hantzsch reaction. All reactions were carried out using 10 mg of the catalyst at 80 °C under solvent-free conditions. More specifically, 3 different aryl halide substituted aromatic aldehydes were tested: para- bromo and chloro substituted benzaldehyde gave the 2,3-Dihydroquinazolin-4(1H)-one product in the same yield (Table 3, entries 3, 8). Likewise, para-methyl and para-methoxy substituted aryl aldehydes were successfully converted in 92–95% yields (Table 3, entry 4–6). In addition, aryl aldehydes with steric and electronic hindered effects showed moderate reactivity and afforded the corresponding heterocyclic products in moderate to good yields (Table 3, entry 6, 10). Similarly, the functionalized aryl aldehydes containing both electron-donating and electron-withdrawing groups felt efficient condensation reactions.

A probable mechanistic path for the formation of 2,3-dihydroquinazolin-4(1H)-ones, catalyzed by green [Hercynite@SiO2-l-Arginine-Ni] MNPs, is presented in Scheme 3 [21]. The presence of Ni metal Hercynite@SiO2-Argenin enhances its catalytic efficiency by increasing the number of Lewis acid sites. It is assumed that during the course of the reaction, [Hercynite@SiO2-l-Arginine-Ni] MNPs coordinated with the carbonyl oxygen of aromatic aldehyde enhanced the electrophilic character of carbonyl carbon and then were attacked by nitrogen of the amino group of the anthranilamide, leading to the formation of intermediate (I). Furthermore, [Hercynite@SiO2-l-Arginine-Ni] activates the intermediate (I) by coordinating with oxygen, which results in assisting the elimination of a water molecule to form the Schiff-base adduct (II), which—after amide-iminol tautomerization—subsequently undergoes intramolecular cyclization to form intermediate (IV). Finally, it was followed by the 1,5-proton transfer to form the corresponding 2,3-dihydroquinazolin-4(1H)-ones as the final product.

Reusability study

Practical application of the heterogeneous catalysis systems has the following features, i.e., ease of separation and the recovery of catalyst. To gain an insight into this issue, an array of experiments was designed and carried out to investigate the recovery and reutilize the [Hercynite@SiO2-l-Arginine-Ni] nanocatalyst in the Hantzsch synthesis of polyhydroquinolines and click synthesis of 2,3-dihydroquinazolin-4(1H)-ones model reactions. All reactions were conducted under similar conditions. Figure 9 shows that the [Hercynite@SiO2-l-Arginine-Ni] can be reused up to 5 times. Besides, it was observed that the catalytic activity was not significantly reduced and the catalyst had good recyclability, which confirms the high stability of the supported nickel complex in the last reuse.

Hot-filtration test

A hot filtration test in ethanol indicated that the removal of the solid catalyst by magnetic hot filtration of the heterogeneous catalyst from the original reaction mixture completely stopped the reaction. The obtained results show that the Ni-Complex immobilized on Hercynite@SiO2 core–shell played an efficient catalytic role in the successful synthesis of the corresponding target molecules. Furthermore, ICP-AES analysis of the filtrate solution showed no detectable amount of Ni, indicating no leaching of nickel species from the supported complex. All these findings strongly supported an active and genuine heterogeneous nature of catalysis.

Comparison

In the last part of our studies, to demonstrate the profit of [Hercynite@SiO2-l-Arginine-Ni] as a heterogeneous catalyst in Hantzsch Synthesis of Polyhydroquinolines and click synthesis of 2,3-dihydroquinazolin-4(1H)-ones, our resultant and reaction conditions were compared with those of the reported acid, base, and metal catalysts in these reactions (Table 4). As depicted in Table 4, the [Hercynite@SiO2-l-Arginine-Ni] is the most efficient catalyst for these reactions. Significantly, most of the reported methods toil from the absence of commonness for the condensation reactions of the deactivated aldehydes. In addition, the reported synthetic paths have some limitations, such as requiring extreme temperature or long duration, large amounts of the catalyst, and most importantly, the use of hazardous solvents to give excellent yields. Promising results obtained in the presence of [Hercynite@SiO2-l-Arginine-Ni] should be ascribed to the nanoporous structure of the catalyst.

Conclusion

In summary, a facile and green method for the synthesis of a novel nanomagnetic nickel complex heterogenized on Hercynite@SiO2 core shell was successfully designed. [Hercynite@SiO2-l-Arginine-Ni] nanocatalyst was found to be efficient for a one-pot Hantzsch synthesis of polyhydroquinolines and click synthesis of 2,3-dihydroquinazolin-4(1H)-ones under solvent-free conditions with superior characteristics such as activity, selectivity, durability, and reusability, which are important factors for sustainable industrial applications. A broad range of aromatic aldehydes were converted to the corresponding products in excellent yields with high purities and in shorter reaction time under mild reaction conditions. [Hercynite@SiO2-l-Arginine-Ni] nanocatalyst showed high stability and reusability over five reaction runs under mild aerobic conditions. Overall, the whole process can be considered as an ideal tool because a highly efficient, selective, and green approach was developed along with an easy catalyst recovery, low catalyst loading, atom economy, and green reagents. Moreover, the synthesis of both the nanocatalyst and the desired organic products was achieved in green conditions, and additionally, the catalyst was recovered and reused several times.

Data availability

The data that support the findings of this study are available in the supporting information of this article.

References

S. Rezayati, F. Kalantari, A. Ramazani, S. Sajjadifar, H. Aghahosseini, A. Rezaei, Inorg. Chem. 61, 992 (2022)

M. Koolivand, M. Nikoorazm, A. Ghorbani‐Choghamaran, M. Mohammadi, Appl. Organomet. Chem. e6656 (2022) (in press)

Z. Zareai, M. Khoobi, A. Ramazani, A. Foroumadi, A. Souldozi, K. Ślepokura, T. Lis, A. Shafiee, Tetrahedron 68, 6721 (2012)

A. Rezaei, O. Akhavan, E. Hashemi, M. Shamsara, Chem. Mater. 28, 3004 (2016)

A. Rezaei, O. Akhavan, E. Hashemi, M. Shamsara, Biomacromol 17, 2963 (2016)

S. Rezayati, A. Ramazani, S. Sajjadifar, H. Aghahosseini, A. Rezaei, ACS Omega 6, 25608 (2021)

F. Kalantari, A. Ramazani, M.R. Poor Heravi, H. Aghahosseini, K. Ślepokura, Inorg. Chem. 60, 15010 (2021)

H. Aghahosseini, A. Ramazani, N.S. Jalayer, Z. Ranjdoost, A. Souldozi, K. Ślepokura, T. Lis, Org. Lett. 21, 22 (2019)

F. Ghobakhloo, D. Azarifar, M. Mohammadi, H. Keypour, H. Zeynali, Inorg. Chem. (2022) (in press)

H. Farhid, V. Khodkari, M.T. Nazeri, S. Javanbakht, A. Shaabani, Org. Biomol. Chem. 19, 3318 (2021)

Z. Esam, M. Akhavan, A. Bekhradnia, M. Mohammadi, S. Tourani, Catal. Lett. 150, 3112 (2020)

C.G. Neochoritis, T. Zarganes-Tzitzikas, K. Katsampoxaki-Hodgetts, A. Dömling, J. Chem. Educ. 97, 3739 (2020)

A. Heusler, J. Fliege, T. Wagener, F. Glorius, Angew. Chemie Int. Ed. 60, 13793 (2021)

M. Sam, M.G. Dekamin, Z. Alirezvani, Sci. Rep. 11, 2399 (2021)

O. Quinonero, C. Lemaitre, M. Jean, N. Vanthuyne, C. Roussel, D. Bonne, T. Constantieux, C. Bressy, X. Bugaut, J. Rodriguez, Org. Lett. 23, 3394 (2021)

N. Hussain-Khil, A. Ghorbani-Choghamarani, M. Mohammadi, Sci. Rep. 11, 15657 (2021)

M. Kazemi, M. Mohammadi, Appl. Organomet. Chem. 34, e5400 (2020)

S.M. Ramish, A. Ghorbani-Choghamarani, M. Mohammadi, Sci. Rep. 12, 1479 (2022)

M. Mohammadi, A. Ghorbani-Choghamarani, RSC Adv. 12, 2770 (2022)

M. Badolato, F. Aiello, N. Neamati, RSC Adv. 8, 20894 (2018)

A. Ghorbani-Choghamarani, H. Aghavandi, M. Mohammadi, J. Porous Mater. 28, 1167 (2021)

M.A. Zolfigol, H. Ghaderi, S. Baghery, L. Mohammadi, J. Iran. Chem. Soc. 14, 121 (2017)

A. Ghorbani-Choghamarani, M. Mohammadi, T. Tamoradi, M. Ghadermazi, Polyhedron 158, 25 (2019)

A. Ghorbani-Choghamarani, H. Aghavandi, M. Mohammadi, J. Porous Mater. 28, 1167 (2021)

M. Subaramanian, G. Sivakumar, E. Balaraman, Org. Biomol. Chem. 19, 4213 (2021)

P.P. Nair, R.M. Philip, G. Anilkumar, Org. Biomol. Chem. 19, 4228 (2021)

H. Mu, G. Zhou, X. Hu, Z. Jian, Coord. Chem. Rev. 435, 213802 (2021)

T. Tamoradi, S.M. Mousavi, M. Mohammadi, New J. Chem. 44, 8289 (2020)

A. Ghatak, M. Das, ChemistrySelect 6, 3656 (2021)

N. Gao, J. Salisu, C. Quan, P. Williams, Renew. Sustain. Energy Rev. 145, 111023 (2021)

L.-R. Wen, N.-N. Wang, W.-B. Du, Q. Ma, L.-B. Zhang, M. Li, Org. Biomol. Chem. 19, 2895 (2021)

M. Mohammadi, M. Khodamorady, B. Tahmasbi, K. Bahrami, A. Ghorbani-Choghamarani, J. Ind. Eng. Chem. 97, 1 (2021)

A. Ghorbani-Choghamarani, Z. Taherinia, M. Mohammadi, Environ. Technol. Innov. 24, 102050 (2021)

M. Mohammadi, A. Ghorbani-Choghamarani, New J. Chem. 44, 2919 (2020)

A. Ghorbani-Choghamarani, M. Mohammadi, L. Shiri, Z. Taherinia, Res. Chem. Intermed. 45, 5705 (2019)

V. Umamaheswari, J. Catal. 210, 367 (2002)

F. Hajizadeh, A. Amiri, B. Maleki, F. MohammadiZonoz, Microchem. J. 175, 107176 (2022)

A. Ghorbani-Choghamarani, H. Aghavandi, M. Mohammadi, Appl. Organomet. Chem. 34, e5804 (2020)

M.A. Ghasemzadeh, B. Mirhosseini-Eshkevari, M.H. Abdollahi-Basir, BMC Chem. 13, 119 (2019)

A. Ghorbani-Choghamarani, G. Azadi, Appl. Organomet. Chem. 30, 247 (2016)

E.J. Verwey, P.W. Haayman, F.C. Romeijn, J. Chem. Phys. 15, 181 (1947)

N. Kurnaz Yetim, F. Kurşun Baysak, M.M. Koç, D. Nartop, J. Mater. Sci. Mater. Electron. 31, 18278 (2020)

H.S. Yaddanapudi, K. Tian, S. Teng, A. Tiwari, Sci. Rep. 6, 33659 (2016)

F. Laves, H. Wallbaum, Zeitschrift Für Angew. Mineral. 4, 17 (1941)

J. Rakhtshah, S. Salehzadeh, M.A. Zolfigol, S. Baghery, J. Coord. Chem. 70, 340 (2017)

S. Askari, M.M. Khodaei, M. Jafarzadeh, Catal. Letters (2021) (in press)

S.-J. Ji, Z.-Q. Jiang, J. Lu, T.-P. Loh, Synlett 2004, 0831 (2004)

K.H. Narasimhamurthy, S. Chandrappa, K.S. Sharath Kumar, K.B. Harsha, H. Ananda, K.S. Rangappa, RSC Adv. 4, 34479 (2014)

B. Mitra, G. Chandra Pariyar, P. Ghosh, RSC Adv. 11, 1271 (2021)

M. Desroses, M. Scobie, T. Helleday, New J. Chem. 37, 3595 (2013)

T. Tamoradi, M. Ghadermazi, A. Ghorbani-Choghamarani, Appl. Organomet. Chem. 32, e3974 (2018)

H. Alinezhad, M. Tarahomi, B. Maleki, A. Amiri, Appl. Organomet. Chem. 33, 428 (2019)

N. Taheri, F. Heidarizadeh, A. Kiasat, J. Magn. Magn. Mater. 428, 481 (2017)

E. Pourian, S. Javanshir, Z. Dolatkhah, S. Molaei, A. Maleki, ACS Omega 3, 5012 (2018)

T. dos Santos, C. Grundke, T. Lucas, L. Großmann, G.C. Clososki, T. Opatz, European. J. Org. Chem. 2020, 6429 (2020)

T. Tamoradi, S.M. Mousavi, M. Mohammadi, New J. Chem. 44, 3012 (2020)

S.B. Bharate, N. Mupparapu, S. Manda, J.B. Bharate, R. Mudududdla, R.R. Yadav, R.A. Vishwakarma, ARKIVOC 2012, 308 (2012)

S. Zhaleh, N. Hazeri, M.T. Maghsoodlou, Res. Chem. Intermed. 42, 6381 (2016)

Acknowledgements

This work was supported by the research facilities of Ilam University, Ilam, Iran, and Bu-Ali Sina University, Hamedan, Iran.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mohammadi, M., Ghorbani-Choghamarani, A. Complexation of guanidino containing l-arginine with nickel on silica-modified Hercynite MNPs: a novel catalyst for the Hantzsch synthesis of polyhydroquinolines and 2,3-Dihydroquinazolin-4(1H)-ones. Res Chem Intermed 48, 2641–2663 (2022). https://doi.org/10.1007/s11164-022-04706-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-022-04706-9