Abstract

A novel copper (II) catalyst supported on polyethylenimine-functionalized magnetic graphene oxide (denoted Cu@PEI-MGO) has been developed and applied for the cyclization of benzylacetamide with 2-aminobenzamide to afford 2-arylquinazolin-4(3H)-ones in acetonitrile as an inexpensive, non-toxic and reusable solvent medium. Cu@PEI-MGO was characterized by transmission electron microscopy, scanning electron microscopy, thermo-gravimetric analysis, and Fourier-transform infra-red spectroscopy.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Copper is an important catalyst due to its high activity and selectivity in modern organic synthesis [1,2,3]. Facile separation and recovery of catalysts is a significant issue, while immobilization on nanoparticles is a favorable approach. Among different nanoparticles which are used as supports, magnetic graphene oxide (MGO) has attracted interest because of its high surface area, stability, easy separability and unique potential technical applications [4,5,6]. Poly(ethyleneimine) (PEI) is a nitrogen-rich and water-compatible polymer with unique properties including physical and chemical stabilities, good water solubility, and high content of functional groups. Due to these advantages, it has attracted interest for the functionalization of nanoparticles [7,8,9].

Quinazoline-4(3H)-one core is an important biologically active nitrogen-containing heterocyclic scaffold because of its extensive biological and pharmacological activities. Anticancer [10], antimicrobial [11], anti-inflammatory [12], anticonvulsant [13], anti-ulcer [14], antibacterial [15], and antivirus [16] properties have been reported for these heterocyclic compounds. Additionally, the quinazoline-4(3H)-one subunit has been widely applied in medicinal chemistry. Methaqualone, luotonin, piriqualone and bouchardatine are a few illustrative examples of potentially pharmacologically active quinazolineones (Fig. 1) [17].

Regarding the remarkable biological activities of quinazolines, it is not surprising that various procedures for their preparation have been reported in the literature. The typical approaches generally include condensation of 2-aminobenzamide with aldehydes, alkyl halides, primary amines or alcohols, reductive cyclization of 2-nitrobenzamide with aldehydes or primary alcohols, reaction of isatoic anhydride with amidoximes, or ammonium salts and aldehydes, and so on [18]. Also, the synthesis of quinazolines under oxidation conditions by reaction of 2-halo or 2-aminobenzamides with benzylic substrates, such as benzyl halides or benzyl amines under copper-promoted aerobic oxidation, or by use of H2O2 as an oxidant, has recently been explored [19]. Thus, we wish to develop these procedures for the synthesis of quinazolin-4(3H)-ones using sequential oxidative cyclization of primary benzyl amines with 2-aminobenzamide in acetonitrile as an appropriate and convenient reaction medium.

We have previously reported several efforts for the development of efficient and eco-friendly methodologies for the preparation of biologically active target molecules [20,21,22], and also on extending methodologies based on transition metal-catalyzed reactions [23,24,25,26,27,28]. In continuation of our previous efforts, we here introduce a novel copper (II) catalyst supported on polyethylenimine-functionalized magnetic graphene oxide, Cu@PEI-MGO. The catalyst has been used for the synthesis of 2-arylquinazolin-4(3H)-ones 3a–j by reaction of 2-aminobenzamide 1 with benzylacetamide 2a–j in acetonitrile as a green solvent in reflux conditions with N-hydroxyphthalimide (NHPI) and O2 as oxidant (Scheme 1).

Experimental

All chemicals were purchased from Merck and Fluka. All yields refer to isolated products. Melting points were determined in a capillary tube and are not corrected. The progress of the reactions was followed by TLC using silica gel SILG/UV 254 and 365 plates. 1H and 13C NMR spectra were recorded on a Brucker (Rheinstetten, Germany) NMR spectrometer at 500 and 125 MHz using tetramethylsilane (TMS) as the internal standard. IR spectra of the compounds were obtained on a FT-IR Magna 550 spectrographs (KBr disks) (Nicolet, Madison, WI, USA). All products are known compounds and were characterized by comparing the IR, 1H and 13C NMR spectroscopic data and their melting points with the literature values. A TGA diagram was recorded via TGA Q500 V20.13 Build 39. SEM images were recorded by a HITACHI S-4160 instrument. A CM30 300 kV instrument was used to record TEM images.

Preparation of magnetic graphene oxide

According to our previous report, the GO was manufactured from graphite using a modified Hummer’s method [27]: briefly, 1 g of graphite powder was added to a continuously stirred solution of 50 mL H2SO4 98% in an ice bath, then 2 g KMnO4 was gently added to it. It should be noted that the rate of addition was carefully controlled to avoid a sudden increase in the mixture temperature. The reaction mixture stirred for 2 h at temperatures below 10 °C, followed by another 1 h at 35 °C. Then, the reaction mixture was diluted with 50 mL of deionized water in an ice bath and the temperature was kept below 100 °C. After 1 h of stirring, the mixture was further diluted to 150 mL with deionized water. Then, 10 mL of H2O2 30% was added to the mixture which changed its color to brilliant yellow. The resulting solid was separated by centrifuging and washed thoroughly with 5% HCl aq. solution and deionized water to neutralize it. Finally, the resultant product was dried at 60 °C for 24 h.

For the preparation of the magnetic graphene oxide (MGO), MGO nanosheets were synthesized by co-precipitation of Fe3+ and Fe2+ in the presence of GO [27]. The solution of Fe3+ and Fe2+ was prepared in a 2:1 mol ratio. Next, 50 mg of GO was dispersed in 40 mL of water by sonication for 45 min. Then, a 50-mL solution of FeCl3 (1 g) and FeCl2 (375 mg) in deionized water was added to the latter solution. The reaction temperature was raised to 85 °C and ammonia solution 30% was added to it, increasing the pH to 10. After 45 min of vigorous stirring, the solution was cooled to room temperature, and the obtained black precipitate was centrifuged at 6000 rpm for 10 min, washed thoroughly with deionized water and dried at 60 °C for 24 h.

Preparation of polyethylenimine-functionalized magnetic graphene oxide (PEI-MGO)

To produce the polyethylenimine-functionalized magnetic graphene oxide (PEI-MGO) nanosheets, the necessary carboxylic acid functional groups were introduced by taking 50 mg of MGO in deionized water (4 mg mL−1) and sonicating it for 1 h, and then 50 mL NaOH 1 M was added to it and sonicated for 3 h. Afterwards, HCl was added to neutralize it and the solution was filtered and then rinsed. Then, 50 mg of the modified MGO was homogenized in 70 mL of deionized water by ultrasonication for 10 min. Next, 10 mg of 1-ethyl-3-(3-dimethylaminopropyl)carbodiimide and 8 mg of N-hydroxysuccinnimide were added to the latter solution. This mixture was stirred for 1 h and homogenized by ultrasonication for another 30 min. Then, 2.5 mmol of PEI (MW = 1200) was added into the suspension and sonicated for 30 min. Finally, the reaction was carried out at 90 °C for 1 h under stirring. The obtained PEI-MGO was purified by magnetic separation and washed with deionized water until neutral, and dried under vacuum at 60 °C for 24 h to achieve PEI-MGO nanosheets.

Preparation of copper supported on polyethylenimine functionalized magnetic graphene oxide (Cu@PEI-MGO)

To a mixture of PEI-MGO (50 mg) in DMF (10 mL) was added 0.4 mmol of CuCl2·2H2O. The mixture was stirred at room temperature for 10 h. The reaction mixture was filtered and the solid material was washed sequentially with 25 mL of acetone and then dried in a vacuum oven at 40 °C. Finally, the Cu@PEI-MGO catalyst was obtained as a dark solid.

General procedure for synthesis of products 3a–j

A mixture of 2-aminobenzamide (1.0 mmol), benzylacetamide (1.0 mmol), Cu@PEI-MGO (5.0 mg) and NHPI (2.0 mmol) was stirred in acetonitrile (5 mL) in reflux conditions for 4 h under an oxygen atmosphere. After completion of the reaction (monitored by TLC), the reaction mixture was cooled, the catalyst was separated with an external magnet and the product was extracted with ether. The ether layer was decanted, dried, and concentrated under reduced pressure, and the semisolid residue was purified by column chromatography on silica gel (eluent: hexane–EtOAc) affording 3a–j.

Spectral data

2-Phenylquinazolin-4(3H)-one ( 3a )

1H NMR (DMSO-d6, 500 MHz): δ 7.51–7.61 (4H, m), 7.75 (1H, d, J = 8.0 Hz), 7.84 (1H, t, J = 8.0 Hz), 8.16 (1H, d, J = 8.0 Hz), 8.20 (2H, d, J = 7.0 Hz), 12.50 (1H, s, NH). 13C NMR (DMSO-d6, 125 MHz): δ 120.9, 125.7, 126.4, 127.4, 127.6, 128.4, 131.2, 132.6, 134.4, 148.6, 152.1, 162.1; IR (KBr) (νmax/cm−1): 3314 (NH), 1662 (C=O).

2-(4-Methylphenyl)quinazolin-4(3H)-one ( 3b )

1H NMR (DMSO-d6, 500 MHz): δ 2.39 (3H, s, CH3), 7.35 (2H, d, J = 8.5 Hz), 7.50 (1H, t, J = 8.0 Hz), 7.72 (1H, d, J = 8.0 Hz), 7.82 (1H, t, J = 8.0 Hz), 8.10 (2H, d, J = 8.5 Hz), 8.14 (1H, d, J = 8.0 Hz), 12.39 (1H, s, NH). 13C NMR (DMSO-d6, 125 MHz): δ 20.8, 120.8, 125.7, 126.2, 127.2, 127.5, 129.0, 129.8, 134.3, 141.3, 148.8, 152.1, 162.1; IR (KBr) (νmax/cm−1): 3319 (NH), 1658 (C=O).

2-(2-Methoxyphenyl)quinazolin-4(3H)-one ( 3c )

1H NMR (DMSO-d6, 500 MHz): δ 3.88 (3H, s, OCH3), 7.08 (1H, t, J = 7.0 Hz), 7.19 (1H, d, J = 8.5 Hz), 7.50–7.55 (2H, m), 7.70 (1H, d, J = 8.0 Hz), 7.49 (1H, d, J = 7.5 Hz), 7.82 (1H, t, J = 7.5 Hz), 8.16 (1H, d, J = 7.5 Hz), 12.00 (1H, s, NH). 13C NMR (DMSO-d6, 125 MHz): δ 55.7, 111.8, 120.3, 120.9, 122.4, 125.6, 126.3, 127.2, 130.3, 132.1, 134.2, 148.9, 152.1, 157.1, 161.0; IR (KBr) (νmax/cm−1): 3323 (NH), 1662 (C=O).

2-(4-Methoxyphenyl)quinazolin-4(3H)-one ( 3d )

1H NMR (DMSO-d6, 500 MHz): δ 3.85 (3H, s, CH3), 7.08 (2H, d, J = 8.5 Hz), 7.48 (1H, t, J = 7.5 Hz), 7.70 (1H, d, J = 7.5 Hz), 7.80 (1H, t, J = 7.5 Hz), 8.14 (1H, d, J = 7.5 Hz), 8.20 (2H, d, J = 8.5 Hz), 12.33 (1H, s, NH). 13C NMR (DMSO-d6, 125 MHz): δ 55.3, 113.8, 120.6, 124.7, 125.7, 125.9, 127.1, 129.3, 134.3, 148.8, 151.7, 161.7, 162.2; IR (KBr) (νmax/cm−1): 3312 (NH), 1668 (C=O).

2-(Thiophen-2-yl)quinazolin-4(3H)-one ( 3e )

1H NMR (DMSO-d6, 500 MHz): δ 7.24 (1H, t, J = 6.0 Hz), 7.49 (1H, t, J = 8.0 Hz), 7.66 (1H, d, J = 8.0 Hz), 7.80 (1H, t, J = 8.0 Hz), 7.86 (1H, d, J = 6.0 Hz), 8.13 (1H, d, J = 8.0 Hz), 8.23 (1H, d, J = 6.0 Hz), 12.62 (1H, s, NH). 13C NMR (DMSO-d6, 125 MHz): δ 120.8, 125, 126.1, 126.8, 128.3, 129.2, 131.9, 134.5, 137.2, 147.7, 148.5, 161.6; IR (KBr) (νmax/cm−1): 3316 (NH), 1664 (C=O).

2-(4-Fluoropheny)quinazolin-4(3H)-one ( 3f )

1H NMR (DMSO-d6, 500 MHz): δ 7.38 (2H, t, J = 9.0 Hz), 7.52 (1H, t, J = 7.5 Hz), 7.73 (1H, d, J = 7.5 Hz), 7.83 (1H, t, J = 7.5 Hz), 8.15 (1H, d, J = 7.5 Hz), 8.26 (2H, dd, J = 9.0, 5.5 Hz), 12.53 (1H, s, NH); 13C NMR (DMSO-d6, 125 MHz): δ 115.4 (d, 2JC–F = 22.6 Hz), 120.7, 125.7, 126.4, 127.2, 129.1, 130.2 (d, 3JC–F = 8.8 Hz), 134.4, 148.4, 151.3, 162.5 (d, 1JC–F = 104.3 Hz), 164.9; IR (KBr) (νmax/cm−1): 3315 (NH), 1664 (C=O).

2-(2-Chlorophenyl)quinazolin-4(3H)-one ( 3g )

1H NMR (DMSO-d6, 500 MHz): δ 7.50 (1H, t, J = 8.0 Hz), 7.75–7.62 (3H, m,), 7.67 (1H, d, J = 7.5 Hz), 7.71 (1H, d, J = 8.0 Hz), 7.85 (1H, t, J = 8.0 Hz), 8.19 (1H, d, J = 8.0 Hz), 12.58 (1H, s, NH); 13C NMR (DMSO-d6, 125 MHz): δ 121.1, 122.8, 125.7, 126.9, 127.0, 127.3, 129.4, 130.7, 131.4, 133.7, 134.4, 148.5, 152.1, 161.2; IR (KBr) (νmax/cm−1): 3316 (NH), 1657 (C=O).

2-(4-Chlorophenyl)quinazolin-4(3H)-one ( 3h )

1HNMR (DMSO-d6, 500 MHz): δ 7.51 (1H, t, J = 8.0 Hz), 7.60 (2H, d, J = 8.0 Hz), 7.75 (1H, d, J = 8.0 Hz), 7.80 (1H, t, J = 8.0 Hz), 8.16–8.20 (3H, m), 12.63 (1H, s, NH); 13C NMR (DMSO-d6, 125 MHz): δ 121.9, 125.2, 126.8, 127.3, 128.5, 129.6, 131.8, 134.6, 136.1, 148.4, 150.3, 163.2; IR (KBr) (νmax/cm−1): 3316 (NH), 1664 (C=O).

2-(3-Nitrophenyl)quinazolin-4(3H)-one ( 3i )

1H NMR (DMSO-d6, 500 MHz): δ 7.57 (1H, t, J = 7.5 Hz), 7.79–7.86 (3H, m), 8.17 (1H, d, J = 7.0 Hz), 8.41 (1H, d, J = 7.0 Hz), 8.61 (1H, d, J = 7.0 Hz), 9.02 (1H, s), 12.82 (1H, s, NH); 13C NMR (DMSO-d6, 125 MHz): δ 121.2, 122.5, 125.6, 125.7, 126.9, 127.4, 130.1, 133.8, 134.3, 134.5, 147.9, 148.2, 152.2, 162.0; IR (KBr) (νmax/cm−1): 3318 (NH), 1659 (C=O).

2-(4-Nitrophenyl)quinazolin-4(3H)-one ( 3j )

1H NMR (DMSO-d6, 500 MHz): δ 7.50 (1H, t, J = 8.0 Hz), 7.75 (1H, d, J = 8.0 Hz), 7.86 (1H, t, J = 8.0 Hz), 8.16 (1H, d, J = 8.0 Hz), 8.35–8.44 (4H, m), 12.75 (1H, s, NH); 13C NMR (DMSO-d6, 125 MHz): δ 120.1, 124.6, 125.7, 128.3, 128.7, 129.2, 135.7, 137.5, 146.3, 146.9, 152.7, 160.2; IR (KBr) (νmax/cm−1): 3314 (NH), 1657 (C=O).

Results and discussion

For the preparation of the Cu@PEI-MGO catalyst, graphene oxide (GO) was first prepared by the oxidation of purified natural graphite. MGO was constructed by coprecipitation of Fe2+ and Fe3+ on the surface of the GO. The obtained MGO was then functionalized by PEI, which is a nitrogen-rich and water-compatible polymer, and therefore acts as a ligand for copper, and makes the catalyst water dispersible. Finally, copper was supported on PEI-MGO to form Cu@PEI-MGO as an efficient reusable catalyst. The preparation steps are shown in Scheme 2.

The Cu@PEI-MGO catalyst was characterized by different methods. To determine the Cu content of Cu@PEI-MGO, the inductively coupled plasma (ICP) technique was used which showed the copper content of the catalyst to be 0.35 mmol/g of the catalyst.

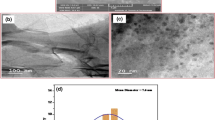

Transmission electron microscopy (TEM) and scanning electron microscopy (SEM) were applied for more characterization of the catalyst (Fig. 2a, b, respectively). In the TEM image, the presence of magnetic nanoparticles in the structure of Cu@PEI-MGO can clearly be observed. The magnetic iron oxide nanoparticles can be seen as dark spots with diameters of about 15 nm in the sheet-like GO structures. In the SEM image in Fig. 2b, the surface morphology of Cu@PEI-MGO can be observed.

For more detailed study, Fourier-transform infra-red spectroscopy (FT-IR) spectroscopy was applied. The FT-IR spectra of GO and Cu@PEI-MGO can be seen in Fig. 3a, b, respectively. The strong bands at 3428 and 1245 cm−1 in Fig. 3a can be correlated with the vibrations of the O–H bond. The peaks at 1719 and 1637 cm−1 can be attributed to the vibration of carbonyl bonds in the structure of GO. In Fig. 3b, in addition to the peaks assigned above, a peak at 576 cm−1 can be assigned to Fe–O–Fe vibrations. The peak at 3236 cm−1 can be correlated with N–H vibrations in the structure of the PEI.

As the final characterization step, the thermo-gravimetric analysis (TGA) of Cu@PEI-MGO was recorded (Fig. 4). According to the diagram, a sharp decrease from about 300 to 550 °C is attributed to the decomposition of the polyethylenimine of the catalyst. Fig. S1 shows the x-ray diffraction pattern of the Cu@PEI-MGO catalyst before and after use. The diffraction peaks confirm the desired structure of the catalyst.

The magnetic behavior of the catalyst was evaluated by a vibrating-sample magnetometer (VSM) analysis, and the result is shown in Fig. 5. The superparamagnetic behavior of Cu@PEI-MGO can clearly be observed in the VSM curve. The exact loading of the copper on PEI-MGO is a significant factor. Therefore, ICP was used for the determination of the copper content in the catalyst. The ICP results showed that the Cu content is ~ 0.078 mmol per each gram of Cu@PEI-MGO.

After characterization of Cu@PEI-MGO, the activity of the catalyst was evaluated in the synthesis of quinazolinones from the reaction of 2-aminobenzamide and benzylacetamides in the presence of N-hydroxyphthalimide as the oxidizing agent.

To achieve optimized reaction conditions, the effect of different variables was investigated for the synthesis of 2-phenylquinazolin-4(3H)-one 3a as the model system. The effect of various oxidants and solvents was then investigated (Table 1), which shows that the best yields of the product was obtained with N-hydroxyphthalimide (2.0 mmol) as the oxidant and acetonitrile as the reaction medium in reflux conditions for 4 h (Entry 2). We note that performing the reaction in the presence of different amounts of Cu@PEI-MGO proved that the product is obtained in the highest yield when 5 mol% of the catalyst is used. No increase in the yield was observed with higher catalyst amounts, while in the absence of Cu@PEI-MGO, no product is formed. This observation proves that the presence of Cu@PEI-MGO is necessary for the reaction.

To investigate the scope of this reaction, the reaction between 2-aminobenzamide 1 and various benzylacetamide derivatives 2a–j, carrying both electron-donating and electron-withdrawing substituents, were explored under the optimized conditions to afford the 2-arylquinazolin-4(3H)-ones 3a–j in 62–84% yields (Fig. 6).

A great advantage of Cu@PEI-MGO is its reusability. In order to test the recycling ability of this catalyst, it was easily separated by an external magnet, washed with water and ethanol, and used again for the next reaction. The catalyst is recyclable for 10 consecutive reactions as can be seen in Fig. 7. The reusability results showed no decrease in catalytic activity. For the recycling study, the catalyst was isolated via an external magnet after each cycle and washed with ethanol (3 × 15 mL). Then, the isolated Cu@PEI-MGO was dried, and reused for a subsequent round of the reaction.

A suggested mechanism can be seen in Scheme 3. In the first step, benzylacetamide (2) oxidizes to compound (4) in the presence of quinazolin-4(3H)-ones (PINO). Compound (4) will form the peroxide compound (6) in two steps, which convert to (7) in the presence of Cu@PEI-MGO. Compound (7), finally converts to (9), which reacts with 2-aminobenzaimde (1) and produces compound (10). The desired compound (3) will be prepared from (10) in the presence of Cu@PEI-MGO and PINO.

Conclusion

In summary, a novel copper catalyst supported on modified MGO is introduced. The MGO is functionalized by PEI. The advantage of PEI is the high nitrogen content in its structure which can be efficiently applied as the ligand for the catalyst. The hydrophilic nature of PEI makes the catalyst highly water dispersible and therefore it easily performs the reaction in acetonitrile. The reaction between benzylacetamides and 2-aminobenzamide in the presence of Cu@PEI-MGO and NHPI in acetonitrile provides an efficient approach to the synthesis of 2-aryl quinazolin-4(3H)-ones of potential synthetic and pharmacological interest. The simplicity of the starting materials, the reusability of the catalyst, good yields of the products, and the use of acetonitrile as a cheap and green solvent are the main advantages of this method.

References

D. Vargas-Hernandez, J.M. Rubio-Caballero, J. Santamaría-González, R. Moreno-Tost, J.M. Merida-Robles, M.A. Perez-Cruz, A. Jimenez-Lopez, R. Hernandez-Huesca, P. Maireles-Torres, J. Mol. Catal. A: Chem. 383, 106 (2014)

X. Meng, J. Zhang, B. Chen, Z. Jing, P. Zhao, Catal. Sci. Technol. 6, 890 (2016)

L. Chen, B.E. Lemma, J.S. Rich, J. Mack, Green Chem. 16, 1101 (2014)

J. Hu, Y.L. Dong, X.J. Chen, H.J. Zhang, J.M. Zheng, Q. Wang, X.G. Chen, J. Chem. Eng. 236, 1 (2014)

Y. Yao, Y. Cai, F. Lu, F. Wei, X. Wang, S. Wang, J. Hazard. Mater. 270, 61 (2014)

M. Nasrollahzadeh, M. Maham, A. Rostami-Vartooni, M. Bagherzadeh, S.M. Sajadi, RSC Adv. 5, 64769 (2015)

F. Li, S.F. Zhao, L. Chen, A. Khan, D.R. MacFarlane, J. Zhang, Energy Environ. Sci. 9, 216 (2016)

X. Wen, X. Qiao, X. Han, L. Niu, L. Huo, G. Bai, J. Mater. Sci. 51, 3170 (2016)

T.V. Thu, P.J. Ko, T.V. Nguyen, N.T. Vinh, D.M. Khai, L.T. Lu, Appl. Organomet. Chem. 31, 3781 (2017)

Y. Zhang, Y.J. Huang, H.M. Xiang, P.Y. Wang, D.Y. Hu, W. Xue, B.A. Song, S. Yang, Eur. J. Med. Chem. 78, 23 (2014)

R. Arora, N.S. Gill, A. Kapoor, J. Pharm. Allied Health Sci. 4, 15 (2014)

A.M. Alaa, L.A. Abou-Zeid, K.E.H. ElTahir, M.A. Mohamed, M.A.A. El-Enin, A.S. El-Azab, Bioorg. Med. Chem. 24, 3818 (2016)

N.A. Noureldin, H. Kothayer, E.S.M. Lashine, M.M. Baraka, W. ElEraky, S.A.E. Awdan, Arch. Pharm. 350, 1600332 (2017). https://doi.org/10.1002/ardp.201600332

X.X. Qi, Z.Z. Song, J.L. Gong, Z.Y. Fang, X.F. Wu, Chin. Chem. Lett. 27, 21 (2016)

S.S. Kazemi, A. Keivanloo, H. Nasr-Isfahani, A. Bamoniri, RSC Adv. 6, 92663 (2016)

S. Liu, W. Wang, L. Jiang, S. Wan, L. Zhang, R. Yu, T. Jiang, Chem. Biol. Drug Des. 86, 1221 (2015)

K. Tereshima, H. Shimamura, A. Kawase, Y. Tanaka, T. Tanimura, T. Kamisaki, Y. Ishizuka, M. Sato, Chem. Pharm. Bull. 43, 2021 (1995)

R. Mekala, R. Akula, R.R. Kamaraju, C.K. Bannoth, S. Regati, J. Sarva, Synlett 25, 821 (2014)

L. He, H. Li, J. Chen, X.F. Wu, RSC Adv. 4, 12065 (2014)

A. Yahya-Meymandi, H. Nikookar, S. Moghimi, M. Mahdavi, L. Firoozpour, A. Asadipour, P.R. Ranjbar, A. Foroumadi, J. Iran. Chem. Soc. 14, 771 (2017)

M. Eghtedari, Y. Sarrafi, H. Nadri, M. Mahdavi, A. Moradi, F.H. Moghadam, S. Emami, L. Firoozpour, A. Asadipour, O. Sabzevari, A. Foroumadi, Eur. J. Med. Chem. 128, 237 (2017)

F. Farjadmand, H. Arshadi, S. Moghimi, H. Nadri, A. Moradi, M. Eghtedari, F. Jafarpour, M. Mahdavi, A. Shafiee, A. Foroumadi, J. Chem. Res. 40, 188 (2016)

S.E. Sadat-Ebrahimi, S.S. Irannezhad, A. Moghimi, M. Yahya-Meymandi, A.Shafiee Mahdavi, A. Foroumadi, J. Chem. Res. 39, 495 (2015)

M. Saeedi, F. Goli, M. Mahdavi, P. Sarihi, A. Asadipour, A. Shafiee, A. Foroumadi, J. Chem. Res. 38, 131 (2014)

M. Mahdavi, V. Lotfi, M. Saeedi, E. Kianmehr, A. Shafiee, Mol. Divers. 20, 677 (2016)

M. Mahdavi, H. Lijan, S. Bahadorikhalili, L. Ma’mani, P.R. Ranjbar, A. Shafiee, RSC Adv. 6, 28838 (2016)

S. Bahadorikhalili, L. Ma’mani, H. Mahdavi, A. Shafiee, RSC Adv. 5, 71297 (2015)

L. Ma’mani, S. Miri, M. Mahdavi, S. Bahadorikhalili, E. Lotfi, A. Foroumadi, A. Shafiee, RSC Adv. 4, 48613 (2014)

Acknowledgements

This study was supported by the research council of Tehran University of Medical Sciences (TUMS), and the Iran National Science Foundation (INSF).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sayahi, M.H., Bahadorikhalili, S., Saghanezhad, S.J. et al. Copper (II)-supported polyethylenimine-functionalized magnetic graphene oxide as a catalyst for the green synthesis of 2-arylquinazolin-4(3H)-ones. Res Chem Intermed 44, 5241–5253 (2018). https://doi.org/10.1007/s11164-018-3420-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-018-3420-2