Abstract

FeO x , MnO x and Fe–Mn–O x catalysts were prepared by the co-precipitation method and used for the selective catalytic reduction (SCR) of NO x by NH3 at low temperature. Fe–Mn–O x catalyst showed the best catalytic activity and above 80% NO x conversion was obtained at 50–150 °C. Nearly 80% N2 selectivity of Fe–Mn–O x catalyst was acquired at the whole temperature range. The excellent low-temperature SCR activity and N2 selectivity were ascribed to the abundant surface acid sites, the formation of Fe–O–Mn species, co-existence of multiple valence states (Mn4+, Mn3+ and Mn2+) and the proper redox ability. In addition, the interaction between Fe and Mn species over the Fe–Mn–O x catalyst was responsible for the improvement of SCR performance and N2 selectivity.

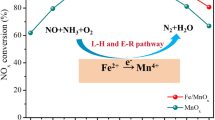

Graphical Abstract

Fe–Mn–O x catalysts were prepared by the co-precipitation method and used for the selective catalytic reduction (SCR) of NO x by NH3 at low temperature. The formation of Fe–O–Mn species contributed to the co-existence of multiple valence states (Mn4+, Mn3+, Mn2+, Fe3+ and Fe2+), resulting in an increase in catalytic activity and N2 selectivity. Besides, the abundance of acid sites was responsible for the superior N2 selectivity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nitrogen oxides (NO x ) are the main source of environmental pollution such as the greenhouse effect, acid deposition and photochemical smog, which is harmful to human health and environment [1,2,3]. The mature de-NO x technology is selective catalytic reduction of NO by NH3 (NH3-SCR), and V2O5–WO3 (or MO3)/TiO2 catalysts have been widely used and operated at 300–400 °C in power stations [4, 5]. However, there are still some drawbacks of traditional commercial catalysts, such as the poor low-temperature activity, the formation of N2O at high temperature and the narrow reaction temperature window (300–400 °C) [6, 7]. Moreover, the NH3-SCR catalyst bed is placed upstream of dedusting and desulfurization under the reheating the flue gas conditions, resulting in a decrease in the catalytic activity due to the high concentrations of dust and SO2 [8]. In addition, the temperature of the flue gas after dedusting and desulfurization is in the temperature range of 50–150 °C. Hence, the SCR device is located downstream of the dedusting and desulfurization units, leading to the inferior SCR performance of traditional SCR catalysts at low temperatures (below 150 °C). To solve the above problems, great efforts are made to develop the SCR catalysts with superior low-temperature catalytic performance below 150 °C to avoid gas preheating.

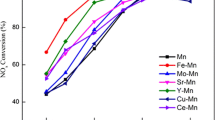

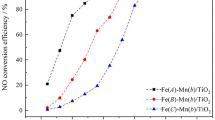

Mn-containing catalysts have been explored and regarded as highly active catalysts for low-temperature NH3-SCR Co-doping of the other components, phase composition of Mn-containing species, and valence states have been explored for these Mn-containing NH3-SCR catalysts [9,10,11,12,13]. Cr–MnO x mixed-oxide catalyst can exhibit excellent SCR activity in the range of 120–220 °C, and the co-existence of Mn4+–Mn3+ plays a crucial role in the improvement of catalytic activity [14]. Thirupathi et al. [15] proved that the high reducibility of MnO2 phase plays an important role in the superior SCR performance over the nickel-doped Mn/TiO2 catalyst. Kang et al. [16] reported that Cu–Mn mixed oxides are active at low temperature and the formation of Cu0.01Mn0.25O x contributes to the improvement of low-temperature catalytic activity. Qi et al. [17, 18] found that MnO x –CeO2 catalyst presents above 95% NO x conversion and excellent resistance to H2O + SO2 at 150 °C. Above all, the Mn-based catalysts with the excellent low-temperature catalytic activity can be assigned to the superior oxidation ability and various chemical valence states (Mn4+, Mn3+ and Mn2+). A proper molar ratio of Mn3+/Mn4+ plays a critical role for enhancing NH3-SCR performance over Mn-based catalysts. Besides, for Mn-based catalysts, the excellent oxidation of NH3–NO x (NO and NO2) can lead to poor N2 selectivity due to the excellent redox ability, which have restrained its further development in the field of low-temperature catalysis. Therefore, Mn-based catalysts should be improved through modification in order to adjust the N2 selectivity and low-temperature SCR activity.

Fe2O3 is widely employed due to the abundant surface acidity in the NH3-SCR reaction [19, 20]. It was reported [21] that the surface acidity can be significantly improved by the addition of Fe species and then contributed to the excellent N2 selectivity. Chen et al. [8] proved that the introduction of Fe species can improve the low-temperature catalytic activity and N2 selectivity. FeMnO x mixed-oxide catalysts showed potential catalytic performance at low temperature. Sb et al. [22] also demonstrated that the presence of Fe3Mn3O8 phase in FeMnO x catalyst contributes to the catalytic activity. Low-temperature SCR activity, resistance to H2O + SO2 and synergetic effect of Fe and Mn have been previously explored [23,24,25]. However, it deserves further explorations to investigate relationships among the N2 selectivity, surface acidity and redox properties.

In this work, the FeO x , Fe–Mn–O x and MnO x catalysts are prepared by co-precipitation method and used for selective catalytic reduction of NO with NH3. The influence of surface acidity and catalyst structure on the catalytic performance of the samples is studied. The catalysts structure, surface acidity, redox ability and SCR activity of the samples are characterized by XRD, Raman, N2 physisorption, XPS, H2-TPR and NH3-TPD.

Experimental

Catalyst synthesis

The FeO x , Fe–Mn–O x and MnO x catalysts were prepared by the co-precipitation method. As for the FeO x catalyst, the preparation process was as follows: Firstly, Fe(NO3)3·9H2O was dissolved in deionized water. Secondly, the ammonia solution (25 wt%) was gradually dripped with continuous stirring for 0.5 h at 25 °C until the pH value reached 10. Afterwards, the precipitates were maintained at 80 °C for 5 h under stirring conditions. Finally, the resulting sample was filtered, washed, and dried at 105 °C overnight, and then it was calcined at 550 °C for 5 h. The obtained solid powders were denoted as FeO x . The preparation process of Fe–Mn–O x (50 wt% FeO x and 50 wt% MnO x ) and MnO x catalysts was the same as that of FeO x catalyst.

Catalytic activity test

The experimental tests were operated in a fixed-bed quartz reactor (8 mm i.d.) with 0.4 mL catalysts. The concentrations of simulated gases were as follows: 5 vol% O2, 600 ppm NH3, 600 ppm NO and N2 as balance gas. The total gas flow rate remained 400 mL/min, corresponding to gas hourly space velocity (GHSV) of 60,000 h−1. The concentration of NO x (NO and NO2) was continuously detected by the ECOM·J2KN flue gas analyzer. The N2O concentration was measured by a gas chromatograph (Fuli, 9790).

Physicochemical characterization

Powder X-ray diffraction (XRD) patterns were carried out on an X-ray diffractometer (Rigaku, D/max-2200, Japan). The scanning range was at 10°–70° at a step of 6° min−1. Raman spectra were carried out on a Renishaw-2000 Raman spectrometer using the 532-nm line of an Ar ion laser as the excitation source. N2 adsorption–desorption experiments were operated using a Tristar II 3020 automated gas sorption system. The samples were outgassed at 400 °C for 3 h before N2 adsorption. The specific surface areas were calculated from the Brunauer–Emmett–Teller (BET) equation.

X-ray photoelectron spectroscopy (XPS) was performed on an ULVAC PHI 5000 Versa Probe-II equipment operating at 10−9 Pa with an Al Ka radiation (1486.6 eV) to investigate and characterize the chemical states and surface atomic concentration of the samples. The observed spectra were referenced to the C 1 s binding energy value of 284.8 eV.

The NH3 temperature-programmed desorption (NH3-TPD) and the H2 temperature-programmed reduction (H2-TPR) experiments were employed on a GC-9750 with 0.03 g of the catalyst. Before the NH3-TPD/H2-TPR experiments, the catalysts were pretreated at 400 °C for 60 min in pure N2 and cooled to the desired temperature. For the NH3-TPD, the catalyst was cooled to 50 °C in pure N2 followed by saturation for 40 min with a stream of NH3(4%)/N2. After saturation, the sample was flushed in a pure N2 flow for 50 min at 100 °C. After that, the NH3-TPD was operated in N2 at a heating rate of 10 °C min−1 from 50 to 500 °C. As for H2-TPR, The H2-TPR runs were implemented in a flow of 5 vol% H2/Ar (30 mL min−1) from 100 to 700 °C with a heating rate of 10 °C min−1. The NH3 desorption (or H2 uptake) was detected by a thermal conductivity detector (TCD).

Results and discussion

Catalytic performance of FeO x , Fe–Mn–O x and MnO x catalysts

The catalytic activity and N2 selectivity of FeO x , Fe–Mn–O x and MnO x catalysts are shown in Fig. 1. It was found that the pure FeO x had little activity in the temperature range of 50–150 °C. The MnO x catalyst showed excellent SCR activity and over 85% of NO x conversion at 125 °C. Fe–Mn–O x exhibited a noticeable better catalytic activity than FeO x and MnO x , and above 80% NO x conversion of Fe–Mn–O x was acquired at 50–150 °C.

Figure 1b shows the N2O concentration and N2 selectivity of FeO x , Fe–Mn–O x and MnO x catalysts. For FeO x catalyst, it was hard to quantify the N2 yield due to its poor catalytic activity. However, plenty of N2O formed over the MnO x catalyst. Furthermore, the amount of N2O increased with the increase of the reaction temperature and the maximum of N2O reached 220 ppm at 150 °C, which resulted in poor N2 selectivity and the N2 selectivity decreased sharply from 100 to 60%. As for Fe–Mn–O x , the N2 selectivity was significantly improved in comparison with that of MnO x and nearly 80% N2 selectivity was obtained at 150 °C. The phenomenon indicated that the introduction of Fe species into MnO x could increase the low-temperature catalytic activity and N2 selectivity.

XRD analysis

Figure 2 presents the XRD patterns of the FeO x , Fe–Mn–O x and MnO x catalysts. As shown in Fig. 2, the diffraction peaks of tetragonal Mn3O4 phase (PDF: 80-0382) and cubic Mn2O3 phase (PDF: 78-0390) were observed in the XRD patterns of MnO x catalyst. The diffraction peaks of hexagonal Fe2O3 phase (PDF: 89-0598) appeared for the FeO x catalyst. As for Fe–Mn–O x catalyst, the diffraction peaks of Mn3O4, Mn2O3 and Fe2O3 phase were not observed. The phenomenon indicated that Fe–Mn–O x possessed low crystallization or Fe and Mn species existed as amorphous forms over Fe–Mn–O x . Kharas et al. reported [26] that the low crystallization or amorphous forms of active species over NH3-SCR catalysts could contribute to the improvement of catalytic activity. This might be a reason that Fe–Mn–O x showed the best SCR performance among the samples.

Raman analysis

To further study the structure of FeO x , Fe–Mn–O x and MnO x catalysts, Raman spectra were operated and the results are shown in Fig. 3. The spectrum of FeO x exhibited the Raman peaks at 1317, 611, 410, 295, 245 and 226 cm−1, which could be assigned to Fe2O3 [8, 27, 28]. Furthermore, the peak at 503 cm−1 was observed, which was attributed to Fe3O4 [8, 27, 28]. For MnO x , the MnO2 (627, 540, 368 and 265 cm−1), Mn2O3 (315 cm−1) and Mn3O4 (657 and 485 cm−1) were detected [8, 27, 28]. Besides, the intensity peak of Mn3O4 was much stronger than that of other Mn species, which was in good accord with XRD results. As for Fe–Mn–O x catalyst, a broad weak peak centered at 650 cm−1 was observed, which proved the formation of Fe–O–Mn bands [8]. The phenomena implied that the addition of Fe species into MnO x could affect the microstructure.

N2 adsorption–desorption isotherms

Figure 4 shows the N2 adsorption–desorption isotherms (a) and the BJH pore size distribution curves (b) of the FeO x , Fe–Mn–O x and MnO x catalysts. According to IUPAC classification, it was obvious from the Fig. 4a that the samples presented type IV isotherms, which was assigned to the typically characteristic of mesopores (2–50 nm) [29]. Furthermore, the closure points of the hysteresis loops over MnO x and FeO x occurred when the value of P/P0 was 0.87 and 0.81, respectively, while the value was 0.50 over Fe–Mn–O x . The closure points of the hysteresis loops of Fe–Mn–O x dramatically shifted to lower P/P0 compared with that of MnO x and FeO x . The phenomenon suggested that more abundance of mesoporous was formed over Fe–Mn–O x , which contributed to pore structure and BET specific areas, resulting in the improvement of catalytic activity in the NH3-SCR reaction. Figure 4b shows the BJH pore size distributions of the FeO x , Fe–Mn–O x and MnO x catalysts. It was clear that the main pore sizes of the three samples were distributed in the size range of 2–50 nm, which was assigned to the mesopore. The intensity of the peak over Fe–Mn–O x was visibly higher than that of FeO x and MnO x , which implied that Fe–Mn–O x possessed the most amount of mesopores among the samples, which could contribute to the favored pore structures and offered more active sites for the SCR reactions, leading to the enhancement of SCR performance.

Table 1 exhibits the BJH desorption pore volume and the BET surface area of the FeO x , Fe–Mn–O x and MnO x catalysts. The total pore volume decreased: Fe–Mn–O x (0.278 cm3/g) > MnO x (0.250 cm3/g) > FeO x (0.166 cm3/g). Besides, the BET surface areas were 26, 28 and 89 m2/g over the FeO x , MnO x and Fe–Mn–O x , respectively. Combined with Fig. 4a, b results, it was inferred that the mesopores of FeO x and MnO x samples mainly presented in the inter-particle mesoporosity. In addition, the BET surface areas and total pore volume of Fe–Mn–O x dramatically were increased compared with those of MnO x and FeO x , which demonstrated that the addition of Fe species into MnO x over Fe–Mn–O x could improve the pore structure of the Fe–Mn–O x catalyst.

XPS analysis

The XPS spectra of Fe 2p for the FeO x , Fe–Mn–O x and MnO x catalysts are shown in Fig. 5a. It was observed that the two peaks were located at about 709 and 723 eV, which could be attributed to Fe 2p3/2 and Fe 2p1/2, respectively [30]. Compared to FeO x catalyst, the red shift in the binding energy was observed over Fe–Mn–O x . The phenomenon proved that the interaction between Fe and Mn species existed, and then formed the Fe–O–Mn bond, which was demonstrated by Raman results. Besides, the satellite peaks centered at around 718 and 723 eV were observed, which implied that the Fe species consisted of Fe3+ and Fe2+ [31, 32]. In order to investigate the effect of Fe3+ and Fe2+ species on the catalytic activity and N2 selectivity over Fe–Mn–O x , the peaks of Fe 2p were fitted into six peaks for FeO x and Fe–Mn–O x . The peak positions of Fe 2p for Fe3+ species were located at about 711.5 and 725.3 eV, and the peaks at about 709.3 and 723 eV were attributed to the Fe2+ species [31, 32]. The relative amount of Fe3+ and Fe2+ was measured, and the results were shown in Table 2, the surface concentration of Fe3+ was about 30.9 and 37.5% over FeO x and Fe–Mn–O x catalyst, respectively. These suggested that the introduction of Fe species into MnO x could improve the surface concentration of Fe3+. Delahay et al. reported [33] that the oxidation step of NO to NO2 was operated over Fe3+ sites in a NH3-SCR reaction, which could accelerate the so-called “fast reaction”, resulting in an improvement of catalytic activity, especially for the low-temperature SCR activity. Therefore, more amounts of Fe3+ could contribute to the formation of more NO2. Fe–Mn–O x catalyst with the highest Fe3+ (37.5%) surface concentration having the best catalytic performance at 50–150 °C, which was demonstrated by the results of NH3-SCR activity.

The characteristic peaks for Mn 2p XPS spectra over MnO x and Fe–Mn–O x are presented in Fig. 5b. By performing a peak fitting deconvolution, the Mn 2p3/2 spectra appeared as three peaks: 640.6–641.8 (Mn2+ species), 642.3–643.6 (Mn3+ species) and 645–646 (Mn4+ species) eV, respectively [34]. Kapteijn et al. [35] reported that Mn3+ species contributed to the improvement of N2 selectivity, while Mn4+ could increase the catalytic activity, especially for the low-temperature SCR activity. However, the surface concentration of Mn3+ and Mn4+ over Fe–Mn–O x decreased compared with that of MnO x , and MnO x possessed the inferior catalytic activity and poor N2 selectivity at 50–150 °C. Lu et al. [36] proved that the co-existence of multiple valence Mn species was favored by the oxidation reduction reaction, resulting in the enhancement of low-temperature catalytic activity. Besides, the binding energy of Mn species of Fe–Mn–O x shifted towards a lower value in comparison with that of MnO x . This demonstrated that the strong interaction between Mn and Fe species existed, which could lead to an increasing in the outer electron cloud density of Mn species, and shielding effect improved. The phenomenon could improve the electron transfer ability, and then promoted the redox property. Therefore, the N2 selectivity and catalytic performance of Fe–Mn–O x and MnO x should be further investigated.

Figure 5c presents the peak separation of the O 1s region for the FeO x , Fe–Mn–O x and MnO x catalysts. The peak at 530.1–531.7 eV was assigned to chemisorbed oxygen O α , and the lattice oxygen at 528.5–530.1 eV was denoted as O β ) [37, 38]. As shown in Fig. 4b, the ratio of O α /(O α + O β ) over MnO x and FeO x was 35.9 and 12.4%, respectively. Fe–Mn–O x possessed 22.8% O α /(O α + O β ). It was reported [39] that higher chemisorbed oxygen (O α ) was favored by the outstanding SCR performance. However, the SCR performance of MnO x was inferior compared with Fe–Mn–O x . It was also well known that the over-oxidation ability of SCR catalysts could cause the ammonia oxidation, and then reduce the catalytic activity. This might be the reason that MnO x with higher O α concentration showed the poor SCR performance. Furthermore, the O α and O β binding energy for Fe–Mn–O x was lower than that of the MnO x and FeO x , which suggested that the O α and O β of Fe–Mn–O x possessed the most electron cloud density, leading to the generation of more reactive electrophilic oxygen species, which could remarkably enhance the catalytic activity of Fe–Mn–O x [40].

H2-TPR analysis

The H2-TPR profiles of the FeO x , Fe–Mn–O x and MnO x catalysts are exhibited in Fig. 6. It was found that FeO x presented two reduction peaks at 394 and 622 °C, which was assigned to the reduction of Fe2O3–Fe3O4 (394 °C), Fe3O4–FeO (622 °C) [41,42,43], respectively. MnO x exhibited two stages of reduction at 303 and 440 °C, which was interpreted as the reduction of Mn2O3–Mn3O4 and then to MnO, respectively [44]. The TPR curve of Fe–Mn–O x showed the reduction peaks at 310, 460, and 560 °C. The reduction peak at 310 °C could correspond to the reduction of Mn2O3–Mn3O4. A broad peak centered at 460 °C could be attributed to the synergetic reduction of Fe2O3–Fe3O4 and Mn3O4–MnO. The phenomenon implied that the interaction between Fe and Mn species over Fe–Mn–O x existed. Besides, the reduction of Fe3O4–FeO over Fe–Mn–O x shifted towards lower temperature in comparison with that of FeO x . It was established that a shift in the peak position of the reduction temperature was closely related to many factors, such as a change in the amount of chemisorbed oxygen, structural defects and phase composition. The reduction temperature of Mn2O3–Mn3O4 over Fe–Mn–O x moved to a higher value compared with that of MnO x . Furthermore, the reduction temperature of Fe3O4–FeO over Fe–Mn–O x was lower than that of FeO x . These indicated that the redox property of Fe–Mn–O x was induced in comparison with that of MnO x but improved for FeO x . Thereby, MnO x showed the inferior catalytic activity due to the excellent redox ability, which could lead to the NH3 oxidation to NO x at high temperature. Combined with the Raman results, it was inferred that the presence of Mn–O–Fe species could increase the catalytic performance, which further confirmed that the interaction between Fe and Mn species occurred. Hence, the Fe–Mn–O x catalyst exhibited the superior catalytic activity at 50–150 °C.

NH3-TPD analysis

NH3-TPD analysis was done in order to explore the influence of surface acidity on the catalytic performance and N2 selectivity over FeO x , Fe–Mn–O x and MnO x catalysts. As shown in Fig. 7, MnO x showed one broad weak NH3-desorption peak at 50–500 °C, which suggested that the MnO x possessed the weak, medium and strong acid sites. For the FeO x catalyst, it showed the NH3-desorption peak at the temperature range of 100–500 °C, and the intensity of peak was higher than that of MnO x , which indicated that the surface acidity of FeO x catalyst was stronger than that of the MnO x . It was observed that the NH3-desorption peak of Fe–Mn–O x was much stronger than those of FeO x and MnO x . The phenomenon implied that Fe–Mn–O x exhibited the most amount of surface acid sites, which might depend on the formation of Fe–O–Mn species. It was reported [8] that the presence of the Fe3Mn3O8 phase (Fe–O–Mn species) could contribute to the improvement of surface acidity, and then improved the SCR performance. Consequently, the Fe–Mn–O x catalyst showed the best catalytic activity at 50–150 °C among the samples. Besides, the peak of NH3 desorption was spanned at 50–375 °C, proving that the Fe–Mn–O x catalyst possessed more quantities of weak and medium acid sites. It was generally accepted that the improvement of the surface acidity of SCR catalysts could inhibit the oxidation of ammonia at high temperatures, and then promoted the catalytic activity and N2 selectivity [45, 46]. Qu et al. reported [47] that the appropriate amounts of surface acid sites could adsorb and activate NH3, which was thought to be the important steps for the reduction of NO with NH3, and thus enhance the SCR performance and N2 selectivity. Long et al. [48] also declared that the ammonia species could be adsorbed on acid sites to generate NH4+ ions and coordinated NH3 species, and reacted with NO x ad-species, leading to the superior catalytic performance. Therefore, the enhancement of surface acidity could improve the NH3-adsorption capacity, and then increased the catalytic activity. Therefore, the surface acidity could improve the catalytic activity and N2 selectivity over Fe–Mn–O x catalyst.

Conclusions

Fe–Mn–O x with high SCR activity and N2 selectivity was prepared by the co-precipitation method. More than 80% NO x conversion and nearly 80% N2 selectivity were acquired in the temperature range of 50–150 °C. The surface species, the structure, the redox properties and the surface acidity were responsible for the excellent catalytic activity and N2 selectivity. The formation of Fe–O–Mn species could improve the SCR performance due to the enhancement of surface acidity, resulting in an increase in the catalytic activity and N2 selectivity. Besides, the presence of Fe3+ and Mn4+ could contribute to the enhancement of low-temperature SCR activity, while Mn3+ was in favored for the superior N2 selectivity over Fe–Mn–O x catalyst. In addition, the interaction between Fe and Mn species existed and then accelerated the formation of surface acidity, leading to the improvement of low-temperature catalytic activity and N2 selectivity.

References

Y. Peng, W.Z. Si, X. Li, J.J. Chen, J.H. Li, J. Crittenden, J.M. Hao, Environ. Sci. Technol. 50, 9576 (2016)

T. Boningari, P.G. Smirniotis, Curr. Opin. Chem. Eng. 13, 133 (2016)

J.H. Li, H.Z. Chang, L. Ma, J.M. Hao, R.T. Yang, Catal. Today 175(1), 147 (2011)

H.Z. Chang, L. Ma, S.J. Yang, J.H. Li, L. Chen, W. Wang, J.M. Hao, J. Hazard. Mater. 262, 782 (2013)

Z. Song, P. Ning, Q. Zhang, X. Liu, J. Zhang, Y. Wang, Y. Duan, Z. Huang, J. Mol. Catal. A Chem. 413, 15 (2016)

A. Grossale, I. Nova, E. Tronconi, D. Chatterjee, M. Weibel, J. Catal. 256(2), 312 (2008)

C.J. Tang, H.L. Zhang, L. Hong, Catal. Sci. Technol. 6(5), 1248 (2016)

Z. Chen, F. Wang, H. Li, Q. Yang, L. Wang, X. Li, Ind. Eng. Chem. Res. 51, 202 (2012)

D.K. Pappas, T. Boningari, P. Boolchand, P.G. Smirniotis, J. Catal. 334, 1 (2016)

P.R. Ettireddy, N. Ettireddy, T. Boningari, R. Pardemann, P.G. Smirnioti, J. Catal. 292, 53 (2012)

B. Thirupathi, P.G. Smirniotis, Appl. Catal. B: Environ. 110, 195 (2011)

P.G. Smirniotis, D.A. Peña, B.S. Uphade, Angew. Chem. Int. Ed. 40, 2479 (2011)

M. Kang, E.D. Park, J.M. Kim, J.E. Yie, Appl. Catal. A 327(2), 261 (2007)

Z. Chen, Q. Yang, H. Li, L. Wang, S.C. Tsang, J. Catal. 276, 56 (2010)

B. Thirupathi, P.G. Smirniotis, J. Catal. 288, 74 (2012)

M. Kang, E. Park, J. Kim, J.E. Yie, Catal. Today 111, 236 (2006)

G. Qi, R.T. Yang, J. Catal. 217, 434 (2003)

G. Qi, R.T. Yang, R. Chang, Appl. Catal. B 51, 93 (2004)

S. Brandenberger, O. Kröcher, A. Wokaun, A. Tissler, R. Althoff, J. Catal. 268, 297 (2009)

M. Schwidder, M.S. Kumar, U. Bentrup, J. Pérez-Ramírez, A. Brückner, W. Grünert, Micropor. Mesopor. Mater. 111, 124 (2008)

S.H. Begum, C.T. Hung, Y.T. Chen, S.J. Huang, P.H. Wu, X.X. Han, S.B. Liu, J. Mol. Catal. A Chem. 423, 423 (2016)

Z. Chen, X. Li, Y. Qing, H. Li, X. Gao, Y. Jiang, F. Wang, L. Wang, Acta Phys. Chim. Sin. 25, 601 (2009)

L.J. France, Q. Yang, W. Li, Z.H. Chen, J.Y. Guang, D. Guo, L.F. Wang, X.H. Li, Appl. Catal. B Environ. 203–215, 206 (2017)

R.Q. Long, R.T. Yang, R. Chang, Chem. Commun. 452, 5 (2002)

Z.H. Chen, F.R. Wang, H. Li, Q. Yang, L.F. Wang, X.H. Li, Ind. Eng. Chem. Res. 202–212, 51 (2012)

K.C.C. Kharas, Appl. Catal. B Environ. 2, 207 (1993)

M.V. Reddy, T. Yu, C.H. Sow, Z.X. Shen, C.T. Lim, G.V. Subba Rao, B.V.R. Chowdari, Adv. Funct. Mater. 17, 2792 (2007)

X.H. Nie, X.G. Li, C.W. Du, Y.Z. Huang, H. Du, J. Raman Spectrosc. 40, 76 (2009)

B. Guan, H. Lin, L. Zhu, B. Tian, Z. Huang, Chem. Eng. J. 181–182, 307 (2012)

T. Yamashita, P. Hayes, Appl. Surf. Sci. 254, 2441 (2008)

S.J. Roosendaal, B. van Asselen, J.W. Elsenaar, A.M. Vredenberg, F.H.P.M. Habraken, Surf. Sci. 442, 329 (1999)

S. Shwan, R. Nedyalkova, J. Jansson, J. Korsgren, L. Olsson, M. Skoglundh, Ind. Eng. Chem. Res. 51, 12762 (2012)

G. Delahay, D. Valade, A. Guzman-Vargas, B. Coq, Appl. Catal. B Environ. 55, 149 (2005)

G. Qi, R.T. Yang, J. Phys. Chem. B 108, 15738 (2004)

F. Kapteijn, L. Singoredjo, A. Andreini, J.A. Moulijn, Appl. Catal. B 3, 173 (1994)

X. Lu, C.Y. Song, C.C. Chang, Y.X. Teng, Z.S. Tong, X.L. Tang, Ind. Eng. Chem. Res. 53, 11601 (2014)

Y.S. Eom, S.H. Jeon, T.A. Ngo, J. Kim, T.G. Lee, H. Catal. Lett. 121, 219 (2008)

L. Chen, J.H. Li, M.F. Ge, Chem. Eng. J. 170, 531 (2011)

Z.B. Wu, R.B. Jin, Y. Liu, H.Q. Wang, Catal. Commun. 9, 2217 (2008)

F. Arena, G. Trunfio, J. Negro, B. Fazio, L. Spadaro, Chem. Mater. 19, 2269 (2007)

G. Giecko, T. Borowiecki, W. Gac, J. Kruk, Catal. Today 137, 403 (2008)

M.R. Morales, B.P. Barbero, L.E. Cadús, Appl. Catal. B 74, 1 (2007)

K. Sirichaiprasert, A. Luengnaruemitchai, S. Pongstabodee, Int. J. Hydrogen Energy 32, 915 (2007)

S.P. Dey, S. Gedevanishvili, W. Zhang, F. Rasouli, Appl. Catal. B 56, 241 (2005)

Z.C. Si, D. Weng, X.D. Wu, R. Ran, Z.R. Ma, Catal. Commun. 11, 1045 (2010)

L. Chen, J.H. Li, M.F. Ge, R.H. Rong, Catal. Today 153, 77 (2010)

R.Y. Qu, X. Gao, K.F. Cen, J.H. Li, Appl. Catal. B Environ. 142–143, 290 (2013)

R.Q. Long, R.T. Yang, J. Catal. 190, 22 (2000)

Acknowledgements

The project was supported by the National Program on Key Basic Research Project of China (973 Program, 2014CB643404), the National Natural Science Foundation of China (21567030 and 11447191) and the Natural Science Fund item of Yunnan Province under the Grant Number 2013FD033.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Xia, F., Song, Z., Liu, X. et al. Improved catalytic activity and N2 selectivity of Fe–Mn–O x catalyst for selective catalytic reduction of NO by NH3 at low temperature. Res Chem Intermed 44, 2703–2717 (2018). https://doi.org/10.1007/s11164-018-3255-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-018-3255-x