Abstract

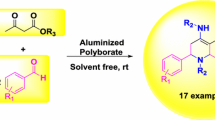

An eco-friendly procedure for synthesis of 2,3-dihydroquinazoline-4(1H)-one, 2H-indazolo[2,1-b]phthalazinetrione, and benzo[4,5]imidazo[1,2-a]pyrimidine derivatives by three-component reaction, with phosphoric acid supported on alumina as catalyst, is described. Noticeable features of the method are that it is solvent-free, work-up is easy, yields are excellent, and the catalyst is reusable.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Multi-component reactions (MCRs) are important in combinatorial chemistry because of the ability to synthesize target compounds with greater efficiency and atom economy by generating structural complexity in a single step from three or more reactants [1]. In addition, MCRs have the advantage of simplicity and synthetic efficiency over conventional chemical reactions [1]. MCRs have attracted much attention for construction of heterocyclic “drug-like” libraries [1–4].

2,3-Dihydroquinazoline-4(1H)-ones are an important class of heterocyclic compounds with a wide range of biological activity and pharmacological properties [5]. They can also be easily oxidized to their quinazolin-4(3H)-one analogues, which also have biological activity [5–7].

Phthalazine derivatives have been reported to have anticonvulsant [8], cardiotonic [9], and vasorelaxant [10] activity. Dihydropyrimidine derivatives have significant therapeutic and medicinal properties [11–13]. Several marine alkaloids containing the dihydropyrimidine structure have interesting biological activity, for example antiviral, antibacterial, and anti-inflammatory [14, 15]. Many functionalized derivatives of dihydropyrimidines have been used as calcium channel blockers, antihypertensive agents and α1A antagonists [16, 17]. Therefore, preparation of this heterocyclic structure has attracted much attention.

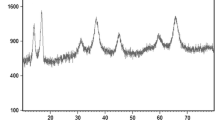

Phosphoric acid supported on alumina was prepared for the first time by Araujo et al. [18], by mixing alumina with phosphoric acid. This heterogeneous catalyst was characterized and catalytic evaluation of oleic acid conversion to biofuels and biolubricant was studied [18]. The best catalytic performance was achieved by use of the highest-surface-area alumina impregnated with H3PO4, a solid which combined high total acidity with a large number of mesopores [18]. By use of 31P NMR data [19], two aspects of the structure of the catalyst were confirmed (Scheme 1):

-

1

different phosphorus and aluminium interactions in bridging structures [19]; and

-

2

linear phosphorus and aluminium bonding [19].

Development of efficient and environmentally benign chemical methods in which heterogeneous recyclable catalysts are used under solvent-free conditions is a major challenge for chemists in organic synthesis [20]. In continuation of our research on solid heterogeneous acidic catalysts [21], we report herein a practical method for synthesis of 2,3-dihydroquinazoline-4(1H)-one, 2H-indazolo[2,1-b]phthalazinetrione, and benzo[4,5]imidazo[1,2-a]pyrimidine derivatives under thermal solvent-free conditions in the presence of H3PO4–Al2O3(50 % w/w) (Schemes 2, 3, 4).

Results and discussion

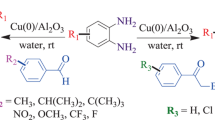

Synthesis of 2,3-dihydroquinazoline-4(1H)-ones

To optimize the reaction conditions for preparation of 2,3-dihydroquinazoline-4(1H)-ones, we heated isatoic anhydride (1 mmol), aniline (1.1 mmol), and benzaldehyde (1 mmol) at 100 °C in the presence of different amounts of H3PO4–Al2O3 as catalyst under solvent-free conditions. It was found that 120 mg catalyst resulted in maximum yield (89 %) in minimum time (33 min). Further increasing the amount of catalyst (150 mg) led to shorter reaction times (1 or 2 min) but with decreasing the yield of the product. Thus, 120 mg catalyst was found to be the optimum quantity and sufficient to promote the reaction. To optimize the reaction temperature we performed this model reaction with H3PO4–Al2O3 (120 mg) at different temperatures under solvent-free conditions. The best results were obtained by use of 120 mg catalyst at 120 °C (Tables 1, 2).

Next, we applied this optimum procedure to a diversity of primary amines or ammonium acetate (as the source of ammonia), aldehydes, and isatoic anhydride. We studied the scope of this reaction for preparation of a variety of 2,3-dihydroquinazolin-4(1H)-one derivatives (Table 3). As shown in Table 3, the direct three-component reactions worked well with a variety of aromatic aldehydes including those bearing electron-withdrawing and electron-donating groups, for example OMe, Cl, Br, and NO2, and the desired compounds were obtained in good to high yields (Table 3, Entries 1–31).

We also applied this efficient and environmental friendly approach to the synthesis of heterocyclic 3-(2′-benzothiazolo)-2,3-dihydroquinazolin-4(1H)-ones by three-component condensation of 2-aminobenzothiazole, isatoic anhydride, and aromatic or aliphatic aldehydes under thermal solvent-free conditions. The products were obtained in good yields (Scheme 5; Table 3, Entries 9–18).

Three 3-(2′-benzimidazolo)-2,3-dihydroquinazolin-4(1H)-one derivatives were synthesized for the first time by three-component condensation reaction of 2-aminobenzimidazole, isatoic anhydride, and aryl aldehydes under the same conditions (Scheme 6; Table 3, Entries 19–21).

If ammonium acetate is used as the source of ammonia (Scheme 2, R = H) in this reaction, 2-aryl-2,3-dihydroquinazolin-4(1H)-one derivatives are produced in good to high yields (Table 3, Entries 22–31).

The mechanism suggested for the H3PO4–Al2O3-catalyzed preparation of 2,3-dihydroquinazoline-4(1H)-ones is shown in Scheme 7. According to mechanisms reported in the literature [22, 23, 30], H3PO4–Al2O3 can act as catalyst on isatoic anhydride and produce the reactive intermediate I. N-Nucleophilic primary amine attack on the carbonyl unit of I produces the reactive intermediate II, which affords III by decarboxylation. Proton transfer by III affords the 2-amino-N-substituted amide IV. Subsequent reaction of the activated aldehyde with IV furnishes the imine intermediate V. The amide functional group in intermediate IV could be formed by tautomerism in the presence of the catalyst. Thus, intermediate VI could be prepared by intermolecular nucleophilic attack of the amide nitrogen on the activated imine carbon, and subsequent 1,5-proton transfer yields the final 2,3-dihydroquinazoline-4(1H)-ones as products (Scheme 7).

We also investigated recycling of the catalyst under solvent-free conditions, using reaction of isatoic anhydride with aniline and benzaldehyde (Table 3, Entry 1) as a model. After completion of the reaction, the reaction was cooled to room temperature and the crude solid product was dissolved in ethyl acetate. The mixture was filtered for separation of the catalyst. The catalyst was washed with ethyl acetate (2 × 5 mL). The recovered solid catalyst was dried under vacuum and used for subsequent catalytic runs. The recovered catalyst was reused five times without any loss of its activity (Fig. 1).

In Table 4 our results from preparation of 2,3-dihydroquinazoline-4(1H)-ones are compared with those reported in the literature [22, 24, 25, 30–33]. The table shows that H3PO4–Al2O3 is the most efficient catalyst with regard to reaction times and product yield..

Synthesis of 2H-indazolo[2,1-b]phthalazinetriones

To optimize the conditions for preparation of 2H-indazolo[2,1-b]phthalazinetrione derivatives, reaction of benzaldehyde, dimedone, and phthalhydrazide was selected as model system. The reaction was performed at different temperatures (60, 80, 100, 120, and 150 °C) and with different amounts of catalyst (0.08, 0.1, 0.12, and 0.13 g) under solvent-free conditions. The best results were obtained by use of a 1.0:1.0:1.2 molar ratio of dimedone, phthalhydrazide, and aldehyde in the presence of 0.12 g H3PO4–Al2O3 as catalyst at 100 °C under solvent-free conditions (Scheme 3, Tables 5, 6).

Using these optimized reaction conditions, the scope and efficiency of these procedures were investigated for synthesis of a wide variety of substituted 2H-indazolo[2,1-b]phthalazinetriones. Interestingly, a variety of aryl aldehydes, including ortho, meta, and para-substituted and with electron-donating or electron-withdrawing substituents, participated well in this reaction and gave the 2H-indazolo[2,1-b]phthalazinetrione derivatives in good to excellent yield (Table 7).

A possible mechanism for formation of 2H-indazolo[2,1-b]phthalazine-1,6,11(13H)-triones is proposed in Scheme 8. Knoevenagel condensation of dimedone I and arylaldehyde II forms a heterodiene III. Subsequent Michael-type addition of the phthalhydrazide IV to the heterodiene III followed by cyclization and dehydration affords the corresponding product VI.

Reusability of catalysts is an important benefit, because of their suitability for commercial application. Thus, recovery and reusability of H3PO4–Al2O3 was investigated, with reaction of benzaldehyde, dimedone, and phthalhydrazide as model. In this procedure, after completion of the reaction, the reaction mixture was cooled to room temperature, and the crude solid product was dissolved in ethyl acetate. The mixture was filtered for separation of the catalyst. The catalyst was washed with ethyl acetate (2 × 5 ml). The recovered catalyst was dried at 100 °C and used for subsequent catalytic runs. The recovered catalyst was reused five times without any loss of its activity (Fig. 2).

To show the merits of this work we compared results obtained by use of H3PO4–Al2O3 with those reported in the literature [35–38] for synthesis of 3,3-dimethyl-13-phenyl-3,4-dihydro-2H-indazolo[1,2-b]phthalazine-1,6,11(13H)-trione by reaction of benzaldehyde, dimedone, and phthalhydrazide. As shown in Table 8, H3PO4–Al2O3 is an effective catalyst with regard to reaction time, amount of the catalyst, and product yield. Thus, this procedure with H3PO4–Al2O3 catalyst is convincingly superior to some catalytic methods reported in the literature (Table 8).

Synthesis of benzo[4,5]imidazo[1,2-a]pyrimidines

To prepare benzo[4,5]imidazo[1,2-a]pyrimidines more efficiently in minimum time, at low temperature, and with the minimum amount of catalyst, reaction of benzaldehyde (1 mmol), methyl acetoacetate (1 mmol), and 2-aminobenzothiazole (1 mmol) was selected as model system to study the effect of different reaction temperatures (60, 80, 100, 120 and 150 °C) and different amounts of catalyst (0.08, 0.1, 0.12, 0.13, 0.14 g). The best result was obtained by use of a 1.0:1.0:1.0 molar ratio of benzaldehyde, methyl acetoacetate, and 2-aminobenzothiazole in the presence of 120 mg H3PO4–Al2O3 as catalyst at 100 °C under solvent-free conditions (Tables 9, 10).

Using these optimized reaction conditions, the scope and efficiency of the procedure were investigated for synthesis of a wide variety of substituted benzo[4,5]imidazo[1,2-a]pyrimidines. Interestingly, a variety of ortho, meta, and para-substituted aryl aldehydes participated well in this reaction and gave the benzo[4,5]imidazo[1,2-a]pyrimidine derivatives in good to excellent yield (Table 11). Table 11 shows that aromatic aldehydes carrying electron-donating or electron-withdrawing substituents react well under these conditions.

According to the literature [39], the reaction presumably proceeds in two steps. Condensation of aldehyde 1 and the β-dicarbonyl compound 2 by standard Knoevenagel reaction produces 3-benzylidene-2,4-pentanedione 3. 2-Aminobenzimidazole or 2-aminobenzothiazole 4 then reacts with intermediate 3 by Michael addition and produces intermediate 5. Cyclization and subsequent dehydration then afford benzo[4,5]imidazo[1,2-a]pyrimidine derivatives 6 (Scheme 9).

In Table 12 the results obtained in this work are compared with those reported in the literature for use of TMGT [39], and sulfamic acid [40]. The table shows that H3PO4–Al2O3 (50 % w/w) is the most efficient catalyst for preparation of 4H-pyrimido[2,1-b]benzazoles with regard to reaction time, temperature, and yield. The catalyst is also widely applicable (Table 12).

We also investigated recycling of the catalyst under solvent-free conditions for reaction of benzaldehyde, ethyl acetoacetate, and 2-aminobenzimidazole as model. After completion of the reaction, the mixture was cooled to room temperature and the crude solid product was dissolved in ethyl acetate. The mixture was filtered for separation of the catalyst. The catalyst was washed with ethyl acetate (4 × 5 mL) and the recovered catalyst was then dried in an oven at 100 °C for 3 h. The recovered catalyst was then used for subsequent catalytic runs. It was reused five times without any loss of its activity (Fig. 3).

Conclusion

We have developed a green and straightforward procedure for synthesis of 2,3-dihydroquinazoline-4(1H)-one, 2H-indazolo[2,1-b]phthalazinetrione, and benzo[4,5]imidazo[1,2-a]pyrimidine derivatives using H3PO4–Al2O3 as reusable catalyst under solvent-free conditions. These procedures have several advantages, including cleaner reactions, easier work-up, reduced reaction times, and eco-friendly strategy.

Experimental

General

All reagents were purchased from Merck and Aldrich and used without further purification. H3PO4–Al2O3 (50 % w/w) was prepared in accordance with a procedure reported elsewhere [41]. All yields refer to isolated products after purification. Products were characterized by comparison of spectroscopic data (FT-IR, 1H NMR, 13C NMR spectra) and melting points with those of authentic samples. NMR spectra were recorded on a Bruker Avance DEX 500 MHz instrument. The spectra were measured in CDCl3 relative to TMS (0.00 ppm). IR spectra were recorded on a Jasco FT-IR 460 plus spectrophotometer. Melting points were determined in open capillaries with a Buchi 510 melting point apparatus. TLC was performed on Polygram SIL G/UV 254 silica gel plates.

General procedure for preparation of 2,3-dihydroquinazoline-4(1H)-one derivatives

A stirred mixture of isatoic anhydride (1 mmol), primary amine (1.1 mmol) or ammonium acetate (1.2 mmol), aldehyde (1 mmol) and H3PO4–Al2O3 (120 mg, 50 w/w %) was reacted in an oil bath at 120 °C for the appropriate time. After completion of the reaction (monitored by TLC) the mixture was cooled to room temperature and the crude solid product was dissolved in ethyl acetate and filtered for separation of the catalyst. The organic filtrate solution was concentrated. The solid crude product was purified by recrystallization from aqueous EtOH (70 %). All the products were characterized by comparison of their spectroscopic and physical data with those of authentic samples [22–29]. Spectral data of unknown products are given below.

3-(Benzo[d]thiazol-2-yl)-2-(2,5-dimethoxyphenyl)-2,3-dihydroquinazolin-4(1H)-one (Table 3, Entry 17)

m.p.: 225–226 °C, IR (KBr) ν/cm−1: 3383, 1671, 1612, 1503, 1439, 1303, 1284, 1237, 753; 1H NMR (500 MHz, DMSO-d 6 ): δ (ppm): 8.00 (1H, d, J = 7.8 Hz), 7.85 (1H, d, J = 8.1 Hz), 7.72 (2H, d, J = 8.1 Hz), 7.59 (1H, d, J = 3.3 Hz), 7.40 (1H, t, J = 7.4 Hz), 7.33 (2H, q, J = 7.5 Hz), 6.99 (1H, d, J = 8.8 Hz), 6.86 (1H, d, J = 8.2 Hz), 6.79–6.76 (2H, m), 6.32 (1H, s), 3.87 (3H, s), 3.49 (3H, s); 13C NMR (125 MHz, DMSO-d 6 ): δ (ppm): 162.0, 156.9, 152.4, 150.5, 147.5, 146.5, 135.3, 132.5, 128.0, 127.9, 126.1, 124.0, 121.5, 120.9, 118.0, 115.4, 112.7, 112.6, 112.5, 112.4, 65.1, 56.2, 55.0; MS (EI, 70 eV) m/z (%): 43 (23), 57 (24), 69 (32), 77 (19), 105 (18), 132 (32), 149 (21), 210 (25), 238 (17), 268 (80), 283 (100), 417 (79); Anal. Calcd. for: C23H19N3O3S: C, 66.17; H, 4.59; N, 10.07 %. Found: C, 66.16; H, 4.60; N, 10.05 %.

3-(Benzo[d]thiazol-2-yl)-2-(2,3-dichlorophenyl)-2,3-dihydroquinazolin-4(1H)-one (Table 3, Entry 18)

m.p.: 246–248 °C, IR (KBr) ν/cm−1: 3378, 3065, 1639, 1619, 1513, 1432, 1389, 1243, 753, 738; 1H NMR (500 MHz, DMSO-d 6 ): δ (ppm): 8.14 (1H, s), 7.99 (1H, d, J = 6.9 Hz), 7.92 (1H, d, J = 7.0 Hz), 7.73–7.68 (2H, m), 7.53 (1H, d, J = 7.2 Hz), 7.38 (2H, s), 7.31 (1H, s), 7.18 (1H, d, J = 7.2 Hz), 7.04 (1H, d, J = 6.9 Hz), 6.88–6.84 (2H, m); 13C NMR(125 MHz, DMSO-d 6 ) δ (ppm): 161.5, 156.7, 147.3, 145.2, 139.1, 135.6, 132.9, 132.5, 130.6, 129.6, 128.3, 128.2, 126.2, 124.1, 124.0, 121.6, 121.0, 118.7, 115.9, 112.7, 66.8; MS (EI, 70 eV) m/z (%): 43 (16), 57 (21), 77 (36), 105 (25), 130 (19), 186 (24), 211 (20), 254 (17), 276 (89), 291 (100), 390 (17), 425 (20); Anal. Calcd. for: C21H13Cl2N3OS: C, 59.16; H, 3.07; N, 9.86 %. Found: C, 59.20; H, 3.10; N, 9.92 %.

3-(1H-benzo[d]imidazol-2-yl)-2,3-dihydro-2-(4-nitrophenyl) quinazolin-4(1H)-one (Table 3, Entry 19)

m.p.: > 300 °C, IR (KBr) ν/cm−1: 3360, 3209, 3078, 1685, 1613, 1518, 1343, 1243, 1160, 1107, 998; 1H NMR (500 MHz, DMSO-d 6 ) δ (ppm): 12.6 (1H, s), 8.34 (1H, d, J = 5.4 Hz), 8.17 (2H, d, J = 8.5 Hz), 7.79 (1H, d, J = 7.7 Hz), 7.59–7.55 (3H, m), 7.45–7.36 (3H, m), 7.16–7.10 (2H, m), 6.94 (1H, d, J = 7.9 Hz), 6.81 (1H, t, J = 7.9); 13C NMR(125 MHz, DMSO-d 6 ) δ (ppm): 161.0, 150.4, 148.6, 147.2, 145.7, 138.9(2C), 133.0, 128.3, 127.8(2C), 123.7(2C), 123.3(2C), 117.5, 115.2(2C), 115.0, 113.8, 72.9; MS (EI, 70 eV) m/z (%): 43 (27), 57 (31), 77 (37), 105 (37), 119 (39), 152 (21), 178 (28), 194 (26), 207 (88), 220 (95), 236 (47), 253 (100), 268 (32), 385 (94); Anal. Calcd. for: C21H15 N5O3: C, 65.45; H, 3.92; N, 18.17 %. Found: C, 65.59; H, 3.76; N, 18.21 %.

3-(1H-benzo[d]imidazol-2-yl) -2-(2-methoxyphenyl) -2,3-dihydroquinazolin-4(1H)-one (Table 3, Entry 20)

m.p.: 275 °C, IR (KBr) ν/cm−1: 3383,3205, 3208, 2923, 2836, 1669, 1614, 1538, 1494, 1450, 1385, 1278, 1240, 1109, 1020, 747; 1H NMR (500 MHz, DMSO-d 6 ) δ (ppm): 12.54 (1H, s), 7.86 (1H, d, J = 7.8 Hz), 7.53 (2H, d, J = 8.1 Hz), 7.44 (1H, d, J = 3.4 Hz), 7.39 (1H, d, J = 7.5 Hz), 7.29 (1H, t, J = 7.6 Hz), 7.22 (1H, t, J = 7.7 Hz), 7.11–7.05 (3H, m), 6.89 (1H, d, J = 7.4 Hz), 6.83 (1H, d, J = 8.1 Hz), 6.74 (2H, q, J = 7.2 Hz), 3.93 (3H, s); 13C NMR (125 MHz, DMSO-d 6 ) δ (ppm): 162.6, 156.4, 146.5(2C), 139.7, 134.8, 133.0, 129.5, 127.9, 127.2, 125.0, 121.3(2C), 119.6, 117.7, 117.2, 115.3, 113.5, 111.7, 111.4, 64.6, 55.7; MS (EI, 70 eV) m/z (%): 77 (27), 105 (24), 132 (41), 167 (23), 194 (25), 209 (20), 220 (88), 236 (93), 253 (76), 339 (42), 370 (100); Anal. Calcd. for: C22H18N4O2: C, 71.34; H, 4.90; N, 15.13 %. Found: C, 71.30; H, 4.61; N, 15.10 %.

3-(1H-benzo[d]imidazol-2-yl) -2-(2,5-dimethoxyphenyl) -2,3-dihydroquinazolin-4(1H)-one (Table 3, Entry 21)

m.p.: 235 °C, IR (KBr) ν/cm−1: 3353, 3150, 2928, 1657, 1612, 1533, 1499, 1447, 1388, 1292, 1226, 1048, 1024; 1H NMR (500 MHz, DMSO-d 6 ) δ (ppm): 12.55 (1H, s), 7.86 (1H, d, J = 7.6 Hz), 7.53 (2H, d, J = 7.5 Hz), 7.39 (2H, s), 7.30 (1H, t, J = 7.5 Hz), 7.12–7.06 (2H, m), 6.97 (1H, d, J = 8.8 Hz), 6.84 (1H, d, J = 8.1 Hz), 6.77 (2H, q, J = 6.8 Hz), 6.43 (1H, s), 3.87 (3H, s), 3.50 (3H, s); 13C NMR (125 MHz, DMSO-d 6 ) δ (ppm): 162.5, 152.3, 150.4, 146.5, 139.7, 134.8, 133.0, 128.4, 127.8, 121.3(2C), 117.8, 117.2(2C), 115.3, 113.5, 112.9, 112.2, 112.1, 111.7, 64.5, 56.1, 55.1; MS (EI, 70 eV) m/z (%): 77 (27), 105 (34), 132 (42), 194 (25), 210 (30), 220 (79), 236 (31), 250 (42), 268 (39), 283 (48), 341 (16), 369 (100), 400 (38); Anal. Calcd. for: C23H20N4O3: C, 68.99; H, 5.03; N, 13.99 %. Found: C, 69.01; H, 5.02; N, 13.89 %.

General procedure for preparation of 2H-indazolo[2,1-b]phthalazinetrione derivatives

A mixture of phthalhydrazide (10 mmol), dimedone (10 mmol), aldehyde (12 mmol), and H3PO4–Al2O3 (0.1 g, 50 % w/w) was heated at 100 °C in an oil bath for the appropriate time (Table 3). After completion (monitored by TLC) the reaction mass was cooled to 25 °C then the solid residue was dissolved in ethyl acetate. The catalyst was washed with (2 × 5 ml) ethyl acetate. The recovered catalyst was dried at 100 °C. The filtrate solution was evaporated and the solid crude product was purified by recrystallization from aqueous EtOH (25 %) to obtain the pure products. The compounds were characterized by comparison of their physical and spectral data with those reported in the literature [34–37]. Selected spectral data for one product are given below.

3,3-Dimethyl-13-(4-chlorophenyl)-3,4-dihydro-2H-indazolo[1,2-b]phthalazine-1,6,11(13H)-trione (Table 7, Entry 2)

m.p.: 259–261 °C 1H NMR (500 MHz, CDCl3): δ = 1.23 (s, 3H), 1.24(s, 3H), 2.35 (s, 2H), 3.26 (dd, J = 1.8, 19.0 Hz, 1H), 3.45 (d, J = 19.0 Hz, 1H), 6.45 (s, 1H), 7.31–8.38 (m, 8H) ppm; 13C NMR (125 MHz, CDCl3): δ = 28.6, 28.8, 34.6, 38.1, 50.8, 64.4, 118.2, 127.7, 128.2, 128.6, 128.8, 128.9, 129.1, 133.8, 134.4, 134.7, 134.9, 151.2, 154.4, 156.1, 192.1 ppm; IR (KBr, cm−1): 3037, 2958, 1687, 1654, 1623, 1467, 1390, 1362, 1311, 1268, 1147, 1013, 840, 794, 697.

General procedure for preparation of benzo[4,5]imidazo[1,2-a]pyrimidine derivatives

A stirred mixture of aldehyde (1 mmol), β-dicarbonyl compound (1 mmol), 2-aminobenzimidazole or 2-aminobenzothiazole (1 mmol), and H3PO4–Al2O3 as catalyst (0.12 g, 50 % w/w) was reacted in an oil bath at 120 °C for the appropriate time. On completion of the reaction (indicated by TLC) the mixture was cooled to room temperature. The crude solid product was dissolved in ethyl acetate, and filtered for separation of the catalyst. The organic filtrate solution was concentrated. The solid product was purified by recrystallization from aqueous EtOH (96 %). The authenticity of the products was established by comparing their melting points and FT-IR, 13C NMR, and 1H NMR spectra with those of known compounds [39–41]. The spectral data for the unknown compounds (Table 11, Entries 10 and 12) are given below.

Methyl-2-methyl-4-(4-methoxyphenyl)-4H-primido[2,1-b][1,3]benzothiazole-3-carboxylate (Table 11, Entry 10)

IR (KBr) (ν): 3415, 3064, 2921, 1702, 1596, 1510, 1432, 1384, 1242, 1081, 738 cm−1; 1H NMR (500 MHz, CDCl3): δ = 2.49 (s, 3H), 3.76 (s, 3H), 6.57 (s, 1H), 7.08 (d, J = 8.1 Hz, 1H), 7.21 (t, J = 7.6 Hz, 1H), 7.31–7.28 (m, 1H), 7.53–7.47(m, 2H), 7.77 (d, J = 7.7 Hz, 1H), 8.11 (ddd, J = 10.0 Hz, J = 2.0 Hz, J = 0.9 Hz) 8.31 (t, J = 1.93 Hz, 1H) ppm; 13C NMR (125 MHz, CDCl3): δ = 23.7, 51.3, 57.2, 102.0, 111.4, 121.9, 122.5, 123.4, 123.9, 124.5, 126.9, 130.0, 132.9, 137.4, 143.2, 148.3, 155.8, 163.6, 166.6 ppm; MS (EI, 70 eV) m/z (%): 381(27), 322(7.4), 259(100), 199(16), 175(6), 134(5); Anal. Calcd for C19H15N3O4S: C, 59.83; H, 3.96; N, 11.02 %; Found: C, 59.66; H, 3.79; N, 10.98 %.

Ethyl-2-methyl-4-(3-chlorophenyl)-4,10-dihydropyrimido[1,2-a][1,3]benzimidazole-3-carboxylate: (Table 11, Entry 12)

IR (KBr) (ν): 3235, 3102, 3025, 2980, 2927, 2853, 1655, 1572, 1515, 1284, 1111, 1013, 835, 730 cm−1; 1H NMR (500 MHz, CDCl3): δ = 1.31 (t, J = 7.10 Hz, 3H), 2.79 (s, 3H), 4.20 (m, 2H), 6.46 (s, 1H), 7.15 (m, 2H), 7.22 (t, J = 7.0 Hz, 1H), 7.27 (d, J = 8.4 Hz, 2H), 7.38 (d, J = 8.5 Hz, 2H), 7.56 (d, J = 7.95 Hz, 1H), 10.4 (s, 1H); 13C NMR (125 MHz, CDCl 3): δ = 14.2, 19.5, 56.3, 60.0, 98.9, 109.6, 116.4, 120.8, 121.1, 122.7, 123.5, 128.7 (2C), 131.3, 133.8, 139.9, 141.0, 146.2, 146.5, 165.7 ppm; MS (EI, 70 eV) m/z (%): 367(50), 338(29), 294(21), 256(100), 228(38), 182(14), 90(7); Anal. Calcd for C20H18ClN3O2: C, 65.31; H, 4.93; N, 11.42 %; Found: C, 65.28; H, 4.72; N, 11.41 %.

References

H. Bienayme, C. Hulme, G. Oddon, P. Schmitt, Chem. sEur. J. 6, 3321 (2000)

D.J. Ramon, M. Yus, Angew. Chem. Int. Ed. 44, 1602 (2005)

C. Hulme, V. Gore, Curr. Med. Chem. 10, 51 (2003)

J. Gerencser, G. Dormon, F. Darvas, QSAR Comb. Sci. 25, 439 (2006)

T. Jen, B. Dienel, F. Dowalo, H. Van Hoeven, P.B. Bender Loev, J. Med. Chem. 16, 633 (1973)

R.J. Abdel-Jalil, W. Volter, M. Saeed, Tetrahedron Lett. 45, 3475 (2004)

J.F. Wolfe, T.L. Rathman, M.C. Sleevi, J.A. Campbell, T.D. Greenwood, J. Med. Chem. 33, 161 (1990)

S. Grasso, G. De Sarro, N. Micale, M. Zappala, G. Puia, M. Baraldi, C. Demicheli, J. Med. Chem. 43, 2851 (2000)

Y. Nomoto, H. Obase, H. Takai, M. Teranishi, J. Nakamura, K. Kubo, Chem. Pharm. Bull. 38, 2179 (1990)

N. Watanabe, Y. Kabasawa, Y. Takase, M. Matsukura, K. Miyazaki, H. Ishihara, K. Kodama, H. Adachi, J. Med. Chem. 41, 3367 (1998)

C.O. Kappe, Eur. J. Med. Chem. 35, 1043 (2000)

C.O. Kappe, W.M.F. Fabian, Tetrahedron 53, 2803 (1997)

C.O. Kappe, Tetrahedron 49, 6963 (1993)

B.B. Snider, Z. Shi, J. Org. Chem. 58, 3828 (1993)

L.E. Overman, M.H. Rabinowitz, P.A. Renhowe, J. Am. Chem. Soc. 117, 2657 (1995)

K.S. Atwal, B.N. Swanson, S.E. Unger, D.M. Floyd, S.A. Moreland, B.C. O’Reilly, J. Med. Chem. 34, 806 (1991)

K.S. Atwal, G.C. Rovnyak, S.D. Kimball, D.M. Floyd, S. Moreland, B.N. Swanson, J.Z. Gougoutas, J. Schwartz, K.M. Smilie, M.F. Mallay, J. Med. Chem. 33, 2629 (1990)

L.R.R.D. Araujo, C.F. Scofield, N.M.R. Pastura, W.D.A. Gonzalez, Mater. Res. 9, 181 (2006)

K.R. Dixon, Phosphorus to bismuth, in Multinuclear NMR, 2nd edn., ed. by J. Mason (Plenum Press, London, 1989)

H.R. Shaterian, F. Shahrekipoor, M. Ghashang, J. Mol. Catal. A Chem. 272, 142 (2007)

H.R. Shaterian, H. Yarahmadi, M. Ghashang, Tetrahedron 64, 1263 (2008)

J.X. Chen, D. Wu, F. He, M.C. Liu, H.J. Wu, C. Ding, W.K. Su, Tetrahedron Lett. 49, 3814–3818 (2008)

L-M.L.Wang, J-H. Shao Hu. T. Yu, L. Zhang, J. Fluor. Chem. 129, 1139 (2008)

M. Dabiri, P. Salehi, S. Otokesh, M. Baghbanzadeh, G. Kozehgarya, A.A. Mohammadi, Tetrahedron Lett. 46, 6123 (2005)

M. Dabiri, P. Salehi, M.A. Baghbanzadeh, M.A. Zolfigol, M. Agheb, S. Heydari, Catal. Commun. 9, 785 (2008)

A. Shaabani, A. Rahmati, R. Moghimi, J. C. R. Chim. 11, 759 (2008)

P. Salehi, M. Dabiri, M.A. Zolfigol, M. Baghbanzadeh, Synlett, 1155 (2005)

J.X. Chen, W.K. Su, H.Y. Wu, M.C. Liu, C. Jin, Green Chem. 9, 972 (2007)

P. Salehi, M. Dabiri, M. Baghbanzadeh, M. Bahramnejad, Synth. Commun. 36, 2287 (2006)

H.R. Shaterian, A.R. Oveisi, M. Honarmand, Synth. Commun. 40, 1231 (2010)

M. Akazome, J. Yamamoto, T. Kondo, Y. Watanabe, J. Organomet Chem. 494, 229 (1995)

Z.H. Zhang, H.Y. Lu¨, S.H. Yang, J.W. Gao, J. Comb. Chem. 12, 643 (2010)

A. Safar-Teluri, S. Bolouk, Monatsh. Chem. 141, 1113 (2010)

H.R. Shaterian, A. Hosseinian, M. Ghashang, Arkivoc (ii), 59 (2009)

H.R. Shaterian, F. Khorami, A. Amirzadeh, R. Doostmohammadi, M. Ghashang, J. Iran. Chem. Res. 2, 57 (2009)

M. Sayyafi, M. Seyyedhamzeh, H.R. Khavasi, A. Bazgir, Tetrahedron 64, 2375 (2008)

J.M. Khurana, D. Magoo, Tetrahedron Lett. 50, 7300 (2009)

G. Sabitha, C. Srinivas, A. Raghavendar, J.S. Yadav, Helv. Chim. Acta 93, 1380 (2010)

A. Shaabani, A. Rahmati, S. Naderi, Bioorg. Med. Chem. Lett. 15, 5553 (2005)

C.S. Yao, S. Lei, C.H. Wang, C.X. Yu, Q.Q. Shao, S.J. Tu, Chin. J. Chem. 26, 2107 (2008)

T. Shujiang, S. Qingqing, Z. Dianxiang, C. Longji, S. Feng, L. Chunmei, J. Heterocycl. Chem. 44, 1401 (2007)

Acknowledgments

We are grateful to the University of Sistan and Baluchestan Research Council for partial support of this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shaterian, H.R., Fahimi, N. & Azizi, K. New applications of phosphoric acid supported on alumina (H3PO4–Al2O3) as a reusable heterogeneous catalyst for preparation of 2,3-dihydroquinazoline-4(1H)-ones, 2H-indazolo[2,1-b]phthalazinetriones, and benzo[4,5]imidazo[1,2-a]pyrimidines. Res Chem Intermed 40, 1879–1898 (2014). https://doi.org/10.1007/s11164-013-1087-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-013-1087-2