Abstract

To develop more potential angiotensin converting enzyme (ACE) inhibitors, a series of captopril (Cap) derivatives were synthesized, including Cap-glycine methyl ester, Cap-l-alanine methyl ester, Cap-l-aspartic acid dimethyl ester, Cap-l-lysine methyl ester, Cap-O-acylisourea, acetyl captopril, and benzoyl captopril. The resulting products were characterized by IR and UV–visible spectroscopy and MS, which showed the desired products were successfully synthesized. This could serve as a guide for rational design of highly potent ACE inhibitors.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Research on hypertension has gained worldwide importance because of its high frequency and the concomitant risks associated with cardiovascular diseases. It has been identified as leading risk factor for mortality [1]. It is recognized that angiotensin converting enzyme (ACE) is important in the regulation of hypertension [2, 3]. ACE catalyzes the conversion of decapeptide (angiotensin I) to the potent vasoconstring octapeptide (angiotensin II). Inhibition of ACE activity leads to a decrease in the concentration of angiotensin II and consequently reduces blood pressure [4, 5]. Several ACE inhibitors, for example captopril (Cap), enalapril, and lisinopril are in clinical use for treatment of hypertension [6]. However, all these drugs have side effects, including the inducement of dry cough, taste disturbances, skin rashes, first dose hypotension, and acute renal failure, thus justifying the search for newer analogues of ACE inhibitors for safe use.

Cap, molecular formula C9H15NO3S, is an orally active ACE inhibitor used for treatment of hypertension and congestive heart failure [7]. Cap, which is water-soluble, is usually prescribed to patients who are chronically ill and require long-term use for its therapeutic benefits. It is regarded as a preferred drug in antihypertensive therapy because of its effectiveness, low price, and low toxicity. It is a first-line drug for treatment of various types of hypertension.

Much work has been performed on modification of Cap. Enomoto et al. [8] studied the synthetic modification of structurally similar N-mercapto acyl-l-proline, additional introduction of a large substituent group with the (S) configuration at the C4 position of proline yielded much more potent leukotriene A4 hydrolase inhibitors than Cap. S-Nitrosocaptopril (S-CapSNO) is an example of synthetic S-nitrosothiols with great therapeutic potential, which is formed by nitrosylation of Cap, has a primary structure, and is stable in vitro. Cap is a thiol that inhibits the activity of ACE, causing vasodilation. Nitrosylation of this compound to form CapSNO does not interfere with the inhibition properties of ACE [9]. Sacha et al. [10] studied the effect of S-CapSNO on blood glucose concentration and hemodynamic data. The results show that CapSNO significantly reduced both systolic and diastolic blood pressure, this was accompanied by an increase in heart rate. The anti-hypertensive property of CapSNO was more significant than that of Cap. CapSNO was more potent than Cap in reducing blood pressure, suggesting that CapSNO may act via a combined mechanism that involves ACE inhibition and NO release.

To extend the time of action of the drug and improve its efficacy, a series of Cap ester derivatives including different fatty esters or aromatic esters have been synthesized. The activity of carboxylic acid diester derivatives is greater than that of single-ester derivatives, and all have greater antihypertensive activity than Cap, and a longer time of action.

Among the bioactive peptides, ACE inhibitory peptides and antihypertensive peptides have been extensively researched, because hypertension is a major risk factor in cardiovascular disease, including heart disease [11, 12]. However, to the best of our knowledge, Cap derivatives modified by use of an amino acid methyl ester have never been reported. Addition of a peptide bond may increase protein binding, slow the rate of hydrolysis, and prolong its half-life. Moreover, because a chiral center is added its efficacy may be unexpected.

The purpose of this study was to construct more reliable chemical feature-based pharmacophore models for ACE inhibitory peptides; these models may serve as a guide to identifying selective ACE inhibitory peptides. Herein we report and discuss the results obtained.

Experimental

Apparatus and reagents

FTIR spectra were recorded with a Nicolet Avatar FT/IR-360 spectrophotometer (USA). UV–visible absorption spectra between 200 and 800 nm were recorded with a TU-1901 dual beam spectrophotometer (Purkinje General Instrument, Beijing, China). An HP6890/5973 Agilent 1,100 Liquid mass spectrometer and a WRS-1-type melting point apparatus were also used.

Glycine (AR); Sinopharm Chemical Reagent. l-Alanine (BR); Sinopharm Chemical Reagent. l-Asparaginic acid (BR), Sinopharm Chemical Reagent. l-Lysine (BR), Sinopharm Chemical Reagent. Cap: 99.5 %, Changzhou Pharmaceutical Factory. 1-Ethyl-3-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC·HCl): 98.5 %; National Pharmaceutical Group Chemical Reagent. 1-Hydroxy-2,5-pyrrolidinedione (NHS): 98 %; National Pharmaceutical Group Chemical Reagent. N,N-Dimethylpyridin-4-amine (DMAP): 99 %; Aladdin Reagent. Acetyl chloride (AR); Aladdin Reagent. Benzoyl chloride (AR); Aladdin Reagent. All other chemicals were of analytical grade and used without further purification.

Synthesis of amino acid methyl ester hydrochloride

Glycine methyl ester hydrochloride

Glycine 2.50 g (33 mmol) was suspended in CH3OH (20 mL) with magnetic stirring, and SOCl2 (45 mmol) was then added dropwise at −5 to 0 °C. During this process the suspension became clear. The reaction mixture was subsequently stirred for 1 h at 0 °C followed by an additional 2 h period at room temperature, then heated under reflux for 4 h. The solvent was evaporated under reduced pressure and the residue was recrystallized from methanol–ether (5:1), stored in a refrigerator for 12 h, filtered, and dried in vacuo to afford the expected product in 88 % yield. White solid, m.p. 172–174 °C. IR(KBr): 3113.28 cm−1 (ν s (N–H)), 1749.86 cm−1 (ν s (C=O)), 1397.05 cm−1 (δ (CH3)), 1260.14 cm−1 (ν as (C–O–C)). MS: 125 [M]+, 90 [M − HCl + 1]+. The other amino acid methyl ester hydrochlorides were synthesized by the same method.

l-Alanine methyl ester hydrochloride

White solid, yield: 86 %, m.p. 108–110 °C. IR(KBr): 2954.68 cm−1 (ν as (CH3)), 1747.06 cm−1 (ν s (C=O)), 1584.66 cm−1 (δ (N–H)), 1253.77 cm−1 (ν as (C–O–C)). MS: 103 [M − HCl]+.

l-Aspartic acid dimethyl ester hydrochloride

White solid, yield: 83 %, m.p. 172–175 °C. IR(KBr): 3200.41 cm−1 (ν s (N–H)), 1742.87 cm−1 (ν s (C=O)), 1680.92 cm−1 (δ (N–H)), 1459.70 cm−1 (ν s (O–CH3)), 1212.88 cm−1 (ν as (C–O–C)). MS: 161 [M − HCl]+.

l-Lysine methyl ester hydrochloride

White solid, yield: 92 %, m.p. 200–203 °C. IR(KBr): 2944.79 cm−1 (ν as (CH3)), 1739.52 cm−1 (ν s (C=O)), 1400.48 cm−1 (δ (CH3)), 1242.48 cm−1 (ν as (C–O–C)). MS: 160.1 [M − HCl]+.

Synthesis of the C-terminal modification of Cap

Cap-Glycine methyl ester

The compound was synthesized in accordance with the literature [13, 14]. Cap 0.435 g (2 mmol), EDC·HCl 0.46 g (2.4 mmol), NHS 0.2762 g (2.4 mmol), and DMAP 0.0293 g (0.24 mmol) were dissolved in dichloromethane (10 mL) with magnetic stirring. The reaction mixture was subsequently stirred for 1 h at 0 °C followed by an additional 4 h period at room temperature. Glycine methyl ester hydrochloride 0.3 g (2.4 mmol) dissolved in dichloromethane (5 mL) was added and the pH was adjusted to 8–9 by addition of triethylamine (TEA). The mixture was stirred at room temperature for 24 h. The reaction was monitored by TLC (CH3OH–NH3·H2O = 14:1) until the disappearance of Cap. The solid was removed from the mixture by filtration, and the filtrate was washed with 0.1 M HCl solution and dried with anhydrous MgSO4. After filtration, the filtrate was evaporated under vacuum to give the desired product in 42 % yield as a white solid. IR(KBr): 3070.19 cm−1 (δ (N–H) octave of amide I), 1749.99 cm−1 (ν s (C=O) of ester group), 1680.86 cm−1 (ν s (C=O) of amide I), 1538.30 cm−1 (δ (N–H) of amide II), 1279.84 cm−1 (ν s (C–N) of amide III), 1207.59 cm−1 (ν as (C–O–C)). MS: 288 [M]+. Cap-l-alanine methyl ester was synthesized by the same method.

Cap-l-Alanine methyl ester

White solid, yield: 38.5 %, IR(KBr): 2924.95, 1741.28 cm−1 (ν s (C=O) of ester group), 1679.39, 1652.58 cm−1 (ν s (C=O) of amide I), 1540.19 cm−1 (δ (N–H) of amide II), 1280.07 cm−1 (ν s (C–N) of amide III), 1082.49 cm−1 (ν as (C–O–C)). MS: 301 [M − 1]+.

Cap-l-Aspartic acid dimethyl ester

The compound was synthesized in accordance with the literature [15]. Cap 0.435 g (2 mmol), EDC·HCl 0.46 g (2.4 mmol), NHS 0.2762 g (2.4 mmol), and DMAP 0.0293 g (0.24 mmol) were dissolved in H2O (4 mL) with magnetic stirring. The reaction mixture was subsequently stirred for 1 h at 0 °C followed by an additional 4 h period at room temperature. l-Aspartic acid dimethyl ester hydrochloride 0.3557 g (1.8 mmol) dissolved in H2O (4 mL) was added and the pH was adjusted to 8–9 by addition of NaHCO3 solid powder. The mixture stirred at room temperature for 24 h. The reaction was monitored by TLC (CH3OH–NH3·H2O = 14:1) until the disappearance of Cap. The reaction mixture was concentrated in vacuo and the crude residue was purified by chromatography on a silica gel column by use of CH3OH–NH3·H2O as eluent (14:1) affording the expected product in 40.2 % yield as a white solid. MS: 360.1 [M]+. Cap-l-lysine methyl ester was synthesized by the same method.

Cap-l-lysine methyl ester

White solid, yield: 34.4 %. MS: 360 [M + 1]+.

Synthesis of Cap-O-acylisourea

Cap 0.4350 g (2 mmol), EDC·HCl 0.46 g (2.4 mmol), and DMAP 0.0293 g (0.24 mmol) were dissolved in CHCl3 (10 mL) with magnetic stirring. The mixture was subsequently stirred for 4 h at room temperature. The reaction was monitored by TLC (CH3OH–NH3·H2O = 14:1) until the disappearance of Cap. The mixture was then washed with 0.1 M HCl solution and dried with anhydrous MgSO4. After filtration, the filtrate was evaporated under vacuum to give the desired product as a white solid. MS: 373.1 [M + 1]+.

Synthesis of the S-terminal modification of Cap

Acetyl captopril

The compound was synthesized in accordance with the literature [16]. Cap 0.87 g (4 mmol) was dissolved in dichloromethane (15 mL) with magnetic stirring. Keeping the temperature at −5 to 0 °C, acetyl chloride 0.35 ml (4.8 mmol) was added dropwise to the solution over 30 min, and the pH was adjusted to 8–9 by addition of TEA. The reaction mixture was subsequently stirred for 4 h at room temperature. Solid was removed from the mixture by filtration, and the filtrate was washed with 0.1 M HCl solution and dried with anhydrous MgSO4. After filtration, the filtrate was evaporated under vacuum to give the desired product in 59.8 % yield as a white solid. IR(KBr): 2975.94 cm−1 (ν as (CH3)), 2925.31 cm−1(ν as (CH2)), 2879.92 cm−1 (ν s (CH3)), 1741.22 cm−1 (ν s (C=O) of carboxyl), 1686.19 cm−1 (ν s (C=O) of thioester), 1636.20 cm−1 (ν s (C=O) of amide I), 1460.36 cm−1 (δ (CH2)), 1428.15 cm−1 (S–CH2), 1331.57 cm−1 (ν s (C–N) of amide III), 1190.71 cm−1 (ν s (C–O) of carboxyl), 754.81 cm−1 (C–S). MS: 259 [M]+.

Benzoyl captopril

The compound was synthesized in accordance with the literature [17]. Sodium hydroxide pellets 0.35 g (8.7 mmol) and Cap 0.87 g (4 mmol) were mixed and dissolved in 14 mL of a toluene–water (1:2.5) solution at 5 °C. Benzoyl chloride 0.4 mL (3.3 mmol) was then added to this solution over 30 min, maintaining the temperature between 5 and 15 °C. The reaction was left to proceed for an additional 30 min at room temperature. The mixture was then diluted to twice its volume with water and the aqueous phase was washed twice with benzene (10 mL). The organic phase was discarded, and the aqueous layer was subsequently chilled to 4 °C, acidified to pH 2–3 with HCl (6 M), and extracted three times with CHCl3. The organic phase was dried with anhydrous MgSO4. After filtration, the filtrate was evaporated under vacuum to give the desired product as a colorless oil in 65 % yield. IR(KBr): 2972.62 cm−1 (ν as (CH3)), 2915.31 cm−1 (ν as (CH2)), 2876.28 cm−1 (ν s (CH3)), 1740.30 cm−1 ((C=O) of carboxyl), 1712.65 cm−1 (ν s (C=O) of thioester), 1637.31 cm−1 (ν s (C=O) of amide I), 1314.04 cm−1 (C–N) of amide III), 775.94 cm−1 (C–S). UV–Vis: 203, 237, 267 nm. MS: 321 [M]+.

Results and discussion

Synthesis

A series of amino acids, including glycine, l-alanine, l-aspartic acid, and l-lysine, were converted to corresponding amino acid methyl ester hydrochlorides in good to excellent yield.

A variety of reagents have been reported for transformation of amino acids into the amino acid methyl esters, including gaseous hydrochloric acid [18], thionyl chloride [19], and TMSCl–MeOH [20]. We eventually performed the synthesis with SOCl2/CH3OH. This method has several advantages: easy operation, mild reaction conditions, simple workup, and good yields.

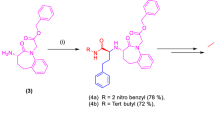

The covalent attachment of amino acid methyl esters to Cap has been achieved by formation of amide bonds between the carboxyl group in Cap and the amino group in the amino acid methyl esters, as illustrated in Scheme 1.

Different coupling methods, reaction conditions, and solvents were investigated. For synthesis of Cap-glycine methyl ester, we tried different solvents, for example dichloromethane and DMF, different coupling reagents (EDC·HCl/HOBt/DMAP) were also tried. The results showed that, under these conditions, although the target compound can be obtained, the yield is low. It is difficult to obtain the other Cap derivatives, because of the solubility of the other amino acid methyl ester hydrochlorides in organic solvents. Finally, we performed the reaction in distilled water; very gratifyingly, the reaction proceeded and provided fairly pure product.

Coupling of Cap and other amino acid methyl esters was performed by use of EDC·HCl/NHS/DMAP in H2O at ambient temperature. Use of water as reaction medium has received much attention in the context of green chemistry for several reasons:

-

1

it is inexpensive, safe, and environmentally benign;

-

2

reactions in aqueous medium eliminate the additional efforts needed to make the substrates and reagents dry before use and thus reduce/eliminate the consumption of drying agents, energy, and time; and

-

3

the unique physical and chemical properties of water can be utilized to realize reactivity or selectivity that cannot be achieved in organic solvents [21].

In pursuit of our recent efforts to develop environmentally friendly synthetic methodologies by carrying out reactions in H2O, very gratifyingly, the desired product was got in this way.

The synthetic route to Cap-O-acylisourea, a key intermediate in this acylation reaction, is shown in Scheme 2. Generally speaking, direct synthesis of the amide by coupling methods includes three processes:

-

1

formation of the O-acylisourea;

-

2

many additives have a X–OH structure (NHS, HOBt) that can form active esters with the carboxylic acid; and

-

3

nucleophilic reaction between amine and active ester.

This intermediate produced by the addition reaction is then converted to the amide by adding the amine.

In the synthesis of acetyl captopril and benzoyl captopril, we selected acetyl chloride and benzoyl chloride as esterification reagents, as illustrated in Scheme 3, this may greatly shorten the reaction time and furnish the product in high yield. Because the activity of acetyl chloride is higher than that of benzoyl chloride, in the synthesis of acetyl captopril, we control the temperature at −5 to 0 °C, this might reduce side reactions. In the synthesis of benzoyl captopril, it is better to control the temperature at 5–15 °C, if the temperature is too low, the solvent may freeze, so molecular motion is substantially reduced and formation of target compounds could be reduced.

Characterization

In the IR spectrum of the amino acid methyl ester hydrochloride, 1,750–1,735 cm−1 is the C=O stretching vibration of ester group, 1,260–1,160 cm−1 is the C–O–C asymmetric stretching vibrations, which proved successful synthesis of the intermediates. The melting point was also consistent with the literature, which is further confirmation.

The target compounds were characterized by IR and MS. Taking Cap-glycine methyl ester as example, in the IR spectrum of Cap-glycine methyl ester, 3070.19 cm−1 is the N–H deformation octave vibration of amide I, 1749.99 cm−1 is the C=O stretching vibration of the ester group, 1680.86 cm−1 is the C=O stretching vibration of amide I, 1538.30 cm−1 is the N–H deformation vibration of amide II, 1279.84 cm−1 is the C–N stretching vibration of amide III, and 1207.59 cm−1 is the C–O–C asymmetric stretching vibration. This was very good proof of the presence of the amide bond, and showed the synthesis was successful. Simultaneously, MS also proved synthesis of the target compounds was successful.

The thioester bond is a characteristic functional group in acetyl captopril and benzoyl captopril. In the IR spectrum 1686.19 and 1712.16 cm−1 can be ascribed to thioester, the difference between them may be caused by inductive and mesomeric effects. There is a benzene ring in benzoyl captopril, this prompted us to prove the identity of the compound by use of UV–visible spectroscopy. Three peaks belonging to captopril, the E 2 band of the benzene ring, and the B band of the benzene ring proved the synthesis was successful. MS also proved successful synthesis of the target compounds.

These captopril derivatives will provide useful information for the design of new drugs to combat high blood pressure.

Conclusion

In this study we designed and synthesized a series of captopril derivatives, including Cap-glycine methyl ester, Cap-l-alanine methyl ester, Cap-l-aspartic acid dimethyl ester, Cap-l-lysine methyl ester, Cap-O-acylisourea, acetyl captopril, and benzoyl captopril. The products were characterized by IR and UV–visible spectroscopy and MS, which proved successful synthesis of the desired compounds. These Cap derivatives could serve as a guide for the rational design of highly potent ACE inhibitors.

References

S. Kantevari, D. Addla, P.K. Bagul, B. Sridhar, S.K. Banerjee, Bioorg. Med. Chem. 19, 4772–4781 (2011)

Z.L. Wang, S.S. Zhang, H.W. Jin, W. Wang, J.X. Huo, L.S. Zhou, Y.F. Wang, F.Q. Feng, L.R. Zhang, Eur. J. Med. Chem. 46, 3428–3433 (2011)

G. Tulipano, V. Sibilia, A.M. Caroli, D. Cocchi, Peptides 32(4), 835–838 (2011)

M.R. Ehlers, E.A. Fox, D.J. Strydom, J.F. Riordan, Proc. Natl. Acad. 86, 7741–7745 (1989)

J. Pourahmad, M.J. Hosseini, S. Bakan, M. Ghazi-Khansari, Pest. Biochem. Physiol. 99, 105–110 (2011)

M. Prabhu, S. Palaian, A. Malhotra, P. Ravishankar, D. Bista, R. Almeida, P. Mishra, Kathmandu Univ. Med. J. 3, 296–304 (2005)

J.K. Wang, L. Gao, Y. Liu, J. Chem. Eng. Data 55, 966–967 (2010)

H. Enomoto, Y. Morikawa, Y. Miyake, F. Tsuji, M. Mizuchi, H. Suhara, K. Fujimura, M. Horiuchi, M. Ban, Bioorg. Med. Chem. Lett. 18, 4529–4532 (2008)

J. Loscalzo, D. Smick, N. Andon, J. Cooke, J. Pharmacol. Exp. Ther. 249, 726–729 (1989)

C. Sacha, A.L. Ruby, D. Tara, M. Donovan, J. Appl. Biomed. 7, 123–131 (2009)

R.J. FitzGerald, H. Meisel, Br. J. Nutr. 84, S33–S37 (2000)

D.D. Kitts, K. Weiler, Curr. Pharm. Des. 9(16), 1309–1323 (2003)

S.H. Lee, X. Qi, J.Y. Yoon, K. Nakamura, Y.S. Lee, Tetrahedron 58, 2777–2787 (2002)

S. Pichlmair, M.D. Lera Ruiz, K. Basu, L.A. Paquette, Tetrahedron 62, 5178–5194 (2006)

H.P. Li, L. Qin, Z.D. Wang, S. Li, Res Chem Intermed. DOI 10.1007/s11164-011-0473-x

R. Ghosh, S. Maiti, A. Chakraborty, Tetrahedron Lett. 46, 147–151 (2005)

J. Gariepy, S. Remy, X.G. Zhang, J.R. Ballinger, B.P. Eleonora, M. Rauth, S.K. Bisland, Bioconj. Chem. 13, 679–684 (2002)

G.A. Pher, G. David, T. David, J. Org. Chem. 62, 7364–7375 (1997)

M.J. Simon, E.U. Jonathan, K. Marcel, B. Reto, L.H. John, B. Colin, H.G. Ian, J. Med. Chem. 48, 5932–5941 (2005)

J.B. Li, Y.W. Sha, Molecules 13, 1111–1119 (2008)

S.V. Chankeshwara, A.K. Chakraborti, Org. Lett. 8(15), 3259–3262 (2006)

Acknowledgments

This work was supported by the National Natural Science Foundation of China (no. 20775010), the Natural Science Foundation of Hunan Province of China (06JJ2038) and the Graduate Innovation Fund of Hunan Province of China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Hp., Zhang, Jj., Qin, L. et al. Synthesis and characterization of captopril derivatives. Res Chem Intermed 39, 621–629 (2013). https://doi.org/10.1007/s11164-012-0584-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-012-0584-z