Abstract

Herein, we have described a novel and concise synthesis of the potent angiotensin-converting enzyme (ACE) inhibitor, benazepril hydrochloride (7) in trifluoroethanol via an Ugi three-component reaction in shorter reaction times. The key step is the trifluoroacetic acid-mediated hydrolysis of secondary amides (4a and 4b) followed by esterification as a domino process to form corresponding ethyl ester (6). Mainly two universal convertible isocyanides (1a and 1b) were used for the synthesis of benazepril hydrochloride.

Graphic abstract

Synopsis: An efficient synthesis of benazepril hydrochloride using Ugi three-component reaction.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

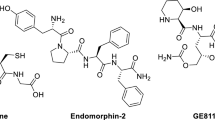

Multicomponent reactions (MCRs)1 are the most powerful methods in which at least three starting materials react to each other to form compounds with a diverse skeleton in one pot. MCRs are widely used synthetic tool to manufacture different pharmaceutical compounds due to their high atom economy, high efficiency with low cost. The Ugi reaction is one of the most applied multicomponent reactions due to easy access to different scaffolds in shorter reaction times. A classical Ugi three-component reaction (U-3CR) combines an amine, carbonyl compound and isocyanide to get α-amino amides. There are numerous pharmaceutical compounds used as angiotensin-converting enzyme (ACE) inhibitor contains α-amino amides structural frameworks like benazepril, lisinopril, quinapril and enalapril (Figure 1).

ACE inhibitors used to lower high blood pressure, prevent heart failure and to treat diabetic kidney diseases.

We recently reported3e efficient synthesis of quinapril hydrochloride using Ugi multicomponent reaction. We thought to develop a synthesis of benazepril hydrochloride. Literature survey revealed that there are many synthetic approaches reported for the synthesis of benazepril HCl. These methods involved multiple steps2b, 2e for the synthesis of benazepril HCl. Use of costly advance intermediates like L-Homophenyl alanine ethyl ester (LHPE), 4-(2-nitrophenyl)-4-oxo-but-2-enoic acid methyl ester,2a ethyl-(R)-2-hydroxy-4-phenylbutyrate,2c (S)-3-amino-1,3,4,5-tetrahydro-2H-benzo[b]azepin-2-one, critical asymmetric Aza-Michael reaction and cumbersome chiral separations2a are some of the demerits of prior art synthesis.

Herein we describe an efficient synthesis of angiotensin-converting enzyme (ACE) inhibitor, benazepril hydrochloride (7) in trifluoroethanol via an Ugi three-component reaction in shorter reaction times using cheaper starting materials with good yields.

2 Experimental

2.1 Raw materials and physical measurement

All reagents purchased from Sigma Aldrich, S. D. Fine chemical. NMR data recorded on Bruker 500 MHz, AVANCE III HD and Software Topspin at room temperature in CDCl3 and DMSO d6 using TMS as an internal reference standard. HRMS data recorded on Waters Xevo G2 QTOF mass spectrometer. Specific optical rotation recorded on Rudolph Research Analytical, Autopol V plus instrument. IR spectra recorded on Perkin spectrum 400 FTIR spectrophotometer. Isonitriles are commercially available, were outsourced. All compounds were analyzed by Chiral HPLC, SHIMADZU LC-2010 CHT, CHROMELEON version 6.80, CHIRALPACK AD-H column, Particle size 5 µm, Dimensions 4.6 mmϕ x 250 mmL. Oven temperature 30 °C, mobile phase ethanol: n-Hexane (20:80) ratio. Flow rate 1 mL/min.

2.2 General procedure for Ugi three-component reaction (4a, 5a)

A solution of 3-phenylpropanal (2) (4.1gm, 30.85 mmol, 1 eq.), (S)-2-(3-amino-2-oxo-2, 3, 4, 5-tetrahydro-1Hbenzo[b]azepin-1-yl) acetate (3)3f (10 gm, 30.85 mmol, 1 eq.) in 2, 2, 2 trifluoroethanol (50 mL) was stirred for 30 min. To this reaction mixture, 2-nitrobenzyl isocyanide (1a) (4.9 gm, 30.85 mmol, 1 eq.) and catalyst TiCl4 (0.30 gm, 0.0015 mmol, 0.05 eq.) was added. The reaction was monitored using thin-layer chromatography (ethyl acetate/hexane, 70:30). After completion of the reaction (7 h), the reaction mixture was concentrated under reduced pressure. The residue was dissolved in ethyl acetate and the organic layer was washed with aqueous (5%) NaHCO3 solution (100 mL). The organic layer was dried over sodium sulphate (10 gm), filtered it and evaporated under reduced pressure to get compound (4a and 5a) crude showing (dr = 91:9) 18 gm. After column chromatography (Yield 4a = 78%, 5a = 5%). Similarly, compound (4b and 5b) was synthesized by the same procedure described above. Crude showing (dr =87:13). After column chromatography (Yield 4b = 72%, 5b = 9%), these diastereomeric mixture was column chromatographically separated. Silica 100–200 mesh, Mobile phase Ethyl acetate: Hexane (70:30)

2.3 Benzyl 2-((S)-3-(((S)-1-((2-nitrobenzyl) amino)-1-oxo-4-phenylbutan-2-yl) amino)-2-oxo-2,3,4,5-tetrahydro-1H-benzo[b]azepin-1-yl)acetate (4a)

Yield 15 gm, 78%, Yellow Oil. [α]D 25 – 145.0° (c 0.9, EtOH). IR (KBr) ν max 696, 735, 1184, 1521, 1660, 1746, 2930, 3326 cm-1. 1H NMR (500 MHz, CDCl3), δ (ppm) 1.87–2.02 (m, 4H), 2.28–2.33 (m, 1H), 2.49–2.53 (m, 1H), 2.69–2.74 (m, 2H), 2.96–3.01 (m, 2H), 3.19–3.26 (m, 1H), 4.38 (d, J = 17.5 Hz, 1H), 4.54–4.62 (m, 2H), 4.79 (d, J = 17.5 Hz, 1H), 5.15 (s, 2H), 7.01 (d, J = 8 Hz, 1H), 7.16–7.48 (m, 16H), 7.97 (d, J = 8 Hz, 1H), 8.00 (t, J = 6 Hz, 1H). 13C NMR (125 MHz) δ: 28.2, 31.9, 35.9, 38.1, 40.6, 50.3, 57.7, 62.1, 67.2, 122.5, 125.0, 125.8, 126.9, 127.8, 128.3, 128.4, 128.4, 128.5, 128.6, 129.5, 131.9, 133.6, 133.9, 135.1, 135.9, 140.3,141.4, 148.0, 168.5, 173.8, 174.2. HRMS calculated (m/z) [M+H] +: 621.2635; Found; 621.2635.

2.4 Benzyl 2-((S)-3-(((S)-1-(tert-butylamino)-1-oxo-4-phenylbutan-2-yl) amino)-2-oxo-2,3,4,5-tetrahydro-1H-benzo[b]azepin-1-yl)acetate (4b)

Yield 12 gm, 72%, Yellow Oil. [α]D 25 – 146° (c 0.9, EtOH). IR (KBr) ν max 701, 1032, 1751, 2973, 3707 cm-1. 1H NMR (500 MHz, CDCl3), δ (ppm) 1.22 (s, 9 H), 1.82–1.89 (m, 1H), 1.94–2.06(m, 3H), 2.22–2.31 (m, 1H), 2.52–2.56 (m, 1H), 2.67–2.79 (m, 2H), 2.83–2.86 (m, 1H), 3.08–3.11 (m, 1H), 3.24–3.31 (m, 1H), 4.43 (d, J =17 Hz, 1H), 4.81 (d, J =17 Hz, 1H), 5.17 (s, 2H), 7.04–7.38 (m, 15H).13C NMR (125 MHz) δ: 28.3, 28.6, 32.0, 36.0, 38.4, 50.2, 50.3, 57.5, 62.9, 67.2, 122.6, 125.8, 127.0, 127.9, 128.3, 128.4, 128.4, 128.4, 128.6, 129.3, 135.1, 135.8, 140.4, 141.7, 168.6, 173.0, 173.8. HRMS calculated (m/z) [M+H] +: 542.2941; Found; 542.2941.

2.5 Benzyl 2-((R)-3-(((S)-1-((2-nitrobenzyl) amino)-1-oxo-4-phenylbutan-2-yl)amino)-2-oxo-2,3,4,5-tetrahydro-1H-benzo[b]azepin-1-yl)acetate (5a)

Yield 1.0 gm, 5%, Yellow Oil. [α]D 25 + 141.0° (c 0.9, EtOH). IR (KBr) ν max 699, 762, 1254, 1742, 2980, 3467 cm-1. 1H NMR (500 MHz, MeOD), δ (ppm) 1.88–1.97 (m, 3H), 2.0–2.31 (m, 1H), 2.47–2.51 (m, 1H), 2.64–2.69 (m, 2H), 3.00–3.12 (m, 3H), 4.43–4.46 (m, 1H), 4.56–4.68(m, 3H), 5.12 (q, J= 12.5 Hz), 7.11–7.46 (m, 16H), 7.95–7.97 (m, 1H). 13C NMR (125 MHz) δ:29.1, 32.9, 36.9, 38.5, 41.2, 51.4, 58.7, 62.9, 68.0, 123.5, 125.9, 126.9, 128.2, 129.0, 129.3, 129.3, 129.4, 129.4, 129.5, 130.4, 131.4, 134.7, 134.7, 136.9, 137.1, 142.0, 142.8, 149.5, 170.4, 175.5, 176.7. HRMS calculated (m/z) [M+H] +: 621.2635; Found; 621.2633.

2.6 Benzyl 2-((R)-3-(((S)-1-(tert-butylamino)-1-oxo-4-phenylbutan-2-yl) amino)-2-oxo-2,3,4,5-tetrahydro-1H-benzo[b]azepin-1-yl)acetate (5b)

Yield 1.5 gm, 9%, Yellow Oil. [α]D 25 + 140° (c 0.9, EtOH). IR (KBr) ν max 701, 1262, 1418, 1736, 2983 cm-1. 1H NMR (500 MHz, DMSO-d6), δ (ppm) 1.08 (s, 9 H), 1.63–1.73 (m, 2H), 1.90–1.97(m, 1H), 2.12–2.17 (m, 1H), 2.50–2.57 (m, 2H), 2.59–2.65 (m, 1H), 2.69–2.71 (m, 1H), 2.96–3.00 (m, 1H), 3.03–3.10 (m, 1H), 7.10–7.38 (m, 15H).13C NMR (125 MHz) δ:27.5, 28.1, 31.4, 35.4, 37.2, 49.4, 49.8, 56.4, 61.4, 66.1, 122.6, 125.6, 126.4, 127.5, 128.0, 128.1, 128.2, 128.2, 128.3, 128.4, 128.9, 135.6, 140.7, 141.9, 169.0, 172.3, 173.0. HRMS calculated (m/z) [M+H] +: 542.2941; Found; 542.2944.

2.7 Ethyl(S)-2-(((S)-1-(2-(benzyloxy)-2-oxoethyl)-2-oxo-2, 3, 4, 5-tetrahydro-1H-benzo[b]azepin-3-yl) amino)-4-phenylbutanoate (Benzyl Benazepril) (6)

A solution of compound (4a) (15 gm, 24.19 mmol, 1eq.), TFA (5.5 gm, 48.38 mmol, 2 eq.) in ethanol (60 mL) was refluxed for 5 h. The reaction was monitored using TLC (ethyl acetate/hexane, 7:3). After completion reaction, the mixture was evaporated under reduced pressure at 40–45 °C. The residue was extracted with ethyl acetate and the organic layer was washed with aqueous saturated NaHCO3 (60 mL). The organic layer was separated and dried over sodium sulphate. Organic layer was filtered and evaporated to get compound (6) as a thick yellow oil (Yield 11 gm, 77%).

Similarly, (4b) (12 gm, 22.18mmol, 1 eq.), TFA (5 gm, 44.36 mmol, 2 eq.), ethanol (60 mL) was converted to (6) using above process and (Yield 10.5 gm, 92%).

2.8 Ethyl(S)-2-(((S)-1-(2-(benzyloxy)-2-oxoethyl)-2-oxo-2, 3, 4, 5-tetrahydro-1H-benzo[b]azepin-3-yl) amino)-4-phenylbutanoate (Benzyl Benazepril) (6)

Yield 11 gm, 77%, thick yellow oil. [α]D 25 – 140° (c 0.9, EtOH). IR (KBr) ν max 738, 1026, 1186, 1667, 3030, 3435 cm-1. 1H NMR (500 MHz, CDCl3), δ (ppm) 1.14 (t, J = 7 HZ, 3H), 1.90–2.07 (m, 4H), 2.36–2.44 (m, 1H), 2.52–2.56 (m, 1H), 2.66–2.76 (m, 2H), 3.18–3.25 (m, 2H). 3.28–3.31 (m, 1H), 4.01–4.12 (m, 2H), 4.49 (d, J = 17 HZ, 1H), 4.75 (d, J = 17 HZ, 1H), 5.17 (s, 2H), 7.11 (d, J = 7.5 Hz, 1H), 7.17–7.22 (m, 5H), 7.26–7.37 (m, 8H). 13C NMR (125 MHz) δ: 14.1, 28.3, 32.0, 35.0, 37.7, 50.4, 56.9, 60.1, 60.6, 67.1, 122.3, 125.9, 126.9, 127.7, 128.3, 128.4, 128.4, 128.4, 128.6, 129.6, 135.2, 136.1, 140.7, 141.4, 168.7, 174.0, 174.1. HRMS calculated (m/z) [M+H] +: 515.2468; Found; 515.2468.

2.9 2-((S)-3-(((S)-1-ethoxy-1-oxo-4-phenylbutan-2-yl) amino)-2-oxo-2,3,4,5-tetrahydro-1H-benzo[b]azepin-1-yl)acetic acid (7): (benazepril HCl)

A solution of compound (6) (11 gm, 21.4 mmol, 1 eq.) was subjected for hydrogenation in ethanol using 10% Pd/C (2 gm) under 60 psi for 3 h at room temperature. The reaction was monitored by TLC (ethyl acetate/hexane, 7:3). After completion of the reaction, the reaction mixture was filtered over a celite bed and the bed was washed with ethanol (5 mL). The filtrate was concentrated under reduced pressure. A residue was dissolved in ethyl acetate and treated with HCl gas for 1 h to form a white slurry. It was filtered, solid refluxed in ethyl acetate and acetone (95: 5 ratio) (50 mL) for 20 min, then filtered, and dried under vacuum at 40–45 °C to get benazepril HCl (7).

2.10 2-((S)-3-(((S)-1-ethoxy-1-oxo-4-phenylbutan-2-yl) amino)-2-oxo-2,3,4,5-tetrahydro-1H-benzo[b]azepin-1-yl)acetic acid (7): (benazepril HCl)

Yield 9.0 gm, 91%, (lit 7c, d M. p. = 188–190 °C) M. p. = 185–189 °C, White Solid, (lit 7c, d [α] D = -141° (c 0.9, EtOH), [α] D 20 = -141° (c 0.9, EtOH). IR (KBr) ν max 732, 751, 1209, 1389, 1523, 1672, 1737, 2434, 3121 cm-1. 1H NMR (500 MHz, CD3OD), δ (ppm) 1.22 (t, J = 7.5 Hz, 3H), 2.24–2.29 (m, 2H), 2.39–2.65 (m, 1H), 2.69–2.79 (m, 1H), 2.80–2.87 (m, 3H), 3.32–3.37 (m, 1H), 3.93–4.0 (m, 2H), 4.13–4.24 (m, 2H), 4.62 (d, J = 17.5 Hz, 1H), 4.66 (d, J = 17.5 Hz, 1H), 7.23–7.41 (m, 9H). 13C NMR (125 MHz) δ: 14.2, 28.1, 31.8, 33.1, 34.7, 51.4, 59.0, 60.2, 63.9, 124.1, 127.6, 128.9, 129.4, 129.7, 130.7, 135.5, 141.0, 141.1, 168.2, 169.7, 171.8. HRMS calculated (m/z) [M+H] +: 425.1998; Found; 425.1998.

3 Results and Discussion

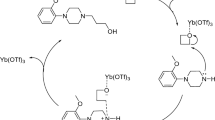

We reported the use of Ugi three-component reaction for the synthesis of quinapril HCl.3e We used these optimized conditions to design new methodology for the synthesis of benazepril HCl. A novel synthetic route designed for the preparation of benazepril HCl which began with Ugi three-component reaction involved the reaction of amine, carbonyl compound and convertible isocyanide (Figure 2).

The selection of convertible isocyanides is the key parameter to obtain the desired product in which secondary amide needs to be converted into ethyl ester to yield benazepril HCl.

Accordingly, isocyanides were chosen in Ugi reaction such that resulting amides could be easily converted into corresponding ethyl ester. The rational to choose these convertible isocyanides were its commercial availability and easy conversion of secondary amides obtained from Ugi reaction to corresponding ethyl ester.

There are many convertible isocyanides reported in the literature.4,5,6 We screened two isocyanides namely 2-nitrobenzyl isocyanide (1a),5 tertiary butyl isocyanide (1b).5b These convertible isocyanides were chosen due to their commercial availability. The conversion of secondary amides obtained from these isocyanides to the corresponding ester was achieved using sulfuric acid.5b

Initially, 2-nitrobenzyl isocyanide (1a), 3-phenylpropanal (2) and benzyl (S)-2-(3-amino-2-oxo-2, 3, 4, 5- tetrahydro-1H-benzo[b]azepin-1-yl) acetate (3) was reacted in methanol furnished major diastereomer (4a) along with minor diastereomer (5a), (dr 67:33). The reaction was completed in 40 h. The use of phosphoric acid (PPA) did not improve reaction time and yield.

The results of screening different reactions conditions are shown below Table 1.

Literature report revealed that 2,2,2, trifluoroethanol (TFE) was widely used solvent for Ugi reaction hence we thought to use TFE as a solvent for the above reaction. TiCl4 was also known for such kind of Ugi reaction. Accordingly, we conducted the reaction of 2-nitrobenzyl isocyanide (1a), 3-phenylpropanal (2) and benzyl (S)-2-(3-amino-2-oxo-2, 3, 4, 5- tetrahydro-1H-benzo[b]azepin-1-yl) acetate (3) using TiCl4 as a catalyst in 2,2,2, trifluoroethanol (TFE). The reaction was completed in 7 h yielding major diastereomer (4a) along with minor diastereomer (5a), (dr 91:9).

The enhanced reaction rate of Ugi reaction could be attributed to the formation of iminium ion by the high ionizing ability of 2,2,2, trifluoroethanol.5b This diastereomeric mixture was chromatographically separated to get chirally pure major diastereomer (4a) and minor diastereomer (5a).

The major diastereomer (4a) was subjected for esterification using TFA in ethanol to furnish ethyl (S)-2-(((S)-1-(2-(benzyloxy)-2-oxoethyl)-2-oxo-2,3,4,5-tetrahydro-1H-benzo[b]azepin-3-yl)amino)-4-phenylbutanoate (6). Debenzylation of benazepril ester (6) was carried out using 10% Pd/C and 60 psi H2 (g) in ethanol to give required benazepril HCl. (7). It was confirmed and characterized by SOR, HRMS, IR, 13C NMR, 1HNMR and Chiral HPLC.7

The spectral and analytical data of benazepril HCl (7) suggest that major diastereomer (4a) has a sense of diastereoinduction (S, S). The observed (S, S) stereoinduction of major diastereomer (4a) could be due to existing chiral center in benzyl (S)-2-(3-amino-2-oxo-2, 3, 4, 5- tetrahydro-1H-benzo[b]azepin-1-yl) acetate (3) that facilitates the stereoselective attack of isocyanide nucleophile to chiral imine which was formed in the reaction from 3-phenylpropanal (2) and benzyl (S)-2-(3-amino-2-oxo-2,3,4,5- tetrahydro-1H-benzo[b]azepin-1-yl) acetate (3).

Similarly, tertiary butyl isocyanide (1b), 3-phenylpropanal (2) and (S)-2-(3-amino-2-oxo-2, 3, 4, 5-tetrahydro-1H-benzo[b]azepin-1-yl) acetate (3) was reacted in 2,2,2, trifluoroethanol (TFE) in presence of catalyst TiCl4, gave corresponding major diastereomer (4b) along with minor diastereomer (5b) (Table 2). (dr 87:13). This diastereomeric mixture was chromatographically separated.

Major diastereomer (4b) was successfully converted to (S)-2-(((S)-1-(2-(benzyloxy)-2-oxoethyl)-2-oxo-2,3,4,5-tetrahydro-1H-benzo[b]azepin-3-yl)amino)-4-phenylbutanoate (6) by using TFA in ethanol. Subsequent debenzylation of benazepril ester (6) was carried out using 10% Pd/C and 60 psi H2 (g) in ethanol to give required benazepril HCl. (7). It was confirmed and characterized by SOR, HRMS, IR, 13C NMR, 1HNMR and Chiral HPLC.7

The spectral and analytical data of benazepril HCl (7) suggest that major diastereomer (4b) has a sense of diastereoinduction (S, S). The synthetic scheme developed for benazepril HCl is depicted in Figure 3.

Reagents and conditions: (i) 2, 2, 2 Trifluroethanol, TiCl4, Purification (ii) TFA, Ethanol (iii) Ethanol, Pd/C, Conc HCl, H2 (g) 60 psi.

4 Conclusions

In summary, we have developed a novel and efficient synthesis of ACE inhibitor, benazepril HCl using convertible isocyanides. The present method offers the following competitive advantages: i) shorter reaction time ii) higher yields.

References

(a) Zhang Y, Ao Y-F, Huang Z-T, Wang D-X, Wang M-X and Zhu J 2016 Chiral Phosphoric Acid Catalyzed Asymmetric Ugi Reaction by Dynamic Kinetic Resolution of the Primary Multicomponent Adduct Angew. Chem. Int. Ed. 55 5282; (b) Diehl A M, Ouadoudi O, Andreadou E and Manolikakes G 2018 A catalyst-free Petasis reaction of sulfonamides as amine components, glyoxylic acid, and aryl- or alkenyl boronic acids tolerates a broad range of functional groups and provides a wide array of α-amino acid derivatives Synthesis 50 3936; (c) Dömling A and Ugi I 2000 Multicomponent Reactions with Isocyanides Angew. Chem. Int. Ed. 39 3168

(a) Yu L-T, Huang J-L, Chang C-Y and Yang T-K 2006 Formal Synthesis of the ACE Inhibitor Benazepril·HCl via an Asymmetric Aza-Michael Reaction Molecules 11 641; (b) Watthey J W H (Novartis AG) 1986 Benzazepin-2-ones, process for their preparation, pharmaceutical preparations containing these compounds and the compounds for therapeutical use. EP 0072352 March 5; (c) Kumar Y, De S, Thaper R K and Kumar D S M 2002 Process for the preparation of benazepril. WO 2002076375A2, October 3; (d) Castar J, Serradell M N 1984 Drugs Fut. 9 317; (e) Chaudhuri N K, Patera R, Markus B and Sung M-S 1987 Synthesis of 14Clabeled 3-([1-ethoxycarbonyl-3-phenyl-(1S)-propyl] amino)-2,3,4,5-tetrahydro-2-oxo-1H-1-(3S)-benzazepine-1-acetic acid hydrochloride ([14C] CGS 14824A) J. Label. Compd. Radiopharm. 24 1177

(a) Godet T, Bonvin Y, Vincent G, Merle D, Thozet A and Ciufolini M A 2004 Titanium Catalysis in the Ugi Reaction of α-Amino Acids with Aromatic Aldehydes Org. Lett. 6 3281; (b) Seebach D, Adam G, Gees T, Schiess M and Weigand W 1988 Scope and limitations of the TiCl4-mediated additions of isocyanides to aldehydes and ketones with formation of α-hydroxycarboxylic acid amides Chem. Ber. 121 507; (c) Soeta T, Takashita S, Sakata Y and Ukaji Y 2016 Phosphinic acid-promoted addition reaction of isocyanides to (Z)- hydroximoyl chlorides: efficient synthesis of α-(hydroxyimino) amides Org. Biomol. Chem. 14 694; (d) Zhao W, Huang L, Guan Y and Wulff W D 2014 Three Component Asymmetric Catalytic Ugi Reaction-Concinnity from Diversity via Substrate Mediated Catalyst Assembly Angew. Chem. Int. Ed. 53 3436; (e) Borase B B, Godbole H M, Singh G P, Upadhyay P R, Trivedi A, Bhat V and Shenoy G G 2019 Application of Ugi three component reaction for the synthesis of quinapril hydrochloride Synth. Commun. 50 48; (f) Ho J Z, Gibson T S and Semple J E 2002 Novel, Potent Non-Covalent Thrombin Inhibitors Incorporating P3-Lactam Scaffolds Bioorg. Med. Chem. Lett. 12 743

(a) van der Heijden G, Jong J A W (Sjaak), Ruijter E and Orru R V A 2016 2-Bromo-6-isocyanopyridine as a Universal Convertible Isocyanide for Multicomponent Chemistry Org. Lett. 18 984; (b) Cioc R C, Preschel H D, van der Heijden G, Ruijter E and Orru R V A 2016 Trityl Isocyanide as a Mechanistic Probe in Multicomponent Chemistry: Walking the Line between Ugi- and Strecker-type Reactions Chem. Eur. J. 22 7837; (c) Park S J, Keum G, Kang S B, Koh H Y and Kim Y 1998 A Facile Synthesis of N-Carbamoylmethyl- a -aminobutyro lactones by the Ugi Multicomponent Condensation Reaction Tetrahedron Lett. 39 7109

(a) Chandgude A L, Li J and Dömling A 2017 2-Nitrobenzyl Isocyanide as a Universal Convertible Isocyanide Asian J. Org. Chem. 6 798; (b) Balalaie S, Motaghedi H, Tahmassebi D, Bararjanian M and Bijanzadeh H R 2012 A facile and efficient synthesis of 2,2,2-trifluoroethyl 2-[(E)-N-phenylcinnamamido]-2-phenylacetates in trifluoroethanol via sequential Ugi four-component reaction/esterification Tetrahedron Lett. 53 6177

(a) Nicolaou K C, Gray D L F and Tae J 2004 Total Synthesis of Hamigerans and Analogues Thereof. Photochemical Generation and Diels−Alder Trapping of Hydroxy quinodimethanes J. Am. Chem. Soc. 126 613; (b) Barbier J, Wegner J, Benson S, Gentzsch J, Pietschmann T and Kirschning A 2012 Total Synthesis of a Noricumazole A Library and Evaluation of HCV Inhibition Chem. Eur. J. 18 9083; (c) Santra S, Andreana T and Andreana P R 2016 Convertible Isocyanides: Application in Small Molecule Synthesis, Carbohydrate Synthesis, and Drug Discovery (Location: John Wiley & Sons Inc.); (c) L Le HV Fan and Ganem B 2011 A practical and inexpensive ‘convertible’ isonitrile for use in multicomponent reactions Tetrahedron Lett. 52 2209

(a) Jeffrey W, Watthey H and Chappaqua N Y 1984 3-Amino (1) benzazepin-2-one-1-alkanoic acids US4473575, September 25; (b) Jeffrey W, Watthey H and Chappaqua N Y 1986 3- Amino (1) benzazepin-2-one-1-alkanoic acids. US4575503, March 11; (c) Watthey J W H, Stanton J L, Desai M, Babiarz J E and Finn B M 1985 Synthesis and Biological Properties of (Carboxyalky1) amino-Substituted Bicyclic Lactam Inhibitors of Angiotensin Converting Enzyme J. Med. Chem. 28 1511; (d) Chang C-Y and Yang T-K 2003 Asymmetric synthesis of ACE inhibitor-Benazepril HCl via a bioreductive reaction Tetrahedron Asymm. 14 239

Acknowledgements

The authors acknowledge Lupin Research Park and Manipal Academy of Higher Education for providing the opportunity to take up this research work. Thankful to Lupin Research Park, R& D, Analytical team for supporting the analysis.

Author information

Authors and Affiliations

Corresponding author

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Borase, B.B., Godbole, H.M., Singh, G.P. et al. Use of convertible isocyanides for the synthesis of benazepril hydrochloride. J Chem Sci 133, 35 (2021). https://doi.org/10.1007/s12039-021-01892-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12039-021-01892-8