Abstract

Tellurium nanotube-based bismuth telluride (Te/Bi2Te3) nanocomposite powders have been synthesized by the polyol process using Bi (NO3)3, TeCl4 as the metal precursors, dioctyl ether as the solvent, and 1,2-hexadecanediol as the reducing agent. The synthesized nanocomposite powders showed the characteristic microstructure where many single crystalline Bi2Te3 nanoparticles are bonded on the tubular structure, which has a length of a few microns and a diameter of 200 nm. EDX results showed the nanocomposite powders consist of tubular structure of Te materials and nanoparticles of Bi with Te atoms. These results reveal that direct synthetic process for heterostructured nanomaterials of tube/nanoparticles were developed via the one-pot process without any templates or additional process. The synthesized unique structure of Te/Bi2Te3 nanocomposite powders can be utilized in thermoelectric applications due to controllable thermal and electric conductivity by combination between porous structures and nanostructuring.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Thermoelectric (TE) materials have attracted much attention due to their high efficiency of solid-state energy conversion for cooling and power-generation application in electronic devices at ambient temperature over the past decades [1]. It is well known that the performance of TE materials depends on the dimensionless figure of merit, ZT = T(α2/ρκ), where T is the absolute temperature, α is the Seebeck coefficient, and ρ and κ are the electrical resistivity and thermal conductivity, respectively. On the basis of this relationship, a reasonable combination of thermal conductivity and electrical conductivity plays an important role as critical factor in improving the ZT value. Therefore, current researches have been focusing on making nanocrystalline bismuth telluride materials to get high thermoelectric performances [2, 3]. Especially, as Hicks and Dresselhaus [4] have reported, nanosized powders are effectively utilized as raw materials for nanograined bulk samples because 1D or 2D nanostructured materials produce well-controlled Seebeck coefficients and electrical conductivity due to their characteristic quantum effects. Zhao et al. [5] showed enhanced TE performance by making nanoporous and nanostructured bulk based on bismuth telluride nanotubes, and Tang et al. [6] fabricated nanolayer-structured Bi2Te3 with reasonably high TE properties by a rapid solidification process, followed by spark plasma sintering. Representatively, it is very well known that Poudel et al. [7] demonstrated the nanostructured Bi–Te based system which has high ZT of 1.1 at 300 K. So far, most of the previous studies using thermoelectric nanopowders have focused on the fabrication of nanograined bismuth telluride bulk materials with high thermoelectric properties. In fact, these results demonstrated that lattice thermal conductivity reduction induced by the phonon-scattering effect will more efficiently occur in heterostructures, which means nanocomposites materials of different sizes or shapes. Unfortunately, unlike general approaches to make normal Bi–Te nanoparticles, rods, and even nanotubes [8], there has been little research results on such heterostructures, except for Deng et al.’s results [9], which produce a Bi2Te3 sheet on a Te rod. The solvothermal process they developed seems to be available to synthesize heterostructure of Te rods and nucleation, growth of Bi2Te3 via solution of Te, and followed by Bi2Te3 nucleation.

In this study, we develop a one-pot synthetic process to produce the bismuth telluride heterostructure in nanocomposite powder form as raw materials that can be used for a nanograined bulk. The process to synthesize Te nanotubes and Bi2Te3 particles is simply unified by using a polyol process via a chemical route. We confirm that the unique nanocomposite structures consisting of Bi2Te3 nanoparticles and Te nanotubes are simultaneously formed by the developed process, unlike Deng et al.’s solvothermal approach. We expect that synthesized Te nanotubes and Bi2Te3 nanoparticles might reduce the lattice thermal conductivity by increasing phonon scattering due to its low-dimensional and heterostructure natures.

Materials and methods

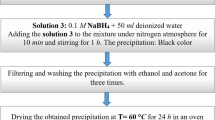

For Bi and Te source, Bi(III) nitrate pentahydrate (Bi(NO3)3·5H2O)and Te (IV) chlorides (TeCl4) were used as precursors, respectively. The 99.0% purity of dioctyl ether was used as a solvent because it has a high boiling point of about 286°C, which is available in this experiment. We mixed 5 mmol Bi(III) nitrate pentahydrate, 7.5 mmol Te (IV) chloride, 10 mmol oleylamine as a surfactant, and 80 mmol 1,2-hexadecandiol into 100 ml of dioctyl ether. The above-mentioned chemicals used in this study were purchased from Sigma-Aldrich Co. In a three-neck flask, the mixed solution was heated to the temperature of 280°C at a rate of about 10 K/min under Ar gas atmosphere. After holding at a given temperature for 120 min, the mixture was air-cooled on the mantle to room temperature. During heating, the Bi(NO3)3 and TeCl4 were reduced into Bi and Te by the added polyol reducing agents. Based on the reduction potentials of Bi of Te ions in the solvents, subsequent nucleation of the Te and Bi atoms were intended to reduce two materials subsequently from Te to Bi atoms to form heterostructures by making Te seeds. The formed bismuth telluride (Bi2Te3) powders were separated from the solution by a centrifugation process and then dispersed in 2 ml of n-hexane. The surface morphology and composition of the nanocomposite powders were characterized by field emission scanning electron microscope (FE-SEM, MIRA II LMH, TESCAN) and the diffraction pattern of the Te nanotubes and Bi2Te3 particles was collected from field emission transmission electron microscope (FE-TEM, 200 kV, JEM 2100F, JEOL). Powder X-ray diffraction (XRD) data was obtained by the model no. X’pert MPD 3040 with Cu Kα radiation.

Results and discussion

Formation of Te nanotube-based Bi2Te3 nanocomposite powders

Figure 1a, b and c shows the schematic formation procedures of Te nanotubes and nucleation and growth of Bi2Te3 nanoparticles. Tellurium (Te), an important semiconductor with a band gap of about 0.35 eV at room temperature, exhibits a large quantity of useful properties, such as nonlinear optical response, photoconductivity, and thermoelectric properties, which result in their potential applications in electronic devices [10]. It is well known that the trigonal tellurium and selenium nanowires or nanotubes could be directly nucleated and grown from their solution processes such as hydrothermal, reflux, and solvothermal without the use of a physical template due to their crystal structures consisting of extended and helical chains [10]. In our Bi and Te system, during the heating process, dissolved Bi and Te ions in dioctyl ether are formed into Te, Bi, and Bi2Te3 subsequently within the solution by the electrons supplied from 1,2 hexadecanediol, which acts as a reducing agent. The expected reaction and standard reduction potentials of ionized Bi and Te [10] in solvent could be described as follows.

Equations (1) and (2) give the information on the standard reduction potentials (E 0) determining the sequence of reduction of Bi and Te ions. E 0 of Te is higher than that of Bi, which means that Te should be reduced first, even though both elements are dissolved in a certain solvent, simultaneously. Te atoms then have the opportunity to form nanorods or nanotubes, as shown in Fig. 1b and e. According to Zhang et al.’s [11] results, the formation of a nanotube is dominant at the initial stage of chemical reaction and the nanotube is changed into the nanorod by filling the pores as time progresses until all of the Te atoms are exhausted in the solution. In our experiment, however, there are Bi atoms to form Bi2Te3 in the solution. Hence, Bi atoms seem to be subsequently formed and heterogeneously nucleated into Bi2Te3 nanoparticles on the Te nanotube surfaces as depicted in Fig. 1b and c. The SEM images in Fig. 1e show Te nanotubes formed at the initial stage of the chemical reaction without any templates. The diameter and the length of the synthesized nanocomposite powders are ranging from 100 to 200 nm and a few micrometers, respectively. Added surfactant, oleylamine played a role as inhibitors to prevent agglomeration among formed Bi/Te compounds. In general, the addition of surfactants or change of process parameters such as reaction time affects the nucleation and growth process of nanoparticles [12]. As shown in Fig. 1b, it is designed that Bi and Te atoms are precipitated within surfactant-micelle or outside. According to reaction time, Bi atoms were nucleated on the Te nanotubes acting as seeds and made the alloying of Bi2Te3, which is a rombohedral-hexagonal crystal structure, as shown in Fig. 1f. The X-ray diffraction (XRD) pattern in Fig. 2 indicates that the synthesized Te/Bi2Te3 nanocomposite powders show representatively the rhombohedral-hexagonal lattice structure of Bi2Te3 phase determined by JCPDS no. 15-0863.

Schematic illustration of a dissolved Bi and Te ions in solvent, b formation of Te nanotubes and Bi atoms nucleation, c Bi2Te3 nanoparticles attached Te nanotube, SEM morphologies of d precipitated Bi/Te compounds in the solution at 280°C after a 1-min reaction, e formed Te nanotubes at 280°C for 10-min reaction, f formed Te/Bi2Te3 nanocomposite powders as the final product at 280°C for 120-min reaction

X-ray diffraction (XRD) result of Te/Bi2Te3 nanocomposite powders as shown in Fig. 1f

Microstructures of Te/Bi2Te3 nanocomposite powders

The SEM image of Fig. 3a clearly shows the surface morphology where many nano-sized particles are periodically attached on the nanotube. It is expected that the size of nanoparticles has become large if the reaction time is enough to give the opportunity growing Bi2Te3 nanoparticle exhausting all of Bi source in the solvent. As results of EDX in Fig. 3a, the region of nanotube indicates only Te element while the 100-nm-sized particle shows both Bi and Te element, which is alloyed into Bi2Te3. Most of the powders above 90% have Te/Bi2Te3 heterostructures and approximately 5% of Te nanotubes are observed in the final product (Fig. 1f ). It is expected that all the Bi and Te materials will be changed into Bi2Te3 phases when extremely long reaction times occur. From the high-resolution TEM images shown in the inset of Fig. 3b, the nanotube region shows the hexagonal lattice structures of Tellurium and it is confirmed that the diffraction pattern of nanosized particle is corresponding to Bi2Te3 phases with (110) plane. The synthesized single Te/Bi2Te3 nanocomposite powder has diameters of a few micrometers and 100–200 nm, respectively. As Zhao et al. confirm, Te nanotubes include the structure features of both porous and low-dimensional materials, that is to say, the formation of hollow tube channels leads to a strong phonon-scattering effect like the cages in a porous compound, one-dimensional nanotubes, and two-dimensional nature. From these results, we speculate the synthesized nanocomposite powders can be effectively utilized to enhance the thermoelectric performance due to nanostructuring effect. These factors make Te nanotube-based Bi2Te3 nanocomposite powders very promising TE materials. In the near future, the effect of heterostructure consisting of Te nanotube and Bi2Te3 nanoparticles should be studied for the possibility to achieve highly enhanced TE performance.

a Morphology of single Te/Bi2Te3 nanocomposite powder, EDX results for nanotube and nanoparticle, respectively. b TEM image of single nanocomposite powder showing heterostructure of Bi/Te nanomaterials: left-upperinset reveals hexagonal crystal structure of Te nanotube and inset diffraction pattern of right-down indicates (110) of Bi2Te3 plane

Conclusions

In summary, the simplified chemical process to synthesize Te/Bi2Te3 nanocomposite powders was developed by using a polyol reducing agent. The designed one-pot process resulted in a valuable heterostructure from the formation of a Te nanotube, nucleation, and growth of Bi2Te3 nanoparticle that was investigated with the reaction time. The synthesized heterostructure showed the microstructures of Bi2Te3 nanoparticles attached to the Te nanotube surface and the formation kinetics of metal salt reduction could be explained by difference of standard reduction potentials (E 0) of the ionized Bi and Te salt in the solvent. We expect that these heterostructured Te/Bi2Te3 nanomaterials are useful for unique thermoelectric building blocks to obtain advanced TE materials with high thermoelectric figure-of-merit.

References

R. Venkatasubramanian, E. Silvola, T. Colpitts, B. O’Quinn, Nature 413, 597–602 (2001)

M. Toprak, Y. Zhang, M. Muhammed, Mater. Lett. 57, 3976–3982 (2003)

X.A. Fan, J.Y. Yang, R.G. Chen, W. Zhu, S.Q. Bao, Mater. Sci. Eng. A 438–440, 190–193 (2006)

L.D. Hicks, M.S. Dresselhaus, Phys. Rev. B 47, 12727 (1993)

X.B. Zhao, X.H. Ji, Y.H. Zhang, T.J. Zhu, J.P. Tu, X.B. Zhang, Appl. Phys. Lett. 86, 062111 (2005)

X. Tang, W. Xie, H. Li, W. Zhao, Q. Zhang, Appl. Phys. Lett. 90, 012102 (2007)

B. Poudel, Q. Hao, Y. Ma, Y. Lan, A. Minnich, B. Yu, X. Yan, D. Wang, A. Muto, D. Vashaee, X. Chen, J. Liu, M.S. Dresselhaus, G. Chen, Z. Ren, Science 320, 634–638 (2008)

Y.Q. Cao, T.J. Zhu, X.B. Zhao, J. Alloy Compd. 449, 109–112 (2008)

Y. Deng, C.W. Cui, N.L. Zhang, T.H. Ji, Q.L. Yang, L. Guo, J. Solid State Chem. 179, 1575–1580 (2006)

Chemical Rubber Company, Handbook of Chemistry and Physics, 90th edn. (Chemical Rubber Company, Cleveland, OH, 2007)

H. Zhang, D. Yang, X. Ma, D. Que, J. Crystal Growth 289, 568–573 (2006)

A. Sarkar, S. Kapoor, T. Mukherjee, Res. Chem. Intermed. 35(1), 71–78 (2009)

Acknowledgments

This study was supported by a grant from the Fundamental R&D Program for Core Technology of Materials funded by the Ministry of Knowledge Economy (MKE), Republic of Korea.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, K.T., Kim, DW. & Ha, G.H. Direct synthesis of Te/Bi2Te3 nanocomposite powders by a polyol process. Res Chem Intermed 36, 835–841 (2010). https://doi.org/10.1007/s11164-010-0188-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-010-0188-4