Abstract

Peroxidases are ubiquitously found in all vascular plants and are promising biocatalysts for oxidization of wide range of aromatic substrates including various industrial dyes. Peroxidases can catalyze degradation of chemical structure of aromatic dyes either by precipitation or by opening the aromatic ring structure. Both soluble and immobilized peroxidases have been successfully used in batches as well as in continuous processes for the treatment of aromatic dyes present in industrial effluents. Plant peroxidases are stable catalysts that retain their activities over a broad range of pH and temperatures. The performance of an enzyme for degradation process depends upon the structure of dyes and the operational parameters like concentration of enzyme, H2O2 and dye, incubation time, pH, and temperature. Recalcitrant dyes can also be mineralized by plant peroxidases in the presence of redox mediators. Thus, plant peroxidases are easily available, inexpensive, and ecofriendly biocatalysts for the treatment of wastewaters containing a wide spectrum of textile and non-textile synthetic dyes. This article reviews the recent developments in isolation and characterization of plant peroxidases and their applications for bioremediation of synthetic dyes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Peroxidases (EC1.11.1.7; hydrogen-peroxide oxidoreductases) are the heme-containing glycoproteins that catalyze the oxidation of different substrates such as aromatic amines, phenols, polyaromatic hydrocarbons (PAHs), etc., in the presence of hydrogen peroxide [1]. Peroxidases are present in almost all vascular plants and are assumed to be involved in wide range of physiological phenomena including cross-linking of cell wall polysaccharides [2, 3], wound healing, defense mechanisms against pathogens, scavenging of H2O2 from cytosol and chloroplast [4], detoxification of heavy metals and reactive oxygen species during oxidative stress and cellular metabolic processes [5, 6], and biodegradation reactions [7]. Plant peroxidases have been exploited for various commercial applications due to their wide substrate specificity and extensive bio-catalytic activities [8]. They have been applied in fluorescent sensors [9], clinical diagnostics [8], and in food manufacturing industry ([10]. They are also involved in air pollution damage control [11] and bio-bleaching processes [12]. Moreover, they have potential for soil detoxification, biotransformation of organic compounds, removal of phenolics and aromatic amines from polluted water and water-miscible organic solvents. The abilities of soluble and immobilized peroxidases for decolorization and removal of synthetic dyes from dye-contaminated water and industrial effluents have also been reported [8].

Dye-contaminated wastewater discharging from various industries like dye manufacturing, textile processing, cosmetics, food processing, leather, and paper is becoming a major source of water pollution [13]. In fact, synthetic dyes have become an integral part of our lives as these are being extensively used in various products ranging from clothes to leather accessories to furniture to meet the fashion demands of modern lifestyle [14]. However, the extensive use of these dyes is problematic as 12 % of the total dye used is released into industrial effluents without any treatment and detoxification. Approximately 280,000 t/year of dyes are discharged into the water bodies all over the world [15]. The average concentration of dye in textile industry effluents has been reported as 300 mg/l [16]; however, the colors are highly visible at a dye concentration of more than 1 mg/l and thus affecting the transparency, gas solubility, and esthetic merit of contaminated water. Moreover, these dyes are mutagenic and carcinogenic in nature due to their synthetic origin and complex aromatic structures [17] and are hazardous to aquatic life. The untreated dye-containing effluents are also being directly used in agriculture that is a route for residual dyes to get entry into the food chain that has serious implications on plants, animals, and human life.

Various techniques have been applied to remove dyes from industrial wastewaters prior to their release into the wastewater streams and the aquatic environment. These techniques include microbial [18] photolytic [19], photocatalytic [20], bioremediation, and various traditional treatments [21]. All these methods have some advantages, disadvantages, and financial and environmental impacts. The physicochemical methods (sedimentation, flocculation, coagulation, membrane filtration, ozonation, and adsorption) are expensive and mostly require the use of environmentally hazardous chemical substances and in most cases generate large amounts of sludge that needs an additional treatment for safe disposal. Conventional biological methods, such as activated sludge are ineffective in dye treatment because most of the dyes pass through these treatment plants without undergoing any structural changes [22]. The treatment of dyes by fungal cultures is effective but it requires a long time for complete dye mineralization [23]. Among all these options, the development of a balanced chemical and biochemical approach to transform the pollutants into less toxic compounds is one of the most effective solutions.

The enzymatic treatments have attracted much attention as cost effective and environment-friendly techniques for detoxification of dye-contaminated industrial effluents [24–26]. Enzymes are also recyclable for use in repeated industrial batch operations. The peroxidases are stable, extremely efficient in milder reaction conditions, and non-selective in their catalytic action. Moreover, these enzymes can work on a wide range of substrates and can also catalyze the degradation of organic pollutants present in a very low concentration at the contaminated sites [27–29]. The application of peroxidases for treatment of textile dyes provides a more practicable system, with a number of advantages including (a) a very simple system with minimal requirements of chemicals, (b) cost-effective and ecofriendly system, (c) stable enzyme, and (d) short treatment times [22]. Moreover, peroxidases can be used for treatment of wider spectrum of aromatic dyes and can degrade/transform their heterocyclic structures by opening the complex aromatic rings [30]. This article will provide a literature review and developments on isolation, characterization, and applications of plant peroxidases with special emphasis on bioremediation of industrial dyes and effluents.

Characterization of Peroxidases

Peroxidases are ubiquitous enzymes that exist in almost all higher plants and perform several biological functions. The multiple functions of peroxidases are due to the presence of their many isozymic forms. The first plant peroxidase was characterized from horseradish [31], and subsequently different peroxidases have been isolated, purified, and characterized from many plants including cauliflower, radish, potato, oil palm, vanilla bean, royal palm, date palm, black gram, olives, strawberries, soybean, turnip, and bitter gourd [32–39]. Their activity largely depends upon environmental factors like pH and temperature and the presence of redox mediators.

Effect of pH

The activity of peroxidase is significantly affected by conformation of enzyme active site because enzymes initiate their catalytic actions by physically and chemically attaching the substrate at their active sites, and the shape of active site are, therefore, of vital importance. Any fluctuation in pH is expected to cause change in the shape of enzyme active site by changing ionic state of amino acids and thus leading to enzyme activity loss [40]. De Leonardis et al. [34] purified an ascorbate peroxidase (APX) from potato tuber and examined the effect of pH on peroxidase activity in a pH range from 5.5 to 9.5. A broad pH optimum was observed at approximately pH 7 for the APX. The optimum pH of potato and Jatropha curcas leaves peroxidases for different substrates (such as guaiacol, ABTS, catechol, ferulic acid, pyrogallol, O-phenylenediamine, O-dianisidine) has been reported in pH range of 3.5–5.5, except for pyrogallol and ABTS [37, 41]. A sharp decline in activity for each substrate at pH other than the optimal range indicated the preference for acidic medium. The optimum pH for oil palm leaf peroxidases (POD) with guaiacol as a substrate has been found at pH 5.0 which indicated that the enzyme can work better in an acidic medium [35]. Leucaena leucocephala legume peroxidase was stable over a pH range of 4.5–7.0, with optimum pH 5 [5]. However, the enzyme activity reduced significantly at pH lower than 3 and higher than 8.8. The pH effect on two cationic peroxidases (SmaPrx2 and SmaPrx3) from Selaginella martensii has also been reported [42]. The SmaPrx2 activity decreased sharply with increase in pH and the enzyme became inactive at pH above 6.0. SmaPrx3 also showed maximum activity at pH 5.0; however, it remained active over a wider pH range.

The isoenzymes, mPOD I and mPOD II membrane-bound peroxidases (mPOD I and mPOD II), from Metroxylon sagu also had pH optima at 6.0 and 5.5, respectively [43] with guaiacol substrate. Similarly, peroxidase from peels of Citrus reticulata var. showed maximum activity at pH 6.0 [44] and the peroxidase from a local chick pea cultivar showed maximum activity at pH 5.5 [45].

Two peroxidase fractions, anionic (Px-ani) and cationic (Px-cat), from spring cabbage heads had same optimum pH 6.0. Px-cat fraction showed almost equal activity at neutral pH (7.0) suggesting that Px-cat fraction was stable in neutral pH range [46]. Red cabbage (Brassica oleracea var. capitata f. rubra) also exhibited a maximum activity at pH 7.0 [47]. Similarly, the optimum pH of Camellia sinensis peroxidase was 6.5 [48]. The peroxidase from black gram husk [39], date palm [38], and cauliflower (B. oleracea L. var. botrytis) leaves [32] showed optimum activities at pH 5.5. Similarly, peroxidase from pearl millet hybrid HHB exhibited maximum activity at pH 5.6 [49].

A purified cationic peroxidase (CysPrx) from the leaves of artichoke and an anionic peroxidase POIII from horseradish cv. showed more than 50 % of activity at broad range of pH from 4.0 to 8.0 with optimum pH 5.5 using guaiacol as a substrate [4, 50]. Above and below this pH, the enzyme activity decreased because pH changes the ionization state of amino acids of enzymes. The loss of enzyme activity at low pH might result from the instability of heme attachment to the enzyme. Also at high pH, decrease in activity might be the result of commutative effect of denaturation of protein and changes in ionic state of heme group. Contrary to the above findings, Márquez et al. [36] reported an acid peroxidase from vanilla bean. The enzyme exhibited optimum activity at an acidic pH of approximately 3.8, suggesting that the enzyme may be present in an acidic environment of the cell, such as vacuoles. The enzyme activity decreased gradually with an increase in pH up to pH 7 and total activity loss was observed at pH 9.0. Similarly, the peroxidase from avocado showed an optimum activity at pH 3.8 [51]. The two acidic peroxidase isoforms from the sheaths of bamboo shoots had same optimum pH of 4.5 [52]. The purified Cocos nucifera isoenzymes TCWP1 and TCWP2 exhibited their maximal activities at pH 4.5 and 5.0, respectively [53]. Optimum activities using guaiacol as the hydrogen donor were obtained for sweet corn at pH 4.8 and for waxy corn at pH 6.0 [54]. Peroxidase from Citrus medica leaf was found to be active in wide range of pH (5.0–8.0). However, the enzyme showed optimum activity at pH 6.0 [55]. The optimum pH of Zizania latifolia peroxidase was also found to be 6.0 [56]. Peroxidase from garlic bulb (Allium sativum L.) showed an optimum activity at pH 5 [57]. Peroxidase from papaya (Carica papaya) fruit exhibited maximum activity at pH 7.0 [58].

In the light of available information, it can be concluded that most of the plant peroxidases are acidic in nature showing maximum activities within the pH range of 3.5 to 5.5. However, some plant peroxidases have their optimum activity in neutral medium and only a few in slightly alkaline medium.

Effect of Temperature

The performance of enzyme is generally affected by temperature. With an initial increase in temperature, the enzyme activity increases because, on one hand, the enzyme active site assumes its more favorable conformation and, on the other hand, the kinetic energy of the molecules increases leading to enhanced interaction between enzyme active sites and substrate molecules, until an optimum temperature value reaches at which the enzyme shows a maximum activity. However, with further increase in temperature, the enzyme activity starts decreasing due to denaturation and disruption of the three-dimensional conformation of enzyme molecule, thus inducing changes in enzyme active site that will no longer accept the substrate in optimal fashion.

Different plant peroxidases are optimally active in different temperature ranges and their thermal stabilities are also considerably variable, depending on their amino acid composition and three-dimensional conformation. Various cold active, mesophilic, and thermostable peroxidases have been isolated from different plant sources. Lucerne root peroxidases showed different temperature optima with different substrates such as 2,7-diaminofluorene (DAF), pyrogallol, and guaiacol. The optimum temperature for DAF was lower (35 °C) than those for guaiacol and pyrogallol (60 °C) [59]. The peroxidase from peels of C. reticulata var. showed maximum activity at 60 °C [44]. Optimum temperature for olive peroxidase was 34.7 °C [60] and from anionic horseradish peroxidase, it was 40 °C [50]. The optimum temperature of Z. latifolia peroxidase was 40 °C [56]. Peroxidase from garlic bulb (A. sativum L.) showed optimum temperature in the range of 25 to 40 °C [57]. Similarly, the peroxidase from papaya (C. papaya) fruit exhibited a maximum activity at 40 °C [58].

The peroxidase from a local chick pea cultivar showed maximum activity at 45 °C [45]. Red cabbage (B. oleracea) showed a maximum activity at 30 °C [47]. Similarly, the peroxidase from pearl millet hybrid HHB [49] and C. sinensis peroxidase [48] exhibited maximum activities at 30 °C. Peroxidase from C. medica leaf showed optimum activity at 50 °C; however, the enzyme was active in wide range of temperature (30–80 °C) [55]. Peroxidase from avocado showed optimum activity at 51 °C [51]. The cauliflower (B. oleracea L. var. botrytis) leaves peroxidase is optimally active at 50 °C [32] and peroxidases isolated from Eupatorium odoratum [61] and tree legume L. leucocephala [5] show optimal catalytic activity at 55 °C. A peroxidase purified from date palm leaves also had optimum activity at 55 °C but the enzyme was thermostable and active up to 80 °C [38]. A peroxidase from leaves of J. curcas exhibited maximum activity at 60 °C and was found to preserve more than 90 % of its optimum activity at broad range of temperature from 55 to 75 °C [41].

Márquez et al. [36] isolated a cold-active peroxidase from vanilla bean which showed maximum activity at 16 °C and retained 78 % of its maximum activity at 5 °C. The two isozymes, POX-I and POX- II, from buckwheat seed had 30 and 10 °C as their optimum temperatures, respectively [62]. However, the two fractions of peroxidase, anionic (Px-ani) and cationic (Px-cat), from spring cabbage heads were optimally active at same 40 °C temperature [46]. The optimum temperatures for function of two acidic peroxidase isoforms from the sheaths of bamboo shoots were 55 and 45–55 °C, respectively [52]. The purified C. nucifera isoenzymes TCWP1 and TCWP2 exhibited its maximal activity at 40 °C [53].

In conclusion, the peroxidases isolated from different plant species have different temperature optima ranging from 5 to 60 °C; however, most of above plant peroxidases showed an optimum temperature within the range 30 to 60 °C.

pH and Thermal Stability

The pH and thermal stabilities of peroxidase are very important characteristics of peroxidases that determine their usefulness and suitability in diverse industrial processes [37]. The pH and thermal stability curves for different enzymes are highly variable depending upon the extent of hydrogen, ionic, covalent, and hydrophic interchain and/or intrachain bonds formed between the R-groups of amino acids present in their chemical structures. The protein melting temperature of horseradish peroxidase was found to be 69 °C [63]. The peroxidase from a local chick pea cultivar retained 50 % activity at temperature 68 °C [45]. Peroxidase from black gram husk was also stable up to 70 °C for 10 min at pH 5.5 [39] and oil palm peroxidase was quite stable and retained more than 90 % of its original activity up to 80 °C for 60 min in alkaline pH range [35]. Vanilla bean peroxidase was very versatile catalyst as it was stable at highly alkaline pH 12 even after incubation for 26 h at low temperatures of 4–15 °C, and it also showed thermal stability at 70 °C after 1 h incubation at pH 7 [36].

Peroxidase from Raphanus sativus was stable in pH 4–7 range after incubation for 24 h and at 40 °C temperature for 60 min [64]. Peroxidase from E. odoratum was also stable enzyme with half-life (at 50 °C) of around 34 h [61]. A moderate thermally stable peroxidase was reported from olives, showing 60 and 85 % decrease in activity by incubating at 40 °C for 5 and 10 min, respectively [60].

The four peroxidases from the roots of Withania somnifera were stable in the range of pH from 3–9 and at 60 °C after 5-h incubation [65]. However, the temperature stabilities of two isoenzymes (POX I and POX II) from buckwheat seed were very low. POX I was stable up to 30 °C) after incubation for 4 h and lost most of its activity at temperatures above 40 °C, whereas POX II was stable at 0 to 20 °C after 4 h and became unstable at 30 °C and the two peroxidases were denatured at temperature 60 and 50 °C, respectively [62]. However, a cationic peroxidase from artichoke leaves was stable from 5–45 °C temperature range after 10-min incubation [4].

An anionic peroxidase from horseradish cv. Balady roots was found to show reasonable thermal stability and preserved 87, 51, and 29 % of its maximum activity after 15-min incubation at 50, 60, and 70 °C, respectively [50]. Bitter gourd peroxidase retained 50 % of its maximum activity after 60-min incubation at 60 °C and showed pH stability in alkaline pH range [8]. Peroxidase from the leaves of J. curcas was reported to show unusual stability under high temperature and extreme pH conditions. The enzyme retained 70 % of its original activity after incubating at 70 °C for 1 h and more than 93 % of maximum activity was observed after 2-h incubation under wide range of pH from 3–12 [41]. The pH and thermal stabilities of date palm peroxidase were observed in 4.0–8.0 pH range at 75 °C for 60 min [38]. The C. sinensis peroxidase was thermostable showing activity up to 60 °C [48]. Peroxidase from pearl millet hybrid HHB 94 was significantly more stable in the pH range of 6.0–6.8 and at temperature below 35 °C [49]. The peroxidase enzyme, extracted from vegetable sources radish, tomato, turnip, and cabbage was found to be stable at an optimum temperature range of 55–65 °C and at an optimum pH of 6–6.5 [66]. Peroxidase from fresh-cut Z. latifolia was stable in the pH range 4.0–7.0 while retained only 2.21 % of the activity after 1 min at 60 °C [56]. The two acidic peroxidase isoforms from the sheaths of bamboo shoots were stable between 30 and 60 °C [52]. The purified C. nucifera isoenzymes TCWP1 and TCWP2 were stable up to 50 °C for 1 h [53]. Peroxidase from garlic bulb (A. sativum L.) extract appeared highly stable since 50 % of its activity was retained at 50 °C for 5 h [57]. The Viscum angulatum peroxidase is highly thermostable and retains partial activity even after an 80 °C treatment for 10 min [67].

From the above discussion, it is concluded that the peroxidase from different plant species showed thermal stability within the range of 40 to 80 °C. The peroxidase from one plant species was found to be thermally stable at 20 °C. However, most of the plant peroxidases are highly thermostable showing stability at 70 °C. The peroxidases isolated from different plant species showed pH stabilities at different pH ranging from 4–12.

Effect of Substrates

Enzymes show different catalytic activities on various substrates depending upon the chemical nature, chemical composition, and structure of the substrates. The kinetic constants like Michaelis-Menton constant (K m; affinity of the enzyme to its substrate) and maximum activity (V max) of an enzyme are different for specific substrates. Lower K m and higher V max of an enzyme for a particular substrate reflect that the enzyme has more affinity for that substrate and is having high catalytic efficiency. The values of these constants for an enzyme on a given substrate are very useful indicators for its application in a particular industrial process that utilizes that substrate.

For example, the apparent K m values for two peroxidase fractions cationic (Px-cat) and anionic (Px-ani) from spring cabbage were found to be different for four different substrates. For Px-cat fraction, the apparent K m values were the following: 0.357 mM (for O-dianisidine), 6.41 mM (for guaiacol), 0.0377 mM (for ABTS), and 0.121 mM (for H2O2 with ABTS), and for Px-cat fraction, the apparent K m values were the following: 0.286 mM (for O-dianisidine), 13.89 mM (for guaiacol), 0.0625 mM (for ABTS), and 0.078 mM (for H2O2 with ABTS). The study revealed that the Px-cat and Px-ani has low affinity toward guaiacol and both of the fractions showed highest affinity for ABTS [46]. The values of K m of an anionic peroxidase from horseradish cv. Balady roots using H2O2 and guaiacol as the substrate were 3.3 and 16.4 mM, respectively, and the catalytic efficiency V max was 0.69 and 0.71 U/ml for H2O2 and guaiacol, respectively [50]. Whereas the K m value of oil palm leaf peroxidase for guaiacol, ABTS, and pyrogallol were 3.96, 1, and 0.84 mM, respectively [35] and vanilla bean peroxidase had nearly the same K m (3.8 mM) for guaiacol [36]. The K m and V max values of a peroxidase from peels of C. reticulata var. using guaiacol as substrate were 0.66 mM and 380 μmol/ml/min [44]. The K m values for the two isozymes, POX I and POX II, from buckwheat seed were found to be different for various substrates. The K m values of POX I and II for quercetin are (0.071 and 0.028 mM), ABTS (0.016 mM for POX II), ascorbic acid (0.043 and 0.029 mM), O-dianisidine (0.229 and 0.137 mM), and for guaiacol (0.288 and 0.202 mM). The data revealed that the POX II had higher affinity than POX I for all of the substrates. The POX I did not react with ABTS. Further, POX I and II had lower K m values for quercetin, ascorbic acid, and ABTS than for O-dianisidine and guaiacol [62], and K m values of date palm leaves peroxidase for guaiacol and H2O2 were 0.77 and 0.045 mM, respectively [38]. The K m values for J. curcas peroxidase were determined for six substrates. The results showed that among these six substrates, guaiacol, ABTS, and o-phenylenediamine showed high affinity toward J. curcas peroxidase with the K m values of 0.17, 0.19, and 0.67 mM, respectively, while the K m values of other substrates O-dianisidine (2.45 mM), pyrogallol (7.36 mM), and ferulic acid (8.48 mM) were 15- to 50-fold higher than that of guaiacol, indicating a relatively low affinity [41]. The K m values of a tree legume L. leucocephala peroxidase with guaiacol and H2O2 were found to be 2.9 and 5.6 mM, respectively [5].

The K m and V max for the two peroxidase isoezymes (mPOD-I and mPOD-II) from M. sagu were determined for selected monophenols (guaiacol and p-cresol), diphenols (chlorogenic acid, catechin, epicatechin, catechol, and 4-methylcatechol), triphenol (pyrogallol) and TMBZ. The results showed that The K m and V max for the two peroxidase isoezymes (mPOD-I and mPOD-II) from M. sagu using guaiacol indicated that the enzymes were not that efficient. The higher K m values (32.2 and 22.9 mM) for the two peroxidase isoezymes (mPOD-I and mPOD-II, respectively) from M. sagu using guaiacol indicated that the enzymes were not that efficient. However, the K m values of H2O2 are significantly low (0.08 and 0.06 mM for mPOD-I and mPOD-II, respectively) for both isoenzymes that revealed a strong hydrophobic interactions between the substrate and the heme group at the enzyme active site. However, in terms of catalytic efficiency (V m /K m ), mPOD-I was found to follow the order: TMBZ (134) > chlorogenic acid (75.6) > epicatechin (5.5) > catechin (3.4) > guaiacol (3.1) > pyrogallol (2.1) > 4-methylcatechol (1.4) > catechol (1.1). With mPOD-II, the efficiencies for different substrates showed a slightly different order: TMBZ (237) > chlorogenic acid (98.2) > pyrogallol (11.4) > epicatechin (4.7) > guaiacol (4.4) > catechin (3.6) > 4-methylcatechol (2.5) > catechol (1.1). High values of catalytic efficiencies of chlorogenic acid, catechin, and epicatechin oxidations by mPOD were due to their low K m values and thus having high affinities for peroxidase [43].

The K m and V max for cauliflower peroxidase in guaiacol oxidation were found to be 7.14 mM and 204.1 μ M/min [32] and for R. sativus peroxidase, the corresponding values were 0.25 mM and 90.90 U/min, respectively [33]. For guaiacol substrate, the K m and V max values of red cabbage (B. oleracea var. capitata f. rubra) were found as 0.048 mM and 1.46 EU/ml/min, respectively [47]. K m and Vmax values of C. sinensis peroxidase were 0.01 mg/ml (0.04 mM) and 0.03 mg/ml (0.12 mM), respectively [48]. For guaiacol, K m values for sweet corn POD and waxy corn POD were 11.01 and 23.01 mM, respectively [54]. The K m value of C. medica leaves peroxidase with guaiacol was found to be 8 mM [55]. The K m value of Z. latifolia peroxidase for guaiacol was 10 mM [56]. The K m value for C. nucifera peroxidase isoenzymes TCWP1 and TCWP2 were determined to be 1.63 and 4.0 mM, respectively [53]. The apparent K m values of peroxidase from garlic bulb (A. sativum L.) extract for guaiacol and H2O2 were 9.5 and 2 mM, respectively [57].

In the light of above discussion, K m for different substrates has been shown to vary depending upon the source of the peroxidase and the type of substrate used.

Effect of Metal Ions

Different peroxidases require different metal ions as their prosthetic groups or activators to perform their role as oxidative agents. Al-Senaidy and Ismael [38] reported the effect of different metal ions on the date palm peroxidase activity. The metal ions Ca2+, Mg2+, Mn2+, Zn2+, and Fe2+ enhanced the enzyme activity whereas enzyme was slightly inhibited by Cd2+ ions. No change in activity was observed with Al3+, Cu2+, Na+, and K+ ions. Black gram husk peroxidase was found to be stimulated by Ca2+ Zn2+, Li+, Mg2+, Ba2+, Ca2+, and Fe3+ ions at 5 mM and moderately inhibited by Mn2+, Cd2+, Al3+, Na+, and K+ ions [39]. The activity of J. curcas peroxidase was enhanced by Pb2+, Zn2+, and Cu2+ and inhibited by Ba2+ ions. A very low inhibition was observed with Mn2+ and Mg2+ whereas Al3+, Ni2+, Co2+, Li+, and Cd2+ showed no significant effect on peroxidase activity [41].

The effect of metal ions on the activities of two peroxidase isoenzymes (mPOD-I and mPOD-II) from M. sagu has also been reported [43]. Al3+, Fe3+, Ca2+, and Ni2+ enhanced the activity of mPOD-I better than mPOD-II, while Mg2+, Hg2+, and Cu2+ had no significant stimulatory influence on either isoenzyme activity, whereas both isoenzymes were moderately inhibited by Zn2+ and Co2+. However, Cu2+, Mg2+, and Ca2+ showed a little inhibitory effect on vanilla bean peroxidase while Hg2+ and Fe2+ had significant inhibitory effects [36]. Contrary to that, the horseradish cv. Balady peroxidase was stimulated by Fe3+ and inhibited by Cu2+, Ca2+, Zn2+, and Hg2+[50]. No remarkable increase or decrease in peroxidase activity was observed in cauliflower peroxidase by most of the metal ions. However, Hg2+ slightly decreased the peroxidase activity while all other metal ions showed no significant effect on cauliflower peroxidase activity [32, 68]. Peroxidase from pearl millet hybrid HHB 94 activity was enhanced by Ca2+ and Fe3+ [49]. The C. medica leaves peroxidase was activated by some metals such as Ca2+, Cu2+, Mg2+, and Co2+, while it was inhibited by Fe2+, Zn2+, Hg2+, and Mn2+[55]. Metals ions such as Cu+, Fe2+, and Mn2+ had weak inhibitory activity on purified avocado peroxidase [51]. The activity of C. nucifera peroxidase isoenzymes TCWP1 and TCWP2 were enhanced with the addition of 1 mMMn2+ [53]. Zn2+, Hg2+, Mn2+, Co2+, and Al3+ slightly inhibited the activity of local chick pea cultivar peroxidase while Mg2+ and Ca2+ had no effect on enzyme activity [45]. Metal ions like Mg2+, Mn2+, Cd2+, Cu2+, and Al3+ enhanced the activity of peroxidase from peels of C. reticulata var. whereas Co2+, Cr3+, Hg2+, Ca2+, Pb, Zn2+, Sr2+, and Ni2+s slightly inhibited the enzyme activity [44].

Peroxidase-Mediated Degradation of Dyes

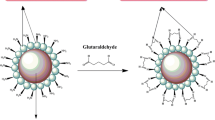

In the early 1980s, scientists have developed an idea of using oxidoreductases for the treatment of water contaminated by aromatic pollutants [24]. The major oxidoreductases are peroxidases that have great potential in treating a wide spectrum colored compounds [27, 68, 69]. During the past two decades, a lot of research has been done to develop methods based on plant peroxidases for treatments of dyes. Peroxidases from different plant species such as horseradish, Momordica charantia, turnip, cauliflower bud (B. oleracea), soybean, tomato, white radish, Saccharum uvarum, potato (Solanum tuberosum), Trichosanthes diocia have been isolated and effectively used for degradation of both azo and non-azo dyes [70, 71].

All peroxidases share the same mechanism of catalysis in which the heme groups are the main constituents and are responsible for catalyzing the reactions in the presence of hydrogen peroxide. The heme part is attached to His 170 (the so-called proximal histidine) of the enzyme [72]. Where the iron is five coordinated to the four pyrrole nitrogen of the heme and side chain N atom of proximal histidine [5]. The sixth coordination position of iron is free that determines the high spin state of iron in native form [73, 74] but available to H2O2 during enzyme catalysis [75]. The mechanism involved multistep reactions. The first step of this catalytic cycle is the reaction of hydrogen peroxide with Fe(III) resting state of peroxidase. H2O2 oxidizes the enzyme to compound I and itself reduces into water [73]. Compound I is two oxidizing equivalents above the resting state and contains an oxoferryl (Fe(IV) = O) center and a porphyrin cationic radical. Compound I undergoes one electron reduction by an electron donor substrate and generates a compound II and a substrate radical. Compound II is one oxidizing equivalent above the resting state in which cationic radical is reduced to its resting state while the Fe(IV) oxoferryl specie remains intact [75]. Finally, the second substrate molecule reduces the compound II to the native state of enzyme Fe(III) [76].

The resulting substrate radicals may undergo non enzymatic reactions (e.g., radical coupling steps) to generate various products like dimers, trimers, and higher oligomers that may take part in subsequent turnovers as reducing substrates [75].

Factors Affecting the Peroxidase-Mediated Degradation of Dyes

The rate and efficiency of degradation process highly depends upon the number of operational parameters as well as structure of dye molecule. The effect of various parameters such as pH, temperature, reaction time, concentration of dye, enzyme, and hydrogen peroxide has been studied by many scientists to optimize the degradation process.

Effect of pH

Enzyme-mediated degradation of dyes is significantly affected by pH. Thus, studies were carried out to optimize this parameter and optimum pH for the removal of dyes has been reported for many peroxidases. Mohan et al. [77] investigated the optimum pH for degradation of Acid Black 10 BX (20 mg/l) catalyzed by horseradish peroxidase. The study revealed that the maximum degradation occurred at pH 2 and a continuous decrease in degradation was observed with an increase in pH from 3 to 9. Jamal et al. [71] studied the effect of pH range (2–10) on decolorization of Disperse Red 19 and Disperse Black 9 catalyzed by T. diocia (pointed gourd) peroxidase. An acidic range of pH (3.0–6.0) was observed to be better suited for decolorization of both dyes with maximum decolorization at pH 4.0 (optimum pH). The decolorization of dyes was completely ceased in an alkaline medium. Similarly, the Reactive Red 2, Disperse Black 9, Reactive Blue 4, Reactive Black 5, and Disperse Orange 25 showed significant decolorization with cauliflower bud peroxidase in the pH range of 3–7; however, all these dyes were decolorized maximally at pH 4 [78]. The maximum decolorization of Drimarene orange KGL dye was also observed to be at pH 4.0 by orange peroxidase [79]. The decolorization of Basic violet 3 dye catalyzed by Citrus limon (lemon) peroxidase was found to be maximum at pH 4.5 [80]. In another report, Jamal et al. [81] examined the effect of pH on percent decolorization of Reactive Blue 15, Reactive Orange 15, Reactive Red 4, Reactive Yellow 2, Disperse Red 19, Disperse Yellow 7, Disperse Black, and Disperse Orange 15 mediated by T. diocia peroxidase. All the dyes showed significant decolorization in acidic range. Maximum decolorization of Disperse Red 19, Disperse Yellow 7, Disperse Black, and Disperse Orange 15 was achieved at pH 4 and Reactive Blue 15, Reactive Orange 15, Reactive Red 4, and Reactive Yellow 2 showed maximum decolorization at pH 5. However, significant decrease in percent decolorization was observed in an alkaline medium. Akhtar et al. [69] determined the effect of pH on bitter gourd peroxidase-mediated decolorization of Reactive Orange 86, Reactive Blue 4, Reactive Orange 4, Reactive Blue 160, Reactive Red 120, Reactive Red 11, Reactive Yellow 84, and Reactive Blue 171. Most of the dyes showed maximum decolorization in the pH range of 3.0–4.0 and the decolorization decreased in all the dyes with the increase in pH up to 6. However, a slightly increase in the decolorization was observed at pH 7.0. For degradation of Remazol blue, the horseradish peroxidase activity was observed to be maximum at pH 2.5 [27] while the best pH for horseradish peroxidase-mediated degradation of Disperse Red 343 was found to be 5 [82]. Maximum degradation of Remazol Turquoise Blue G 133) using the soybean peroxidase was obtained at an acidic pH 3.3 [83]. Matto and Husain [84] treated the four direct dyes, Direct Red 23, Direct Red 239, Direct Blue 80, and Direct Yellow 4, with salt-fractionated turnip (Brassica rapa) peroxidase in the buffers of different pH values in the presence of redox mediators, 1-hydroxybenzotriazole/violuric acid (HOBT/VA). All the dyes were maximally decolorized within the pH range from 5.0 to 5.5. In another study Matto and Husain [85] investigated the effect of pH on decolorization of textile industrial effluents mediated by soluble and immobilized Bitter gourd peroxidase. Maximum decolorization of textile effluent both by soluble and immobilized Bitter gourd peroxidase was obtained at pH 5. Subsequently, the effluent removal dropped significantly at pH 6.0. Satar and Husain [86] reported that the decolorization of reactive dyes, Reactive Red 120 and Reactive Blue 171, treated independently with soluble and immobilized white radish peroxidase increased with the increase in pH up to 5 (maximum decolorization) and then decreased remarkably with further increase in pH of the medium. Ulson de Souza et al. [87] evaluated that the horseradish peroxidase showed a better performance at pH 4.0, for decolorization of Remazol Turquoise Blue G 133 %, and the decolorization efficiency was reduced with an increase in pH. The optimum pH for soybean (SBP)-mediated Trypan Blue degradation appeared to be pH 4 (where almost 60 % of the dye could be degraded in 1 min). Surprisingly, SBP was also very active at lower pH values of 2 and 3. At pH 3, SBP was almost comparable in activity as pH 4, whereas even at pH 2, 40 % of the dye could be degraded. However, at higher pH values of 8 and 9, the dye shows significantly poor degradation [88]. Ali et al. [89] reported that the soybean peroxidase enzyme was most active in the pH range of 3–5 for degradation of Crystal Ponceau 6R dye. Terres et al. [90] reported that the aqueous solutions of Indigo Carmine dye catalyzed by the enzyme horseradish peroxidase (HRP) were decolorized at pH 4, 5, and 6. Gholami-Borujeni et al. [91] evaluated that decolorization of acid blue-25 (AB-25) dye with horseradish peroxidase was maximum at pH 7 and 0.8. Preethi et al. [92] explored that the horseradish peroxidase exhibited higher percentage of color removal of C.I. Acid Blue 113 dye at various pH values such as 4, 6.6, and 9. The decolorization of Naphthol Blue Black with horseradish peroxidase was found to be the highest at a pH range of 4–6 [93].

Enzymes have an optimum pH range at which their activities are maximum. The above discussion gave an idea about the optimum pH range of different plant peroxidases for degradation of different textile dyes. The maximum degradation of dyes by majority of plant peroxidases was observed within the pH range of 2 to 5.

Effect of Temperature

Enzymatic reactions are well known to be temperature dependent. Many studies have been carried out to explore the effect of temperature on peroxidase catalyzed degradation of dyes. Jamal et al. [78] determined the effect of temperature on decolorization of Reactive Red 2, Disperse Black 9, Reactive Blue 4, Reactive Black 5, and Disperse Orange 25 with cauliflower bud peroxidase. The data revealed that all the dyes showed a maximum decolorization at 40 °C. In another report, the optimum temperature for maximum decolorization of textile and non-textile dyes catalyzed by T. dioca peroxidase was observed [81]. Among the textile dyes, the reactive dyes (Reactive Blue 15, Reactive Orange 15, Reactive Red 4, Reactive Yellow 2) exhibited a maximum decolorization at 50 °C whereas the disperse dyes (Disperse Red 19, Disperse Yellow 7, Disperse Black, and Disperse Orange 15) showed a maximum dye color change at 40 °C in the presence optimum concentration of 1.0 and 0.2 mM HOBT, respectively. Matto and Husain [84] reported that Direct Red 23, Direct Red 239, Direct Yellow 4, and Direct Blue 80 decolorized maximally at 30 °C with turnip peroxidase. In another report, Matto and Husain [85] evaluated the influence of temperature on the decolorization of textile industrial effluent by soluble and immobilized bitter gourd peroxidase. The results revealed that the textile effluent was maximally decolorized in the presence of both soluble and immobilized bitter gourd peroxidase at 40 °C. Above this temperature, the rate of effluent decolorization was decreased. Disperse Red 19 and Disperse Black 9 showed a maximum decolorization at 42 °C with T. diocia peroxidase [71]. Akhtar et al. [69] studied the effect of temperature on partially purified bitter gourd (M. charantia) peroxidase catalyzed decolorization of textile and other industrially important dyes. The Reactive Blue 4, Reactive Blue 171, Reactive Blue 160, Reactive Red 120, Reactive Red 11, Reactive Orange 86, Reactive Orange 4, and Reactive Yellow 84 were found to decolorize maximally at 42 °C with partially purified BGP. In another study, Akhtar et al. [68] investigated the effect of different temperatures (30–80 °C) on the decolorization of above-mentioned dyes by soluble and immobilized bitter gourd peroxidase. It is revealed that the decolorization of all the dyes was maximum at 40 °C both by soluble and immobilized BGP. Further, at lower temperatures, there was no difference in the dye decolorization by soluble and immobilized BGP but at higher temperatures the decolorization was significantly greater in immobilized enzyme-treated samples. Maximum degradation of Disperse Red 343 with horseradish peroxidase was observed at 50 °C [82]. The decolorization of Basic violet 3 dye catalyzed by C. limon (lemon) peroxidise was found to be optimum at 4.5 °C [80]. Pirillo et al. [94] reported the effect of different temperatures (25, 45, and 65 °C) on horseradish peroxidase catalyzed decolorization of Eriochrome Blue Black R and Fluorescein. The results showed that maximum decolorization of Eriochrome Blue Black R was obtained at temperature 25 and 45 °C and a slight decrease in decolorization was observed at 65 °C while in case of Fluorescein, maximum decolorization was achieved at 25 °C. Satar and Husain [86] studied the effect of varying temperatures (20–80 °C) on decolorization of reactive dyes, Reactive Red 120 and Reactive Blue 171, mediated by soluble and immobilized (Celite-adsorbed ) white radish peroxidase in the presence of 0.75 mM H2O2 and 0.4 mM HOBT in 50 mM sodium acetate buffer of pH 5.0 for 1 h. The results indicated that both the dyes showed maximum decolorization at 40 °C. However, there was not much difference in percent decolorization by immobilized white radish peroxidase between temperatures 30–50 °C. Above and below these temperatures, the percent decolorization was markedly decreased. Similarly, SBP appears to work well at 25 °C; however, a slight increase in degradation of Trypan Blue dye was observed on increasing the temperature up to 50 °C [88]. Terres et al. [90] reported that the aqueous solutions of Indigo Carmine dye catalyzed by the enzyme horseradish peroxidase (HRP) were decolorized at temperatures between 40 and 60 °C. Maximum color removal of C.I. Acid Blue 113 dye with horseradish peroxidase was achieved at 20 °C [92]. The maximum decolorization of Drimarene orange KGL by orange peroxidase was obtained at 60 °C [79].

The study of effect of temperature on decolorization/degradation of textile dyes/effluents by different plant peroxidases revealed that maximum decolorization was achieved within the temperature range of 25–50 °C, with majority of plant peroxidase showed maximum decolorization at 40 °C. The rate of dye decolorization was decreased above and below the temperature-maxima. The inactivation of enzyme at high temperature might involve two factors: (i) reactions between hydrogen peroxide and intermediates of the enzyme’s catalytic cycle and (ii) irreversible reactions between the enzyme and free radicals. Reducing the reaction rate by lowering temperature leads to a reduction in the rate of free radicals generation and therefore the rate of enzyme deactivation have been slowed [95].

Optimum Contact Time

Another important factor in enzymatic degradation of dyes is the catalyst/substrate contact time which gives a maximum removal. Jamal et al. [71] studied the extent of decolorization of disperse dyes, Disperse Red 19 and Disperse Black 9, mediated by T. diocia peroxidase as a function of time. Maximum decolorization of Disperse Red 19 (25 mg/l, 5.0 ml) and Disperse Black 9 (50 mg/l, 5.0 ml) was observed within 1 h of incubation. However, no effective increase was observed when the dyes were further incubated for longer times. Sufficient amount of Disperse Red 19 was decolorized within 20 min while the decolorization of Disperse Black 9 was slow in the same time interval. However, maximum decolorization of Reactive Red 2, Disperse Black 9, Reactive Blue 4, Reactive Black 5, and Disperse Orange 25 was achieved in 90 min of contact with cauliflower bud peroxidase [78]. Jamal et al. [81] reported the effect of different time intervals (30–300 min) on T. diocia peroxidase-mediated decolorization of reactive (Reactive Blue 15, Reactive Orange 15, Reactive Red 4, Reactive Yellow 2) and disperse (Disperse Red 19, Disperse Yellow 7, Disperse Black, and Disperse Orange 15) dyes. Maximum decolorization for reactive and disperse dyes was obtained within 1 h of incubation with T. diocia peroxidase. However, further decolorization of these dyes progressed slowly up to 4 h, although no effective increase in decolorization was seen even when the dyes were further incubated for longer times. Among the reactive dyes, Reactive Blue 15 decolorized almost completely at 4-h incubation whereas Reactive Red 4, Reactive Yellow 2, and Reactive Orange 15 showed decolorization up to 86, 81, and 78 %, respectively, under similar conditions. The disperse dyes, Disperse Red 19, Disperse Yellow 7, and Disperse Black 9, decolorized to 80, 72, and 72 %, respectively. Disperse Orange 15 was found to be comparatively weakly degraded and decolorized to a lesser extent under similar conditions with a maximum of 61 %. Satar and Husain [86] reported the effect of time on decolorization of reactive dyes, Reactive Red 120 and Reactive Blue 171, catalyzed by soluble and immobilized white radish peroxidase (WRP). Both dyes were decolorized maximally by soluble and immobilized WRP within 1 h of incubation and no effective increase in decolorization was observed with further increase in incubation time. Moreover, at a same time period and identical experimental conditions, dye solutions treated with I-WRP were decolorized to a greater extent as compared to S-WRP. The S-WRP decolorized RR 120 to 66 % and RB 171 to 65 %; however, 80 % (RR 120) and 74 % (RB 171) decolorization was observed with I-WRP. Satar and Husain [96] optimized the incubation time of disperse dyes, Disperse Brown 1 (DB 1) and Disperse Red 17 (DR 17), with soluble and immobilized bitter gourd peroxidase (BGP) for their maximum decolorization. Maximum decolorization of the dyes was observed within 120 min of incubation. DR 17 and DB 1 were decolorized 60 and 41 % by soluble BGP while immobilized BGP decolorized DR 17 and DB 1 more efficiently to 90 and 59 %, respectively. Sufficient amount of DR 17 was decolorized within 30 min while the decolorization of DB 1 was observed to be slow. However, it was observed that the incubation time of 60 min was sufficient for maximum decolorization of dyes in batch process by soluble BGP and no further increase in decolorization was observed on incubation for longer time. Ulson de Souza et al. [87] investigated the efficiencies of the decolorization of the dyes Turquoise Blue G 133 % and Lanaset Blue 2R as a function of contact time with horseradish peroxidase and reported that only 5 min of contact with the enzyme was required for 94 % decolorization of the dye Lanaset Blue 2R and 45 min of contact with the enzyme for 59 % decolorization of Turquoise Blue G 133 %. Similarly, the optimum contact time for decolorization of Basic violet 3 dye catalyzed by C. limon (lemon) peroxidise was found to be 5 min [80]. Optimum contact time for horseradish peroxidase-mediated degradation of Acid Black 10 BX (20 mg/l) was observed to be 45 min [77]. Remazol Turquoi G 133 % (50 mg/l) showed a maximum decolorization in 50 min of contact with turnip peroxidase [97]. Optimum incubation time for bitter gourd peroxidase catalyzed decolorization of Reactive Blue 160 and Reactive Blue 4 was observed to be 1 h [68]. Shaffiqu et al. [28] reported that Procion Green HE-4BD and Supranol Green were completely decolorized within 1 h of incubation time with Saccharum spontaneum leaf peroxidase (specific activity of 0.23 IU/mg) whereas, Procion Brilliant Blue H-7G, Chrysoidine, and Direct Blue were degraded more than 70 % in 60 min of incubation time. Fifty milligrams per liter of the dyes, Supranol Green, Crystal Violet, and Methyl Orange, were degraded 26, 36, and 68 %, respectively, in 2- to 4-h incubation with Ipomea palmate leaf peroxidase (specific activity of 0.827 U/mg) and 25 mg/l level of Brilliant Green, Direct Blue, and Chrysoidine were degraded 54, 15, and 44 %, respectively, with 1 to 2 h of incubation time. The incubation time of 160 min were required for decolorization of 60 ppm of Drimarene orange KGL by 33 U/ml of orange peroxidase [79]. Preethi et al. [92] mentioned that 30 mg/l of C.I. Acid Blue 113 dye was maximally degraded with 0.08 U of horseradish peroxidase in 45 min of contact time. An aqueous solution of 2.5 × 10−5 mol/l of Indigo Carmine dye was decolorized by horseradish peroxidase (HRP) between 30 and 60 min of contact time [90]. Gholami-Borujeni et al. [91] determined that 75-min contact time was optimum for horseradish peroxidase catalyzed decolorization of acid blue-25 (AB-25) dye.

In the light of above discussion, it is concluded that the incubation time of dye with peroxidase for decolorization varies from 5 min to 4 h depending upon the chemical nature of dye to be treated and the species of plant; however, most of the dyes decolorized within 1 h of incubation with plant peroxidases.

Optimum Dose of Enzyme

An optimal concentration level of enzyme is necessary to keep the reaction at a high and steady rate. Mohan et al. [77] reported that the 2.205 U/ml of enzyme dose of horseradish peroxidase was found to be the optimum for maximum degradation of Acid Black 10 BX (20 mg/l) at specified experimental conditions. An enzyme concentration (cauliflower bud peroxidase) of 0.36 U/ml was found to be optimum for maximum decolorization of Reactive Red 2, Disperse Black 9, Reactive Blue 4, Reactive Black 5, and Disperse Orange 25 [78]. The turnip peroxidase concentration of 10.83 U/ml was noted to be optimum for maximum decolorization of 50 mg/l Remazol Turquoi G 133 % [97]. Akhtar et al. [68] studied the effect of increasing concentration (0.133–0.339 EU/ml) of partially purified bitter gourd peroxidase (BGP) on Reactive Red 120, Reactive Blue 171, Reactive Blue 160, and Reactive Blue 4. The decolorization of all the four dyes was continuously improved by increasing concentration of BGP. Reactive Blue 4 showed complete decolorization with 0.399 EU/ml of BGP. Then they treated the four dyes with stepwise addition of enzyme, by adding 0.133 EU of BGP/ml at each step to the decolorizing solution. Rapid decolorization was observed at each enzyme addition. Reactive Blue 160 was almost completely decolorized after the third enzyme addition while complete decolorization of Reactive Blue 4 was observed after the second addition of enzyme. Decolorization of Reactive Blue 171 and Reactive Red 120 was also enhanced with stepwise addition of enzyme. Maximum degradation of Disperse Red 343 was observed with horseradish peroxidase concentration of 89.7 U/ml [82]. The decolorization of 7.5 mg/l of Basic violet 3 dye catalyzed by C. limon (lemon) peroxidase was found to be maximum at 42 U/ml of enzyme dose [80]. The maximal decolorization for disperse dyes, Disperse Red 19 and Disperse Black 9, was observed at T. diocia peroxidase concentration of 0.45 Um/l [71]. An enzyme concentration (cauliflower bud peroxidase) of 0.36 U/ml was found to be optimum for maximum decolorization of Reactive Red 2, Disperse Black 9, Reactive Blue 4, Reactive Black 5, and Disperse Orange 25 [78]. In another study, Jamal et al. [81] reported that the T. diocia peroxidase concentration of 0.45 EU/ml was required for maximum decolorization of reactive (Reactive Blue 15, Reactive Orange 15, Reactive Red 4, Reactive Yellow 2) and disperse (Disperse Red 19, Disperse Yellow 7, Disperse Black, and Disperse Orange 15) dyes; however, the extent of decolorization of each dye was different. Matto and Husain [84] investigated the effect of increasing concentration (0.094–0.330 U/ ml) of turnip peroxidase (TP) on decolorization of Direct Red 23, Direct Red 239, Direct Yellow 4, and Direct Blue 80. An increase in concentration of TP has resulted in enhanced decolorization, with maximum decolorization at 0.236 U/ml in the presence of HOBT, while as in the presence of VA, there was slight increase in percent decolorization after 0.236 U U/ml of TP. Matto and Hussain [85] reported the effect of increasing concentrations of soluble and immobilized BGP (0.08–0.32 U/ml) on decolorization of textile industrial effluent. An increase in the BGP concentration up to 0.28 U/ml of reaction mixture resulted in the highest effluent decolorization to 28 and 70 % by soluble and immobilized BGP, respectively. Ulson de Souza et al. [87] evaluated the horseradish peroxidase concentrations (2.985–29.85 U/ml); for maximum decolorization of Turquoise Blue G 133 %, it was observed that at the concentration of 14.985 U/ml, the decolorization of the dye was 58 %; however, when the concentration was increased to twofold, the decolorization was 62 %. From these results, it was concluded that often, using a higher concentration of enzyme, the decolorization of the dye was not significantly influenced. Satar and Husain [86] investigated that the decolorization of the Reactive dyes, Reactive Red 120 (100 mg/l) and Reactive Blue 171 (120 mg/l), was maximum in the presence of 0.4 U/ml of soluble and immobilized white radish peroxidase. In another investigation, Satar and Husain [96] reported that 25 U of soluble and immobilized bitter gourd peroxidase are required for maximum decolorization of Disperse Brown 1 (50 mg/l) and Disperse Red 17 (25 mg/l). Similarly, the soybean peroxidase (SBP) dose was found to have significant influence on degradation reaction of Trypan Blue. The increase in the SBP dose from 10 to 80 units/ml resulted in a gradual increase in the dye removal (16–64 %) and seems to be levelling off at 80 units/ml. As seen for the rate of dye degradation, the % dye degradation also increased with increasing SBP concentration, but showed lesser increase in % degradation at higher enzyme concentrations. This can explained on the basis that in the initial stages, the reaction between dye and SBP is quite fast and becomes slower when SBP increases, as there is not enough dye molecules available for the reaction [88]. Ali et al. [89] observed that the optimum concentration of soybean peroxidase for degradation of 40 ppm of Crystal Ponceau 6R dye was 0.27 μM. Gholami-Borujeni et al. [91] determined that 1 U/ml crude and pure horseradish peroxidase was optimum for (80 and 94 %, respectively) decolorization of acid blue-25 (AB-25) dye. The orange peroxidase concentration of 33 U/ml was found to be sufficient to decolorize 40 mg/l of Drimarene orange KGL [79]. The horseradish peroxidase concentrations of 0.08 U can degrade 30 mg/l of C.I. Acid Blue 113 dye up to 80 % [92]. A dye concentration of 2.5 × 10−5 mol/l of Indigo Carmine dye was decolorized by 2 mg of horseradish peroxidase [90].

In the light of above reported results, it is concluded that decolorization of dyes increases with the increase in concentration of peroxidase, up to an optimum concentration, where the decolorization is maximum. Further addition of enzyme does not show any significant increase in the decolorization of the dyes.

Optimum Concentration of dye

Enzymatic reactions are significantly affected by concentration of substrate. If the amount of substrate increases gradually (keeping enzyme concentration constant), the rate of reaction will increase until a maximum value reaches. By further increasing the amount of substrate, the rate of enzymatic reaction will not increase. Studies were carried to optimize concentration of Acid Black 10 BX for maximum degradation with horseradish peroxidase. The results showed that 30 mg/l of dye concentration was found to be optimum for maximum decolorization [77]. Silva et al. [97] reported that the degradation of Remazol Turquoise G 133 % with turnip peroxidase increased by increasing dye concentration until 40 mg/l and then became constant. Maximum elimination of Alizarin with horseradish peroxidase was obtained at the dye concentration of 50 mg/l [98]. The decolorization of Drimarene orange KGL by 33 U/ml of orange peroxidase was observed to be effective up to 60 ppm of dye [79]. Horseradish peroxidase-mediated decolorization of Eriochrome Blue Black R was maximum (92.5 %) at the dye concentration of 150 mg/l. However, Fluorescein decolorization in the presence of horseradish peroxidase was maximum (almost 85 %) at 25 mg/l of dye concentration and decreased to 35.7 % as the dye concentration increased to 150 mg/l [94]. Maximum decolorization of Solar Blue A and Solar Flavine 5G with R. sativus peroxidase was observed with 20 mg/l of each dye. Higher concentration of both the dyes resulted in decreased decolorization of the dyes [33]. In a similar report, different concentrations of Trypan blue (10, 20, 40, and 80 ppm) were treated with soybean peroxidase to get the optimum concentration of dye. It was observed that the removal was most effective at the lowest dye concentration (10 ppm). Further increase in dye concentration up to 80 ppm resulted in relatively slower dye removal [88]. Ali et al. [89] reported that under optimized conditions, 40 ppm of Crystal Ponceau 6R dye solution could be completely degraded in under 1 min by soybean peroxidase in the presence of H2O2 and a redox mediator. Asmita and Jadhav [99] studied that the percentage decolorization of Reactive Blue 160 mediated by Tagetes patula peroxidase was reduced with increased concentration of dye. The highest percentage (90 %) decolorization was obtained at 20 mg/l and lowest (57 %) at 100 mg/l dye concentration, while 74, 67, and 62 % decolorization was observed with 40, 60, and 80 mg/l of dye concentrations, respectively. Similarly, the degradation of C.I. Acid Blue 113 dye mediated by horseradish peroxidase is higher at low concentration of dye from 20 to 30 mg/l. Beyond which, the degradation of dye is decreasing abruptly as the concentration of dye increases [92]. Terres et al. [90] reported that a dye concentration of 2.5 × 10−5 mol/l of Indigo Carmine dye was decolorized by 2 mg of horseradish peroxidase.

The optimum concentration of dyes for maximum decolorization with peroxidase depends upon the nature of dye and source of peroxidase; however, most of the dyes decolorized maximally with plant peroxidases within the concentration range of 20–50 mg/l.

Optimum Concentration of Hydrogen Peroxide

H2O2 acts as a co-substrate of peroxidase and takes part in catalytic mechanism of peroxidase by oxidizing the enzyme into a reactive intermediate radical which accepts the aromatic substrates (dye molecules) and converts them into radicals which may further polymerize or degrade into small products. So the dye removal efficiency of peroxidase is also affected by the concentration of hydrogen peroxide. Mohan et al. [77] reported that 0.6 μl/l of H2O2 dose was optimum for maximum degradation of Acid Black 10 BX (20 mg/l) by horseradish peroxidase. Jamal et al. [78] reported that H2O2 concentration of 0.75 mM was sufficient for maximum decolorization of Reactive Red 2, Disperse Black 9, Reactive Blue 4, Reactive Black 5, and Disperse Orange 25 with cauliflower bud peroxidase. Silva et al. [97] studied the effect of hydrogen peroxide on decolorization of Remazol Turquoise G 133 % (50 mg/l) with turnip peroxidase. The results obtained revealed that the H2O2 concentration of 100 μmol/l showed a better enzyme performance. The concentrations of hydrogen peroxide did not show a significant effect in decolorization of dye; however, the concentration above 200 μmol/l had an inhibitory effect. Multiple H2O2 additions avoided loss of enzyme activity. Jamal et al. [71] investigated that the percent decolorization of Disperse Red 19 and Disperse Black 9 with T. diocia peroxidase enhanced with the increasing concentration of hydrogen peroxide and became maximum at a concentration of 0.8 mM. Further increase in hydrogen peroxide concentration did not change the decolorization till 1.2 mM concentration of hydrogen peroxide. In a similar study, the H2O2 doses of 0.8 and 0.7 mM were observed to be sufficient for enhanced decolorization of Solar Blue A and Solar Flavine 5G, respectively, with R. sativus peroxidase [33]. The maximum decolorization of 40 ppm of Drimarene orange KGL by orange peroxidase was observed to be with 2 mM of H2O2 [79]. Maximum decolorization of Remazol Turquoise Blue G and Lanaset Blue 2R by horseradish peroxidase has been reported with H2O2 concentration of 2 × 10−3 mmol/l [83].

Terres et al. [90] reported that the hydrogen peroxide concentration between 0.3 and 0.003 % with 2 mg of horseradish peroxidase favored decolorization of Indigo Carmine dye. However, Gholami-Borujeni et al. [91] determined that 0.8 mM/l H2O2 was optimum for horseradish peroxidase catalyzed decolorization of acid blue-25 (AB-25) dye. Optimum H2O2 concentration to degrade 30 mg/l of C.I. Acid Blue 113 dye with 0.08 U horseradish peroxidase was found to be 14 μl [90]. Ali et al. [89] determined that the 0.175 mM concentration of H2O2 was optimum for degradation of 40 ppm of Crystal Ponceau 6R dye with 0.27 μM of soybean peroxidase.

Experiments were done wherein the % degradation of Trypan Blue with soybean peroxidase was measured as a function of H2O2 concentration. Increasing H2O2 concentration led to increased dye degradation. However, after reaching the maximum dye degradation with 64 μM H2O2, further increase in H2O2 did not cause any additional dye degradation. On the contrary, higher H2O2 was detrimental to the process, most likely due to damaging the enzyme itself. This shows the critical significance of optimizing H2O2 concentrations in these enzyme-based dye degradation approaches. Hydrogen peroxide concentrations were also optimized at higher dye concentrations (20–80 ppm), and the results showed that 64 μM was the optimum H2O2 concentration for 10–40 ppm but much higher H2O2 concentration was necessary for 80 ppm dye concentration. In order to achieve complete dye degradation and to clearly understand the role of H2O2 in SBP-mediated Trypan Blue degradation, H2O2 was added in sequential increments and noted that when initial amount of H2O2 (64 μM) was added, the dye degradation immediately increased to about 60 %. At this stage, all the H2O2 seems to have been consumed. The % degradation became more (75 %) after another addition of (64 μM) H2O2 while the added H2O2 is consumed in the process. A stepwise continuous addition of H2O2 caused further degradation of the TB solution till more than 90 % of the degradation was observed [88].

Conclusion

Peroxidases are ubiquitously found in all vascular plants. Their activity largely depends upon the environmental factors like pH and temperature. Peroxidases have been isolated and characterized from different plant species by many researchers. In this review article, we have reviewed the various publications on isolation and characterization of plant peroxidases and summarized the results of various factors affecting their activities. It is concluded that peroxidase from most of the plant species showed optimum temperature in the range of 30–75 °C. Most of peroxidases are acidic in nature (some are neutral and slightly alkaline); however, they retained up active over a broad pH range of 3.5–7. Peroxidases showed broad pH and high temperature stability. Most of the peroxidases retained their activity over a broad range of pH 4–11 and at high temperatures up to 70 °C (in some cases 90 °C) even after a long-time incubation. Their activities are not significantly affected in the presence of many metal ions. Peroxidases participate in the catalysis of a wide range of substrates, and interestingly these enzymes have been successfully used from the past two decades for the treatment of textile dyes. The various published reports on plant peroxidase-mediated bioremediation of dyes have been reviewed and cited in this article. The findings revealed the effectiveness of the peroxidase for catalyzing the degradation process of a wide range of industrial dyes. However, the degradation process efficiency of peroxidase seems to be dependent upon the operational parameters like concentration of enzyme, H2O2 and dye, incubation time, pH, and temperature. Peroxidases from different plant sources were found to be more tolerant to high temperature and a wide range of operational pH. We can conclude so far that plant peroxidases are easily available, inexpensive, and ecofriendly biocatalysts for the removal of wide spectrum of textile and non-textile dyes.

References

Dunford, H. B. (1999). Heme peroxidases (p. 480). New York: Willey-VCH 190-192.

Manu, B. T., & Rao, U. J. S. P. (2009). Calcium modulated activity enhancement and thermal stability study of a cationic peroxidase purified from wheat bran. Food Chemistry, 114, 66–71.

Lee, T. M., & Lin, Y. H. (1995). Changes in soluble and cell wall-bound peroxidase activities with growth in anoxia-treated rice (Oryza sativa L.) coleoptiles and roots. Plant Science, 106, 1–7.

Cardinali, A., Tursi, N., Ligorio, A., Giuffrida, M. G., Napolitano, L., Caliandro, R., Sergio, L., Di Venere, D., Lattanzio, V., & Sonnante, G. (2011). Purification, biochemical characterization and cloning of a new cationic peroxidase isoenzyme from artichoke. Plant Physiology and Biochemistry, 49, 395–403.

Pandey, V. P., & Dwivedi, U. N. (2011). Purification and characterization of peroxidase from Leucaena leucocephala, a tree legume. Journal of Molecular Catalysis B: Enzymatic, 68, 168–173.

De Gara, L. (2004). Class III peroxidases and ascorbate metabolism in plants. Phytochemistry Reviews, 3, 195–205.

Zhang, Z., Pang, X., Xuewu, D., Ji, Z., & Jiang, Y. (2005). Role of peroxidase in anthocyanin degradation in litchi fruit pericarp. Food Chemistry, 90, 47–52.

Fatima, A., Husain, Q., & Khan, R. H. (2007). A peroxidase from bitter gourd (Momordica charantia) with enhanced stability against organic solvent and detergent: a comparison with horseradish peroxidase. Journal of Molecular Catalysis B: Enzymatic, 47, 66–71.

Purello R, S. Gurrieri and Lauceri, R. 1999. Porphyrin assemblies as chemical sensors. Coordination Chemistry Reviews, 683–706

Moreira, P. R., Bouillenne, F., Almeida-Vara, E., Xavier Malcata, F., Frère, J. M., & Duarte, J. C. (2006). Purification, kinetics and spectral characterisation of a new versatile peroxidase from a Bjerkandera sp. isolate. Enzyme and Microbial Technology, 38, 28–33.

Mi Young, L. (2002). Effects of Na2SO3 on the activities of antioxidant enzymes in geranium seedlings. Phytochemistry, 59, 493–499.

Dubey, A., Diwakar, S. K., Rawat, S. K., Kumar, P., & Batra, N. (2007). Characterization of ionically bound peroxidases from apple (Mallus pumilus) fruits. Preparative Biochemistry & Biotechnology, 37, 47–58.

Bhatnagar, A., & Jian, A. K. (2005). A comparative adsorption study with different industrial wastes as adsorbents for removals of cationic dyes from water. Journal of Colloid and Interface Science, 281(1), 49–55.

Rauf, M. A., & Ashraf, S. S. (2009). Fundamental principles and application of heterogeneous photocatalytic degradation of dyes in solution. Chemical Engineering Journal, 151, 10–18.

Jin, X., Liu, G., Xu, Z., & Yao, W. (2007). Decolorization of a dye industry effluent by Aspergillus fumigatus XC6. Applied Microbiology and Biotechnology, 74(1), 239–243.

Neill, C. O., Freda, R. H., Dennis, L. H., Nidia, D. L., Helena, M. P., & Wouter, D. (1999). Colour in textile effluents—sources, measurements, discharge contents and simulation: a review. Journal of Chemical Technology and Biotechnology, 74, 1009–1018.

Fu, Y., & Viraraghavan, T. (2001). Fungal decolorization of dye wastewaters: a review. Bioresource Technology, 79, 1037–1040.

Kaushik, & Malik, A. (2009). Microbial decolorization of textile dyes through isolates obtained from contaminated sites. Journal of Scientific and Industrial Research, 68, 325–331.

Fartode, A. P., & Parwate, D. V. (2014). UV photolytic decolorization study of synthetic waste water containing Indigo Carmine dye in presence of H2O2. International Journal of Chemical and Physical Sciences, 3(3), 22–31.

Chanathaworn, J., Bunyakan, C., Wiyaratn, W., & Chungsiriporn, J. (2012). Photocatalytic decolorization of basic dye by TiO2 nanoparticle in photoreactor. Songklanakarin Journal of Science and Technology, 34(2), 203–210.

Abdullah, F. H., Rauf, M. A., & Ashraf, S. S. (2007). Kinetics and optimization of photolytic decoloration of carmine by UV/H2O2. Dyes and Pigments, 75, 194–198.

Mielgo, I., Lo Pez, C., Moreira, M. T., Feijoo, G., & Lema, J. M. (2003). Oxidative degradation of azo dyes by manganese peroxidase under optimized conditions. Biotechnology Progress, 19, 325–331.

Palma, C., Moreira, M. T., Mielgo, I., Feijoo, G., & Lema, J. M. (1999). Use of fungal bioreactor as a pretreatment or post treatment step for continuous decolorization of dyes. Water Science and Technology, 40, 131–136.

Husain, Q., & Jan, U. (2000). Detoxification of phenols and aromatic amines from polluted waste water by using phenol oxidases. Journal of Scientific and Industrial Research, 59, 286–293.

Duran, N., & Esposito, E. (2000). Potential applications of oxidative enzymes and phenoloxidase-like compounds in wastewater and soil treatment: a review. Applied Catalysis B: Environmental, 28, 83–99.

Torres, E., Bustos-Jaimes, I., & Bogne, S. L. (2003). Potential use of oxidative enzymes for the detoxification of organic pollutants. Applied Catalysis B: Environmental, 46, 1–15.

Bhunia, A., Durani, S., & Wangikar, P. P. (2001). Horseradish peroxidase catalyzed degradation of industrially important dyes. Biotechnology and Bioengineering, 72, 562–567.

Shaffiqu, T. S., Roy, J. J., Nair, R. A., & Abraham, T. E. (2002). Degradation of textile dyes mediated by plant peroxidases. Applied Biochemistry and Biotechnology - Part A Enzyme Engineering and Biotechnology, 102–103, 315–326.

Verma, P., & Madamwar. (2002). Decolorization of synthetic textile dyes by lignin peroxidase of Phanerochaete chrysosporium. Folia Microbiologica, 47, 283–286.

Husain, Q. (2010). Peroxidase mediated decolorization and remediation of wastewater containing industrial dyes: a review. Reviews in Environmental Science and Biotechnology, 9, 117–140.

Zamorano, L. S., Roig, M. G., Villar, E., & Shnyrov, V. (2007). The versatile peroxidases. Current Topics in Biochemical Research, 9, 1–26.

Kalsoom, U., Bhatti, H. N., Bhatti, I. A., & Asgher, M. (2010). Kinetics and thermodynamics of thermal inactivation of peroxidase from cauliflower (Brassica oleracea L. var. Botrytis) leaves. Asian Journal of Chemistry, 22(10), 7883–7890.

Bhatti, H. N., Kalsoom, U., & Habib, A. (2012). Decolorization of direct dyes using peroxidase from Raphanus sativus (F04 SL). Journal of the Chemical Society of Pakistan, 34, 257–262.

De Leonardis, S., Dipierro, N., & Dipierro, S. (2000). Purification and characterization of an ascorbate peroxidase from potato tuber mitochondria. Plant Physiology and Biochemistry, 38, 773–779.

Deepa, S. S., & Arumughan, C. (2002). Purification and characterization of soluble peroxidase from oil palm (Elaeis guineensis Jacq.) leaf. Phytochemistry, 61, 503–511.

Márquez, O., Waliszewski, K. N., Oliart, R. M., & Pardio, V. T. (2008). Purification and characterization of cell wall-bound peroxidase from vanilla bean. LWT - Food Science and Technology, 41, 1372–1379.

Sakharov, I. Y., Vesgac, M. K., Galaev, I. Y., Sakharova, I. V., & Pletjushkina, O. Y. (2001). Peroxidase from leaves of royal palm tree Roystonea regia: purification and some properties. Plant Science, 161, 853–860.

Al-Senaidy, A. M., & Ismael, M. A. (2011). Purification and characterization of membrane-bound peroxidase from date palm leaves (Phoenix dactylifera L.). Saudi Journal of Biological Sciences, 18, 293–298.

Ajila, C. M., & Prasada Rao, U. J. S. (2009). Purification and characterization of black gram (Vigna mungo) husk peroxidase. Journal of Molecular Catalysis B: Enzymatic, 60, 36–44.

Campbell, N. A., Reece, J. B., Urry, L. A., Cain, M. L., Wasserman, S. A., Minorsky, P. V., & Jackson, R. B. (2008). Biology (8th ed., pp. 151–155). San Francisco: Pearson Benjamin Cummings.

Cai, F., OuYang, C., Duan, P., Gao, S., Xu, Y., & Chen, F. (2012). Purification and characterization of a novel thermal stable peroxidase from Jatropha curcas leaves. Journal of Molecular Catalysis B: Enzymatic, 77, 59–66.

Martínez-Cortés, T., Pomar, F., Espiñeira, J. M., Merino, F., & Novo-Uzal, E. (2012). Purification and kinetic characterization of two peroxidases of Selaginella martensii Spring involved in lignification. Plant Physiology and Biochemistry, 52, 130–139.

Onsa, G. H., Bin Saari, N., Selamat, J., & Bakar, J. (2004). Purification and characterization of membrane-bound peroxidases from Metroxylon sagu. Food Chemistry, 85, 365–376.

Nouren, S., Bhatti, H. N., Bhatti, I. A., & Asghe, M. (2013). Kinetic and thermal characterization of peroxidase from peels of Citrus reticulata var. Kinnow. The Journal of Animals and Plant Sciences, 23(2), 430–435.

Bhatti, H. N., Najma, A., Asgher, M., Hanif, M. A., & Zia, M. A. (2006). Purification and thermal characterization of a novel peroxidase from a local chick pea cultivar. Protein and Peptide Letters, 13(8), 799–804.

Belcarz, A., Ginalska, G., Kowalewska, B., & Kulesza, P. (2008). Spring cabbage peroxidases—potential tool in biocatalysis and bioelectrocatalysis. Phytochemistry, 69, 627–636.

Somtürk, B., Kalınand, R., & Özdemir, N. (2014). Purification of peroxidase from red cabbage (Brassica oleracea var. capitata f. rubra) by affinity chromatography. Applied Biochemistry and Biotechnology, 173(7), 1815–1828.

Shah, S., Borahand, D., & Yadav, R. N. S. (2013). Extraction and characterization of peroxidase from Camellia sinensis. Proceedings of the National Academy of Sciences, India Section B: Biological Sciences, 84(2), 343–348.

Goyal, P., & Chugh, L. K. (2013). Partial purification and characterization of peroxidase from pearl millet (Pennisetum glaucum [L.] R. Br.) grains. Journal of Food Biochemistry, 38(2), 150–158.

Mohamed, S. A., Abulnaja, K. O., Ads, A. S., Khan, J. A., & Kumosani, T. A. (2011). Characterisation of an anionic peroxidase from horseradish cv. Balady. Food Chemistry, 128, 725–730.

Rojas-Reyes, J. O., Robles-Olvera, V., Carvajal-Zarrabal, O., Matinez, C. C., Waliszewski, K. N., & Aguilar-Uscanga, M. G. (2014). Purification and characterization of peroxidase from avocado (Persea americana mill, cv. Hass). Journal of the Science of Food and Agriculture, 94(9), 1844–1853.

Hsu, S., Chung, Y., Chang, C., & Sung, H. (2012). Purification and characterization of two acidic peroxidase isoforms from the sheaths of bamboo shoots. International Journal of Food Science & Technology, 47(9), 1872–1881.

Balasubramanian, M., & Boopathy, R. (2013). Purification and characterization of peroxidases from liquid endosperm of Cocos nucifera (L.): biotransformation. Journal of Molecular Catalysis B: Enzymatic, 90, 33–42.

Liu, F., Niu, L., Li, D., Liu, C., & Jin, B. (2012). Kinetic characterization and thermal inactivation of peroxidase in aqueous extracts from sweet corn and waxy corn. Food and Bioprocess Technology, 6(10), 2800–2807.

Mall, R., Naik, G., Mina, U., & Mishra, S. K. (2013). Purification and characterization of a thermostable soluble peroxidase from Citrus medica leaf. Preparative Biochemistry & Biotechnology, 43(2), 137–151.

Luo, H., Jiang, J., Jiang, L., Zhang, L., & Yu, Z. (2012). Purification and characterization of peroxidase from fresh-cut Zizania latifolia. Journal of Food Biochemistry, 36(3), 309–316.

Marzouki, S. M., Limam, F., Smaali, M. I., Ulber, R., & Marzouki, M. N. (2005). A new thermostable peroxidase from garlic Allium sativum. Applied Biochemistry and Biotechnology, 127(3), 201–214.

Pandey, V. P., Singh, S., Singh, R., & Dwivedi, U. N. (2012). Purification and characterization of peroxidase from papaya (Carica papaya) fruit. Applied Biochemistry and Biotechnology, 167(2), 367–376.

Criquet, S., Joner, E. J., & Leyval, C. (2001). 2,7-Diaminofluorene is a sensitive substrate for detection and characterization of plant root peroxidase activities. Plant Science, 161, 1063–1066.

Saraiva, J. A., Nunes, C. S., & Coimbra, M. A. (2007). Purification and characterization of olive (Olea europaea L.) peroxidase—evidence for the occurrence of a pectin binding peroxidase. Food Chemistry, 101, 1571–1579.

Rani, D. N., & Abraham, T. E. (2006). Kinetic study of a purified anionic peroxidase isolated from Eupatorium odoratum and its novel application as time temperature indicator for food materials. Journal of Food Engineering, 77, 594–600.

Suzuki, T., Honda, Y., Mukasa, Y., & Kim, S.-j. (2006). Characterization of peroxidase in buckwheat seed. Phytochemistry, 67, 219–224.

Bhatti, H. N., Akbar, M. N., & Zia, M. A. (2007). Kinetics of irreversible thermal denaturation of horseradish peroxidase. Journal of the Chemical Society of Pakistan, 29, 99–102.

Aruna, N., & Lali, A. (2001). Purification of a plant peroxidase using reversibly soluble ion-exchange polymer. Process Biochemistry, 37, 431–437.

Johri, S., Jamwal, U., Rasool, S., Kumar, A., Verma, V., & Qazi, G. N. (2005). Purification and characterization of peroxidases from Withania somnifera (AGB 002) and their ability to oxidize IAA. Plant Science, 169, 1014–1021.

Rathnamsamy, S., Singh, R., Auxilia, R., & Vedhahari, B. N. (2014). Extraction of peroxidase from various plant sources and its biodegradation studies on phenolic compounds. BioTechnology: An Indian Journal, 9(4), 160–165.

Das, M. K., Sharma, R. S., & Mishra, V. (2011). A novel cationic peroxidase (VanPrx) from a hemi-parasitic plant (Viscum angulatum) of Western Ghats (India): purification, characterization and kinetic properties. Journal of Molecular Catalysis B: Enzymatic, 71, 63–70.

Akhtar, S., Khan, A. A., & Husain, Q. (2005). Partially purified bitter gourd (Momordica charantia) peroxidase catalyzed decolorization of textile and other industrially important dyes. Bioresource Technology, 96, 1804–1811.

Akhtar, S., Khan, A. A., & Husain, Q. (2005). Potential of immobilized bitter gourd (Momordica charantia) peroxidases in the decolorization and removal of textile dyes from polluted wastewater and dyeing effluent. Chemosphere, 60, 291–301.

Khan, A. A., & Husain, Q. (2007). Decolorization and removal of textile and non-textile dyes from polluted wastewater and dyeing effluent by using potato (Solanum tuberosum) soluble and immobilized polyphenol oxidase. Bioresource Technology, 98, 1012–1019.

Jamal, F., Pandey, P. K., & Qidwai, T. (2010). Potential of peroxidase enzyme from Trichosanthes diocia to mediate disperse dye decolorization in conjunction with redox mediators. Journal of Molecular Catalysis B: Enzymatic, 66, 177–181.