Abstract

A facile and highly efficient method for the synthesis of 5-substituted-1H-tetrazoles in the presence of CuO/aluminosilicate as an effective heterogeneous nanocatalyst is reported. A series of aliphatic and aromatic nitriles underwent a [3 + 2] cycloaddition reaction with sodium azide to afford tetrazoles under reflux conditions in DMF. The yields of the obtained tetrazoles were good to excellent and the reaction times were also acceptable. The CuO/aluminosilicate is readily prepared, environmentally friendly, reusable and showed high catalytic performance. The catalyst was characterized by powder X-ray diffraction, energy‐dispersive X‐ray mapping and SEM techniques. Moreover, the procedure is simple, cost effective and reliable that holds potential for further applications in organic syntheses and industrial requirements.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Tetrazoles form an important class of nitrogen-rich heterocycles with a wide range of applications in organic synthesis, coordination and medicinal chemistry [1,2,3]. They are extensively used in agriculture as herbicides and fungicides, material sciences and nanostructured compounds [4,5,6]. Tetrazoles have also been frequently used as stabilizers in photography [7–9]. The nitrogen content of tetrazoles is 80%, which is the largest percent among the heterocyclic compounds. So, tetrazoles and their derivatives have been explored as the main constituents in various explosives and propellant compounds [7]. Tetrazoles were synthesized for the first time in 1885, by Bladin [10]. Since then, many attempts have been made to develop more efficient and eco-friendly methods for the construction of tetrazole frameworks [10,11,12,13].

In recent years, considerable efforts have been devoted to the synthesis of 5-substituted-1H-tetrazoles. Therefore, a great number of catalysts such as nano ZnO, nano CuO, tetrabutylammonium hydrogen sulfate (TBAHS), Cu-MCM-41 nanoparticles, organoaluminum azides, CoY/zeolite, OSU-6, Cu(OAc)2, NH4OAc, [Pd(OAc)2]dabco/ZnBr2, mesoporous ZnS, CuSO4·5H2O, H2SO4@SiO2 have been introduced [1,2,3,4,5,6, 14,15,16,17,18,19,20,21,22,23].

Although plenty of these methods are efficient, the limitations and disadvantages of some of them realized from their long reaction times, low yields, harsh reaction conditions, expensive reagents, toxic and stringent metal catalysts, tedious separation procedures. Therefore, it is of great importance to introduce more efficient catalysts and also develop more benign methods to avoid these drawbacks.

The successful application of heterogeneous catalysts in organic transformations is well documented. In this regard, heterogeneous catalysts, especially micelle-templated silica and other mesoporous high surface area support materials, play more serious roles in chemical transformations catalyzed by solid acids [24,25,26,27,28,29,30]. Nowadays, copper catalysts have received much more attentions, due to their low toxicity, ease of preparing and handling, good selectivity and high efficiency. Therefore, chemists have started to reconsider and update new approaches of the copper catalysts [31,32,33,34,35,36].

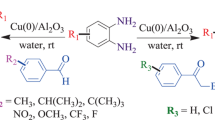

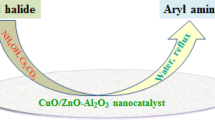

Recently, Babu et al. has reported a CuO/aluminosilicate catalyst in α-arylation of β-diketones with aryl halides and also Heck coupling of styrene with aryl halides in water [37, 38]. On the basis of our previous experience in applying copper catalysts [36], herein we report CuO/aluminosilicate mediated synthesis and functionalization of 5-substituted-1H-tetrazoles from organic nitriles and sodium azide (Scheme 1).

Experimental

Materials and methods

All reagents and solvents were obtained commercially and used without further purification. FT-IR spectra were recorded in KBr pellets at room temperature using a St-jean Baptist Ave Bomem 450 instrument. FT-NMR Spectra (1H and 13C) were recorded on Bruker Avance DPX (400 MHz) in CDCl3 with TMS as internal standard for protons and solvent signals as internal standard for carbon spectra. Chemical shift values are reported in δ (ppm) and coupling constants are given in Hz. The progress of all reactions was monitored by TLC on 2 × 5 cm pre-coated silica gel-60 F-254 plates of thickness of 0.25 mm (Merck). The chromatograms were visualized under UV 254–336 nm or by immersion in tanks of common chemical visualizer such as DNP, H2SO4(conc.), I2, etc.

Procedure for the preparation of CuO/aluminosilicate

The CuO/aluminosilicate was prepared as indicated in references [37] and [38]. Initially, three clear solutions of TEOS (3.79 mmol, 0.84 mL) in absolute ethanol (20 mL), Al(NO3)3·9H2O (56.33 mmol, 12.0 g) in absolute ethanol (40 mL) and CuCl2·2H2O (5.02 mmol, 0.856 g) in absolute ethanol (22 mL) were prepared. Second, a solution of 11% ammonia (18 mL) was added to the solution of TEOS with continuous stirring. Immediately, two other prepared solutions of aluminum nitrate and copper chloride were added to the above mixture. The reaction was exothermic for almost 1 h. The mixture was allowed to stir for 24 h at room temperature and kept it in 25 °C for another 4 days without stirring. The obtained solid gel was heated for 2 h at 100 °C and subsequently calcined at 800 °C for 5 h. CuO/aluminosilicate was obtained as a green powder.

A typical procedure for the synthesis of 5-phenyl-1H-tetrazole

In a 25 mL round-bottomed flask, benzonitrile (1 mmol, 0.1 mL) and sodium azide (1.5 mmol, 0.097 g) were dissolved in DMF (5 mL). CuO/aluminosilicate (35 mg) was added to the reaction mixture and refluxed for 8 h. A tan color suspension was obtained. After the completion of the reaction, i.e. disappearance of nitrile, as monitored by TLC (n-hexane/EtOAc, 4:1, V/V), the reaction vessel was cooled to room temperature. To separate the catalyst, the mixture was centrifuged. The centrifugate was decanted and washed with ethyl acetate. To eliminate any unreacted nitrile, 5 M HCl (15 mL) was added until the reaction mixture became strongly acidic (pH 3). Then the reaction mixture was treated with ethyl acetate (30 mL) and stirred vigorously for 30 min. The resultant organic layer was extracted by n-hexane (3 × 50 mL) and washed with H2O (2 × 50 mL). The solvent was dried by anhydrous CaCl2 and evaporated by vacuo-rotary. A crude crystalline solid 5-phenyl-1H-tetrazole was obtained. To afford a pure product, the prepared tetrazole was recrystallized in hot ethanol. A white crystalline solid 0.091 g (89%, mp. 215–216 °C) was obtained. The product was sufficiently pure, characterized by FT-IR, 1H NMR and 13C NMR and compared with reported spectral data in the literature (Table 3, entry 1).

Results and discussion

The most convenient route for the synthesis of 5-substituted-1H-tetrazoles is via [3 + 2] dipolar cycloaddition reaction between organic nitriles and an azide moiety. In 2001, Demko and Sharpless reported a cycloaddition reaction between organic nitriles and sodium azide in the presence of ZnBr2 [39]. In continuation of our recent works in developing environmentally friendly synthetic methods in click chemistry, we used CuO/aluminosilicate as an efficient nanocatalyst for the synthesis of 5-substituted-1H-tetrazoles from organic nitriles and sodium azide (Scheme 1).

Characterization of the catalyst

The CuO/aluminosilicate catalyst was prepared from the reaction of CuCl2·6H2O, Al(NO3)3·9H2O, and tetraethyl orthosilicate (TEOS) in ethanol-ammonia solution, followed by formation of a gel at room temperature and subsequent calcination at 800 °C [38]. The catalyst was characterized by PXRD, SEM, and energy‐dispersive X‐ray (EDX) mapping techniques.

Powder X-ray diffraction pattern of the prepared CuO/aluminosilicate is shown in (Fig. 1). The analysis of the PXRD result shows that the catalyst crystalizes in a cubic system and the 3D structure of the catalyst is the same as the zeolite-A framework. The peaks observed at 2θ = 6.02 and 14.07° are assigned to the SiO2 and the peaks present at higher 2θ of 31.84, 36.91, 45.57, 59.74, 66.35° are attributed to the CuAl2O4 parts of the aluminosilicate framework. The presence and distribution of copper centers in the aluminosilicate support is confirmed by EDX mapping. The results show uniform distribution of copper atoms over the structure of the aluminosilicate support (Fig. 2). Also, SEM images of the particles showed spherical shaped morphology with an average particle size of about 63 nm (Fig. 3).

To optimize the reaction conditions, initially, the reaction of benzonitrile with sodium azide was selected as a model reaction. Therefore, to develop a better catalytic system, various reaction parameters such as solvent, catalytic loading and temperature were investigated. During our optimization studies, the effect of different types of solvents e.g. nonpolar, polar protic and polar aprotic solvents was screened (Table 1). Noticeably, the reaction was very sensitive to the type of solvent. No product was obtained in H2O, ethanol, toluene, THF, even though the reaction was prolonged up to 24 h (Table 1, entries 1–4). DMSO was effective, but the yields were lower than those obtained in DMF. As shown in Table 1, in terms of time and yield of tetrazole formation, among the various solvents studied, DMF was found to be the best. Hence, DMF was applied for all other reactions.

To evaluate the effect of catalyst loading on reaction rate, various amount of CuO/aluminosilicate was examined (Table 2). It is clearly seen that CuO/aluminosilicate plays an important role in [3 + 2] cycloaddition reaction of the benzonitrile with sodium azide. No product was obtained in the absence of catalyst (Table 2, entry 1). On the basis of the data of Table 2, the best results were achieved when the model reaction was carried out in the presence of 35 mg of CuO/aluminosilicate (Table 2, entry 6). Lower conversions and longer reaction times were observed when the amount of catalyst used was 15–30 mg, whereas a further increase in the amount of catalyst up to 45 mg did not show any significant improvement in the yield.

Temperature was another important factor affecting the rate of reaction, which was also assessed. To study the effect of the temperature, the reaction was initially carried out at room temperature and then elevated to reflux condition. Notably, the reaction did not proceed at room temperature and no product was detected. So, refluxing the reaction mixture in DMF was the best choice. We next investigated the scope and generality of this method in the [3 + 2] cycloaddition reaction of various nitriles with sodium azide in the presence of CuO/aluminosilicate (Table 3).

As shown in Table 3, a series of 5-substituted-1H-tetrazoles were prepared in good to high yields from various aromatic and aliphatic nitriles in the presence of CuO/aluminosilicate as a heterogeneous mesoporous catalyst. As expected, CuO/aluminosilicate showed to be an appropriate nanocatalyst for versatile synthesis of 5-substituted-1H-tetrazoles. All products are known compounds, which were identified by comparison of their spectral data (FT-IR, 1H NMR, 13C NMR) and physical properties such as melting points with those reported in the literature. At first, the disappearance of the spot of nitrile on the middle of TLC plate was observed. Furthermore, the FT-IR spectra revealed the disappearance of a medium and sharp stretching absorption band of C≡N at 2150 cm−1. In addition, the FT-IR spectra of the purified compounds showed the presence of some characteristic absorption bands corresponding to the NH group at 2159–3235 cm−1, (–N–N=N–) at 1233–1293, 1041–1106 and 1110–1189 cm−1 due to tetrazole rings. Additionally, a 13C NMR signal at 154–161 ppm is also assigned to the quaternary carbon of NH–C=N [21].

Remarkably, the activity of nitrile compound toward azide ion play an important role in [3 + 2] cycloaddition reactions. As shown in Table 3, in contrary to the aromatic case, the best yields and times were obtained by aliphatic nitriles. In aromatic nitriles, the low yields accompanied with longer reaction times may be attributed to the significant resonance between the aromatic ring and cyano group, which decreases the electrophilic character of cyano group. In addition, aromatic compounds including electron donating and withdrawing substituents at para- or meta-positions showed no significant difference in product yields or reaction times (Table 3, entries 1–9). Maybe it could be attributed to the strong withdrawing effect of the cyano group that the presence of other groups does not affect considerably its behavior. Bifunctional aliphatic nitriles reacted similarly and provided good yields in formation only one tetrazole ring (Table 3, entries 11–13).

On the basis of related mechanisms of triazole and tetrazole formation in the presence of acidic catalysts reported in the literature [39], a plausible mechanism may be proposed (Scheme 2). It may be supposed that, initially, coordination of Cu catalyst with nitrogen atom of nitrile compound is occurred. Rationally, this complexation will accelerate the cyclization process. This claim is supported by the experimental facts that the reaction did not remarkably proceed in the absence of the Cu catalyst, even, after prolonged reaction time (Table 2, entry 1). After the activation of cyano group by the copper nanocomposite, a [3 + 2] cyclization reaction between the C≡N bond of nitrile compound and azide ion could take place readily. Finally, a stable 5-substituted-1H-tetrazole was obtained by an acidic work-up (Scheme 2).

The reusability capability and recovery of the applied catalyst were also examined in the model reaction. The applied CuO/aluminosilicate was successfully separated from the reaction mixture by centrifugation and reused three times with moderate loss of the catalytic activity (Table 4).

As reported in the literature, a number of derivatives of tetrazoles are shown to display biological activities. So, we were also interested to use our well established method in the synthesis of some of the derivatives of tetrazoles including Ts, Ms and acyl substituents by sequential one pot preparation from benzonitrile (Scheme 3; Table 5).

Conclusion

In summary, it can be claimed that we have developed a new application of CuO/aluminosilicate nanocomposite as an inexpensive, environmentally-friendly and efficient heterogeneous nanocatalyst for the synthesis and functionalization of a broad range of aliphatic and aromatic 5-substituted-1H-tetrazoles in good to high yields. The procedure was simple and clean. It is also worth emphasizing that CuO/aluminosilicate was easily prepared, recovered and reused. It is envisaged that the thermal and chemical stability as well as ease of recovery of CuO/aluminosilicate makes it as a highly efficient and heterogeneous nanocatalyst, which is potentially suitable for further applications in organic syntheses and industrial requirements.

References

Kantam ML, Kumar KBS, Sridhar Ch (2005) Adv Synth Catal 347:1212

Yapuri U, Palle S, Gudaparthi O, Narahari SR, Rawat DK, Mukkanti K, Vantikommu J (2013) Tetrahedron Lett 54:4732

Wang Z, Liu Z, Cheon SH (2015) Bull Korean Chem Soc 36:198

Abdollahi-Albeik M, Moaddeli A (2016) J Chem Sci 128(1):93

Herr RJ (2002) Bioorg Med Chem 10:3379

Voitekhovich SV, Lesnyak V, Gaponik N, Eychmüller A (2015) Small 11(43):5728

Frija LMT, Ismael A, Cristiano MLS (2010) Molecules 15:3757

Kumar S, Kumar A, Agarwal A, Awasthi SK (2015) RSC Adv 5:21651

Frija LMT, Cristiano MLS, Gόmez-Zavaglia A, Reva I, Fausto I (2014) J. Photochem Photobiol C 18:71

Nanjundaswany HM, Abrahamse H (2014) Heterocycles 89(9):2137

Roh J, Vávrová K, Hrabálek A (2012) Eur J Org Chem 31:6101

Maleki A, Sarvary A (2015) RSC Adv 5:60938

Ghodsinia SSE, Akhlaghinia B (2015) RSC Adv 5:49849

Aureggi V, Sedelmeier G (2007) Angew Chem Int Ed 46:8440

Rama V, Kanagaraj K, Pitchumani K (2011) J Org Chem 76:9090

Nammalwar B, Muddala NP, Pitchimani R, Bunce RA (2015) Molecules 20:22757

Heravi MM, Fazeli A, Oskooie HA, Beheshtiha YS, Valizadeh H (2012) Synlett 23:2927

Patil DR, Deshmukh MB, Dalal DS (2012) J Iran Chem Soc 9:799

Zhu Y, Ren Y, Cai C (2009) Helv Chim Acta 92:171

Lang L, Zhou H, Xue M, Wang X, Xu Z (2013) Mater Lett 106:443

Akhlaghinia B, Rezazadeh S (2012) J Braz Chem Soc 23(12):2197

Du Z, Si C, Li Y, Wang Y, Lu J (2012) Int J Mol Sci 13:4696

Nanjundaswamy HM, Abrahamse H (2014) Heterocycles 89(9):2137

Javaherian M, Doraghi F (2015) Reac Kinet Mech Cat 116:235

Maleki B, Shirvan HK, Taimazi F, Akbarzadeh E (2012) Int J Org Chem 2:93

Dabiri M, Salehi P, Baghbanzadeh M, Zolfigol MA, Agheb M, Heydari S (2008) Catal Commun 9:785

Zolfigol MA, Mirjalili BF, Bamoniri A, Zarchi MAK, Zarei A, Khazdooz L, Noei J (2004) Bull Korean Chem Soc 25:1414

Zolfigol MA, Madrakian E, Ghaemi E (2002) Molecules 7:734

Khalafi-Nezhad A, Foroughi H, Doroodmand M, Panahi F (2011) J Mater Chem 21:12842

Soltani Rad MN (2017) J Braz Chem Soc 28(1):11

Long W, Qui W, Guo C, Li C, Song L, Bai G, Zhang G, He H (2015) Molecules 20:21178

Stanley LM, Sibi MP (2008) Chem Rev 108(8):2887

Meldal M, TornØe CW (2008) Chem Rev 108(8):2952

Allen SE, Walvoord RR, Padilla-Salinas R, Kozlowski MC (2013) Chem Rev 113(8):6234

Kolb HC, Finn MG, Sharpless KB (2001) Angew Chem Int Ed 40:2004

Javaherian M, Kazemi F, Ghaemi M (2014) Chin Chem Lett 25:1643

Babu SG, Sakthivel R, Dharmaraj N, Karvembu R (2014) Tetrahedron Lett 55:6873

Babu SG, Neelakandeswari N, Dharmaraj N, Jackson D, Karvembu R (2013) RSC Adv 3:7774

Demko ZP, Sharpless KB (2001) J Org Chem 66(24):7945

Coca A, Turek E (2014) Tetrahedron Lett 55(16):2718

Fazeli A, Oskooie HA, Beheshtiha YS, Heravi MM, Valizadeh H, Bamoharram FF (2013) Monatsh Chem 144(9):1407

Meshram GA, Deshpande SS, Wagh PA, Vala VA (2014) Tetrahedron Lett 55(25):3557

Acknowledgements

This study was supported by the committee grant of Shahid Chamran University of Ahvaz, No. 95/3/02/31400. Authors gratefully thank this support.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Movaheditabar, P., Javaherian, M. & Nobakht, V. CuO/aluminosilicate as an efficient heterogeneous nanocatalyst for the synthesis and sequential one-pot functionalization of 5-substituted-1H-tetrazoles. Reac Kinet Mech Cat 122, 217–228 (2017). https://doi.org/10.1007/s11144-017-1211-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-017-1211-1