Abstract

In this study, bone char (BC) was used as an adsorbent for sodium dodecyl sulfate (SDS) in aqueous solution. Batch studies were performed to address various experimental parameters like contact time (0–360 min), adsorbent dosage (3, 5 and 7 g/L), initial SDS concentration (0.5, 1 and 2 mg/L) for the removal of the SDS. A greater percentage of SDS was removed with a decrease in its initial concentration, and an increase in the amount of adsorbent used. The maximum removal percentage of SDS for 0.5, 1 and 2 mg/L were estimated 80.2, 76 and 60.5 %. The maximum removal of SDS was obtained in the adsorbent dose of 7 g/L. Equilibrium isotherms were analyzed by Freundlich and Langmuir isotherm equations. The Freundlich equation is found to best represent the equilibrium data for the adsorption system. The kinetic study showed that the adsorption of SDS on BC was a gradual process. Pseudo-first order, pseudo-second order, Eluvich and intraparticle diffusion models were used to fit the experimental data. The intraparticle diffusion model was able to provide realistic description of adsorption kinetics.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Surfactants are a diverse group of chemicals that are designed to have cleaning or solubilization properties. The surfactants have also been widely used in households, textiles, fibers, food, paints, polymers, plant protection, cosmetics, pharmaceuticals, mining, oil recovery, pulp and paper industries [1]. Linear alkyl benzene sulfonates, alkyl ethoxy sulfates, alkyl sulfates, alkylphenol ethoxylates, alkyl ethoxylates, and quaternary ammonium compounds are the commonly used commercial surfactants. They generally consist of a polar head group, which is well solvated in water, and a non-polar hydrocarbon tail, which is not easily dissolved in water. Hence, surfactants combine hydrophobic and hydrophilic properties in one molecule [2–8]. Surfactants consist mainly of three types: anionic, nonionic and cationic. Anionic and cationic surfactants together are called ionic surfactants. Ionic surfactants demonstrate approximately two-third of these surfactants. Cationic surfactants demonstrate less than 10 % of the ionic surfactants and remainder is non-ionic surfactant. Therefore, anionic surfactants are the major class of surfactants used in detergent formulations. The common class of anionic surfactant is branched alkyl benzene sulfonate, linear alkyl benzene sulfonate and linear alkyl sulfate. A member of the linear alkyl benzene sulfonates family is sodium dodecyl sulfate (SDS), which is used as detergent, as dispersant, and as anionic surfactant all over world [9, 10]. The surfactant consumption has rapidly increased in the world, hence surfactants may be considered as major contaminants in the environment, especially in surface waters [11, 12]. Besides the toxic effects of surfactants, their existence in waters even under the toxic level causes many adverse effects on biological life. They cause pathological, physiological and biochemical effects on aquatic animals. In aquatic plants species, they have effects such as break-up of the chlorophyll–protein complex, death of the cell by damaging the membrane, delay in metabolism and growth [13]. The conventional methods for surfactant removal from the water environment involve processes such as chemical and electrochemical oxidation, membrane technology, chemical precipitation, photocatalytic degradation, adsorption and, various biological methods [14]. Many of these processes are not cost effective and/or not suitable for application on a field scale. Adsorption technology can be low cost and can be applied in small devices. Adsorbents are “low cost” when they require little processing and are abundant, either in nature, or as a by-product or waste material from another industry [14, 15]. It therefore offers potential for use on household scale, also in low-income households. In this research, BC was used as an adsorbent to remove SDS from the solution. BC or animal char is a granular substance produced by burning animal bones supplied by the animal waste rendering industry as bone meal. From a structural viewpoint, BC consists of 80 % calcium phosphate to form the hydroxyapatite and 10 % carbon. The carbon contained in the porous structure of hydroxyapatite of BC is distributed throughout its structure [16]. BC has been used extensively as an adsorbent for the decolorization of cane sugar. Also, the sorbent was proposed as the defluoridating agent [17]. To the best of our knowledge and based on the literature review, the use of BC as an adsorbent to remove detergents has seldom been reported. The aim of this work was to provide fundamental equilibrium and kinetic information in the sorption of SDS from aqueous solution on BC.

Materials and methods

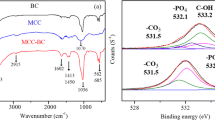

Preparation and characterization of the adsorbent

The bone from cattle was crushed into pieces of 10–15 cm in length, rinsed three times in deionized water and boiled at least three times in distillate water for 4 h to remove fate and residual protein pieces. After that, the bone was dried at 105 °C overnight and cooled in desiccators. The pyrolysis of bone was accomplished in an electric furnace that was externally heated by electric power sources. BC is derived from the pyrolysis of the crushed animal bones by heating them to 900 °C for 4 h. The solid yield from the pyrolysis step was transfer to a desiccator and cooled in room temperature. BC was then pulverized using ASTM standard sieves with range of 10–40 mesh [17].

Adsorbate

A stock solution of SDS (1000 mg/L) was prepared by dissolving SDS (Merck, India) in double distilled water. The chemical structure of SDS is shown in Fig. 1. The concentration range of SDS prepared from stock solution varied between 0.5 and 10 mg/L. All the chemicals used were of analytical reagent grade.

Analysis

The concentrations of SDS in the solutions before and after equilibrium were determined by the acridine orange method. Briefly, acridine orange [(3,6-bis(dimethylamino)], is used for the preparation of 5 × 10−3 M solution to be used as a stock. The sample solution (10 mL) containing SDS (concentration range of 0.1–0.6 mg/L) is taken in a separation funnel. Acridine orange and glacial acetic acid (100 μL of each) are added followed by the addition of 5 mL toluene. The contents are shaken for 1 min and then allowed to settle for 5 min. The aqueous layer is discarded. SDS forms a yellow colored complex with acridine orange. The toluene layer is collected and 2.5 mL of this solution is used directly for the absorbance measurement at a wavelength of 499 nm [13, 18]. The calibration curve is linear in the range of 0–6.0 ppm of SDS concentration. The pH of the solution was measured with a pH meter (Eutech, Singapore) using a combined glass electrode. The BC was characterized by the pH of zero point charge (pHzpc) of the BC; the pHzpc of the BC was determined using the batch equilibrium technique with 1:1,000 and 1:80 solid to liquid ratios in 0.1 (M) KNO3 solution. Potassium nitrate was employed as an inertial electrolyte. The initial pH value of the KNO3 solution was adjusted range from 2 to 12 by adding 0.1 M HNO3 or KOH. The solutions were allowed to equilibrate for 24 h in an isothermal shaker at 25 ± 1 °C. The suspensions were filtered by filter paper, and the pH values were measured again by using of a pH meter. A blank test without BC was also made in order to eliminate the effect of interferences.

Adsorption experiment

The adsorption isotherms for SDS removal were conducted by mixing 0.5–2 mg/L SDS with 3–7 g/L BC. The mixtures were stirred for 6 h allowing the adsorption to reach equilibrium. A mechanical shaker at 100 rpm was used (IKA, Germany) to provide a reproducible and homogeneous mixing. The mixtures were filtered off afterwards. The initial and final SDS concentrations of the solutions were measured with the acridine orange method. The adsorption equilibrium data are conveniently represented by adsorption isotherms, which correlate to the relationship between the mass of the SDS adsorbed per unit mass of BC (qe) and the SDS concentration for the solution at equilibrium (Ce). The experimental data obtained were fitted to the Langmuir adsorption isotherm applied to equilibrium adsorption assuming mono-layer adsorption onto a surface with a finite number of identical sites and is represented as Eq. 1:

where qe is the solid phase equilibrium concentration (mg/g), Ce is the liquid-phase equilibrium concentration of SDS (mg/L), Kc is the equilibrium adsorption constant related to the affinity of binding sites (L/mg), and qm is the maximum amount of SDS per unit weight of BC for complete monolayer coverage [19] qm and Kc can be calculated from the slope and intercept of plots of Ce/qe versus Ce [20].

The Freundlich isotherm was used in study that it was known as heterogeneous adsorption and described by Eq. 2:

where qe is the amount of SDS (mg/g), Ce is the equilibrium concentration of SDS (mg/L), kf and 1/n are the Freundlich constants. Freundlich constants can be determined from the slope and intercept of linear plots of log qe versus log Ce, respectively [20, 21].

Kinetic studies

Adsorption kinetic models represent the adsorption reaction. The conventional models of adsorption reaction are pseudo-first order rate, pseudo-second order rate, Eluvich’s, second-order rate and the adsorption diffusion model. The models can be described by following Eqs. (3, 4, 5, 6):

Pseudo-first order, Eq. 3:

where qe and qt are the adsorption capacity (mg/g) at equilibrium and at time t, k1 is the rate constant of pseudo-first order adsorption (L/min) [21].

The values of log (qe − qt) were linearly correlated with t. The plot of log (qe − qt) versus t should give a linear relationship from which k1 and qe can be determined from the slope and intercept of the plot, respectively.

Pseudo-second-order Eq. 4:

where k1 (1/min) and k2 (g/mg min) are constants of adsorption rate, qt (mg/g) is adsorption capacity at time t (min), qe is adsorption capacity at equilibrium conditions (mg/g).

The plot of (t/qt) and t of Eq. 4 should give a linear relationship from which qe and k2 can be determined from the slope and intercept of the plot [22, 23].

The Eluvich equation is given as:

where α is the initial adsorption rate (mg/g min), β is the desorption constant (g/mg) during any one experiment

The simplified form of the Eluvich equation is:

If SDS adsorption fits the Eluvich model, a plot of qt versus ln t should yield a linear relationship with a slope of (1/β) and an intercept of (1/β) ln(α·β). Recently the Eluvich equation has also been proposed to describe the adsorption process of pollutants from aqueous solutions, such as cadmium removal from effluents using BC, and Cr(VI) and Cu (II) adsorption by chitin, chitosan, and Rhizopus arrhizus [24–26]. The intraparticle diffusion or homogeneous solid diffusion model which can describe mass transfer in an amorphous and homogeneous sphere:

where R is the percent of SDS adsorbed, t is the contact time (h), a is the gradient of linear plots, k id is the intraparticle diffusion rate constant (1/h), a depicts the adsorption mechanism, k id may be taken as a rate factor, i.e. percent SDS adsorbed per unit time [25].

The values of k id were calculated from the slope of such plots and the R 2 values led to the conclusion that the intraparticle diffusion process is the rate-limiting step. Higher values of k id illustrate an enhancement in the rate of adsorption, whereas larger k id values illustrate a better adsorption mechanism, which is related to an improved bonding between SDS and the adsorbent particles.

The amounts of SDS adsorbed per unit mass of the BC (qt) at any time, t, were calculated from the concentrations in solutions before and after adsorption. At any time, the amount of SDS adsorbed, qt (mg/g), by BC was calculated from the mass balance equation as follows:

where qt is the amount of adsorbed SDS on BC at any time (mg/g); C0 and Ct are the concentration of SDS before adsorption and after contact time t (mg/L); V is the volume of SDS solution (L), and W is the mass of BC used (g).

The percent removal of SDS was calculated as follows:

where q is the amount of adsorbed SDS per gram BC (mg/g), C0 is the initial SDS concentration (mg/L), Ce is the concentration of SDS at equilibrium with the solid phase (mg/L), V is the volume of the solution, L, and M is the mass of sorbent used (g) [19, 25, 27–29].

Results and discussion

Some properties of the adsorbent are presented in Table 1. The by pHzpc of an adsorbent is a very important characteristic that determines the pH at which the adsorbent surface has net electrical neutrality. At this value, the acidic or basic functional groups no longer contribute to the pH of the solution. Experiments showed that the pHzpc of the BC was about 8.3. It has been reported that at any pH below pHzpc, the surface charge is positive whereas at pH level above pHzpc the surface charge is negative. Based on the value found for pHzpc, it can be deduced that the BC surface charge is positive as the solution pH is less than 8.3. The positive charge on the surface of the BC may enhance the removal of endotoxins via adsorption. Specific surface area and pore volume were determined with the BET method. The specific surface area of BC particles was 130.75 m2/g. The prepared BC was able to adsorb significant amounts of iodine. The iodine number gives an estimation of the relative surface area of two samples and is usually used to measure the porosity for pores greater than 1.0 nm in diameter. Thus, the iodine number was measured to evaluate the adsorptive capacity of the BC.

Effect of initial SDS concentration

The adsorption of SDS was measured at given contact time (360 min) for three different initial SDS concentrations from 0.5 to 2 mg/L. The plot reveals that the SDS removal efficiency is higher at the starting point (Fig. 2). This is most likely due to the larger surface area of the BC available at beginning for the adsorption of SDS. During the removal process, a significant decrease of SDS concentrations is obtained at 180 min, and it remains constant after equivalent time. Maximum removal percentages of SDS for 0.5, 1 and 2 mg/L were estimated as 80.2, 76 and 60.5 %. At higher concentrations of the adsorbate, lower adsorption yields were observed due to the saturation of the adsorption sites [30]. An increase of BC dose from 3 to 7 g, the adsorption capacity was increased or removal efficiency was decreased (Fig. 3). The evaluation of adsorption conditions reveals that the higher adsorption of SDS occurs in 90 min, and afterward the variation is not significant.

Effect of BC dosage

The removal of SDS using a different dosage of BC (3, 5 and 7 g) was considered at different conditions. The maximum and minimum removal percentages are related to 7 and 3 g of adsorbent doses (Fig. 4). However, the estimated removal percentages of SDS on BC for 3, 5 and 7 g dosage about were 85.9, 88.9 and 92.7 %. Generally, with increasing of adsorbent dosage and constant value of SDS in the liquid phase, the available active sites were increased. Hence, the adsorption capacity was increased and a lower competition effect of adsorbate agents can be observed. The adsorption of SDS increases rapidly with an increase in the amount of BC due to the greater availability of the surface area at higher concentration of the adsorbent. Any further addition of the BC beyond this did not cause any significant change in the adsorption. This may be owing to the overlapping of adsorption sites as a result of overcrowding of adsorbent particles. The maximum removal of SDS was obtained in the adsorbent dose of 7 g/L SDS. Ozer et al. have reported that the particle size range is constant, and the surface area is directly proportional to the mass of adsorbent in the solution. In spite of that, the decrease in adsorption capacity can be explained with the reduction in the effective surface area [31].

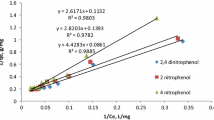

Equilibrium adsorption isotherms

For the distribution of the adsorption molecules between solid phase and liquid solution at the time of reaching the adsorption process to an equilibrium state, the adsorption isotherm is used. Fitting the isotherm data to various isotherm models results in suitable a model for design purposes [28]. To describe the distribution of SDS, the mathematical models such as the Langmuir and Freundlich isotherms were used. These isotherms relate SDS uptake per unit mass of BC (qe) to the equilibrium adsorbate concentration in the bulk fluid phase (Ce). The common sorption isotherms between SDS and BC are shown in Fig. 4. In many adsorption processes, the Langmuir adsorption isotherm has been extensively applied. A basic supposition of the Langmuir isotherm is that the sorption occurs at specific homogeneous sites in the adsorbent. Furthermore, when a site is occupied by a solute, no extra adsorption can occur at that site [32]. The constants in the Langmuir isotherm can be determined by plotting (Ce/qe) versus (Ce). Here kl and qm are the Langmuir constants and the maximum adsorption capacity for the BC (Table 2). The isotherm was used for monolayer adsorption and smooth and homogeneous surface.

Kinetic studies

Kinetic studies are carried out to develop an understanding of controlling reaction pathways and the mechanisms of sorption reactions, and the data can be applied to predict the rate at which the target contaminant is removed from aqueous solutions [33]. In order to evaluate the SDS adsorption, four kinetic models were considered. These models are: (i) pseudo-first order, (ii) pseudo-second order, (iii) Eluvich and (iv) intraparticle diffusion. Fig. 5 illustrates the trends of these models. Also, the kinetic constants are shown in Table 3. According to the obtained results, it can be observed that the Eluvich (Fig. 5c) and intraparticle diffusion (Fig. 5d) models fit better than other kinetic models (R > 0.921.). Also, it can be noted that the lower concentrations of SDS correlated more with intraparticle diffusion, and the Eluvich kinetics is desirable for higher concentrations. As obvious from Fig. 5a, there are three distinct phases. The first step with a sharp slope confirms the external surface adsorption, the second step with a gradual slope can demonstrate the intraparticle diffusion, and the plateau at the end portion confirms the equilibrium. In the intraparticle diffusion model, three different phases were observed first. The higher values of k id (42.36) illustrate an enhancement in the rate of adsorption, whereas lower k id values (30.06) illustrate a better adsorption mechanism, which is related to an improved bonding between SDS and the BC particles (Tables 3). The high correlation coefficient (R 2 = 0.955) indicates the presence of intraparticle diffusion as the rate determining step. The correlation coefficient ranged from 0.0.932 to 0.955 as the initial concentration varied from 0.5 to 2 ppm.

Conclusions

An increase in adsorbent dosage leads to increase in SDS adsorption due to increased number of adsorption sites. A maximum uptake capacity of SDS was obtained at adsorbent dosage of 7 g/L. Equilibrium was attained within 180 min for the adsorption of SDS onto BC. The result suggests that the adsorption of SDS on BC involves a complex mechanism and in the adsorption process with two distinct stages. The initial stages of boundary layer diffusion due to external mass transfer effects, and the later stage, it was due to intraparticle diffusion which contributes to the rate determining step. BC, as high potential adsorbent due to many applications in comparison with others, was shown to be suitable for the removal of SDS, easily. Also, by the higher conformity of the intraparticle diffusion and Eluvich models, it can be asserted that those were considered as desirable kinetics rather than others. Lower concentrations of SDS fitted the intraparticle diffusion better, and the Eluvich kinetics is proper for higher concentrations. In kinetic studies, higher amounts of R 2 occurred with lower concentrations of SDS. The adsorption isotherm studies showed that the Freundlich adsorption isotherm model fits well with the experimental data. The maximum adsorption capacity (q max) was obtained for SDS (0.298 mg/g) with (R 2 = 0.97).

References

Olkowska E, Polkowska z, Namiesnik J (2012) Analytical procedures for the determination of surfactants in environmental samples. Talanta 88:1–13

Aloui F, Kchaou S, Sayadi S (2009) Physicochemical treatments of anionic surfactants wastewater: effect on aerobic biodegradability. J Hazard Mater 164(1):353–359

Ayranci E, Duman O (2007) Removal of anionic surfactants from aqueous solutions by adsorption onto high area activated carbon cloth studied by in situ UV spectroscopy. J Hazard Mater 148(1–2):75–82

Raghumani Singh T, Niraj Luwang M, Srivastava SK (2011) Kinetic studies on sodium dodecyl sulfate micelle inhibited reactions of triphenylmethyl carbocations with cyanide ion. Reac Kinet Mech Cat 104(1):17–26

Tadakamalla K, Marathe KV (2011) Hydrodynamic study and optimization strategy for the surfactant recovery from aqueous solutions. Desalination 266(1–3):98–107

Ying G–G (2006) Fate, behavior and effects of surfactants and their degradation products in the environment. Environ Int 32(3):417–431

Yuksel E, sengil A, ozacar M (2009) The removal of sodium dodecyl sulfate in synthetic wastewater by peroxy-electrocoagulation method. Chem Eng J 152(2–3):347–353

Ying GG (2006) Fate, behavior and effects of surfactants and their degradation products in the environment. Environ Int 32(3):417–431

Gupta S, Pal A, Ghosh PK, Bandyopadhyay M (2003) Performance of waste activated carbon as a low-cost adsorbent for the removal of anionic surfactant from aquatic environment. J Environ Sci Health Part A 38(2):381–397

Levine LH, Garland JL, Johnson JV (2005) Simultaneous quantification of polydispersed anionic, amphoteric and nonionic surfactants in simulated wastewater samples using C18 high-performance liquid chromatography- quadrupole ion-trap mass spectrometry. J Chromatogr A 1062(2):217–225

Adak A, Bandyopadhyay M, Pal A (2005) Removal of anionic surfactant from wastewater by alumina: a case study. Colloids Surf A 254(1–3):165–171

Kruawal K, Sacher F, Werner A, Muller J, Knepper TP (2005) Chemical water quality in Thailand and its impacts on the drinking water production in Thailand. Sci Total Environ 340(1–3):57–70

Lin S-H, Teng M-Y, Juang R-S (2009) Adsorption of surfactants from water onto raw and HCl-activated clays in fixed beds. Desalination 249(1):116–122

Schouten N, van der Ham LGJ, Euverink G-JW, de Haan AB (2007) Selection and evaluation of adsorbents for the removal of anionic surfactants from laundry rinsing water. Water Res 41(18):4233–4241

Mortazavi SB, Asgari G, Hashemian SJ, Moussavi G (2010) Degradation of humic acids through heterogeneous catalytic ozonation with bone charcoal. React Kinet Mech Cat 100(2):471–485

Smiciklas I, Onjia A, Raicevic S, Janackovic Ä, Mitric M (2008) Factors influencing the removal of divalent cations by hydroxyapatite. J Hazard Mater 152(2):876–884

Rezaee A, Ghanizadeh G, Behzadiyannejad G, Yazdanbakhsh A, Siyadat SD (2009) Adsorption of endotoxin from aqueous solution using bone char. Bull Environ Contam Toxicol 82(6):732–737

Adak A, Pal A, Bandyopadhyay M (2005) Spectrophotometric determination of anionic surfactants in wastewater using acridine orange. Ind J Chem Technol 12(2):145–148

RodrIguez A, GarcIa J, Ovejero G, Mestanza M (2009) Adsorption of anionic and cationic dyes on activated carbon from aqueous solutions: equilibrium and kinetics. J Hazard Mater 172(2):1311–1320

Shokoohi R, Vatanpoor V, Zarrabi M, Vatani A (2010) Adsorption of Acid Red 18 (AR18) by activated carbon from poplar wood-A kinetic and equilibrium study. J Chem 7(1):65–72

Tong KS, Azraa A, Noordin MJ (2012) Isotherms and kinetics studies on the removal of methylene blue from aqueous solution by Gambir. IJESD 3(3):232–236

Abechi ES, Gimba CE, Uzairu A, Kagbu JA (2011) Kinetics of adsorption of methylene blue onto activated carbon prepared from palm kernel shell. Arch Appl Sci Res 3(1):154–164

Moussavi G, Talebi S, Farrokhi M, Sabouti RM (2011) The investigation of mechanism, kinetic and isotherm of ammonia and humic acid co-adsorption onto natural zeolite. Chem Eng J 171(3):1159–1169

Cheung CW, Porter JF, McKay G (2001) Sorption kinetic analysis for the removal of cadmium ions from effluents using bone char. Water Res 35(3):605–612

Qiu H, Lv L, Pan B-c, Zhang Q-j, Zhang W-m, Zhang Q-x (2009) Critical review in adsorption kinetic models. J Zhejiang Univ Sci A 10(5):716–724

Sag Y, Aktay Y (2002) Kinetic studies on sorption of Cr(VI) and Cu (II) ions by chitin, chitosan and Rhizopus arrhizus. Biochem Eng J 12(2):143–153

Demirbas E, Kobya M, Senturk E, Ozkan T (2004) Adsorption kinetics for the removal of chromium(VI) from aqueous solutions on the activated carbons prepared from agricultural wastes. Water SA 30(4):533–540

Hameed BH, Din ATM, Ahmad AL (2007) Adsorption of methylene blue onto bamboo-based activated carbon: kinetics and equilibrium studies. J Hazard Mater 141(3):819–825

Sharain-Liew YL, Joseph CG, How SE (2011) Biosorption of lead contaminated wastewater using cattails (Typha angustifolia) leaves: kinetic studies. J Serb Chem Soc 76(7):1037–1047

Özer D, Dursun G, Özer A (2007) Methylene blue adsorption from aqueous solution by dehydrated peanut hull. J Hazard Mater 144(1–2):171–179

Ozer D, Dursun G, Ozer A (2007) Methylene blue adsorption from aqueous solution by dehydrated peanut hull. J Hazard Mater 144(1–2):171–179

Ahmed Muherei M, Junin R (2009) Equilibrium adsorption isotherms of anionic, nonionic surfactants and their mixtures to shale and sandstone. Modern Appl Sci 3(2):158–167

Boparai HK, Joseph M, O’Carroll DM (2011) Kinetics and thermodynamics of cadmium ion removal by adsorption onto nano zerovalent iron particles. J Hazard Mater 186(1):458–465

Acknowledgments

The authors wish to acknowledge the financial support of Tarbiat Modares University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hashemi, S., Rezaee, A., Nikodel, M. et al. Equilibrium and kinetic studies of the adsorption of sodium dodecyl sulfate from aqueous solution using bone char. Reac Kinet Mech Cat 109, 433–446 (2013). https://doi.org/10.1007/s11144-013-0559-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-013-0559-0