Abstract

The aim of this study is the removal of endotoxin from aqueous solution using bone char (BC) as an adsorbent material. The BC was prepared from cattle animal bone by pyrolysis in a furnace at 850°C. The morphology and physico-chemical characteristics of the adsorbent were investigated. Kinetic studies revealed that the adsorption of endotoxin is rapid. The adsorption mechanisms in the endotoxin-BC had a significant contribution from film diffusion. The maximum adsorption efficiency achieved is 98% at an adsorbent dose of 40 g L−1 with an initial endotoxin concentration of 80 Eu mL−1. The results show that the Langmuir isotherm adsorption equation model describe the experimental adsorption isotherm with good accuracy. A survey of the regeneration capabilities showed that the BC could be regenerated and rendered endotoxin free by heating at 350°C for 30 min. The results suggest that BC could be used as effective adsorbent for endotoxin removal.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Endotoxins, also called pyrogens, are biologically active lipopolysaccharides (LPS) that are found in the outer layer of the cell walls of most gram-negative bacteria and some cyanobacteria (Hanora et al. 2006). The release of endotoxins from bacteria takes place either during either cell lyses or multiplication and has a high stability even at high temperatures (stable at 121°C for 1 h) and pH values due to its amphoteric structure (Anderson et al. 2003). The general symptoms of endotoxin exposure for humans include fever, diarrhea, vomiting, hypotension, shock, intravascular coagulation and death (Tessarolo et al. 2006). Endotoxin is not only injurious by itself, but it also augments other toxic agents so that together they may cause greater and more sustained damage. For example, endotoxin may boost the toxicity of ethanol and a variety of drugs (Anderson et al. 2002). Also, it is known that endotoxin may act as a co-allergen, facilitating sensitization to other allergens, or they may increase the severity of allergic disease (Szymanska 2005). The potential pathways of water-associated endotoxin exposure in humans include direct introduction in to the blood stream via semi permeable dialysis membranes and inhalation of moisture-saturated air in showers, swimming pools, hot tubs, saunas, and dental offices (Anderson et al. 2007). Exposure to endotoxins by drinking water used for preparation or dilution of solutions for intravenous injection or dialysis may be even more serious (Castor et al. 2005). Several other settings for endotoxin exposure include sawmills, paper recycling plants (repulping and deinking), fiberglass manufacturing, animal handling, cotton/textile milling, hemp processing and potato sorting (Sarantila et al. 2001; Anderson et al. 2007). Although several exposure routes and the adverse effects of this pollutant have been identified, unfortunately there is only limited information available on untreated surface water, ground water, and drinking water endotoxin concentrations. There are several ways in which endotoxin polluted water can be detoxified. For treat drinking water, the peracetic acid, heat, association of heat and citric acid, oxidation with hydrogen peroxide, or permanganate are most commonly applied. Although these procedures are the most common methods, the energy requirements for heating, control over chemical doses, the safety of operators, storage problems, and the control of their by products are difficult obstacles (Anderson et al. 2002). In contrast with these methods, sorption processes are simple to perform, usually inexpensive, and applicable for decentralized water treatment facilities and on-site decontamination (Daus et al. 2004). A wide variety of different materials has been proposed for the sorption of pollutants (Tsai et al. 2002; Wanngah and Hanafiah 2008). It has recently been suggested that poorly crystallized apatite, such as BC apatite, might represent a low-cost and readily available phosphate source that could be used to as an adsorbent (Smiciklas et al. 2008). Every year in many countries, a large number of domestic animals (sheep and cows) are slaughtered for meat and these animals have a large amount of bone waste that can be used as feedstock or a fuel for energy generation. Some countries have large hydrocarbon resources and no need for this alternative fuel source, but safe bone disposal is a problem. Therefore, using these wastes for producing BC and other products provides a safe and useful disposal route (Purevsuren et al. 2004). BC is a mixed compound adsorbent in which carbon is distributed throughout the porous structure of hydroxyapatite (Ca10(PO4)6(OH)2 or CaHAP). BC is 76% CaHAP, which is not only a major inorganic constituent of teeth and bones but also phosphate rock (Cheung et al. 2001). The physical and chemical properties of CaHAP have been widely reported; studies show that the removal mechanism provide not only an adsorption effect but also a type of ion-exchange reaction between the ions in solution and the calcium ions of the apatites (Danny et al. 2004). Although it is not used on a large scale commercially, BC is occasionally used to treat drinking water (Xie et al. 2004). Its potential as a defluoridating agent and to remove heavy metals from solution has also been reported in the literature (Choy and McKay 2005). In the present study, BC was produced from cattle bone, and it is used as an inexpensive adsorbent to investigate the effectiveness of using BC for endotoxin removal from aqueous solution.

Materials and Methods

All of the chemicals used for the solutions were reagent grade and were used without further purification. The water used in solutions was purified with a MQ-UV water device (Millipore). The electrical conductivity (EC) of the distillated water that was used for the experiments was lower than 3 μmohs cm−1. The pH was measured using Hach pH meter (Hach Co., USA).

All glassware was rendered pyrogen free by heating at 400°C for at least 30 min. The plastic apparatuses were treated with 33% H2O2 then rinsed with pyrogen-free water and dried at 80°C for 8 h. A fresh bottle of pyrogen-free water was used for each experimental run to avoid potential contamination problems. Escherichia coli (ATCC 25922) was obtained from reference laboratory in Tehran, Iran. Endotoxin extraction was performed using the hot phenol–water (Westphal and Jann 1965). The endotoxin concentrations was determined with a limulus amebocyte lysate (LAL) test (Sarantila et al. 1999). The calibration curve was plotted with using the standard endotoxin of E. coli O55:B5 (Choa chrom Co., USA).

The bone from cattle and sheep was crushed into pieces of 10–15 cm in length, rinsed three times in deionized water and boiled at least three times in distillated water for 4 h to remove fate and residual protein pieces. The bone was then dried at 110°C over night and cooled in a desiccator. Pyrolises of bone was performed in a rectangular furnace that was externally heated by electric power sources. The pyrolysis was carried out at 850°C for 4 h so that the heating rate was 35 K min−1. The solid yield from the pyrolysis step was transport to a desiccator and cooled to room temperature. The BC was then pulverized using ASTM standard sieves with range of 10–16 mesh (ASTM 2003); deionized water was used for washing. The solid structures were analyzed using X-ray diffraction (Philips) and scanning electronic microscopy (XL30 Philips model) techniques. The BC was characterized by pHzpc, BET and iodine adsorption from solution. The pHzpc of the BC was determined using the batch equilibrium technique with 1:1000 and 1:80 solid to liquid ratios in 0.1 (M) KNO3 solution. Potassium nitrate was employed as an inert electrolyte. The initial pH value of the KNO3 solution was adjusted range from 2 to 12 by adding 0.1 (M) HNO3 or KOH. The solutions were allowed to equilibrate for 24 h in an isothermal shaker at 25 ± 1°C. The suspensions were filtered through filter paper, and the pH values were measured again using an ion pH meter. A blank test without BC was also made in order to eliminate the influence of interferences (Smiciklas et al. 2000). To measure the surface area, nitrogen gas was used for the adsorption, and the surface areas were calculated via the BET method using a Micromeritics (ASAP-2000). The iodine number (mg iodine/g carbon) was determined by using a 0.1N standardized iodine solution; the titrant was 0.1N sodium thiosulfate (ASTM D 1999).

Batch adsorption experiments were carried out in room temperature (25 ± 1°C) with the shaker set at 150 rpm. Starting with 100 mL flasks, containing various amount of adsorbent (1, 1.5, 2, 2.5 g) and 20 mL of endotoxin solution of known concentration (80 Eu mL−1) were added. After the flasks were shaken for 24 h to reach equilibrium, the supernatants were analyzed to find their endotoxin concentration. The initial and final concentrations of the solutions were measured by the LAL test. The pH of the solutions was adjusted using NaOH or HCl solutions of different concentrations. From preliminary kinetic tests, it was concluded that 6 h was long enough to achieve equilibrium. The endotoxin removal efficiency and amount of endotoxin adsorbed on the adsorbent were calculated by Eqs. 1 and 2, respectively.

where E is the removal efficiency, q is the adsorption amount (Eu g−1), C 0 and C are the concentration of endotoxin in the initial solution and in the supernatant after adsorption, respectively, and V is the volume of solution (mL).

Results and Discussion

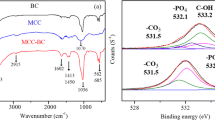

Some properties of the adsorbent are presented in Table 1. The pHzpc of an adsorbent is a very important characteristic that determines the pH at which the adsorbent surface has net electrical neutrality. At this value, the acidic or basic functional groups no longer contribute to the pH of the solution. Experiments showed that the pHzpc of the BC was about 8.3. It has been reported that at any pH below pHzpc the surface charge is positive whereas at pH level above pHzpc the surface charge is negative (Parida et al. 1996). Based on the value found for pHzpc, it can be deduced that the BC surface charge is positive as the solution pH is less than 8.3. The positive charge on the surface of the BC may enhance the removal of endotoxins via adsorption. Specific surface area and pore volume were determined with the BET. The specific surface area of BC particles was 130.75 m2 g−1. The tested BC samples were able to adsorb significant amounts of iodine; The iodine number gives an estimation of the relative surface area of two samples and is usually used to measure porosity for pores greater than 1.0 nm in diameter. Thus the iodine number was measured to evaluate the adsorptive capacity of the BC (Moreno-Castilla et al. 2001). The surface structure of the BC was analyzed using an SEM. The SEM micrographs with 5000× magnifications are shown in Fig. 1. The X-ray diffraction tests reveal that the BC is a mixed adsorbent composed of basic tricalcium phosphate and amorphous carbon (Fig. 2). Structurally, the calcium phosphate is in the hydroxyapatite form. The amorphous carbon fraction is distributed throughout the whole of the entire hydroxyapatite structure but most of the carbon exists as a highly active thin film that covers the porous hydroxyapatite surface.

Fast kinetics is one of the most important aspects of removal processes. Therefore, time domain experiments for endotoxin adsorption were performed (pH 7.0; T = 25 ± 1°C) for up to 24 h of contact time. The data obtained show that a contact time of 6 h is sufficient for achieving equilibrium. The endotoxin binding was fast and the adsorption did not change afterwards. Therefore, 6 h was chosen as the contact time for endotoxin adsorption via BC, considering the analytical speed and removal efficiency. Figure 3 shows the adsorption kinetics of endotoxin on BC at 25 ± 1°C and at neutral pH. A study of the kinetic curve reveals a rapid adsorption within the first 6 h to achieve the equilibrium conditions. The adsorption kinetics may be expressed as (Lalvani et al. 1998).

The equation can be expressed in linearized form as

where R is the endotoxin removal efficiency (%), t is the contact time (min) and kt and m are the constants. A plot of ln R versus ln t show that the sorption kinetics can be divided into two linear phases: (1) the first phase, corresponding to a rapid removal phase and (2) the second phase, where removal becomes constant, indicating equilibrium conditions (Fig. 4). Applying Eq. 4 to the first linear phase, since a maximum occurs in this phase, the values of ln kt and m as calculated are calculated to be 2.21 and 0.68, respectively. In order for pore diffusion to be the rate limiting step, the value of m should be 0.5, i.e., the rate of adsorption should vary with the square root of time (t 0.5). However, in the present study, the rate of adsorption varies as t 0.68, which implies that pore diffusion is not the rate limiting step. Therefore, the rate limiting step may be film diffusion. Furthermore, as shown in Fig. 4, that the plots do not pass through the origin, further suggesting that pore diffusion is not the rate-limiting step and that the process may be controlled by film diffusion mechanism (Poots et al. 1978).

The adsorption isotherm represents the relationship between the amount adsorbed by a unit weight of solid sorbent and the amount of solute remaining in the solution at equilibrium. To deduce the adsorption capacity, the adsorption isotherm was plotted by measuring the equilibrium adsorption of endotoxin at a concentration of 80 Eu mL−1 with various amounts of adsorbent. The measurement was performed at neutral pH as this has been reported as to be the best condition for endotoxin decontamination (Zhang et al. 2007). The data obtained were well fitted to the Langmuir adsorption model. The Langmuir model assumes the presence of a finite number of binding sites, homogeneously distributed over the sorbent surface, presenting the same affinity for sorption of a single layer with no interaction between sorbed species. The well-known Langmuir expression (Yu et al. 2001) is given as follows:

where q e is the amount of endotoxin bound per gram of biomass at equilibrium, C e is the residual endotoxin concentration in solution after binding, Q 0 is the maximum amount of endotoxin per unit weight of biomass required to form a complete monolayer on the surface for a high C e, and b is a constant related to the affinity of the binding sites. Q 0 and b can be determined from linear graphs (a plot of C e/q e versus C e). Figure 5 shows the relationship between the adsorption capability (q e) and equilibrium concentration (C e). The adsorption, in this case, is random due to the existence of active sites with different energies. Table 2 shows the quantities of the constants and correlation coefficient (R 2). The dimensionless equilibrium parameter is defined as R L = 1/(1 + bC 0), where b is the langmuir constant (mL Eu−1) and C 0 is the initial concentration. It has been shown that parameter R L indicates the shape of the isotherm. R L values between 0 and 1 indicate favorable adsorption. The results show that the adsorption capacity of the BC is 29 Eu g−1. These results agree with the results of Zhang et al. (2007), who studied the adsorption capability of a synthetic adsorbent based on a silica gel for the removal of endotoxin. Our results show that the q max of BC is 29 Eu g−1, which is lower than that reported by Zhang et al. (2007). The differences between their study and this study may be related to the adsorbent characteristics because they used histidine as a modifier for the adsorbent, while we used. Because histidine may have adverse public health effects, it cannot be used for water treatment.

The recovery of adsorbed material as well as the regeneration of adsorbent is also an important aspect of water and wastewater treatment. Since the recovery of endotoxin is not necessary and logical in practice, for this research regeneration BC was been carried out by thermal process that was regenerated and rendered endotoxin free by heating at 350°C for 30 min.

References

Anderson WB, Slawson RM, Mayfield CIA (2002) Review of drinking-water-associated endotoxin, including potential routes of human exposure. Can J Microbiol 48:567–587. doi:10.1139/w02-061

Anderson WB, Huch PM, Dixon DG (2003) Endotoxin inactivation in water by using medium-pressure UV lamp. Appl Environ Microbiol 69:3002–3004. doi:10.1128/AEM.69.5.3002-3004.2003

Anderson WB, Dixon DG, Mayfield CI (2007) Estimation of endotoxin inhalation from shower and humidifier exposure reveals potential risk to human health. J Water Health 5:553–572. doi:10.2166/wh.2007.043

ASTM (2003) D2972-88. Standard test method for GAC, vol 11, pp 396–405

ASTM D 4607 (1999) Standard test method for determination of iodine number of activated carbon

Castor ML, Wagstrom EA, Danila RN (2005) An outbreak of Pontiac fever with respiratory distress among workers performing high-pressure at a sugar-beet cleaning processing plant. J Infect Dis 191:1530–1537. doi:10.1086/428776

Cheung CW, Chan CK, Porter JF, McKay G (2001) Combined diffusion model for the sorption of cadmium, copper, and zinc ions onto bone char. Environ Sci Technol 35:1511–1522. doi:10.1021/es0012725

Choy KKH, McKay G (2005) Sorption of metal ions from aqueous solution using bone char. Environ Int 31:845–854. doi:10.1016/j.envint.2005.05.036

Danny CKK, Cheung CW, Choy KKH, Porter JF, McKay G (2004) Sorption equilibria of metal ions on bone char. Chemosphere 54:273–281. doi:10.1016/j.chemosphere.2003.08.004

Daus B, Wennrich R, Weiss H (2004) Sorption of materials for arsenic removal from water: a comparative study. Water Res 38:2948–2954. doi:10.1016/j.watres.2004.04.003

Hanora A, Plieva FM, Hedstrom M (2006) Capture of endotoxin using a supermacroporous monolithic matrix with immobilized polyethyleneimine, lysozyme or polymyxin B. J Biotechnol 118:421–433

Lalvani SB, Wiltowski T, Hubner A, Weston A, Mandich N (1998) Removal of hexavalent chromium and metal cations by a selective and novel carbon adsorbent. Carbon 36:1219–1225. doi:10.1016/S0008-6223(98)00102-X

Moreno-Castilla C, Carrasco-Marin F, Lpoez-Ramon M, Alvarez-Merino M (2001) Chemical and physical activation of olive-mill waste water to produce activated carbons. Carbon 39:1415–1420. doi:10.1016/S0008-6223(00)00268-2

Parida K, Parida KM, Satapathy PK, Das NN (1996) Studies on indian ocean manganese nodules: IV. adsorption of some bivalent heavy metal ions onto ferromanganese nodules. J Colloid Interface Sci 181:456–462. doi:10.1006/jcis.1996.0402

Poots VJP, McKay G, Healy JJ (1978) Removal of basic dye from effluent using wood as an adsorbent. J Water Pollut Control Fed 50:926–931

Purevsuren B, Avid B, Narangerel J, Gerelmaa T, Davaajav YA (2004) Investigation on the pyrolysis products from animal bone. J Mater Sci 39:737–740. doi:10.1023/B:JMSC.0000011545.51724.ad

Sarantila R, Kangas J, Savolainen H (1999) Interlaboratory comparison of endotoxin analyses in occupational exposure. Bull Environ Contam Toxicol 62:25–29. doi:10.1007/s001289900836

Sarantila R, Reiman M, Kangas J, Husman K, Savolainen H (2001) Exposure to endotoxins and microbes in the treatment of waste water and in the industrial debarking of wood. Bull Environ Contam Toxicol 67:171–178. doi:10.1007/s001280107

Smiciklas ID, Milonjic SK, Pfendt P, Raicevic S (2000) The point of zero charge and sorption of cadmium (II) and strontium (II) ions on synthetic hydroxyapatite. Sep Purif Technol 18(2000):185–194. doi:10.1016/S1383-5866(99)00066-0

Smiciklas I, Dimovic S, Sljivic M, Plecas I (2008) The batch study of Sr2+ sorption by bone char. J Environ Sci Health Part A Environ Sci Health Part A Environ Sci Eng 43:210–217

Szymanska J (2005) Endotoxin level as a potential marker of concentration of Gram-negative bacteria in water effluent from dental units and in dental aerosols. Ann Agric Environ Med 12:229–232

Tessarolo F, Caola I, Nollo G (2006) Efficiency in endotoxin removal by a reprocessing protocol for electrophysiology catheters based on hydrogen peroxide plasma sterilization. Int J Hyg Environ Health 209:557–565. doi:10.1016/j.ijheh.2006.05.001

Tsai WT, Hsieh MF, Sun HF, Chien SF, Chen HP (2002) Adsorption of paraquat onto activated bleaching earth. Bull Environ Contam Toxicol 206:557–565

Wanngah WS, Hanafiah MAKM (2008) Removal of heavy metal ions from wastewater by chemically modified plant wastes as adsorbents: a review. Bioresour Technol 99:3935–3948. doi:10.1016/j.biortech.2007.06.011

Westphal O, Jann K (1965) Bacterial lipopolysaccharides. Extraction with phenol–water and further applications of the procedure. Methods Carbohydr Chem 5:83–91

Xie W, Wang Q, Yao J, Ma H, Ohsumi Y, Ogawa HI (2004) Study on advanced treatment of secondary effluent using fixed-bed filled with bone char. Water Air Soil Pollut 159:313–324. doi:10.1023/B:WATE.0000049181.63852.98

Yu B, Zhang Y, Shukla A, Shukla S, Dorris KL (2001) The removal of heavy metals from aqueous solutions by sawdust adsorption removal of lead and comparison of its adsorption with Koper. J Hazard Mater 84:83–94. doi:10.1016/S0304-3894(01)00198-4

Zhang Y, Yang H, Zhou K, Ping Z (2007) Synthesis of affinity adsorbent based on silica gel and its application in endotoxin removal. React Funct Polym 67:728–736. doi:10.1016/j.reactfunctpolym.2007.05.003

Acknowledgments

The researchers would like to acknowledge funding support by the Tarbiat Modares university.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rezaee, A., Ghanizadeh, G., Behzadiyannejad, G. et al. Adsorption of Endotoxin from Aqueous Solution Using Bone Char. Bull Environ Contam Toxicol 82, 732–737 (2009). https://doi.org/10.1007/s00128-009-9690-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00128-009-9690-z