Abstract

Just as calcite precipitation rate is equal to CO3 2− formation rate, this CO3 2− formation rate is equal to that of urea hydrolysis in microbial calcite precipitation. This formative rate of CO3 2− evolved a mode to assay the urea hydrolysis rate, which was influenced by urea and Ca2+ concentrations, pH, and temperature. To contrive the highest Vmax of the Michaelis–Menten enzyme kinetics equation for the fastest urea hydrolysis rate, 35 °C, pH 10, 2 M urea and 2 M Ca2+ were the optimal conditions based on the studies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Microbes and their enzymes play an important role in the natural environment. Given a necessary reaction time, microbes help to coagulate the incompact sand and stones into hard and large-sized rocks [1–4]. These rocks are mostly calcite-based materials [5]. The microbes that are important in this process are called urease-producing bacteria, or carbonate-mineralizing bacteria [6–9]. Urease-producing microbes are indispensible for the calcite precipitation system. This particular mineralization process is labeled as Microbial Calcite Precipitation, the chemical reactions are given in Eqs. 1 and 2 [10–12]

The characteristics of urease in urea hydrolysis stay a core problem in Microbial Calcite Precipitation (MCP) investigation. The reproductive speed of calcite is decided by the rate of urea hydrolysis, which is directly controlled by urease activity [13, 14]. In this case, the influential factors are urease characteristics, urea and Ca2+ concentrations, pH and temperature. Research was carried out aiming at exploring the most useful reaction conditions by analyzing data from urease activity functioning in urea hydrolysis.

Urease specific activity is the activity of a unit amount of bacteria and is defined in Eq. 3 [15]. In that equation, S is urease specific activity (mM urea hydrolysis min−1 OD −1600 ), V is urea hydrolysis rate (mM urea hydrolysis min−1), and D is the optical density of biomass at wavelength of 600 nm (OD600)

The well-known Michaelis–Menten equation in biochemistry is a model of enzyme kinetics [16, 17]. Eq. 4 describes the rate of irreversible enzymatic reactions associating the reaction rate (urea hydrolysis rate in this case) with the concentration of the substrate (urea in this case)

In the equation, V is the reaction rate or urea hydrolysis rate (mM urea hydrolysis min−1), Vmax is the maximum reaction rate (mM urea hydrolysis min−1), KM is the Michaelis–Menten constant (M), which is an approximation of the affinity of the enzyme for the substrate and is numerically equivalent to the substrate concentration at which the rate of conversion is half of Vmax, [S] is the substrate concentration, which is urea concentration (M) in this case.

A small KM indicates high affinity, and a substrate with a smaller KM will approach Vmax in the rate at lower concentrations. Very high [S] values are required to approach Vmax which can be reached only when [S] is high enough to saturate the enzyme. Equation 4 can also be rewritten into a form that serves as the basis of the Lineweaver–Burk plot.

Temperature and pH are both key factors for the urea hydrolysis rate. In fact, there exists a critical value for both of them, when the urea hydrolysis rate reaches Vmax. A high speed of CaCO3 for fast cementation comes out of a high urea hydrolysis rate. The above explanation discloses the importance of discovering the critical values of temperature, pH as well as how Ca2+ affects urea hydrolysis.

The investigation also centered around how Ca2+, pH and temperature separately decided the KM and Vmax values for the urea hydrolysis rate based on the Michaelis–Menten equation and Enzyme Kinetic Module software. To acquire the highest Vmax in the empirical formula of Michaelis–Menten enzyme kinetics for the fastest urea hydrolysis rate, 35 °C, pH 10, 2 M urea and 2 M Ca2+ were the optimal conditions based on the studies.

Method and preparation

Devices applied in the investigation were a 721–100 visual light spectrophotometer from Tian Pu Lab Instruments Company of Shanghai, a DDS-307 electrical conductance device from Kuo Si Chemical Instruments Company of Shanghai, and a FP-0031 shaker from Fei Pu Lab Instruments Company of Changzhou and a XXH-906 household refrigerator.

Urea hydrolysis rate test method

The electrical conductance of the solution of urea and bacteria was monitored and the data were recorded during urea hydrolysis rate derivation [18]. The mechanism is briefly explained below. The electrical conductance was to measure how easily electricity flows along a certain path through an electrical element. The SI derived unit of it is siemens. Conductance was related to resistance by Eq. 5, wherein G is the electrical conductance (S), and R is resistance (Ω)

Electrical conductance can be used to assess the total amount of dissolved ions in the solution rapidly and conveniently. The ions formed in the solution during urea hydrolysis under the catalysis of urease will generate electric conductivity. As a general rule, the more ions there are, the higher the conductance is. The urea hydrolysis rate was acquired and shown as Eq. 6, where the urea hydrolysis rate is given in terms of electrical conductance (DD, siemens) and is divided by time (t, second), then multiplied by a particular constant A. (11.11 mM urea hydrolysis siemens−1)

The test of the urea hydrolysis rate is described below. 25 ml urea solution of a certain concentration, 20 ml de-ionized water and 5 ml bacteria of a certain OD600 value are put in 100 ml beaker at 25 °C into a water bath under 200 rounds min−1 stirring. As soon as the electrical conductance probe is dipped into the beaker, data are recorded in every 30 s, then plotted versus time. The slope of a steadily increasing part of the line at the beginning in the diagram multiplied by the particular constant A is the urea hydrolysis rate.

Vmax, KM and enzyme kinetic module software

Enzyme kinetic module (EKM) takes an analysis and presents the enzyme kinetic data quickly and easily. The procedure of Vmax and KM computations in EKM is demonstrated below. Data entry: manually enter the data of urea concentration and urease hydrolysis rate. Select models: Michaelis–Menten equation model was contrived in this case. Results: a data report including KM and Vmax will be popped out when the calculation is over.

Bacteria culture and reproduction

The culture medium contained 5 g peptone and 3 g beef extract in 1,000 ml distilled water. Then the culture medium was sterilized in a pressure steaming pot under 121 °C for 25 min. 5 ml of urease-producing bacteria were inoculated into 100 ml of the sterilized culture medium. They were put into a 200 ml shaker under 37 °C for 24 h with a shaking speed of 170 rounds min−1.

Urease specific activities of every batch of bacteria used in the investigation were listed in Table 1.

Enzyme kinetics module computation results

Urea

As 1 M urea concentration was maximally adopted in the reported MCP investigation papers [8], two ranges of urea concentrations were used in urea hydrolysis experiments (bacteria batch Nos. 1 and 2). Data in Tables 2, 3 were entered on EKM and KM to compute Vmax.

The KM of urea concentration ranges from 0.02 to 0.2 M and from 0.2 to 2.0 M were 0.014 and 0.022 M, respectively. The Vmax values were 75 and 110 μg min−1.

Ca2+

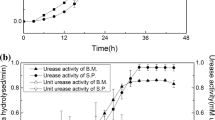

For concentration selection, a wide range of Ca2+ concentrations was taken into account in electricity conductance experiments (bacteria batch Nos. 3 and 4). Results are plotted as in Fig. 1. The KM of Ca2+ concentrations of 1, 2 and 3 M are 0.610, 0.854 and 0.926 M. The corresponding Vmax values are 1.303, 1.581 and 1.291 μg min−1.

Temperature

Water bath thermostatting was adopted to stabilize the reaction at the conditioned temperature, such as 15, 25 and 35 °C (bacteria batch Nos. 5 and 6). Results are plotted in Fig. 2. The KM of 15, 25 and 35 °C are 1.023, 0.263 and 0.133 M. The corresponding Vmax values are 0.115, 0.548 and 0.781 mM min−1.

pH

First, the reaction solutions without bacteria were adjusted to pH of 7, 9, 10 and 11 by acid or alkaline titration (bacteria batch Nos. 7, 8 and 9). Then 5 ml bacteria were added into each solution. Immediately after this, solutions were taken for urea hydrolysis test. Results are plotted in Fig. 3.

The KM of pH of 7, 9, 10 and 11 are 0.449, 0.301, 0.304 and 0.346 M. The corresponding Vmax values are 0.321, 0.278, 0.361 and 0.275 mM min−1 respectively.

Discussion

To find out a fastest urea hydrolysis rate for a fastest calcite precipitation rate, 35 °C was probably the best option based on Vmax computation results with EKM. Similarly, pH 10, 2 M urea and 2 M Ca2+ were selected as the other optimal conditions for a fast MCP process.

On most occasions, a mild MCP process representing CaCO3 precipitation in random positions and in equal sizes will be contributing to the cemented material of a better structure in micro-scale and a better mechanical performance in macro-scale.

Conclusions

In the MCP system, CO3 2− is a clue to form CaCO3 even though it is very difficult to monitor the production rate of CaCO3, for there is a formation of Ca2+, and CaCO3 precipitates immediately after CO3 2− is produced through urea hydrolysis. In other words, it is just as difficult to control the CaCO3 precipitation rate as to control the CO3 2− production rate. The investigation in the paper has developed an electrical conductance method to assay the urea hydrolysis rate as influenced by urea and Ca2+ concentrations, pH and temperature, which is important in discovering all the rules in MCP technique.

References

Whiffin V, Harkes M, Paassen L (2004) Microbial carbonate precipitation as a soil improvement technique. GeoDelft, Delft

Al-thawadi MS (2011) J Adv Sci Eng Res 1:98–114

Dick J, Windt W, Graef B (2006) Biodegradation 17:357

Ghosha S, Mandala BD, Chattopadhyayb SP (2005) Cem Concr Res 35:1980

Castanier S, Me’tayer-Levrel S, Perthuisot JP (1999) Sediment Geol 126:9

Su JF, Wang LX, Ren L (2005) J Appl Polym Sci 97:1755

Choi JC, Kim SD, Han GY (1995) Korean J Chem Eng 32:258

Whiffin V (2004) Microbial CaCO3 precipitation for the production of Biocement. Phd dissertation, Murdoch University, Perth, p 81

Dejong J (2007) Sediment Geol 197:769

Woodlouse J (2001) Nanotechnology 2:1

Kensuke N, Yoshiki C (2001) Chem Mater 13:3245

Hunter GK (1996) Curr Opin Solid State Mater 21:430

Tong H, Ma W, Wang L (2004) Biomaterials 73:3923

Rajam S, Heywood BR, Walker JBA, Mann S, Davey RJ (1991) J Chem Soc Faraday Trans 87:727

Mann S, Heywood BR, Rajam S (1988) Nature 334:692

Heywood BR, Rajam S, Mann S (1991) J Chem Soc Faraday Trans 87:735

Muywuck W, Cox K, Belin N (2008) Constr Build Mater 22:875

Cheng L, Qian CX, Wang RX (2007) Study on the mechanism of calcium carbonate formation induced by carbonate-mineralization microbe. Acta Chim Sin 3:2133–2138

Acknowledgments

The financial support of Jiangsu Planned Projects for Postdoctoral Research Funds is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, L., Qian, Cx., Zhao, Yh. et al. Enzyme kinetic characterization of microbe-produced urease for microbe-driven calcite mineralization. Reac Kinet Mech Cat 108, 51–57 (2013). https://doi.org/10.1007/s11144-012-0487-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-012-0487-4