Abstract

Temperature is a key factor that contributes to microbially induced calcium carbonate precipitation. At low temperatures, low enzyme activity results in a lack of calcium precipitation. In this study, Sporosarcina pasteurii and Bacillus megaterium were compared. Firstly, the optical density curves and enzyme activity curves of both bacteria were obtained during 48-h culture. Then, optical density, enzyme activity, and productive rates for calcium carbonate were measured to analyze the influence of temperature. Finally, the effect of urea concentration on carbonate precipitation was studied by changing the urea concentration that was added during inoculation. The obtained results showed that at high temperature, the growth rate of B. megaterium was close to that of S. pasteurii, while the opposite result was found at low temperature. The urease activities of B. megaterium were similar at different temperature conditions. At high temperature, B. megaterium showed lower enzyme activity, while at low temperature, it surpassed that of S. pasteurii. The same results were found for enzyme activity and for the precipitation rates of calcium carbonate. The addition of urea to the medium increased precipitation rates, and higher urea concentrations increased the obtained precipitation rates. With 20 g/L urea, the precipitation rate of B. megaterium at 15 °C matched that without urea addition at 30 °C. Therefore, adding urea to the medium at the time of inoculation can effectively overcome the low calcium precipitation at low temperature and enable subsequent low-temperature engineering applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

It is well documented that microorganisms contribute to that precipitation of a variety of minerals [13]. Recently, microbially induced carbonate precipitation (MICP) technology has been extensively applied in geotechnical and environmental engineering [9, 39, 50]. The essence of this technology is the binding of metal ions with acid radical ions to form minerals (e.g., calcium carbonate), which forms a fundamental part of a variety of biogeochemical processes [11]. It is widely recognized that carbonate precipitation has insignificant implemented potential as an important aspect of biomineralization [59, 61]. Carbonate mineralization induced by bacteria is currently increasingly applied, e.g., for the production of biomimetic materials, bioremediation, and plugging cementation of porous media cracks [24]. DeJong et al. [12] reported a preference of the distribution of produced carbonate precipitation around particle–particle contacts. As a result, carbonate precipitation emerges in gaps between particles, which contribute to stronger cementation within soils. Previous studies have expanded the boundaries of MICP technique, e.g., enhancing both soil strength and stiffness [39], reducing soil permeability [58], creating expanded treatment zones [36], accelerating biogeochemical reaction rates [35] and seepage control [60].

Urea hydrolysis by indigenous or introduced urease-producing bacteria (e.g., Sporosarcina pasteurii, Sporosarcina aquimarina, and Bacillus megaterium) is one of the most popular pathways used to induce carbonate precipitation [22, 49]. Chu et al. [8] proposed that adsorption/retention of urease activity on sand treated with washed cells of Bacillus sp. was 5–8 times higher than that treated with culture liquid without bacterial cells. Whiffin [57] studied the relationship between temperature and relevant enzyme activity of S. pasteurii within 15–80 °C and reported that the optimum temperature for the enzyme activity was 70 °C. Moyo et al. [40] reported that the optimal temperature of pure urease solution was 50 °C and the optimal temperature of enzyme activity in soil was 60–70 °C. Omoregie et al. [42] reported that optimal urease activities could be achieved at 25–30 °C. Urease can be extremely impaired at low temperatures, leading to insufficient activity [58]. Previous studies applied S. pasteurii to MICP technology at low temperature; however, its rate of precipitation is too low due to the weak activity of bacteria at low temperatures, and it is therefore difficult to bond sand particles together firmly. A specific method was used to improve loose sand by applying bacterial solution every 4 days for five identical cycles [18]. Cheng et al. [6] presented a novel one-phase injection method using low-pH all-in-one biocement solution (i.e., a mixture of bacterial culture, urea, and CaCl2) to prevent the clogging of bioflocs formation and allow the biocement solution to be well distributed inside the soil matrix.

Although MICP technology is widely used in geotechnical and environmental engineering, the main problem with the application of MICP in low-temperature conditions still remains. Vos et al. [55] reported that B. megaterium can grow at temperatures from 3 to 45 °C. However, at 25 °C, the lifetime of urease is 5–8 days [29], and its half-life can be extended at lower temperatures [26, 29]. Jiang et al. [26] focused on quantifying the ureolytic efficiency of B. megaterium and developed a solution with better anoxic ureolytic performance than its oxic counterpart. Low ureolytic efficiency still remained at low temperatures, despite the use of B. megaterium. Consequently, the primary objective of this study was to obtain comparative results between S. pasteurii and B. megaterium and to propose a solution to the problem of low calcium precipitation at low temperatures. Lower temperatures decrease bacterial reproduction; therefore, less intracellular urease entered the reaction solution [27]. Moreover, at lower temperatures, the enzymatic activity significantly decreased, and both factors eventually reflected a decrease in precipitation efficiency. The three concepts can be distinguished via the following: (1) bacterial activity at low temperature; (2) enzymatic activity at low temperature; (3) calcite precipitation efficiency at low temperature. These are discussed separately. The changing rules of optical density curves and enzyme activity curves were obtained during 48-h culture, and a number of contrast testes of optical density, enzyme activity, and precipitation rates for calcium carbonate were conducted to study the influence of temperature. The method of adding urea to the medium during inoculation was proposed to investigate the effect of urea concentration on the amounts of carbonate precipitation of both bacteria. According to the results, urea addition to the medium improved precipitation rates under low-temperature conditions. The obtained results form a solid basis for subsequent low-temperature application tests.

2 Materials and methods

2.1 Bacteria and culture media

In this study, both urease-producing microbes S. pasteurii (ATCC 11859) and B. megaterium (ATCC 14581, a Gram-positive, rod-shaped soil bacterium with size ranging from 2 to 5 µm [33]) were compared. Their precipitation rates at low temperature were determined, since B. megaterium can form endospores that are highly resistant to extreme environmental conditions. B. megaterium can grow at temperatures from 3 to 45 °C [55], indicating that it has the potential to form sufficient precipitation at low temperatures. Although past research has already shown that B. megaterium has a relatively lower ureolysis rate than S. pasteurii under warm conditions (20–30 °C) [4, 57], the selection of B. megaterium is more relevant to this study.

Both types of strains were obtained from the Guangdong culture collection center in China and were cultivated for contrast experiments.

S. pasteurii was cultured on Luria–Bertani medium, which consists of yeast extract 15.0 g/L, polypeptone 10.0 g/L, NaCl 10.0 g/L, and distilled water. According to the ATCC database, Luria–Bertani medium is appropriate for the culture of S. pasteurii and B. megaterium can be cultivated in NA (nutrient agar), TSA (trypticase soy broth agar), and LB (Luria–Bertani) medium. Therefore, Luria–Bertani medium was used to cultivate both bacteria to reduce errors resulting from different culture conditions. Both cultures were incubated at 30 °C under constant shaking at 100 rpm for 48 h and at an initial medium pH of 7.0.

2.2 Growth profile and enzyme activity

2.2.1 Measurement of optical density and enzyme activity

Despite the lack of information about the relationship of optical density and concentration of bacterium per milliliter for B. megaterium, both S. pasteurii and B. megaterium were cultivated in the same medium. The optical density of the medium was not changed by varying temperature and adding urea. Therefore, the OD600 was used to compare different growth characteristics of both bacteria.

Six milliliters of bacterial solution was mixed with 54 ml urea solution (1 mol/L), and the electrical conductivity was measured every 5 min. The average change in conductivity per minute (ms/min) was calculated. Whiffin [57] experimentally derived that it was corresponding to 11 mM urea hydrolyzed/min. Therefore, the change in conductivity per minute (ms/min) can be converted to the amount of urease hydrolysis per unit time, and eventually, the rate of hydrolysis of urea per minute (mM urea hydrolyzed min−1) was obtained via multiplying by the dilution factor of 10, which represents enzyme activity. The relationship 1 mS/cm/min = 11 mM/min was appropriate for 20–25 °C. The temperature range in this study was 15–30 °C beyond which, all temperature conditions needed to be analyzed together; therefore, enzyme activity was used as a common indicator.

2.2.2 Changing rules of bacterial growth and enzyme activity

According to Khan and Amarakoon [28], the number of inoculated microbes greatly impacts their growth characteristic. Therefore, high OD600 values (1.871 and 1.867) of both bacteria were helpful to obtain a clear and reliable changing trend, due to the large range of increasing optical density. During the 48 h of culture, the optical density and enzyme activity of both bacteria were monitored every 3 h. Triplicate samples were prepared to diminish the deviations, and the average values were calculated.

2.2.3 Comparative tests of optical density and enzyme activity of both bacteria

Across the seaboard of China, and over the length of the Yangtze River, the temperature varies from 15 to 25 °C within 10–100 m for most of the year [21, 44, 46, 56]. This is the reason for choosing a temperature range of 15–30 °C for the experiment, even though both bacteria show activity at temperatures below 15 °C. In view of differentiating the effects of temperature on the growth pattern between both bacteria, temperature had to be maintained at four different levels: 15, 20, 25, and 30 °C. The initial pH of the nutrient solution was 7.0, and triplicate samples of each condition were prepared. Khan and Amarakoon [28] reported that growth characteristics would be extremely affected by the amount of added bacterial culture to the liquid culture medium. Therefore, two types of bacteria were inoculated that have similar OD600 values (1.138 and 1.122) to decrease errors. Optical densities were monitored every 12 h over cultivation for 48 h. Urease activities were monitored every 12 h as well.

2.3 Comparative tests of precipitation rates for calcium carbonate

2.3.1 Comparison of precipitation rates under various temperatures

Bacterial solution of S. pasteurii with an OD600 of 1.238 was added to mixed liquor (calcium acetate solution and urea solution), as well as B. megaterium with an OD600 of 1.266. Calcium carbonate produced from calcium chloride is calcite, while it is aragonite with calcium acetate, the bonding effect of which was better than that of calcite under solution conditions [3, 41, 52]. The reason might be that calcium carbonate produced from calcium acetate was mass, available for precipitation, and not dispersive. Consequently, calcium acetate was used as calcium recourse in the mixed solution. The concentrations of calcium acetate and urea in the mixed solution were both 0.5 mol/L. In a sterile environment, eight groups of samples were used, which were further divided into two groups according to the bacteria used. Each of the four resulting groups was prepared corresponding to different temperatures (15, 20, 25, or 30 °C). Every group consisted of three parallel samples, all with an original pH of 7.0. The evaluation criterion was the precipitation rate of calcium carbonate, i.e., the ratio of the actual produced amount of calcium carbonate to the theoretically calculated total amount, which was obtained every day during a 96-h reaction process.

The measuring method of the actual produced amount of calcium carbonate is described in the following:

After the precipitation reaction, filtration was conducted via filter paper and then, the precipitation and the filter paper were dried at 70 °C. The total mass of the filter paper and precipitation was weighted (M1). Then, diluted hydrochloric acid was used to rinse both, followed by cleaning via water rinsing. The raffinate was filtrated each time to ensure that insoluble matter would not be run off. Finally, filter paper and insoluble matter were dried to obtain the total mass (M2). The actual amount of calcium carbonate (Δm) was obtained via M1–M2.

2.3.2 Comparison of precipitation rates under various amounts of added urea

Urea was added to 100 ml of nutrient solution at various concentrations (0 g/L, 5 g/L, 10 g/L, 15 g/L, or 20 g/L, with the same 1% inoculation. The OD600 values of bacterial solutions were 1.197 and 1.201, respectively. Three samples per group were prepared.

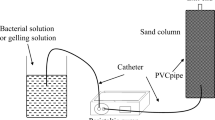

After 48-h culture, the average OD600 values of bacterial solution of B. megaterium corresponding to different urea concentrations were 1.125, 1.121, 1.107, 1.072, and 0.998, while the average OD600 values of S. pasteurii bacterial solution were 1.136, 1.122, 1.112, 1.101, and 1.008, respectively. Then, the mixed solution of calcium acetate and urea was added to study the effect of urea concentration on precipitation rates with both bacteria. The concentrations of calcium acetate and urea in the mixture both remained at 0.5 mol/L. Comparative tests of precipitation rates for calcium carbonate were conducted at a low temperature of 15 °C at pH 7. Precipitation rates under different conditions were calculated every day during the 96-h reaction process.

3 Results

3.1 Changing rules of bacterial growth and enzyme activity

The changing rules of optical density curves and enzyme activity curves between both bacteria are shown in Fig. 1. The numbers of cells with both bacteria slowly increased at first. This slow period of B. megaterium was shorter than that of S. pasteurii. After 3 h, the numbers of cells increased, indicating that the growth speed became very large. Then, the increase in numbers of bacteria slowed down and gradually approached zero. Such a changing rule was found for both strains. Only careful observation showed that the increase in the growth speed of S. pasteurii decreased after that of B. megaterium, while the growth of S. pasteurii stabilized earlier; in other words, S. pasteurii had a stable period for more than 18 h. A similar stable period of B. megaterium could only be seen during the last 12 h.

Figure 1 shows that the enzyme activity curves both rose with time until around 30 h or 36 h. Prior to about 32 h, the enzyme activity of B. megaterium was slightly stronger than that of S. pasteurii; however, it was surpassed by B. megaterium, i.e., S. pasteurii showed a stronger enzyme activity.

The unit enzyme activity of B. megaterium dramatically increased before peaking at the 20th h, then decreasing sharply to the initial level at about the 30th h, as shown in Fig. 1. With regard to S. pasteuri, the unit enzyme activity showed the same changing trend; however, it peaked at the 12th h and decreased at the 33th h; the maximum was a little higher than in B. megaterium.

3.2 The effect of temperature on growth patterns and enzyme activities of both bacteria

3.2.1 Optical density

Temperature exerted a different impact on the growth pattern of both bacteria, as shown in Fig. 2. The cell gross grew with time and reached a stable state within about 30 h, which could be demonstrated not only for S. pasteurii (Fig. 2a) but also for B. megaterium (Fig. 2b). However, bacterial concentrations varied extremely with temperature and the speed of growth of S. pasteurii increased with increasing temperature, especially during the initial 30 h. Apart from the growth law, the eventual stable value also increased with increasing temperatures. A significant difference was found between optical density curve at 15 °C and other curves in the 12th h. The OD600 at a temperature of 15 °C accounted for less than 25% of it at 20 °C. Optical density curves of B. megaterium, however, were basically similar for 20 °C and 30 °C, especially during the initial 10 h. The bacterial concentration at 15 °C was extremely lower than at other temperatures, accounting for about 50% of other curves in the 12th h.

Optical density curves with 15 °C of both bacteria were compared, to choose a relatively suitable strain for low-temperature applications, as shown in Fig. 3. The speed of B. megaterium reproduction exceeded that of S. pasteurii at first and B. megaterium were more numerous than S. pasteurii throughout. The maximum of OD600 of B. megaterium almost equaled 0.8, compared to the OD600 of 0.6 of S. pasteurii. The inflection point was not obvious in the growth curve of B. megaterium, which existed in the growth curve of S. pasteurii at the 12th h.

3.2.2 Enzyme activity

Similar to optical density curves, enzyme activity curves at various temperatures are shown in Fig. 4. The enzyme activity enhanced with time and tended to remain stable for both S. pasteurii and B. megaterium independent of temperature. With regard to B. megaterium (Fig. 4b), the differences were small, specially between 25 and 30 °C, indicating that the enzyme activity curves of B. megaterium were relatively adjacent. An entirely different phenomenon is shown in Fig. 4a. The improvement of enzyme activity became evident at increasing temperature. Furthermore, at high temperatures, such as 25 °C and 30 °C, the urease activities of B. megaterium were lower than that of S. pasteurii. Bachmeier et al. [4] obtained the same result. With higher temperature of 30 °C, the unit enzyme activity of S. pasteurii was clearly higher than those of the other three cases and experienced a slight fluctuation regardless of temperature, as shown in Fig. 4a. The unit enzyme activities of B. megaterium were also not different.

Enzyme activity curves at 15 °C of both bacteria are specifically compared in Fig. 5. The increasing speed and ultimate values of enzyme activity of B. megaterium both exceeded those of S. pasteurii. Similarly, no clear inflection point was found in the enzyme activity curve of B. megaterium, which was found in another curve. Consequently, in the low-temperature condition, the enzyme activity of B. megaterium exceeded that of S. pasteurii [55]. S. pasteurii had a lower unit enzyme activity than B. megaterium during the early phase; however, it then surpassed B. megaterium at around the 20th h, despite their identical value in the end, as shown in Fig. 5.

3.3 Comparative tests of precipitation rates for calcium carbonate

3.3.1 Comparison of precipitation rates under various temperatures

Figure 6 shows different precipitation rates for calcium carbonate under various temperatures calculated on the 1st, 2nd, 3rd, and 4th day, which is the most straightforward indicator of the amounts of precipitation. Figure 6a shows that the amounts of calcium precipitation of S. pasteurii increased with time. The higher the temperature, the more calcium precipitation was obtained. Differences were evident among precipitation rates at diverse temperatures. The precipitation rate was positively correlated with temperature. In particular, the precipitation rate for calcium carbonate at a 15 °C temperature was eventually below 10%. Different results of B. megaterium from Fig. 6b indicated close precipitation rates for calcium carbonate from start to finish, except at 30 °C. The precipitation rate at 30 °C increased, exceeding 25% in the end, which is almost 15% higher than others. Under the 30 °C condition, the precipitation rate of calcium carbonate of B. megaterium was clearly lower than that of S. pasteurii during the early phrase; however, both of them maximized in the end about 27%, which indicates that the increasing range of B. megaterium extremely exceeded the other one. For the temperatures of 20 °C and 25 °C, the initial precipitation rates were similar, while after a 3-day reaction, the precipitation rates of B. megaterium were lower than that of S. pasteurii.

The precipitation rates of calcium carbonate for both bacteria at 15 °C are shown in Fig. 7. More calcium precipitation was produced by B. megaterium in the 1st day. In addition, the precipitation rate of B. megaterium showed a stronger increase during the later period. It thus grew higher during the last phase, reaching 16%, which is approximately twice as high as that of S. pasteurii.

3.3.2 Comparison of precipitation rates under various amounts of added urea

The precipitation rate for calcium carbonate of B. megaterium at the low-temperature condition was still lower than at high temperature. The method of adding urea to the medium was applied to increase the precipitation rates at low temperature, and precipitation rates after 96-h culture are shown in Fig. 8. The precipitation rate increased as urea was added to the medium, compared to urea addition. In addition, precipitation rates became bigger and bigger with increasing urea concentration. The patterns of S. pasteurii and B. megaterium were similar. With identical urea concentration, the precipitation rates of B. megaterium were clearly higher than that of S. pasteurii. When the concentration of urea reached 20 g/L, the precipitation rate of B. megaterium was almost 26%, which was similar to the without urea addition at 30 °C. Furthermore, the precipitation rate of B. megaterium increased from 15 to 26% after urea addition at 20 g/L. The increasing range of S. pasteurii increased from 9 to 15%.

4 Discussions

4.1 The changing rules of bacterial growth and enzyme activity

Fredrickson et al. [15] introduced a method to monitor the absorbance (optical density) of bacterial suspension of S. pasteurii with a spectrophotometer at 600-nm wavelength (OD600). The correlation between the viable cell count and absorbance values was examined by Ramachandran et al. [45], who proposed a formula (Y = 8.59 × 107 Z1.3627) to describe the relationship between Z (optical density) and Y (concentration of bacterium per milliliter), thus indicating that the results of absorbance measurement were reliable. Confirmatory viable bacterial cell numbers were estimated for each condition. When the optical density remained within 0.2–0.8, the formula could be directly used. For cases beyond this range, samples needed to be diluted to meet the range and then the above formula could be used. Optical density was one of the key elements for choosing optimum experimental conditions [28, 57]. In warm and weak acidic/alkaline environments, urease is more active. Urease hydrolyzes urea to generate ammonium ions and carbonate ions, thus increasing solution conductivity. The high correlation coefficients indicate very strong positive linkage between conductivity increase and urea hydrolysis; therefore, that the enzyme activity can be presented by the rate of conductivity increase [2, 7, 57]; van Paassen [53]. Figure 1 shows optical density curves and enzyme activity curves of both bacteria. The changing rules of optical density curves are similar, but few differences persist. Cells stayed in a delayed period where numbers of cells increased slowly. The curvature of optical density curves of S. pasteurii did not change greatly until the 12th h. This implies that the delay period of B. megaterium was shorter, i.e., B. megaterium entered the logarithmic period earlier. The logarithmic period is a very important stage when numbers of cells increased at a strong pace and finally, the speed stabilized at a high level. After the logarithmic period, there was a balanced state where consumption of nutrients equaled the accumulation of harmful metabolites. The concentration of bacterial solution did not change, despite newborn bacteria that were continuously generated. The logarithmic period of S. pasteurii started at the 12th h and lasted until the 30th h, while B. megaterium had a longer period starting at the 2nd h and lasting to the 33th h. This indicates that S. pasteurii entered the stable period earlier at 30 °C.

Mobley and Hausinger [38] and Krajewska [30] both reported that urease is a special enzyme and can be found in many organisms, such as plants, bacteria, fungi, algae, and invertebrates. Under the presence of urease, the hydrolysis of urea is catalyzed to more effectively generate carbonate, and the entire reaction can be controlled easily [63]. Figure 1 shows that the distinction of enzyme activity between both bacteria was small. The ability of urea hydrolysis gradually enhancing with time and eventually tended to a stable value indicated that the changing rule was appropriate for both. After about 32 h, the enzyme activity of S. pasteurii exceeds the another curve. After 36 h, S. pasteurii entered the stable period, 3 h after B. megaterium. Figure 1 shows that the unit enzyme activity of B. megaterium showed a smaller maximum value and a shorter peaking period, and thus, S. pasteurii had a stronger unit enzyme activity at 30 °C. It has been reported that bacteria staying in the logarithmic and stable periods were suitable for tests, since the numbers of cells and the enzyme activity should be considered at the same time [2, 35, 57]. In fact, a linear relationship was found between the OD600 and ureolysis rate of S. pasteurii [31]. The same relationship was found for B. megaterium. Therefore, S. pasteurii cultured for about 30 h was selected for tests, while B. megaterium was cultured for 33 h.

4.2 The effect of temperature on growth pattern and enzymatic activity of both bacteria

4.2.1 Optical density

Figure 2a shows the effect of temperature on the growth patterns of S. pasteurii. The higher the temperature, the higher the numbers of cells. The speed of growth and cell gross in 30 °C both exceeds that of other conditions. The bacterial concentration at 15 °C was much lower than that of others (20, 25, or 30 °C), since low temperatures inhibit the reproduction of bacteria [23]. Temperature greatly contributed to the reproduction of S. pasteurii, which is likely due to a higher sensitivity to temperature [1, 34]. The effect of temperature on B. megaterium was distinctly smaller in comparison, not least between 20 and 30 °C, which enabled B. megaterium to maintain sufficient activity in this extreme environment [33, 54, 55]. However, low temperatures still impaired B. megaterium, leading to extremely low bacterial concentrations at 15 °C, especially during the first 24 h, as shown in Fig. 2b. B. megaterium did not enter the stable stage until the 24th h, which is clearly later than other conditions.

To detect which bacterium was more suitable for the use in tests at low temperature, growth curves of 15 °C are shown in Fig. 3. Significant advantages of B. megaterium could be ignored, and consequently, Jiang et al. [26] chose B. megaterium, instead of S. pasteurii, as urease-producing microbe species. Furthermore, there was no clear inflection point in the growth curve of B. megaterium, due to a shorter delay period. Figure 3 shows that the delay period of B. megaterium was shorter than 12 h, indicating that the bacterium was in the logarithmic period at the 12th h. The longer logarithmic period of B. megaterium contributed to a higher growth speed and bacterial concentration. Hence, one way that temperature affects the growth pattern of bacteria was likely by adjusting the start and end points of the logarithmic period.

4.2.2 Enzyme activity

The influence of temperature on MICP was primarily reflected by enzyme activity [14]. The enzyme catalytic performance could be strengthened with increasing temperature; however, if the temperature varied beyond a specific limit, urease degeneration might happen, resulting in a loss of activity [16, 17]. The changing characteristics of enzyme activity were similar to those of optical density, independent of the tested bacterial species. Figure 4a shows that the influence of temperature on the enzymatic activity of S. pasteurii was large. At 25 °C or 30 °C, the enzyme activity did not reach a balanced state, despite culture for 48 h. Unit enzyme activity also gradually increased during this 48-h period with 30 °C and was slightly (nonsignificantly) bigger at 25 °C than at both other temperatures. With a temperature of 15 °C, the enzyme activity of S. pasteurii was much lower than that of others and there was no significant increase in enzyme activity after 24 h. Unit enzyme activity was also smaller in the other three conditions. Therefore, both enzyme activity and unit enzyme activity showed lower enzymatic activities at low temperatures. Bachmeier et al. [4] arrived at the same conclusion. Moyo et al. [40] also concluded that the optimum temperature for enzyme activity could be found in soil at 60 °C and 70 °C. However, for B. megaterium, low temperature did not greatly impair enzyme activity and high temperature did not dramatically enhance its enzyme activity. As the temperature increased from 25 to 30 °C, urease activities of B. megaterium were not altered vastly. The strong temperature adaptability of B. megaterium is predominantly because the unit enzyme activity of B. megaterium was almost similar despite a big gap between 15 and 30 °C. Several studies arrived at the same conclusions, indicating that the change of urease activities of B. megaterium was slight despite temperature variation [40, 55, 57].

Figure 5 shows a comparison of enzyme activity curves at 15 °C, which is similar to Fig. 3. Bachmeier et al. [4] and Whiffin [57] proposed that B. megaterium has a relatively lower rate of ureolysis than S. pasteurii under warm conditions, which reverses at low temperatures. Both enzyme activity and growth speed of B. megaterium exceeded those of S. pasteurii. Similarly, the inflection point of the enzyme activity curve of B. megaterium was unclear, which existed in the curve of S. pasteurii. This phenomenon could likely be seen due to a shorter than 12-h delay period of B. megaterium. The shorter delay period also resulted in the higher unit enzyme activity of B. megaterium in the 12th h. During tests, the increasing rate of B. megaterium was slowed while the increasing rate of B. megaterium was accelerated; therefore, the amount of S. pasteurii surpassed that of B. megaterium when the bacterial culture time exceeded 20 h. When both entered the stable period, their unit enzyme activity achieved in a similar value. The results acquired from enzyme activity analysis agree with those for the growth pattern. Therefore, B. megaterium was more adaptive to use in low-temperature tests.

4.3 Comparative tests of precipitation rates for calcium carbonate

4.3.1 Comparison of precipitation rates under various temperatures

MICP technology has been used extensively due to the production of calcium precipitation [25]. Only the analysis of precipitation rates for calcium carbonate can demonstrate that whether MICP technology could be applied in low-temperature conditions. It has been proven that many factors impact the type and amount of carbonate precipitations, e.g., the functional attributes of a precipitating microorganism, the rate of urea hydrolysis, urea and calcium dosages, and the presence of amino acids such as glutamic acid [5, 10, 19, 32, 47, 57]. Temperature can affect carbonate precipitations by changing the enzyme activity [14]. Low reproduction and low enzyme activity at low temperature eventually reflect the decrease of precipitation efficiency; therefore, at 15 °C, the precipitation rates for calcium carbonate of S. pasteurii and B. megaterium were clearly smaller than in other conditions. This was also why the effect of temperature on precipitation rates for calcium carbonate of S. pasteurii was larger than that of B. megaterium, as shown in Fig. 6, which is similar to the conclusions obtained from Fig. 4. At 30 °C, the precipitation rate for calcium carbonate of B. megaterium was clearly lower than that of S. pasteurii during the early phrase, which could be ascribed to the low enzyme activity. However, the productivities at the end reached about 27%. The result was significantly lower than most previously reported data [10, 36, 43, 57]. One of the reasons might be that the maximum was limited by the lack of nutrition during the precipitation reaction in this study. The other possible reason might be that when the dosage of gelling was small, the calcium or urea concentration would affect the urease activity to impact the precipitation efficiency. In other words, if there would have been a sufficient nutrition source in the solution, the precipitation rate for calcium carbonate of both S. pasteurii and B. megaterium would eventually have increased. At low temperatures, the precipitation rate for calcium carbonate exceeded that of S. pasteurii all the way due to the higher enzyme activity of B. megaterium.

Comparative results at a temperature of 15 °C are shown in Fig. 7. More calcium carbonate precipitation was produced with B. megaterium, both during the early and the later periods. The results are consistent with the enzyme activity mentioned above. This indicates that the bacterial concentration and the enzyme activity of B. megaterium were slightly impacted by temperature, resulting in a small influence on precipitation rates for calcium carbonate. In contrast, S. pasteurii was very sensitive to temperature changes. The more effective calcium carbonate production of B. megaterium was also due to its shorter delay period.

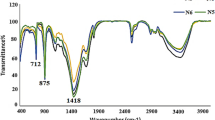

Aragonite is the high-pressure polymorph of calcium carbonate and can also be synthesized at temperatures above 60 °C. However, aragonite is thermodynamically unstable at standard temperature and pressure and tends to change to vaterite and calcite [48]. Moreover, vaterite (similar to aragonite) is a metastable phase of calcium carbonate. Since it is less stable than either calcite or aragonite, vaterite has a higher solubility than either of these phases. Therefore, once vaterite is exposed to water, it converts to calcite (at low temperatures) or aragonite (at high temperature: 60 °C) [62]. The XRD test results with temperature of 15 °C in Fig. 9 show that the polymorph of calcium carbonate produced with B. megaterium is calcite, which is more stable than the main polymorph produced with S. pasteurii (vaterite). These results future demonstrate that B. megaterium was more suitable for MICP at low temperature.

4.3.2 Comparison of precipitation rates under various amounts of urea addition

Urease was produced by bacteria to decompose urea into CO32−, while bonding free calcium ions to generate calcium carbonate precipitation [37]. When the nutrient solution was inoculated with bacteria, while adding urea to the medium at the same time, urea is decomposed into CO32− in advance during the reproduction of bacteria. Calcium carbonate was produced as soon as the calcium source was joined and, accordingly, adding urea to culture solution accelerated the precipitation reaction.

Calcium carbonate precipitation is widespread in nature, and a variety of bacteria play important roles in the precipitation of mineral carbonates [19, 20]. In the process, urea is hydrolyzed via catalysis, thus degrading to carbonate and ammonium, which explains why the pH and carbonate concentration increased in the microbial environment, and why CaCO3 is generated afterward [51]. Therefore, the whole process was divided into two parts: hydrolysis of urea and formation of CaCO3. This study proposed a method of adding urea to the medium to accelerate the MICP process. When an accelerating reaction occurred at low temperature, more precipitation would be produced during the same time frame. Although precipitation rates of the calcium carbonate of B. megaterium were distinctly higher than those of S. pasteurii under low-temperature conditions, they were still lower than under warm temperature conditions. This is why the precipitation rates of calcium carbonate were increased in low-temperature condition.

Urea was decomposed into free carbonate ions in medium in advance. The process of production of calcium carbonate consisted of two parts after the mixed solution was added. The first part was immediate calcification when the calcium source was added, while the second part was the common MICP process, i.e., urea was decomposed first and then united with calcium ions. Precipitation rates both increased with increasing urea concentration independent of the type of bacteria, as more urea was hydrolyzed ahead of mixed solution addition, as shown in Fig. 8. Under identical conditions, precipitation rates of B. megaterium were definitely higher than those of S. pasteurii. The method of adding urea to the medium was useful for both bacteria to produce more precipitation, even though both OD600 values declined. However, by contrasting the spectrum of growth of precipitation rates, the effect of the method on precipitation rates of B. megaterium was shown to exceed that of S. pasteurii. In particular, when the concentration of added urea was 20 g/L, the precipitation rates of B. megaterium after 96-h culture increased from 15 to almost 26%, which almost equaled the precipitation rate without urea addition at 30 °C. As mentioned before, the precipitation rate with 20 g/L of urea concentration was limited by the available calcium source. Different amounts of urea added corresponded to different precipitation rates, specific amounts of precipitation could be produced by controlling the urea concentration. For example, before applying MICP technology to solidify sands or cure cracks at low temperature, a variety of concentrations of urea could be prepared according to pore sizes among sand particles or width of cracks to ensure that appropriate amounts carbonate calcium would be produced.

In summary, the method of adding urea to the medium for the duration of culture expedited the process of MICP and allowed higher precipitation levels, which effectively overcame the problem of deficient calcium precipitation at low temperatures. The reaction kinetics of microbial carbonate precipitation in soil may not be identical to that without soil and in this paper. No relevant study has been published about the precipitation reaction in soil; however, according to many previous studies [10, 28, 36, 57], a strong correlation exists between both types of reactions. Therefore, the results obtained through experiments under batch condition are practical for the reaction in soil, which laid the foundation for subsequent low-temperature tests, such as sands solidification and crack repair.

5 Conclusions

In this study, different temperature conditions were compared to analyze the growth patterns, enzyme activity, and precipitation rates of S. pasteurii and B. megaterium for calcium carbonate. The concentration of urea was varied to evaluate their influence on precipitation results. The following conclusions can be drawn:

-

(1)

At high temperature, the growth speed of B. megaterium is close to that of S. pasteurii. The growth curve of B. megaterium is distinctly higher than that of S. pasteurii at low temperatures, although it is still extremely lower than that of B. megaterium at high temperatures.

-

(2)

Temperature slightly influences the urease activities of B. megaterium, unlike S. pasteurii. With high temperature, the enzyme activity of B. megaterium was lower than that of S. pasteurii, while it was higher at low temperatures.

-

(3)

The same comparative results were found not only for enzyme activity, but also for precipitation rates for calcium carbonate. At low temperatures, the speed of precipitation and the ultimate amounts of calcium carbonate of B. megaterium significantly exceeded those of S. pasteurii.

-

(4)

The method of adding urea to the medium accelerated the precipitation reaction and precipitation rates increased with increasing urea concentration. Under identical conditions, the precipitation rates of B. megaterium were higher than those of S. pasteurii throughout the experiment.

-

(5)

Under addition of 20 g/L of urea to the medium, the precipitation rate of B. megaterium at 15 °C was on the verge of that without urea addition at 30 °C. Therefore, the method of adding urea to medium is effective to address the issue of lacking calcium precipitation at low temperature and provides a foundation for subsequent low-temperature tests and engineering applications.

References

Alexander M (1961) Introduction to soil microbiology. Wiley, New York, pp 428–472

Al-Thawadi S (2008) High strength in situ biocementation of soil by calcite precipitating locally isolated ureolytic bacteria. Murdoch University, Perth

And HC, Antonietti M (1998) Crystal design of calcium carbonate microparticles using double-hydrophilic block copolymers. Langmuir 14(3):582–589

Bachmeier KL, Williams AE, Warmington JR, Bang SS (2002) Enzyme activity in microbiologically-induced calcite precipitation. J Biotechnol 93(2):171–181

Braissant O, Cailleau G, Dupraz C, Verrecchia E (2003) Bacterially induced mineralization of calcium carbonate in terrestrial environments: the role of exopolysaccharides and amino acids. J Sediment Res 73:485–490

Cheng L, Shahin MA, Chu J (2018) Soil bio-cementation using a new one-phase low-pH injection method. Acta Geotech. https://doi.org/10.1007/s11440-018-0738-2

Chin Wei-Tsung, Kroontje W (1962) Conductivity method for estimation of enzyme activity. Agric Food Chem 10:347–348

Chu J, Ivanov V, Naeimi M, Stabnikov V, Liu HL (2014) Optimization of calcium-based bioclogging and biocementation of sand. Acta Geotech 9(2):277–285

Cuthbert MO, McMillan LA, Handley-Sidhu S, Riley MS, Tobler DJ, Phoenix VR (2013) A field and modeling study of fractured rock permeability reduction using microbially induced calcite precipitation. Environ Sci Technol 47(23):13637–13643

De Muynck W, Verbeken K, De Belie N, Verstraete W (2013) Influence of temperature on the effectiveness of a biogenic carbonate surface treatment for limestone conservation. Appl Microbiol Biotechnol 97:1335–1347

DeJong JT, Fritzges MB, Nusslein K (2006) Microbially induced cementation to control sand response to undrained shear. J Geotechn Geoenviron Eng 132(11):1381–1392

DeJong JT, Mortensen BM, Martinez BC, Nelson DC (2010) Bio-mediated soil improvement. Ecol Eng 36(2):197–210

Ehrlich HL (2002) Geomicrobiology. Revised and expanded, 4th edn. Marcel Dekker, New York

Ferris FG, Phoenix V, Fujita Y et al (2004) Kinetics of calcite precipitation induced by ureolytic bacteria at 10 to 20 degrees C in artificial groundwater. Geochim Cosmochim Acta 68(8):1701–1710

Fredrickson JK, Fletcher M, Frederickson JK et al (2001) Subsurface microbiology and biogeochemistry. Wiley, New York

Fujita Y, Taylor JL, Gresham TLT et al (2008) Stimulation of microbial urea hydrolysis in groundwater to enhance calcite precipitation. Environ Sci Technol 42(8):3025–3032

Gat D, Tsesarsky M, Shamir D, Ronen Z (2014) Accelerated microbial-induced CaCO3 precipitation in a defined coculture of ureolytic and non-ureolytic bacteria. Biogeosciences 11(10):2561–2569

Gomez MG, Hunt CE, Martinez BC et al (2015) Field-scale bio-cementation tests to improve sands. Proc ICE Ground Improv 168(3):206–216

Hammes F, Boon N, de Villiers J, Verstraete W, Siciliano SD (2003) Strain-specific ureolytic microbial calcium carbonate precipitation. Appl Environ Microbiol 69:4901–4909

Hammes F, Seka A, Van Hege K, Van de Wiele T, Vanderdeelen J, Siciliano SD, Verstraete W (2003) Calcium removal from industrial wastewater by bio-catalytic CaCO3 precipitation. J Chem Technol Biotechnol 78:670–677

Huang MY, Yuan LI, Yong J et al (2017) Characteristics of ground temperature variation in the northern suburb of Nanjing. J Anhui Agric Sci 45(03):222–225

Hata T, Yokoyama T, Abe H (2013) Investigation of a soil improvement technique for coastal regions on the basis of calcium carbonate precipitation by using the urea hydrolysis rate. Jpn Geotech J 8(4):505–515 (in Japanese)

Hattori T (1973) Microbial life in the soil: an introduction, vol 6. Dekker, New York, p 427

Hoffman M, Deccho AW (1999) Extracellular enzymes within microbial biofilmsand the role of the extracellular polymer matrix. In: Wingender J, Neu TR, Flemming HC (eds) Microbial extracellular polymeric substances: characterization, structure and function. Springer, Berlin, pp 217–227

Ivanov V, Chu J (2008) Applications of microorganisms to geotechnical engineering for bioclogging and biocementation of soil in situ. Rev Environ Sci Biotechnol 7(2):139–153

Jiang NJ, Yoshioka H, Yamamoto K et al (2016) Ureolytic activities of a urease-producing bacterium and purified urease enzyme in the anoxic condition: implication for subseafloor sand production control by microbially induced carbonate precipitation (MICP). Ecol Eng 90:96–104

Keykha HA, Huat BBK, Asadi A et al (2012) Electro-biogrouting and its challenges. Int J Electrochem Sci 7(7):1196–1204

Khan MNH, Amarakoon GGNN (2015) Coral sand solidification test based on microbially induced carbonate precipitation using ureolytic bacteria. Mater Trans 56(10):1725–1732

Krajewska B, Leszko M, Zaborska W (1990) Urease immobilized on chitosan membrane: preparation and properties. J Chem Technol Biotechnol 48(3):337–350

Krajewska B (2009) Ureases I. Functional, catalytic and kinetic properties: a review. J Mol Catal B Enzym 59:9–21

Lauchnor EG, Topp DM, Parker AE, Gerlach R (2015) Whole cell kinetics of ureolysis by Sporosarcina pasteurii. J Appl Microbiol 118(6):1321–1332

Li Wei, Liu L, Chen W, Yu L, Li Wenbing, Yu H (2010) Calcium carbonate precipitation and crystal morphology induced by microbial carbonic anhydrase and other biological factors. Process Biochem 45:1017–1021

Lian B, Hu Q, Chen J, Ji J, Teng HH (2006) Carbonate biomineralization induced by soil bacterium Bacillus megaterium. Geochim Cosmochim Acta 70(22):5522–5535

Madigan MT, Martinko JM, ve Parker J (2003) Brock biology of microorganisms,10th edn. Prentice Hall/Pearson Education

Martin D, Dodds K, Ngwenya BT, Butler IB, Elphick SC (2012) Inhibition of Sporosarcina pasteurii under anoxic conditions: implications for subsurface carbonate precipitation and remediation via ureolysis. Environ Sci Technol 46(15):8351–8355

Martinez B, DeJong J, Ginn T, Montoya B, Barkouki T, Hunt C, Tanyu B, Major D (2013) Experimental optimization of microbial-induced carbonate precipitation for soil improvement. J Geotech Geoenviron Eng 139(4):587–598

Mitchell AC, Phillips AJ, Kaszuba JP et al (2008) Microbially enhanced carbonate mineralization and the geologic containment of CO2. Geochim Cosmochim Acta 72(12):A636

Mobley HLT, Hausinger RP (1989) Microbial ureases: significance, regulation, and molecular characterization. Microbiol Rev 53:85–108

Montoya B, DeJong J, Boulanger R (2013) Dynamic response of liquefiable sand improved by microbial-induced calcite precipitation. Géotechnique 63(4):302–312

Moyo CC, Kissel DE, Cabrera ML (1989) Temperature effects in soil enzyme activity. Soil Biol Biochem 21:935–938

Muynck WD, Cox K, Belie ND et al (2008) Bacterial carbonate precipitation as an alternative surface treatment for concrete. Constr Build Mater 22(5):875–885

Omoregie A, Ghaza K, Senian N et al (2017) Experimental optimisation of various cultural conditions on enzyme activity for isolated Sporosarcina pasteurii strains and evaluation of their biocement potentials. Ecol Eng 109:65–75

Qabany AA, Soga K, Santamarina C (2012) Factors affecting efficiency of microbially induced calcite precipitation. J Geotech Geoenviron Eng 138(8):992–1001

Qin X, Lin Q, Li S (2017) Characteristics of geotemperature field for shallow geothermal energy assessment and utilization in Hangzhou. Taiyangneng Xuebao/Acta Energiae Solaris Sinica 38(3):833–837

Ramachandran SK, Ramakrishnan V, Bang SS (2001) Remediation of concrete using micro-organisms. ACI Mater J Am Concr Inst 98(1):3–9

Ren J, Han Q, Gao H et al (2012) On the distribution law of geothermal formation in winter along Xi’an metro line. Urban Mass Transit 15(10):39–42

Rodriguez-Navarro C, Rodriguez-Gallego M, Ben Chekroun K, González-Munoz MT (2003) Conservation of ornamental stone by Myxococcus xanthus-induced carbonate biomineralization. Appl Environ Microbiol 69:2182–2193

Sand KK, Rodriguezblanco JD, Makovicky E et al (2012) Crystallization of CaCO3 in water–alcohol mixtures: spherulitic growth, polymorph stabilization, and morphology change. Cryst Growth Des 12(2):842–853

Soon NW, Lee LM, Khun TC, Ling HS (2013) Improvements in engineering properties of soils through microbial-induced calcite precipitation. KSCE J Civ Eng 17(4):718–728

Soon NW, Lee LM, Khun TC, Ling HS (2014) Factors affecting improvement in engineering properties of residual soil through microbial-induced calcite precipitation. J Geotech Geoenviron Eng 140(5):04014006

Stocks-Fischer S, Galinat JK, Bang SS (1999) Microbiological precipitation of CaCO3. Soil Biol Biochem 31:1563–1571

Tittelboom KV, Belie ND, Muynck WD et al (2010) Use of bacteria to repair cracks in concrete. Cem Concr Res 40(1):157–166

van Paassen L (2009) Biogrout ground improvement by microbially induced carbonate precipitation. Ph.D. thesis, Delft University of Technology, Netherlands

Vary PS (1994) Prime time for Bacillus megaterium. Microbiology 140(5):1001–1013

Vos P, Garrity G, Jones D, Krieg NR et al (2009) Bergey’s manual of systematic bacteriology—volume 3: the firmicutes. Springer, New York

Wang Y, Luo Z, Li W et al (2015) Simulation of shallow geothermal energy development and groundwater environmental influence. Taiyangneng Xuebao/Acta Energiae Solaris Sinica 36(5):1231–1238

Whiffin VS (2004) Microbial CaCO3 precipitation for the production of biocement. Murdoch University, Perth

Whiffin VS, van Paassen LA, Harkes MP (2007) Microbial carbonate precipitation as a soil improvement technique. Geomicrobiol J 24(5):417–423

Wijngaarden W, Vermolen F, Meurs G, Vuik C (2011) Modelling biogrout: a new ground improvement method based on microbial-induced carbonate precipitation. Transp Porous Media 87(2):397–420

Wu C, Chu J, Wu S et al (2018) Microbially induced calcite precipitation along a circular flow channel under a constant flow condition. Acta Geotech. https://doi.org/10.1007/s11440-018-0747-1

Wu Y et al (2011) Geophysical monitoring and reactive transport modeling of ureolytically-driven calcium carbonate precipitation. Geochem Trans 12(1):7

Zhou GT, Yao QZ, Fu SQ et al (2010) Controlled crystallization of unstable vaterite with distinct morphologies and their polymorphic transition to stable calcite. Eur J Mineral 22(2):259–269

Zoheir A, Talkhan F, Hammad I (2013) Enzyme activity and induction of calcium carbonate precipitation by Sporosarcina pasteurii NCIMB 8841. J Appl Sci Res 9(3):1525–1533

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 51578147) and Scientific Research Foundation of Graduate School of Southeast University (No. YBJJ1846). This work was also supported by “the Fundamental Research Funds for the Central Universities” and “Postgraduate Research and Practice Innovation Program of Jiangsu Province” (No. KYCX18_0107). The authors thank the valuable comments from the reviewers.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sun, X., Miao, L., Tong, T. et al. Study of the effect of temperature on microbially induced carbonate precipitation. Acta Geotech. 14, 627–638 (2019). https://doi.org/10.1007/s11440-018-0758-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-018-0758-y