Abstract

Purpose

To study the effect of three nonionic surfactants on the protein-silicone oil interactions.

Methods

The adsorption of Tween® 80, Pluronic® F68 and Tween® 20 at the silicone oil/water interface (using shifts in frequency (ΔF) and resistance (ΔR) with quartz crystal microbalance) was compared to the adsorption at air/water interface (using surface tension). Effect of surfactants on protein adsorption to the silicone oil/water interface was studied in sequential- and co-adsorption modes. Protein-surfactant binding in the bulk was measured using dynamic surface tension method.

Results

Saturation of air/water and silicone oil/water interfaces by surfactants was observed at similar bulk concentrations. ΔF due to protein adsorption to the interface decreased only when surfactant was present as a pre-adsorbed species. Insignificant differences in the dynamic surface tension values of surfactant solutions were observed in the presence of protein.

Conclusions

Similar hydrophobic forces were responsible for driving the surfactant adsorption at both air/water and silicone oil/water interfaces. Surfactants were effective in reducing the protein adsorption to the silicone oil only when introduced before or along with the protein. No significant binding between the protein and surfactants was observed in the bulk.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Proteins being amphiphilic are generally surface active, and therefore, interact with various interfaces encountered during different pharmaceutical processes of expression, purification, filling, filtration, freeze-thaw, transportation, and storage. The interfaces include both air/water (pumping, filling, transportation, and storage) and solid/water (purification, freeze-thaw, pumping, filling, and storage). Whereas air/water interfaces are always hydrophobic, solid/water interfaces could be both hydrophobic (e.g. Teflon, alkyl substitute chromatography columns and silicone oil), or hydrophilic (e.g. glass, modified chromatographic silica and polyvinylidene fluoride membrane in filters). The interfacial interactions can lead to a change in protein conformation (1,2) resulting in diminished biological activity and aggregation upon storage.

One of the common interfaces encountered by the protein molecules is that of silicone oil/water. Silicone oil is widely used as a lubricant in prefilled syringes and vial stoppers to enable component processability during manufacturing and functionality during delivery (3). Silicone oil has been implicated in protein aggregation and particle formation (4–7) and has been a serious concern in pharmaceutical industry where the prefilled syringe is becoming a container of choice for the delivery of biopharmaceuticals. These protein aggregates/particulates could be less efficacious and may have immunogenic potential, making the drug formulation clinically unacceptable (8).

Protein molecules can encounter two forms of silicone oil in a container, one present as a lubricant coating (a static interface with the formulation phase) and other, that may leach in to the bulk (a dynamic interface with the formulation phase). Both the interfaces with silicone oil may be playing role in the silicone oil induced protein instability. Different groups have studied the interaction of protein with silicone oil using silicone oil spiking (dynamic silicone oil/water interface) (5,7,9) or in actual prefilled syringes (consisting of both static and dynamic silicone oil/water interfaces) (6,10). Although the studies done in prefilled syringes depict a real world scenario, from a point of mechanistic understanding of protein-silicone oil interactions it is important to study separately the protein interactions at a static silicone oil/water interface. This is important because with improved silicone oil coating technologies such as baking, the manufactures have been able to obtain coatings significantly less prone to leach silicone oil (11). In such a case, the area of concern would be the hydrophobic and static silicone oil coating/formulation interface where protein molecules can adsorb, denature and potentially form bulk and/or surface aggregates. However, studies with proteins on such a static silicone oil/water interface are very few (12,13).

Different studies with static hydrophobic interfaces have shown the tendency of protein molecules to undergo denaturation upon adsorption (2,14–18). The denatured protein species were also observed to be present in the bulk following the adsorption step (2,19). These denatured species can combine with similar molecules in the bulk to cause aggregation. Such instability of protein molecules can also potentially occur in a prefilled syringe, where a static silicone oil lubricant coating is in contact with the protein in solution. Moreover, since the prefilled syringes act as storage container as well, this process of protein surface adsorption, denaturation, and desorption can continue to cause increased bulk protein aggregation over the product shelf life (~ 2 years). Any of these steps could be rate limiting in the process. The first step of adsorption could be minimized to prevent the protein stability issues that could arise later. The protein adsorption at hydrophobic interfaces can be inhibited/reduced by the use of nonionic surfactants in protein formulations. The use of the surfactants in biopharmaceuticals for stabilization effect has been attributed mainly to the competition of the surfactant with the protein for a common interface (20–22) and the binding of the surfactant to protein through hydrophobic groups, making protein surface more hydrophilic, and preventing the interfacial protein adsorption (23–25). Other mechanisms such as decreased aggregation by increasing the free energy of unfolding of the protein by binding to its native state have also been proposed (26). Though the surfactants were effective in reducing the silicone oil induced protein instability in a system with spiked silicone oil (7,9), a fundamental understanding of the role of surfactants in affecting the protein-silicone oil interactions at a static silicone oil/water interface is still lacking. Studying the real time adsorption of proteins in the presence of surfactant directly at a static silicone oil/water interface, as present in a lubricated syringe, would provide a better mechanistic understanding of these interactions.

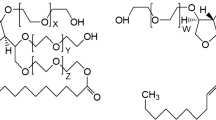

We have previously shown the effect of Tween® 20 on the interactions of a fusion protein with silicone oil (13). Tween® 20 was effective in reducing the protein adsorption as a pre-adsorbed species at the interface. However, the observed effect may not be universal and cannot be extrapolated to other surfactants relevant to the pharmaceutical industry. Therefore, in this study we compare the effect of three nonionic surfactants, Tween® 80, Pluronic® F68 and Tween® 20 on the interactions of an Fc-fusion protein with a thin film of silicone oil. The surfactant adsorption behavior at silicone oil coating/formulation interface (adsorbed amount, saturation behavior, and the nature of adsorbed film) with respect to their adsorption at the air/water interface is also studied.

Materials and Methods

The material used in these studies such as the protein, silicone oil, surfactants, buffer components etc. have been described previously (13). Additionally, Tween® 80 and Pluronic® F68 were obtained from Fisher scientific (Fair Lawn, NJ). The experimental procedures of sample preparation and adsorption studies with protein and surfactant using QCM have also had been described earlier (13).

Quartz Crystal Microbalance (QCM) Setup

The adsorption studies at the silicone oil/water interface were carried out using commercially available QCM apparatus (QCM 200; SRS Inc., Sunnyvale, CA) with silicone fluid (PDMS; 1 million cSt) coated quartz crystals (5 MHz). The studies were conducted in flow injection mode at 25.0°C with the coated crystal mounted in a flow cell. The solvent was made to flow through the system using a syringe pump (NE 1010X; New Era Pump Systems, Inc., Farmingdale, NY) at a rate of 50 μL/minute. Upon reaching a stable baseline with respect to changes in frequency (F) and resistance (R) values in the solvent, sample was introduced. Data i.e. the shifts in the F and R values of the crystal as a function of time were recorded at an interval of 10 seconds using LabView stand alone software (National Instruments Corporation, Austin, TX). The samples were made to remain in contact with the crystal surface until the point of no further shifts in F and R values. These changes in the F and R signals were taken into calculations to determine the mass of species (protein/surfactant) adsorbed at equilibrium to the interface (13). Details related to system handling have been described previously (13,27).

Equilibrium Surface Tension Measurements

The studies were conducted in distilled water at 24.0 ± 0.5°C using a semiautomatic Surface Tensiomat model 21 (Fisher scientific company, NJ) utilizing a platinum-iridium du-Noüy ring. A 15 mL volume of each solution was added to a pre-cleaned petri dish (60 mm × 15 mm), and the dish surface was allowed to saturate for 15 min before discarding the solution. The test solution (15 mL) was then added to the petri dish, covered to prevent any solvent evaporation, and stored for 24 h before making any measurements. The force required to detach the ring from the surface of the solution is proportional to the apparent surface tension (P). The apparent surface tension is then converted to true surface tension (S) by using a correction factor (F):

where F is dependent on the radius and circumference of the ring, radius of the wire used in the ring, apparent surface tension (dial reading), and densities of the two phases. The measurements were conducted in duplicate.

Protein-Surfactant Binding Studies

The binding between the Fc-fusion protein and surfactants was studied using the maximum bubble pressure method at pH 5.0 and 10 mM solution ionic strength. The method employs the measurement of dynamic surface tension at the newly formed surface of a bubble in a solution. The observed surface tension depends on the amount of surface-active species adsorbed onto the newly formed surface, which in turn depends on its size, molecular weight, and the rate at which the interface is generated (bubble rate or surface age). A bubble rate can be chosen where only the smaller sized, free surfactant molecules (higher diffusion rate) contributes to the surface tension, and the contribution from the larger species (protein monomer, protein aggregates, and protein-surfactant complex; smaller diffusion rate) can be avoided. Therefore in a mixture of a surfactant and macromolecule, this technique can be used to monitor the changes in the surface tension caused only by the surfactant. This change in the surface tension can then be related to the concentration of free surfactant molecules in the solution, and hence any binding between protein and the surfactant will be reflected in the measured surface tension values. Details related to the principle and working of the technique are given elsewhere (28,29).

Surface tension measurements were conducted using a surface tensiometer (Sensadyne 9000, Chem-Dyne Research Corp., Mesa, AZ) with two offset glass probes of diameter 0.5 and 4.0 mm and at a bubble rate of 0.2 bubbles/second (surface age - 5 seconds). Calibration of the instrument was performed using triple distilled water and ethanol as high and low surface tension standards, respectively with corresponding surface tension values of 72.1 and 22.4 dynes/cm at 25.0°C. The surface age was kept constant at 5 seconds and readjusted if needed during the titration process. The temperature of the fluid under measurement was kept constant at 25.0 ± 0.1°C using an external water bath. Titrations of the buffer were first performed using a stock surfactant solution to generate a surface tension versus concentration profile. The protein solution (5.0 μM) in buffer was titrated with the same stock of surfactant solution.

Results and Discussion

Surfactant Adsorption at the Silicone Oil/Water and Air/Water Interfaces

Surfactants are commonly added to the protein formulations to provide protection against both the air/water and container/water interfaces. The adsorption behavior of surfactants at air/water interface has been widely studied, however, reports for their adsorption at the interface between container and formulation are lacking (30). In order to determine the bulk surfactant concentrations needed to achieve interfacial saturation, adsorption isotherms for the three nonionic surfactants were generated at the silicone oil/water interface (Fig. 1). All the surfactants show an initial rise in adsorption, which is followed by a plateau. Figure 1 also shows that the Langmuir monolayer adsorption model (Eq. 2) can be used to describe the data for surfactant adsorption at the interface:

where Δm is the adsorbed mass, Δm max is the mass required to get a monolayer coverage on the interface, K ads is the equilibrium adsorption constant, and C is the bulk surfactant concentration at the equilibrium.

Langmuir equation can be applied when the following assumptions are met: (i) the adsorbent surface is homogenous, (ii) the adsorption occurs in one molecular layer, (iii) both the solvent and solute molecules have equal cross sectional areas, and (iv) there are no net solute-solvent or solute-solute interactions, both in the bulk phase and at the interface (31). The last two assumptions are difficult to meet in the adsorption of surfactants from aqueous solutions on to an interface. However, it has been shown by the use of the Flory-Huggins principle that the last two assumptions cause deviations from the Langmuir expression that are in opposite directions to one another, and hence compensate each other, giving a good Langmuir fit to the data (31). This model was therefore used here to determine possible orientation of the surfactant molecules adsorbed at the silicone oil/water interface. Equation 2 can be linearized to Eq. 3 and the mass of surfactant required to achieve monolayer coverage could then be determined:

The area occupied by each molecule and hence, the possible orientation of the surfactant units at the silicone oil/water interface can then be determined using Eq. 4:

where N A is the Avogadro’s number and m (= Δm max ) is the amount of surfactant (in moles/cm2) required to achieve monolayer coverage of the interface. The results are given in Table I and discussed later in comparison with the adsorption data obtained at the air/water interface. For the duration of the experiments, the silicone oil coating was physically stable in the presence of the studied surfactants at concentrations above their CMC (data not shown; see (13) for details).

The adsorption of nonionic surfactants at the air/water interface was studied using equilibrium surface tension measurements as a function of bulk concentration (Fig. 2). All the plots show that the surface tension decreases to a certain concentration characteristic of each compound, when surface tension remains essentially constant (or decreases very gradually as in Pluronic® F68) with a further increase in the concentration. The adsorption of surfactants at the air/water interface is driven by hydrophobic interactions. Closeness of bulk concentrations providing air/water interfacial saturation (Fig. 2) to that required to saturate the silicone oil/water interface (Fig. 1) suggests that the similar hydrophobic forces are also responsible for promoting adsorption of the nonionic surfactants to the silicone oil/water interface.

To obtain information about the adsorption behavior of the surfactants at air/water interface, equilibrium surface tension data were analyzed using the Gibb’s adsorption equation (32):

where Γ 2 is surface excess (mole/m2), R is gas constant, T is temperature, and γ is surface tension. This equation assumes ideal behavior at low concentrations, so the concentration (C) can be used instead of activity. The amount of a solute adsorbed at the air/water interface (surface excess) can be determined from the initial slope of surface tension versus natural log concentration plots for the surfactants studied (Fig. 3). The area occupied per surfactant molecule at the air/water interface can then be determined using the surface excess in Eq. 4. Table I compares the interfacial adsorption data for surfactants at the silicone oil/water and air/water interfaces. All the surfactants, except Tween® 80, were calculated to have greater mass adsorbed at the air/water interface compared to the silicone oil/water interface. The adsorption of surfactant molecules at the air/water interface is associated with a greater molecular flexibility as the penetration of the nonpolar tail is allowed into the air. Therefore, a more compact surfactant layer with greater number of adsorbed molecules (higher adsorbed mass) could be expected in this case. Additionally, Pluronic® F68 has also been suggested to undergo a considerable folding of its hydrophobic poly(propylene) oxide (PPO) moieties at the air/water interface (33), leading to the formation of a more compact layer. This could be the reason for a significantly higher adsorption of Pluronic® F68 at the air/water interface compared to silicone oil/water interface. Tween® 80 showed reduced adsorption at the air/water interface compared to silicone oil/water interface. This result is consistent with the previous report comparing Tween® 80 adsorption at the hydrophobic solid/liquid interface (silane treated glass/water interface) with liquid/vapor interface (34). The greater adsorption at the solid/liquid interface is explained by a more structured adsorbed surfactant layer at the hydrophobic solid/liquid interface leading to a higher packing density.

Table I also shows the area occupied by the surfactant molecules at the air/water and silicone oil/water interfaces. The area has been compared to the area of the surfactant monomer, calculated theoretically, in horizontal orientation, using the bond lengths of the groups present in the fatty acid chains or PPO unit of the surfactants (groups in contact with the hydrophobic interface). For all the surfactants, the experimentally measured areas at the silicone oil/water interface were found to be greater than the area calculated theoretically, suggesting that the monomeric units of surfactants are adsorbed in loosely packed layers. This is because of the hindrance of steric nature associated with the bulky hydrophilic moieties, oxyethylene (Tween® 80 and 20) and PEO (Pluronic®F68), extended into the bulk. Similar adsorption behavior was observed for Tween® 80 and Tween® 20 on the air/water interface. For Pluronic® F68, on the other hand, the area experimentally measured at the air/water interface is significantly lower than the theoretically calculated area, supporting the earlier proposed hypothesis of PPO folding at the air/water interface. The differences observed in the area occupied by each surfactant molecule between air/water and silicone oil/water interface could be attributed to the nature of the two interfaces. In the present case, the silicone oil coating (on crystal surface) in contact with water represents a static and non-penetrable interface. However, air/water is a penetrable and dynamic interface where molecules can achieve greater flexibility, allowing them to form a more compact layer with greater number of molecules at the interface. For Tween® 80, the reason for smaller occupied area at the silicone oil/water interface in comparison to air/water interface is described in the previous paragraph in terms of its higher packing density at the hydrophobic solid/liquid interface.

Viscoelastic Nature of the Adsorbed Layer

Measuring resistance shifts (ΔR) in QCM provides information about the physical nature of the bound layer, i.e. if it is elastic (rigid) or viscoelastic. A bound layer which is elastic in nature dissipates no energy and results in a negligible change in the crystal R value. However, a surface layer which is viscoelastic in nature results in a positive shift in the R value because of the energy loss associated with the viscous nature of the coupling. The ΔR for surfactant adsorption at the silicone oil/water interface, at or above surface saturation concentrations, were 2.53 ± 0.77 Ω (Tween® 80), 3.03 ± 0.52 Ω (Pluronic® F68), and 2.62 ± 0.29 Ω (Tween® 20). The same resistance shift for the protein adsorption under the studied condition was 0.77 ± 0.29 Ω. Fig. 4 shows the plot of ΔR/ΔF for Tween® 80 (0.02%; 152 μM), Pluronic® F68 (0.035%; 41 μM) and Tween® 20 (0.02%; 163 μM). The data are shown for the concentrations achieving saturation of the silicone oil/water interface. For the reference, a completely viscous system can be represented by deionized water where the average slope ΔR/ΔF was determined to be 0.405 ± 0.002 Ω/Hz, and the same slope would be zero for a completely elastic system (13,27). Irrespective of the surfactant type, at saturating bulk concentrations, the interfacially bound surfactant layers were found to have similar magnitude of viscoelastic character (ΔR/ΔF, 0.121 ± 0.003 Ω/Hz). In comparison, the Fc-fusion protein studied here forms a relatively more rigid layer at the silicone oil/water interface (ΔR/ΔF, 0.017 ± 0.007 Ω/Hz). This rigidity of the bound species at the interface is also associated, qualitatively, to the reversibility upon rinsing associated with each layer at the silicone oil/water interface. Surfactants, irrespective of their type, showed on an average 20–25% reversibly bound portion (Fig. 5) whereas, this reversibility was less than 10% for the relatively rigidly bound Fc-fusion protein (Fig. 9).

Protein Adsorption at the Silicone Oil/Water Interface in the Presence of Surfactants

Previously, the maximum adsorption of this protein at the silicone oil/water interface was observed at pH 5.0 and 10 mM solution ionic strength (27), and therefore this condition was chosen for the protein adsorption studies in the presence of surfactant. Protein bulk concentration of 0.1 mg/mL, sufficient to provide silicone oil/water interface saturation, was used (27). For surfactants, the concentration achieving the saturation of the silicone oil/water interface was used. The kinetics of Fc-fusion protein adsorption at the silicone oil/water interface in the presence of Pluronic® F68 has been shown as a representative.

Protein Adsorption Following Surfactant Adsorption

The sequential mode adsorption kinetics of Pluronic® F68 and protein at the silicone oil/water interface as monitored by F and R signal shifts in QCM is shown in Fig. 5. Interfacial adsorption of the surfactant resulted in a decrease in the frequency and an increase in the resistance signal. The observed frequency decrease was significantly lower, while the rise in resonant resistance was significantly higher in magnitude compared to the adsorption of this protein to the silicone oil/water interface alone (Fig. 9, 0–6000 seconds). Upon attaining the stability in the measured F and R signals, the buffer rinsing of the system was performed to remove both the bulk as well as any reversibly adsorbed surfactant molecules. This is indicated by an increase in the frequency and a decrease in the resistance signals upon rinsing. However, not all surfactant could be rinsed away, and on the time scale of these studies a significant portion of the adsorbed molecules stayed at the interface post-solvent rinsing. Such adsorption irreversibility of different surfactants on hydrophobic interfaces has been observed previously, including silicone oil/water (12,13,35,36). A further decrease in the resonant frequency was observed upon protein introduction, indicating the adsorption of protein at the interface. The extent of this frequency reduction, however, was significantly smaller in magnitude in comparison to that observed for the protein adsorption to the silicone oil/water interface in the absence of any surfactant (~40 Hz (40.04 ± 2.71 Hz); Fig. 9, 0–6000 seconds). The data suggest that the presence of pre-adsorbed surfactant at the silicone oil/water interface results in a decrease in the amount of adsorbed protein. Upon rinsing with the solvent, a small frequency increase along with a negligible resistance decrease was observed which is indicative of the desorption of reversibly adsorbed protein molecules (upon rinsing, the resistance drop for the adsorbed protein layer is negligible (Fig. 9, 0–6000 seconds) while, it is significant for the surfactant (Fig. 5, 0–5000 seconds)). At the end of this experiment, the measured resistance value (1.85 Ω; 2.33 ± 0.50 Ω) is still significantly larger than that observed for the protein adsorption to the interface alone (0.77 ± 0.29 Ω) and hence, suggesting that protein did not cause a significant displacement of the surfactant molecules from the silicone oil/water interface. The value of ΔR/ΔF at equilibrium was calculated to be 0.067 ± 0.020 Ω/Hz, suggesting the contribution of both viscous and elastic components to the adsorbed layer.

Figure 6 compares the equilibrium adsorption of the Fc-fusion protein at the silicone oil/water interface in the absence and presence of the pre-adsorbed surfactant. In the presence of surfactant, the data are also distinguished on the basis whether the adsorbed surfactant layer was rinsed or not prior to protein introduction. Each surfactant, when already present at the silicone oil/water interface, showed a significant reduction in protein adsorption to the interface, as compared to the adsorption in the absence of the surfactant. All the surfactants, at saturation concentration, were found to be approximately equally effective in preventing protein adsorption to the silicone oil/water interface. It can be seen that for Tween® 80 and Tween® 20, there were no significant differences in the amount of adsorbed protein whether the pre-adsorbed surfactant was rinsed with buffer or not. However, for Pluronic® F68, there was a higher mass of protein adsorbed when the surfactant was rinsed prior to protein introduction. Desorption of Pluronic® F68, upon rinsing, would create a larger interfacial vacancy compared to desorption of Tween® 80 or Tween® 20 (Pluronic® F68 being a significantly bigger molecule, ~8400 Da vs ~1200–1300 Da for Tween®), allowing more protein to adsorb.

Protein-Surfactant Co-adsorption

In the co-adsorption mode, where the adsorption was studied from a mixture of protein and surfactant, the aim was to investigate if surfactants have any role in preventing protein adsorption to the silicone oil/water interface by binding to the nonpolar groups on the protein surface. The kinetics of adsorption at the silicone oil/water interface from a mixture of protein (0.1 mg/mL) and Pluronic® F68 (0.035%) is shown in Fig. 7. The magnitude of this observed frequency shift is similar to the frequency shift because of protein adsorption to the interface alone (40.04 ± 2.71 Hz), and is also similar to the total frequency shift caused by Pluronic® F68 adsorption followed by protein adsorption to the interface (Fig. 5). The increase in the resonant resistance (2.54 ± 0.11 Ω) accompanying this adsorption, however, is a characteristic of Pluronic® F68 adsorption (3.03 ± 0.52 Ω). Nevertheless, the magnitude of equilibrium frequency decrease is significantly greater than that observed with Pluronic® F68 adsorption alone to the interface (Fig. 5; 0–2000 seconds). This suggests that when a mixture is used, both Pluronic® F68 and the protein are adsorbed to the silicone oil/water interface. Similar adsorption behavior was seen previously with a mixture of poloxamer 188 (Pluronic® F68) and protein (abatacept) to the silicone oil (12). The ΔR/ΔF value obtained at equilibrium (0.057 ± 0.004 Ω/Hz) also suggested the layer to be a mix of protein and surfactant with viscoelasticity intermediate to that obtained with the two species separately at the interface.

Figure 8 shows the amount of surface active species adsorbed at equilibrium to the silicone oil/water interface, when studied from a mixture of fusion protein (0.1 mg/mL) and Tween® 80 (0.02%), Pluronic® F68 (0.035%), or Tween® 20 (0.02%). The figure shows the total mass of the species adsorbed to the interface and does not differentiate between the amount of protein and the surfactant. Though the total adsorbed mass is equal in the absence and presence of surfactant, the adsorbing species are different: protein alone in the absence of surfactant, while both protein and surfactant in case of adsorption studied from a mixture as described next. At interfacial saturating concentrations, the protein adsorption to the silicone oil/water interface produced an average frequency and resistance shift of 40 Hz and 0.77 Ω, respectively, while average values of 18–26 Hz and 2.5–3.0 Ω were obtained with the surfactants. In all the cases of coadsorption studies, when a mixture of protein and surfactant was introduced in to the system, a frequency decrease (> 40 Hz), characteristic of protein adsorption, along with a resistance increase (> 2.5 Ω), characteristic of the surfactant adsorption, was observed, suggesting that both protein and the surfactant adsorbed to the interface.

Surfactant Adsorption Following Protein Adsorption

The effect of nonionic surfactants on the pre-adsorbed protein layer at the silicone oil/water interface was also studied (Fig. 9). In comparison to Pluronic® F68 (Fig. 5; 0–2000 seconds), the adsorption of the protein to silicone oil results in a much larger resonant frequency decrease and a much smaller crystal resonant resistance increase. Rinsing step involving the solvent removed a fraction of the otherwise irreversibly adsorbed protein molecules. Introduction of Pluronic® F68 (0.035%) resulted in a further decrease of resonant frequency, suggesting Pluronic® F68 adsorption. The adsorption of Pluronic® F68 to the interface in the presence of adsorbed protein, however, is significantly less than compared to in the absence of any adsorbed protein. Some desorption of the reversibly adsorbed Pluronic® F68 molecules was seen upon rinsing, as characterized by the changes in the frequency and resistance signals. The final frequency shift measured is much larger than observed with Pluronic® F68 adsorption to the interface alone indicating the inability of Pluronic® F68 to displace the interfacially adsorbed protein molecules on these time scales. Similar behavior was seen in the presence of Tween® 20 (13) and Tween® 80 (data not shown). The value of ΔR/ΔF (0.035 ± 0.003 Ω/Hz), obtained at equilibrium, suggested the elastic nature of the adsorbed layer because of the presence of protein as the predominant species.

The adsorption of protein molecules onto the hydrophobic interfaces is governed by two major factors: (i) the removal of structured water around the nonpolar groups on the protein (also, on the sorbent surface) upon adsorption, and (ii) the structural rearrangements that are possible in the protein molecules at the interface (37). Both the factors result in a large gain in the system entropy. In the bulk solution, the collapse of polypeptide chain into a compact native state is accompanied by a considerable loss of the conformational entropy. The dehydration of the nonpolar surface groups and the resulting entropy gain outweighs this entropy loss resulting in a compact structure which is only marginally stable. However, once the protein is bound to the hydrophobic interface through the nonpolar residues present on its surface, it not only removes those nonpolar groups from water exposure, but now can also change its structure to the large volume denatured state, gaining the lost conformational entropy. This further leads to a stronger and irreversible binding at the interface. This protein has shown to bind rigidly and irreversibly to the silicone oil/water interface (low ΔR/ΔF value; Fig. 4, and small recovery of the frequency shift upon buffer rinse; Fig. 9) resulting in the inability of the surfactant to displace the interfacially adsorbed protein molecules.

Further reduction in the crystal resonant frequency upon introduction of the surfactant following protein adsorption was observed with each surfactant used. This reduction in the frequency could be attributed primarily to the surfactant adsorption at the empty sites between the interfacially adsorbed protein molecules. This is supported by the measured frequency shifts upon the introduction of surfactants post-protein adsorption. Frequency decrease caused by the adsorption of either Tween® 80 (12.34 ± 2.35 Hz) or Tween® 20 (11.52 ± 1.95 Hz) was significantly larger as compared to Pluronic® F68 (5.17 ± 1.97 Hz). This is consistent with the significantly larger size of Pluronic® F68 which would not allow it to permeate all the available vacancies in the adsorbed protein layer, though still accessible to the smaller sized Tween®.

Protein-Surfactant Binding Studies

A surfactant may reduce the interfacial protein adsorption either by competing with protein for the interface, or by binding to the protein surface, or both. In the protein-surfactant co-adsorption mode studies, it was observed that both protein and surfactant adsorbed to the interface (Fig. 7) however, it is not possible to separate the mass contribution from the individual species and hence directly determine if protein-surfactant binding has any role in affecting the protein adsorption to the silicone oil. Thus, to determine if protein-surfactant binding is playing any role, we measured the binding between the Fc-fusion protein and surfactants with the dynamic surface tension studies using maximum bubble pressure technique. A pre-optimized bubble rate of 0.2 bubbles/second (surface age - 5 seconds) was chosen where only the surfactant contributed to a reduction in the surface tension and not the protein (preliminary data, not shown). Figure 10 shows the dynamic surface tension curves (below the CMC of each surfactant) generated for Tween® 80 and Pluronic® F68 in the absence and presence of 5.0 μM Fc-fusion protein, as a function of surfactant concentration at 25.0 ± 0.1°C. In pure buffer, as the concentration of the surfactant in the solution increases, the surface tension decreases with two slopes, an initial steep and a latter shallow. When the same titrations are made in a solution containing Fc-fusion protein, no significant changes in the surface tension values are observed (similar pattern was observed with Tween® 20). This suggests the absence of binding between the protein and surfactants as measured using the bubble pressure technique. The binding of a surfactant to the protein would result in a less number of free surfactant molecules in the bulk and hence a higher surface tension value would be measured. Since no binding is observed between protein and the surfactants in the bulk, the mechanism of protein-surfactant binding may be ruled out in affecting the adsorption of the protein to the silicone oil/water interface. As described before, both protein and surfactant adsorbed to the interface in co-adsorption mode, and the adsorbed layer may be expected to consist of a significant amount of both protein and surfactant. A significant amount of surfactant at the interface could be expected because of the higher diffusion associated with the smaller sized surfactant molecules which would try to preoccupy the interface in the presence of protein. Protein adsorption may then follow in a manner similar to the adsorption of this protein occurring at the pre-adsorbed surfactant layer (Fig. 5). Such an adsorption process will result in a reduction in the interfacially adsorbed protein by the competition mechanism.

The binding of surfactant to a protein depends on the surface hydrophobicity of the protein. Surface hydrophobicity measurements were made by monitoring the fluorescence emission of ANS (8-anilino-1-naphthalenesulfonic acid) or PRODAN (6-propionyl-2-dimethylaminonaphthalene) dyes in the presence of increasing protein concentrations. The concentration of the dye was kept fixed at 40 μM (ANS) and 4 μM (PRODAN) and the protein concentration was varied from 0.02 mg/mL to 0.1 mg/mL. Excitation wavelength used was 375 nm (ANS) and 365 nm (PRODAN) with emission monitored in a range of 400 nm to 650 nm. With increasing Fc-fusion protein concentration, both dyes showed slight blue shifts, and small and gradual increase in the fluorescence intensities (data not shown). In contrast to Fc-fusion protein, a significantly greater blue shift in ANS emission (516 nm in pure buffer to 474 nm with protein) and a much higher increase in the fluorescence intensity with increasing protein concentration were seen with bovine serum albumin, which is consistent with the presence of a large hydrophobic patch on the surface of this fatty acid binding protein (data not shown). Our earlier work studying the binding between human serum albumin and polysorbate 80 (Tween® 80) using maximum bubble pressure technique has shown a significant binding between the two molecules (29) and is consistent with the significant surface hydrophobicity of the albumin as measured here. These results suggest the absence of any large/significant hydrophobic area on the surface of Fc-fusion protein so that a quantifiable signal could be obtained in the presence of either, the surfactant molecules (dynamic surface tension) or the dye molecules (fluorescence). This raises an interesting point that how does the adsorption of such a relatively hydrophilic fusion protein molecule proceeds at the hydrophobic silicone oil/water interface. Interfacial pressure studies for different proteins at the air/water interface using Langmuir trough have shown that irrespective of the protein size, only a small portion of the protein needs to enter the interface for the adsorption to proceed spontaneously (38,39). The cross sectional area of the proteins studied ranged from ~1000 to 10,000 Å2, however, the area required for each protein to enter the interface was within the narrow range of 100 to 175 Å2. This suggests that proteins can just get hold of the interface with a foot of size equivalent to few nonpolar side chains located on its surface. This will be followed by the time dependent changes in protein orientation and its conformation, which are energetically responsible for driving the overall adsorption process (1) .

Conclusions

The adsorption of commonly used nonionic surfactants at static silicone oil/water interface, mimicking the siliconized surface of a lubricated syringe, was observed to be governed by similar hydrophobic forces responsible for their adsorption at air/water interface. All the adsorbed surfactant layers showed similar viscoelastic properties at the silicone oil/water interface, but had a significantly greater viscous character than the adsorbed protein layer. The order in which the surfactant and protein were exposed to the interface affected the adsorption characteristic of each species and gives an insight into the competitive interactions of the fusion protein with the silicone oil in the presence of surfactants. Dynamic surface tension studies suggested absence of any significant binding between the protein and surfactants. The binding of surfactant to protein, hence, should not be a mechanism to reduce protein adsorption at the silicone oil/water interface.

References

Andrade JD. Surface and Interfacial Aspects of Biomedical Polymers, Vol. 2: Protein adsorption. New York; Plenum Press;1985.

Soderquist ME, Walton AG. Structural changes in proteins adsorbed on polymer surfaces. J Colloid Interface Sci. 1980;75(2):386–97.

Smith EJ. Siliconization of parentral drug packaging components. J Parent Sci Tech. 1988;42(4):S3–S13.

Bernstein RK. Clouding and deactivation of clear (regular) human insulin: association with silicone oil from disposable syringes? Diabetes Care. 1987;10(6):786–7.

Jones LS, Kaufmann A, Middaugh CR. Silicone oil induced aggregation of proteins. J Pharm Sci. 2005;94(4):918–27.

Majumdar S, Ford BM, Mar KD, Sullivan VJ, Ulrich RG, D’Souza AJM. Evaluation of the effect of syringe surfaces on protein formulations. J Pharm Sci. 2011;100(7):2563–73.

Thirumangalathu R, Krishnan S, Ricci MS, Brems DN, Randolph TW, Carpenter JF. Silicone oil- and agitation-induced aggregation of a monoclonal antibody in aqueous solution. J Pharm Sci. 2009;98(9):3167–81.

Rosenberg AS. Effects of protein aggregates: an immunologic perspective. AAPS J. 2006;8(3):E501–7.

Ludwig DB, Carpenter JF, Hamel J-B, Randolph TW. Protein adsorption and excipient effects on kinetic stability of silicone oil emulsions. J Pharm Sci. 2010;99(4):1721–33.

Auge KB, Blake-Haskins AW, Devine S, Rizvi S, Li Y-M, Hesselberg M, et al. Demonstrating the stability of albinterferon alfa-2b in the presence of silicone oil. J Pharm Sci. 2011;100(12):5100–14.

Romacker M, Schoenknecht T,Forster R. The rise of prefilled syringes from niche product to primary container of choice: a short history.ONdrugDelivery.2008;4–5.

Li J, Pinnamaneni S, Quan Y, Jaiswal A, Andersson F, Zhang X. Mechanistic understanding of protein-silicone oil interactions. Pharm Res. 2012;29(6):1689–97.

Dixit N, Maloney KM, Kalonia DS. The effect of Tween® 20 on silicone oil–fusion protein interactions. Int J Pharm. 2012;429(1–2):158–67.

Haynes CA, Norde W. Structures and stabilities of adsorbed proteins. J Colloid Interface Sci. 1995;169(2):313–28.

Mollmann SH, Jorgensen L, Bukrinsky JT, Elofsson U, Norde W, Frokjaer S. Interfacial adsorption of insulin: conformational changes and reversibility of adsorption. Eur J Pharm Sci. 2006;27(2–3):194–204.

Joshi O, McGuire J, Wang DQ. Adsorption and function of recombinant factor VIII at solid–water interfaces in the presence of Tween-80. J Pharm Sci. 2008;97(11):4741–55.

Benko B, Vuk-Pavlovic S, Dezelic G, Marićić S. A proton magnetic relaxation study of methaemoproteins bound to monodisperse polystyrene latex particles. J Colloid Interface Sci. 1975;52(3):444–51.

Singla B, Krisdhasima V, McGuire J. Adsorption kinetics of wild type and two synthetic stability mutants of T4 phage lysozyme at silanized silica surfaces. J Colloid Interface Sci. 1996;182(1):292–6.

Norde W, Giacomelli CE. BSA structural changes during homomolecular exchange between the adsorbed and the dissolved states. J Biotechnol. 2000;79(3):259–68.

Chang BS, Kendrick BS, Carpenter JF. Surface-induced denaturation of proteins during freezing and its inhibition by surfactants. J Pharm Sci. 1996;85(12):1325–30.

Krielgaard L, Jones LS, Randolph TW, Frokjaer S, Flink JM, Manning MC, et al. Effect of tween 20 on freeze-thawing- and agitation-induced aggregation of recombinant human factor XIII. J Pharm Sci. 1998;87(12):1593–603.

Mollmann SH, Elofsson U, Bukrinsky JT, Frokjaer S. Displacement of adsorbed insulin by tween 80 monitored using total internal reflection fluorescence and ellipsometry. Pharm Res. 2005;22(11):1931–41.

Bam NB, Randolph TW, Cleland JL. Stability of protein formulations: investigation of surfactant effects by a novel EPR spectroscopic technique. Pharm Res. 1995;12(1):2–11.

Bam NB, Cleland JL, Yang J, Manning MC, Carpenter JF, Kelley RF, et al. Tween protects recombinant human growth hormone against agitation-induced damage via hydrophobic interactions. J Pharm Sci. 1998;87(12):1554–9.

Sukow WW, Sandberg HE, Lewis EA, Eatough DJ, Hansen LD. Binding of the triton X series of nonionic surfactants to bovine serum albumin. Biochemistry. 1980;19(5):912–7.

Chou DK, Krishnamurthy R, Randolph TW, Carpenter JF, Manning MC. Effects of tween 20 and tween 80 on the stability of albutropin during agitation. J Pharm Sci. 2005;94(6):1368–81.

Dixit N, Maloney KM, Kalonia DS. Application of quartz crystal microbalance to study the impact of pH and ionic strength on protein-silicone oil interactions. Int J Pharm. 2011;412(1–2):20–7.

Zeng DL. Investigation of protein-surfactant interactions in aqueous solutions Vol. Ph.D., University of Connecticut, 1997.

Dixit N, Zeng DL, Kalonia DS. Application of maximum bubble pressure surface tensiometer to study protein–surfactant interactions. Int J Pharm. 2012;439(1–2):317–23.

Kerwin BA. Polysorbates 20 and 80 used in the formulation of protein biotherapeutics: structure and degradation pathways. J Pharm Sci. 2008;97(8):2924–35.

Kronberg B. Thermodynamics of adsorption of nonionic surfactants on latexes. J Colloid Interface Sci. 1983;96(1):55–68.

Rosen MJ. Surfactants and Interfacial Phenomena. New York; John Wiley & Sons, Inc., Hoboken, New Jersey, 2004, pp. 34–104.

Prasad KN, Luong TT, FlorenceJoelle Paris AT, Vaution C, Seiller M, Puisieux F. Surface activity and association of ABA polyoxyethylene—polyoxypropylene block copolymers in aqueous solution. J ColloidInterface Sci. 1979;69(2):225–32.

Vogler EA. Practical use of concentration-dependent contact angles as a measure of solid–liquid adsorption. 2. Experimental aspects. Langmuir. 1992;8(8):2013–20.

Joshi O, McGuire J. Adsorption behavior of lysozyme and Tween 80 at hydrophilic and hydrophobic silica-water interfaces. Appl Biochem Biotechnol. 2009;152(2):235–48.

Liu SX, Kim J-T. Study of adsorption kinetics of surfactants onto polyethersulfone membrane surface using QCM-D. Desalination. 2009;247(1-3):355–61.

Haynes CA, Norde W. Globular proteins at solid/liquid interfaces. Colloids Surf B. 1994;2(6):517–66.

MacRitchie F, Alexander AE. Kinetics of adsorption of proteins at interfaces. Part II. The role of pressure barriers in adsorption. J Colloid Sci. 1963;18(5):458–63.

Macritchie F. In C.B. Anfinsen, J.T. Edsall, and F.M. Richards (eds.), Advances in Protein Chemistry, Vol. 32, New York, Academic Press, 1978, pp. 283–326.

Acknowledgments and Disclosures

Biogen Idec is gratefully acknowledged for the material and financial support of this work. Financial support to N.D. in the form of Gerald J. Jackson memorial award and University of Connecticut graduate school doctoral dissertation fellowship are also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dixit, N., Maloney, K.M. & Kalonia, D.S. Protein-Silicone Oil Interactions: Comparative Effect of Nonionic Surfactants on the Interfacial Behavior of a Fusion Protein. Pharm Res 30, 1848–1859 (2013). https://doi.org/10.1007/s11095-013-1028-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-013-1028-1