Abstract

Purpose

To investigate crystallization behavior on the surface of amorphous solid dispersion powder using inverse gas chromatography (IGC) and to predict the physical stability at temperatures below the glass transition temperature (T g).

Methods

Amorphous solid dispersion powder was prepared by melt-quenching of a mixture of crystalline nifedipine and polyvinylpyrrolidon (PVP) K-30. IGC was conducted by injecting undecane (probe gas) and methane (reference gas) repeatedly to the solid dispersion at temperatures below T g. Surface crystallization was evaluated by the retention volume change of undecane based on the observation that the surface of the solid dispersion with crystallized nifedipine gives an increased retention volume.

Results

On applying the retention volume change to the Hancock-Sharp equation, surface crystallization was found to follow a two-dimensional growth of nuclei mechanism. Estimation of the crystallization rates at temperatures far below T g using the Avrami-Erofeev equation and Arrhenius equation showed that, to maintain its quality for at least three years, the solid dispersion should be stored at −20°C (T g − 65°C).

Conclusions

IGC can be used to evaluate crystallization behavior on the surface of a solid dispersion powder, and, unlike traditional techniques, can also predict the stability of the solid dispersion based on the surface crystallization behavior.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

The development phase of drug discovery has been lead to an increase in the percentage of active pharmaceutical ingredients (APIs) with poor water solubility. To improve the water solubility as well as bioavailability, several techniques such as amorphization (1–3), micronization (4,5), and emulsification (6,7) have been considered. Amorphization is the most widely used for enhancing the solubility of drugs, some of which are now commercially available. However, since the amorphous states of APIs are physically unstable compared to their crystalline forms, crystallization occurs during either or both the manufacturing process or drug storage, resulting in a reduction in both solubility and bioavailability.

Recent studies have shown that the crystallization of amorphous APIs occurs faster on the surface than in the bulk. Wu and Yu found this phenomenon to be true for amorphous indomethacin (8). They also reported that the crystallization rate of amorphous indomethacin significantly reduced by gold nano-coating (9). Another study demonstrated that the overall crystallization kinetics of amorphous griseofulvin is dominated by the surface crystallization at temperatures below the glass transition temperature (T g) (10). Surface crystallization is considered to significantly affect the dissolution rate of an amorphous API because the dissolution process depends on the contact between the surface of the API and the dissolution media (11). Thermal analysis, powder X-ray diffraction (PXRD) and solid-state nuclear magnetic resonance (NMR) analysis are often used to evaluate the crystallization of amorphous APIs (12). However, crystallinity on the surface and in the bulk cannot be distinguished via these methods.

Using microscopy, Cai et al. recently proposed a new method that successfully evaluated the surface crystallization of a nifedipine/polyvinylpyrrodone (PVP) K15 solid dispersion film prepared by which melting the mixture of nifedipine and PVP K15 between cover slips and then cooling to room temperature (13). Unfortunately, solid dispersions are normally manufactured in powder forms in which the microscopy method is difficult to apply for quantitative analysis. Therefore, alternative methods are needed to evaluate the surface crystallization of powders.

Inverse gas chromatography (IGC) is one such method that can be used to evaluate the surface properties of the APIs and excipients used for drug formulations (14). IGC can determine the dispersive component of the surface free energy as well as acid and basic parameters and the T g of powders (15,16). Hasegawa et al. demonstrated that the molecular mobility at the surface of an indomethacin solid dispersion evaluated by IGC is higher than the molecular mobility in the bulk as measured via differential scanning calorimetry (DSC) (17). This result is consistent with the fact that the crystallization of amorphous APIs on the surface is faster than that in the bulk. Given the above previous findings, we considered that IGC could potentially be used to specifically detect and evaluate the surface crystallization of solid dispersion powders.

In the present study, the crystallization behavior on the surface of nifedipine/PVP K30 solid dispersion powders was determined using IGC. Nifedipine is a well-studied model compound with low solubility, while PVP is a widely used stabilizer for solid dispersions. The Hancock-Sharp equation (18,19) was subsequently applied to clarify the solid reaction mechanism based on the crystallization behavior. Furthermore, the stability of the solid dispersion at temperatures significantly lower than the T g was estimated based on the surface crystallization behavior.

MATERIALS and METHODS

Materials

Nifedipine and PVP K30 were obtained from Sigma (St. Louis, MO, USA) and Wako Chemicals (Osaka, Japan), respectively. Methanol and undecane were obtained from Kanto Chemical (Tokyo, Japan).

Methods

Preparation of Nifedipine/PVP Solid Dispersion and Crystalline Nifedipine

For the nifedipine/PVP solid dispersion powder (96:4 w/w), 3.84 g of nifedipine and 0.16 g of PVP K30 were dissolved in 120 mL of methanol. After the solvent was evaporated, the solid was put into a stainless plate and melted at 185°C, which is 10°C above the melting point of nifedipine. The molten sample was cooled by immersion in liquid nitrogen to obtain the solid dispersion with amorphized nifedipine. The obtained solid dispersion was ground up gently using an agate mortar and then sieved using an aperture size of 75 μm and 250 μm mesh. Procedures after melting the sample were conducted at a relative humidity of less than 30%. The sieved samples were dried in vacuo with phosphoric pentoxide for about one hour. Solid dispersion powders with different nifedipine:PVP ratios (92:8, 88:12, and 80:20 w/w) were prepared using the same procedure on a 1-g scale. The crystalline nifedipine (75–250 μm), as a control, was also prepared by quench-cooling of received crystalline nifedipine as above and followed by recrystallization at 36°C.

IGC Measurement

A commercial IGC equipped with a flame ionization detector (iGC, Surface Measurement Systems, London, UK) was used to evaluate the surface property of the solid dispersions. A total of 0.4 g of ground powder (particle size between 75 and 250 μm) was packed into a glass column with an inner diameter of 3 mm, and the column was tapped for 10 min. For the measurement of PVP K30, 0.7 g of powder was used. Sample preparation was conducted at a relative humidity of less than 30%. The column was placed in a column oven with the temperature set between 24 and 40°C and subjected to consecutive injections of probe gas (undecane) and reference gas (methane). Undecane was chosen as probe gas because it gave an adequate separation from reference gas. Concentrations of the probe and reference gases were set at 0.03 p/p 0, because this infinite dilution condition could evaluate the surface energy at inhomogeneous surface as described previously (20). Helium was used as a carrier gas with a flow rate of 10 ml/min. The retention volume of probe gas, V, was determined as follows:

where t v and t m are retention times of probe gas and methane, respectively. The retention times were calculated using maximum height of peak since the peaks were almost symmetric. j is a correction factor due to pressure differences and F is the carrier gas flow rate (ml/min).

Polarized Light Microscopic Observation

The surface of the solid dispersions was visually observed using a polarized light microscopy system (BX51, Olympus, Tokyo, Japan). The sample was placed onto a microscope slide glass, and a drop of paraffin was added before the cover slip was placed.

Powder X-ray Diffraction

Physical stability in the bulk of the solid dispersions was evaluated using an X-ray powder diffractometer (RINT-TTRIII; Rigaku, Tokyo, Japan). CuK α radiation was utilized, and the tube voltage and amperage were set to 50 kV and 300 mA. Scanning was conducted at room temperature between 5° to 40° 2θ with a scanning speed of 5°/min. The crystallization rate of nifedipine in the bulk of the solid dispersions was evaluated using the increment of the sum of diffraction peak intensities at 2θ values of 11.9°, 19.6°, and 24.1° of crystalline nifedipine.

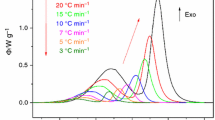

DSC Measurement

Recrystallization and thermal properties of the solid dispersions were evaluated using a differential scanning calorimeter (DSC-Q1000, TA Instruments, New Castle, DE, USA) under 50 mL/min nitrogen gas flow. For evaluation of recrystallization of the solid dispersion, 3 mg of sample was put into an aluminum pan and crimped with an aluminum lid. Samples were equilibrated at –20°C and then heated to 190°C at a heating rate of 2°C/min with modulation amplitude and frequency of ±0.3°C/min. Using the same heating rate, modulation amplitude and frequency, the sample was cooled to –20°C and then heated to 190°C again. For evaluation of thermal properties of the solid dispersion, 2 mg of sample was put into an aluminum pan and crimped with an aluminum lid. Samples were equilibrated at 60°C to erase thermal histories and then cooled to 30°C. DSC measurements were carried out in the temperature range of 30–200°C and at a heating rate of 10°C/min.

Evaluation of Crystallization Behavior by IGC

The crystallization behavior at the surface of the solid dispersion was evaluated using a modified Hancock-Sharp equation:

where V is the retention volume at time t, V 0 is the retention volume at t = 0, and V max is the retention volume when the crystallization at the surface is completed (t = ∞). m and B represent the reaction mechanism and reaction rate, respectively. These parameters and V max were obtained from non-linear curve fitting of Eq. (2) to the retention volume data.

Kinetic Study of Surface Crystallization

The Avrami-Erofeev equation (3) and Polany-Winger equation (4) were applied for the kinetic study of crystallization at the surface of the nifedipine/PVP solid dispersion.

where α represents the percentage of crystallized nifedipine at the surface of the solid dispersion at time t and was calculated as follows:

The reaction (i.e. crystallization) rate, k, was obtained from the linear regression of Eqs. (3) and (5).

The stability prediction of the solid dispersion was conducted using the Arrhenius equation:

where A is a constant, E a is the activation energy, R is the gas constant, and T is temperature.

After linear regression of Eq. (6), k at the temperature for stability prediction was calculated. Using this value and Eq. (3), the time required for surface crystallization to occur at a given amount was estimated.

Data Analysis for Kinetic Studies

Curve fitting and linear regression analysis were conducted using GraphPad Prism 5 (GraphPad Software, La Jolla, CA, USA).

RESULTS AND DISCUSSION

Detection of Crystallization at the Surface of Solid Dispersion Powder by IGC

Figure 1 shows the time course of the retention volume of undecane injected into the nifedipine/PVP K30 solid dispersion powder (96:4 w/w) as obtained by IGC at 40°C. The retention volume remarkably increased over time until it asymptotically approached the maximum volume. To clarify the cause of this change in retention volume, the powder before and after the IGC was observed by polarized microscopy. The surface of the powder was broadly covered with crystallized nifedipine after the IGC measurement, as shown in Fig. 2. Taken together, these findings suggest that the increased retention volume was due to the crystallization of nifedipine on the surface of the powder.

Correlation between the surface crystallization and the increment of retention volume was also confirmed by several observations. First, the retention volume reached near maximum after 15 h when stored at 36°C (Fig. 3a). It took significantly longer for the maximum to be reached at lower temperatures than higher ones: 30 h at 32°C, 60 h at 28°C and 90 h at 24°C (Fig. 3b–d). The crystallization rate should theoretically decrease at lower temperatures, as lower temperatures make the activation energy required for amorphous compounds to crystallize harder to obtain. Second, the rate of increase in retention volume slowed significantly when the amount of PVP in the solid dispersion increased (Fig. 4a–c). For the solid dispersions containing 8% and 12% PVP K30, the retention volume was increased by 80% and 18% in 37 h, respectively. For the solid dispersion containing 20% PVP K30, the retention volume was increased by 5% in 63 h. The increment of PVP content in the solid dispersions was shown to delay crystallization, possibly through interactions with amorphous APIs (21,22). A previous study showed that the surface crystallization rate of nifedipine solid dispersion glass decreases when the amount of PVP increases (13). Third, PXRD analysis of the nifedipine/PVP solid dispersion powder (92:8 w/w) after the IGC measurement, which showed an increase in retention volume of undecane, found a complete halo pattern (Fig. 5a). On the other hand, crystallization was observed on polarized light microscopy (Fig. 5b). These results strongly indicate that the crystallization of this sample occurred only at the surface. Fourth, modulated DSC analysis using the nifedipine/PVP solid dispersion powder (96:4 w/w) after the IGC measurement showed that the reversing heat capacity (C p) in a cooling step at above T g was higher than that in an initial heating step (Fig. 6a). On the other hand, any differences between the reversing C p values in the both steps were not observed for the freshly prepared powder before IGC measurement (Fig. 6b). According to the recent evidence reported by Qi et al. (23), the reversing C p value in the initial heating step was lower than that in cooling step due to the presence of crystalline drug in the sample, suggesting that in the current study, the crystallization might be occurred during IGC measurement. Fifth, IGC measurements of crystalline nifedipine and PVP K30 alone were conducted as control studies. Retention volume of both powders remained constant during IGC measurement (Fig. 7). In addition, the retention volume of crystalline nifedipine showed higher value compared with that of solid dispersions after multiple injections (Fig 3a). These results suggest that the increment of retention volume is correlated with surface crystallization of the solid dispersion.

Nifedipine has hydrophobic aromatic group in its structure. When amorphous nifedipine in the solid dispersion crystallizes, the aromatic group might appear on its surface. This could cause strong interaction between probe gas (undecane) and the powder surface probably given by van der Waals force. Therefore, the retention volume could be larger as the powder surface crystallizes.

Kinetic Studies of Surface Crystallization

To investigate the crystallization mechanism on the surface of the powder in more detail, we applied the Hancock-Sharp equation, an empirical formula that describes solid reactions, to the time course of the retention volume change. Influence of relaxation of amorphous nifedipine in the solid dispersion was ruled out since the retention volume change due to relaxation is significantly smaller than that from crystallization (17). We have already confirmed the same result for nifedipine solid dispersion (data not shown). Table I shows m and B for various temperatures. B decreased as the temperature decreased. m had values ranging between 1.294 and 1.554, which are above the zero-order reaction value of 1.24 (24) and below the two-dimensional growth of nuclei value of 2.00 (25–27). That m was relatively insensitive to temperature suggests that the crystallization mechanism was common for all conditions and that the crystallization rate decreased with temperature.

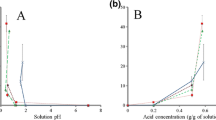

The Hancock-Sharp equation could not clearly distinguish whether the mechanism of the surface crystallization for the nifedipine solid dispersion powder was two-dimensional growth of nuclei or a zero-order reaction. Therefore, the Avrami-Erofeev equation, which is an empirical formula for two-dimensional growth of nuclei, and the Polany-Winger equation, which is an empirical formula for the zero-order reaction, were applied using linear regression analysis. The regression line from the Avrami-Erofeev equation showed good correlation (R 2 = 0.986 to 0.999, n = 2 for each temperatures) with the actual data (Fig. 8), whereas that from the Polany-Winger equation did not (R 2 = 0.862 to 0.975, n = 2 for each temperatures) (Fig. 9). Given these findings, we concluded that the surface crystallization of the nifedipine solid dispersion occurs by a two-dimensional growth of nuclei mechanism. Justification for this conclusion will be discussed in the last sub-section of “Results and Discussion”.

Stability Prediction of the Solid Dispersion Based on the Surface Crystallization Mechanism

The slope of the regression line corresponds to the reaction (in this case, the crystallization) rate. Table II shows the crystallization rate (k) of the nifedipine/PVP K30 solid dispersion powder (96:4 w/w) as obtained by the Avrami-Erofeev equation at various temperatures. From k we can predict the stability at the surface of the solid dispersion powder using the Arrhenius equation. Figure 10 shows an Arrhenius plot using the crystallization rate calculated above. From the plot, E a, and A was calculated as 129.5 (kJmol−1) and 7.8 × 1020 (h−1), respectively. Stability at the powder surface at 5°C (refrigerated), –5°C (T g – 50°C) and –20°C (freezing) was predicted as follows: The time required for 20% of the surface area to crystallize was calculated assuming that a certain amount of surface crystallization would affect the quality (i.e. dissolution rate) of the solid dispersion powder (Table III). Results showed that it would take less than 4 months to crystallize 20% of the surface even at –5°C, which is 50°C below the T g of the solid dispersion. Storing the sample at –20°C, which is 65°C below the T g, will require more than 8 years to crystallize the same amount of the surface, making this condition suitable for storage considering that a lot of commercially available pharmaceutical formulations have three years of their shelf life. A previous study has suggested that a glass should be stored at a temperature at least 50°C below T g to suppress its molecular mobility completely to avoid crystallization (28). Although this rule has been considered very preliminary, the reason that crystallization of a glass occurs at such low temperature has not been fully understood. Our results suggest that instability on the surface of solid dispersion powders could be one reason for crystallization at such low temperature conditions. Considering that surface crystallization can affect the quality of the solid dispersion formulation, surface stability should be considered when determining the storage conditions.

Influence of Surface Crystallization on Bulk Stability of the Solid Dispersion

Bulk crystallization could significantly affect the dissolution rate of solid dispersion powders as well as surface crystallization. Surface crystallization would be involved in bulk crystallization considering that a crystallized compound at surface might act as a nucleus for bulk crystallization. To investigate the influence of surface crystallization on the physical stability of the bulk, nifedipine/PVP K30 solid dispersion powders (96:4 w/w) with various particle sizes were prepared and their stabilities evaluated using PXRD. The diffraction patterns of powders with particles of diameters over 250 μm and stored at 40°C, which is slightly below T g, are shown in Fig. 11a. The diffraction patterns were almost halo-shaped with weak diffraction peaks at 24.1° 2θ that became prominent only after storage for 24 h. The diffraction patterns of powders with particles of diameters between 75 and 250 μm are shown in Fig. 11b. In this case, diffraction peaks were detected after storage for 8 h, and the intensities were higher than those of the larger particles. The diffraction peaks of powders with particles of diameters under 75 μm were detected after storage for 3.5 h, and these intensities were the highest of any examined (Fig. 11c). It should be noted that IGC was conducted using solid dispersion powders with particle diameters between 75 and 250 μm. Although a significant increase in retention volume was detected after beginning the measurement, it took 8 h for the diffraction peak to be detected by PXRD. These results strongly indicate that the crystallization of the solid dispersion powder first occurs on the surface and then gradually proceeds internally such that it can be detected by PXRD as bulk crystallization. This means that the growth of nuclei along the surface of solid dispersion is much faster than that into bulk. Therefore, the surface crystallization mechanism we proposed as two-dimensional growth of nuclei would be consistent with these observations.

The change in the sum of the intensities for the three main peaks—11.9°, 19.6°, and 24.1° 2θ, which represent the amount of crystallized nifedipine—is summarized in Fig. 12. The crystallization rate of the particles increased as the particle size decreased. Also, the T g (approximately 45°C) was independent of the particle size (Fig. 13) according to the DSC measurement. Taken together, these findings indicate that differences in crystallization rates are not due to the uniformity of nifedipine or PVP in the powders. Instead, solid dispersion powder with smaller particle sizes likely crystallized faster because of its larger specific surface area. In other words, surface crystallization of solid dispersion powder would influence its bulk stability depending on its particle size.

CONCLUSIONS

In this study, we have shown that the surface crystallization of the solid dispersion powder can be evaluated using IGC by measuring the retention volume change of a probe gas injected into the powder. Fitting the retention volume data to the Hancock-Sharp equation and the Avrami-Erofeev equation, the crystallization mechanism at the surface of the nifedipine solid dispersion prepared by quench-cooling and followed by grinding was estimated to be two-dimensional growth of nuclei. Assuming this crystallization mechanism, kinetic studies including an estimate for stability were conducted, and the storage temperature required for the nifedipine solid dispersion to maintain its quality was concluded to be “T g − 65°C”. This study demonstrates that IGC can accurately evaluate surface crystallization and estimate the surface stability of solid dispersion powders for pharmaceutical formulations.

References

Gupta P, Kakumanu VK, Bansal AK. Stability and solubility of celecoxib-PVP amorphous dispersions: a molecular perspective. Pharm Res. 2004;21(10):1762–9.

Kennedy M, Hu J, Gao P, Li L, Ali-Reynolds A, Chal B, et al. Enhanced bioavailability of a poorly soluble VR1 antagonist using an amorphous solid dispersion approach: a case study. Mol Pharm. 2008;5(6):981–93.

Onoue S, Sato H, Ogawa K, Kawabata Y, Mizumoto T, Yuminoki K, et al. Improved dissolution and pharmacokinetic behavior of cyclosporine A using high-energy amorphous solid dispersion approach. Int J Pharm. 2010;399(1–2):94–101.

Reverchon E, Della Porta G, Spada A, Antonacci A. Griseofulvin micronization and dissolution rate improvement by supercritical assisted atomization. J Pharm Pharmacol. 2004;56(11):1379–87.

Lin YH, Chen YS, Wu TC, Chen LJ. Enhancement of dissolution rate of mitotane and warfarin prepared by using microemulsion systems. Colloids Surf B Biointerfaces. 2011;85(2):366–72.

Kocbek P, Baumgartner S, Kristl J. Preparation and evaluation of nanosuspensions for enhancing the dissolution of poorly soluble drugs. Int J Pharm. 2006;312(1–2):179–86.

Gao F, Zhang Z, Bu H, Huang Y, Gao Z, Shen J, et al. Nanoemulsion improves the oral absorption of candesartan cilexetil in rats: Performance and mechanism. J Control Release. 2011;149(2):168–74.

Wu T, Yu L. Surface crystallization of indomethacin below T g. Pharm Res. 2006;23(10):2350–5.

Wu T, Sun Y, Li N, de Villiers MM, Yu L. Inhibiting surface crystallization of amorphous indomethacin by nanocoating. Langmuir. 2007;23(9):5148–53.

Zhu L, Jona J, Nagapudi K, Wu T. Fast surface crystallization of amorphous griseofulvin below T g. Pharm Res. 2010;27(8):1558–67.

Craig DQ. The mechanisms of drug release from solid dispersions in water-soluble polymers. Int J Pharm. 2002;231(2):131–44.

Shah B, Kakumanu VK, Bansal AK. Analytical techniques for quantification of amorphous/crystalline phases in pharmaceutical solids. J Pharm Sci. 2006;95(8):1641–65.

Cai T, Zhu L, Yu L. Crystallization of organic glasses: effects of polymer additives on bulk and surface crystal growth in amorphous nifedipine. Pharm Res. 2011;28(10):2458–66.

Planinsek O, Buckton G. Inverse gas chromatography: considerations about appropriate use for amorphous and crystalline powders. J Pharm Sci. 2003;92(6):1286–94.

Grimsey IM, Feeley JC, York P. Analysis of the surface energy of pharmaceutical powders by inverse gas chromatography. J Pharm Sci. 2002;91(2):571–83.

Buckton G, Ambarkhane A, Pincott K. The use of inverse phase gas chromatography to study the glass transition temperature of a powder surface. Pharm Res. 2004;21(9):1554–7.

Hasegawa S, Ke P, Buckton G. Determination of the structural relaxation at the surface of amorphous solid dispersion using inverse gas chromatography. J Pharm Sci. 2009;98(6):2133–9.

Sakata Y, Shiraishi S, Otsuka M. Characterization of dehydration behavior of untreated and pulverized creatine monohydrate powders. Colloids Surf B Biointerfaces. 2004;35(3–4):185–91.

Sakata Y, Shiraishi S, Otsuka M. Characterization of dehydration and hydration behavior of calcium lactate pentahydrate and its anhydrate. Colloids Surf B Biointerfaces. 2005;46(3):135–41.

Swaminathan V, Cobb J, Saracovan I. Measurement of the surface energy of lubricated pharmaceutical powders by inverse gas chromatography. Int J Pharm. 2006;312(1–2):158–65.

Yoshioka M, Hancock BC, Zografi G. Inhibition of indomethacin crystallization in poly(vinylpyrrolidone) coprecipitates. J Pharm Sci. 1995;84(8):983–6.

Taylor LS, Zografi G. Spectroscopic characterization of interactions between PVP and indomethacin in amorphous molecular dispersions. Pharm Res. 1997;14(12):1691–8.

Qi S, Belton P, Nollenberger K, Clayden N, Reading M, Craig DQ. Characterisation and prediction of phase separation in hot-melt extruded solid dispersions: A thermal, microscopic and NMR relaxometry study. Pharm Res. 2010;27(9):1869–83.

Hancock JD, Sharp JH. Method of comparing solid-state kinetic data and its application to the decomposition of kaolinite, brucite, and BaCO3. J Am Ceram Soc. 1972;55(2):74–7.

Avrami M. Kinetics of phage change. I General theory. J Chem Phys. 1939;7:1103–12.

Avrami M. Kinetics of phage change. II Transformation-time relations for random distribution of nuclei. J Chem Phys. 1940;8:212–24.

Avrami M. Kinetics of phage change. III Granulation, phase change and microstructure. J Chem Phys. 1941;9:177–84.

Hancock BC, Shamblin SL, Zografi G. Molecular mobility of amorphous pharmaceutical solids below their glass transition temperatures. Pharm Res. 1995;6:799–806.

Acknowledgments and disclosures

This work was financially supported by Research on Publicly Essential Drugs and Medical Devices, Japan Health Sciences Foundation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Miyanishi, H., Nemoto, T., Mizuno, M. et al. Evaluation of Crystallization Behavior on the Surface of Nifedipine Solid Dispersion Powder Using Inverse Gas Chromatography. Pharm Res 30, 502–511 (2013). https://doi.org/10.1007/s11095-012-0896-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-012-0896-0