Abstract

Purpose

To study the effect of the size of the surface-coated polycaprolactone (PCL) microparticle carriers on the aerosolization and dispersion of Salbutamol Sulfate (SS) from Dry Powder Inhaler (DPI) formulations.

Methods

The microparticles were fabricated using an emulsion technique in four different sizes (25, 48, 104 and 150 μm) and later coated with Magnesium stearate (MgSt) and leucine. They were characterized by laser diffraction and SEM. The Fine Particle Fraction (FPF) of SS from powder mixtures was determined by a Twin Stage Impinger (TSI).

Results

As the carrier size increased from 25 μm to 150 μm, the FPF of the SS delivered by the coated PCL particles increased approximately four fold. A linear relationship was found between the FPF and Volume mean Diameter (VMD) of the particles over this range.

Conclusions

The dispersion behaviour of SS from PCL carriers was dependent on the inherent size of the carriers and the increased FPF of SS with increased carrier size probably reflects the higher mechanical forces produced due to the carrier-carrier collisions or collisions between the carrier particles and the internal walls of the inhaler during aerosolization.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Dry powder inhaler (DPI) formulations for pulmonary drug delivery comprises of the micronized drug (<5 μm) and an inert coarse carrier which is usually incorporated in these systems to reduce the cohesive forces among the micron sized particles thereby improving the flowability and the dispersion of the powders. The addition of carrier particles also acts as a diluent for the drug and allows reproducible metering of the dose of the drug (1,2). The major factors influencing the aerosolization of the drug from the carrier surfaces includes particle size and size distributions, shape and surface properties such as surface roughness, geometry of contact and adhesional forces (1–4). Any changes in the physico-chemical or surface properties of powders in DPI formulations affect the drug detachment and subsequent dispersion from the formulation which finally affects the therapeutic performance of the drug (5–7).

Lactose is the traditional carrier employed in all the currently available DPI formulations. Due to the low efficiency of drug dispersion from lactose, researchers have explored the use of the modified counterparts of lactose to improvise the drug delivery. These studies have focused on improving dispersion of the drugs by optimizing the carrier size (6), smoothing the carrier surface (7), mixing different grades of carriers (8), and using lactose carriers with smooth and rough surface morphologies (7,9). Alternatively, modification of the lactose surfaces has been reported by blending it with fine lactose, magnesium stearate (MgSt) or leucine (10–13) to improve the dispersibility of the drug from the carrier surface. Other sugars such as glucose, sorbitol and xylitol have also been explored as carriers in DPI formulations but they have not able to efficiently generate the desirable fine particle fraction (FPF) of the drug which has been attributed to their hygroscopic nature (14).

The size of the carrier in DPI formulations plays an important role in the dispersion of the drug from DPI formulations as it is one of the factors which affect the detachment of the drugs and ultimately the FPF reaching the lungs. Researchers have carried out studies with various carriers to study the effect of carrier size on the FPF of the drug. There is no clear consensus in the literature on the relationship between carrier size and FPF; some groups have observed an increase in FPF with increasing carrier size (15–17) while others have reported a decrease in the FPF of the drug (6,18–23).

Podczeck reported the effect of the size, shape and surface roughness of ten different grades of lactose monohydrate on the dispersion of salmeterol xinafoate (SX) (22). The author found that the smaller size of the lactose carrier was efficient in obtaining higher FPF of the drug. Steckel et al. demonstrated that a carrier size of <32 μm resulted in the highest FPF of Budesonide when compared with carriers in the size range of 63–90 μm and 125–180 μm (6). Louey et al. determined the dispersion of SS from 10 different grades of lactose and a similar trend was observed; the FPF of the carrier increased with the decreasing carrier diameter (4 μm to 190.8 μm) (20). Similarly, an increased dispersion of SS was observed with decreasing size of lactose (8.60 μm and 20.10 μm) (23). Recently Ooi et al. have demonstrated the use of different sizes of polystyrene spheres as the carriers for the aerosolization of SS. They also found that as the size of the carrier was increased (80 μm, 250 μm and 500 μm) the aerosol performance was decreased (21). Hence in most of the studies increased dispersion of the drugs from the interactive mixtures was observed with the decreased carrier size (10,24–26). Islam et al. also found an inverse relationship between the size (10 μm to 157.6 μm) and the dispersion of SX from lactose carrier (18). They demonstrated that the drug dispersion from these mixtures is complicated by the fact that the FPF is not solely dependent on the size of the lactose carrier but is also dependent on the presence a certain amount of fine particles of lactose (<5 μm) associated with large carriers or added as ternary components which affects the deagglomeration of drug-fine lactose agglomerates (19).

Other parameters such as morphology, surface roughness, surface area and surface energy of the carrier particles also play a significant role in controlling the dispersion of the drug from DPI formulations (9,27,28). Donovan et al. reported the effect of size (32–300 μm) and surface roughness of the lactose carriers on the FPF of Budesonide (29). They found that the FPF of Budesonide decreased as the size of the anhydrous lactose was increased (32–300 μm) but in case of granulated lactose the opposite trend was observed for a similar size range. This difference in the dispersion performance of the lactose was attributed to its surface roughness. Granulated lactose exhibited more surface roughness than the anhydrous lactose and hence it led to increased FPF from increasing size of lactose due to the difference in the carrier morphology.

Similarly, in a study by Byron et al., a higher respirable fraction of terbutaline sulfate was obtained from coarser lactose (53–105 μm) as compared to fine particles of lactose (0–53 μm) (30). Hamishehkar et al. found increased aerosolization properties of insulin-loaded PLGA microcapsules with increasing size (14.1 μm to 167.4 μm) of the sieved mannitol used as a carrier. This occurred due to the presence of larger surface discontinuities on the surface of the mannitol carrier. These surface discontinuities provided the active site on the surface of the carrier for deagglomeration of PLGA microcapsules and their deposition on the carrier surface (16). Recently Hassan et al. demonstrated that increase in the size of pollen-shape hydroxyapatite carrier particles (26.6 μm to 45.9 μm), significantly increased the FPF of the Budesonide (17). This occurred because the larger carrier size has increased surface area per unit weight of the carrier particles. This trend of increased FPF at higher sizes was observed when the carrier to drug ratio was varied (2:1, 10:1 and 45:1) and at different flow rates of 30 L/min and 60 L/min which caused increased detachment of the drug from the carrier surfaces.

It is evident from the above discussion that the contradictory results reported in the literature reveal no clear relationship between the effect of the carrier size and the dispersion of various drugs from DPI formulations. A confounding factor is the irregular geometry of lactose and other sugar particles as well as wide variation in surface roughness and aspect ratio of the particles. This problem is eliminated if the carrier is a smooth spherical synthetic biodegradable polymer of controlled diameter. Polymers have been investigated widely in pulmonary drug delivery to sustain the release of drugs, but they have not been exploited as carriers in DPIs. Very recently, we have reported the use of biodegradable PCL polymer as alternative carriers to lactose for DPI formulations (31). PCL microspheres which were coated with MgSt and leucine were used as carriers to improve the dispersion of salbutamol sulfate (SS) from the surface of the PCL microspheres. In the absence of these coatings no FPF could be detected in the TSI reflecting the high adhesion of SS to PCL (31).

In this context we studied the influence of the particle size of spherical PCL carrier with reproducible surface on the dispersion of SS particles from the binary drug-polymer powder mixture. The relationship between the carrier size and FPF was determined by fabricating microspheres of PCL of four different approximate sizes with the average VMD of 25, 48, 104 and 150 μm and then determining the dispersion of SS from them using the TSI.

Materials and Methods

Chemicals

Micronized salbutamol sulfate (SS) of inhalation grade (volume median diameter [VMD] 5 μm) was obtained from GlaxoSmithKline, Australia. Polycaprolactone (Mw 80,000 Da), polyvinyl alcohol (87-89 % hydrolyzed, Mw 85,000–124,000 Da) and L-leucine were from Sigma Aldrich. MgSt was obtained from PCCA, Australia. Tween 80 and ammonium acetate were purchased from Ajax Chemicals, Australia. HPLC grade methanol (LiChrosolv®) was supplied by Merck, Germany.

Preparation of Polycaprolactone Microspheres

Using an Overhead Stirrer

The microspheres were prepared by oil in water (o/w) solvent evaporation method (32). The polymer PCL was dissolved in 3 mL of dichloromethane (DCM) at 10 % and 15 % concentration. This polymer solution was added dropwise into 40 mL of 1 % w/v aqueous Polyvinyl Alcohol (PVA) solution. The emulsion was stirred with an overhead stirrer (IKA® RW 20 digital Labtek, Model RW20D) for 40 min under ambient pressure at 2000 rpm. Later the stirring was continued for further 20 min under reduced pressure on a rotary evaporator (Rotavapor R-210, BUCHI, Switzerland). Finally the microspheres were washed with deionized water, collected by filtration, and dried in a vacuum desiccator at room temperature.

Homogenization

The same emulsion technique was employed to prepare the microspheres as described above. The PCL polymer solution at 10 % concentration was dissolved in DCM and this solution was added in the aqueous phase (1 % PVA solution). This emulsion was stirred initially at a very high speed (≈8000 rpm or ≈15000 rpm) using a homogenizer (Heidolph DIAX 900, Germany) for 5 min. Then the stirring was continued using an overhead stirrer (IKA® RW 20 digital Labtek, Model RW20D) at 2000 rpm for 4 hours until all the DCM was evaporated from the emulsion. The hardened microspheres were later collected by filtration, washed with deionized water and dried in desiccator at room temperature.

Coating of Microspheres

Solution coatings of MgSt and leucine on polymer microspheres were carried out according to the procedure described in our recently published article (31). Briefly ethanolic solution of MgSt (1 % and 2 % w/v) was prepared with the aid of heat and the aqueous solution of leucine (1 % and 2 % w/v) was prepared in milliQ water. 10 mL of MgSt or leucine solutions were used to coat 4.0 g of polymer microspheres by stirring it for a period of 24 hours. Finally the coated microspheres were collected by filtration and dried in a vacuum desiccator at room temperature.

Particle Size Measurement

The particle size of the different batches of PCL microspheres was measured using the laser diffraction instrument (Malvern Mastersizer, Malvern Instruments Ltd. UK). The PCL carrier particles (400 mg) were dispersed with the aid of sonication in 5 mL of water along with Tween-80 for 5 min. This sonicated sample was added dropwise to the sample cell of a small volume dispersion unit containing 100 mL of distilled water. The sample was added until an obscuration between 15 % and 30 % was obtained. The size distributions and average particle size were measured from five replicates of the sample. The volume mean diameter (VMD) determined from the output of the laser diffraction particle sizing was used as the size parameter to characterize the carrier size distributions.

The average surface area of PCL microspheres was calculated, assuming a spherical geometry, from the VMD of particles determined by laser diffraction.

Scanning Electron Microscopy (SEM)

For surface morphological studies of the carrier particles and the drug-carrier mixture, samples were adhered onto aluminium stubs using double-sided carbon sticky tape and sputtered with gold (BIORAD SC-500 Sputter coater). Several photomicrographs of the samples were taken at different magnifications using a SEM (FEI Quanta 200).

Drug-Carrier Mixture

The interactive mixtures of SS (2.5 %) and PCL microspheres in 5.0 g batches were prepared by a validated hand mixing method (33). The SS powder was placed between two layers of PCL powder in a glass test tube along with three ceramic beads of ca. 10 mm in diameter. The test tube was vigorously shaken by hand for 5 min to ensure proper mixing. The ceramic beads aids in the breaking up the agglomerates formed during mixing by providing a ball milling effect. The homogeneity of these mixtures was confirmed and later they were subjected to in vitro aerosol deposition tests.

Homogeneity Tests

The homogeneity of each drug-carrier mixture prepared as described above was determined by assaying for SS content. 20 × 20 mg samples were taken from the drug-carrier mixtures and dissolved in 10 mL of water. The UV absorbance of the samples was done in triplicate and the amount of SS in each mixture was quantified. The UV spectrum of SS in water was analyzed over a wavelength range of 190–400 nm by a UV spectrophotometer to measure the wavelength of maximum absorbance (λmax). The Beer-Lambert calibration curve was prepared at 276 nm using concentrations ranging from 0 to 500 μg/mL.

In Vitro Aerosol Deposition

Using a Rotahaler® (Glaxo Wellcome) DPI device, in vitro aerosol deposition of the powder formulations was determined by a TSI (Copley, UK). 7 mL of water was placed in stage one (S1) and 30 mL in stage two (S2) of the TSI. The air flow was drawn through the TSI using a vacuum pump (D-63150, Erweka, Germany) and the air flow rate was adjusted to 60 ± 5 L/min at the mouthpiece, prior to each measurement.

The powder formulations were loaded (about 20.0 mg) into hard gelatin capsules (size 3, Fawns and McAllan Pty Ltd.; Australia). The filled capsule was inserted into the Rotahaler which was placed into a moulded mouthpiece attached to the TSI. The Rotahaler was twisted to release the powder into the body of the device and an air volume of 5 L (5 s at 60 L/min) was drawn for each measurement. Each section (Inhaler, S1 and S2) was rinsed with water and the liquid was collected and volume was adjusted to 100 mL. The SS content was measured by HPLC analysis. Five replicates of each mixture were performed for TSI measurement.

The recovered dose (RD) was the total amount of drug collected from the inhaler, S1 and S2. The emitted dose (ED) was the fraction of the RD delivered from the inhaler expressed as a percentage:

The fine particle fraction (FPF) was defined as the fraction of the recovered dose deposited in the lower stage of TSI expressed as a percentage of RD.

High Performance Liquid Chromatography (HPLC)

Salbutamol Sulfate was analyzed by HPLC (Agilent HP1100) using a C18 column (μBondapak®, 3.9x300mm, Waters) and an UV Diode Array detector (Agilent) at a wavelength of 276 nm. A mixture of methanol and 0.2 % w/v ammonium acetate solution (40:60) was used as a mobile phase at a flow rate of 1.0 mL/min by a HPLC pump (Quat pump, Agilent). An injection volume of 100 μl was used. The retention time of SS was found to be 4.3 min. An HPLC calibration curve was prepared from the peak area determined by integration over a concentration range of 0–100 μg/mL.

Statistical Analysis

Comparison between different groups of FPF was performed by one-way analysis of variance (ANOVA) to ascertain statistical significance; p < 0.05 was considered to be statistically significant.

Results and Discussion

Particle Size and Morphology

Salbutamol Sulfate (SS)

The average VMD of the SS powder was found to be 4.5 ± 0.04 μm (Fig. 1). The distribution showed that about 70 % of the particles are below the size of 5 μm. The SEM images showed that SS particles are flat and elongated and exists as cohesive powder (Fig. 2). Laser diffraction particle sizing has been used for measuring particle size based on the Mie theory which assumes that the particles are perfect spheres. However for non-spherical particles (i.e., SS particles), a feature of the actual particle is compared to the imaginary spherical particle (projected volume) referred to as “equivalent spheres”. Thus, to measure the size of a non-spherical/irregular shape, the technique of laser diffraction measures the projected volume of this particle and determines the diameter of an imaginary particle that is equivalent in volume.

PCL Microspheres

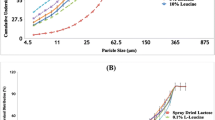

PCL microspheres were fabricated using the oil-in-water emulsion technique. The PCL microspheres were prepared in four different sizes by varying the concentration of the polymer and the speed of the stirring (Table I). The PCL microspheres were coated with MgSt and leucine. The particle size distribution of the PCL microspheres is shown in Fig. 3. The average VMD of the PCL microspheres were found to 25.5 ± 0.2 μm, 48.2 ± 0.1 μm, 104.4 ± 0.4 μm and 150.3 ± 0.4 μm (We will refer to these samples as 26 μm, 48 μm, 100 μm and 150 μm for brevity). The surface morphology of the PCL microspheres coated with MgSt and leucine was studied using SEM which showed that the PCL microspheres were spherical in shape and had irregular surface morphology (Figs. 4 and 5). Some crystals of MgSt appeared on the microparticles (Fig. 4) are from the solution of 1 % MgSt coating. The concentration of MgSt and Leucine in the particles shown in Figs. 4 and 5, respectively is 1 %. It was expected that MgSt would form a continuous thin layer on the surface of the microspheres; however, MgSt deposited in the form of crystals on the carrier surface (Fig. 4) due to the evaporation of the ethanol solvent which was used to dissolve MgSt. However, with 1.0 % leucine solution, the coatings were found to be uniform as opposed to the MgSt coatings (Fig. 5). It is important to note that the crystallization of MgSt occurred more from 2 % MgSt solution coating compared to that of 1 % MgSt solution (SEM data not shown in this paper).

Interactive Mixtures of SS and PCL Carrier

The coated PCL microspheres were dry-mixed with SS and the homogeneity of the mixtures was confirmed using the procedure described above. All the drug-carrier mixtures were found to be homogenous with accuracy greater than 99 % and % Coefficient of Variation <1 %. The drug-loaded PCL microspheres were characterized using SEM imaging which further confirmed that the drugs are adhered onto the surface of the coated PCL carrier (Figs. 6 and 7). As can be seen in the SEM images, as the carrier size increased, there was increased number of the SS particles on the surface of the PCL carrier. This can be explained by the concept of particle number (N) which gives the number of particles per unit weight of the sample and is expressed by the following equation.

where, N is the particle number, d is the diameter of the spherical particle and ρ is the density of PCL (1.145 g/cm3).

It can be seen in Table II, as the size of the carrier particle increases, the particle number decreases. For each sizes of the carrier microspheres, the drug-carrier ratio was maintained constant (2.5%w/w). Hence for a fixed mass of drug, the mass of SS particles per unit area of carrier particles is more in larger size as compared with the small sized microspheres due to the reduction in the carrier particle number. Thus as the carrier size increases the mass of SS particles per unit area on the carrier surfaces also increases, which influenced the dispersion of SS from the carrier surface that has been explained in the sections below.

Effect of Carrier Size on Drug Dispersion

In Vitro TSI Deposition of SS from PCL Carrier

Four different sizes of the MgSt coated and leucine coated PCL microspheres were used as carriers to prepare homogenous mixtures with 2.5 % w/w SS. The microspheres had different particle size distributions with VMD ranging from 25 to 150 μm. The FPF from these interactive mixtures was found to increase as the carrier size is increased. As the VMD increased from 25 to 150 μm, the FPF values increased from 3.6 % to 13.1 % for 1 % MgSt coated PCL microspheres and from 5.3 % to 20.4 % for 2 % MgSt coated PCL microspheres (Table II). Similarly, the FPF of the SS from leucine coated microspheres also increased ranging from 2.8 % to 13.4 % for 1 % leucine coated microspheres and 3.2 % to 13.9 % for 2 % leucine coated microspheres (Table II). The recovered dose of SS in the TSI was found to be 85 % to 98 % and the emitted dose was found to range from 65 % to 75 %. The observed deposition of SS in Rotahaler (mouthpiece/adapter) was on an average 45–50 % and approximately 25–35 %, for 25 μm and the higher sizes (50, 104, 150 μm) carriers, respectively. Thus the FPF of SS was found to be greater with the highest particle size of the carrier.

The relationship between the FPF of SS from 1 % and 2 % MgSt coated PCL microspheres and the size of the microspheres is depicted in Fig. 8. It can be seen very clearly that as the size of the carrier increased there is an increase in the FPF of the drug from both 1 % and 2 % MgSt coated PCL microspheres. The reason behind this has been explained extensively above. There is also significant difference in the FPF of SS amongst the two concentrations of MgSt coatings (p < 0.05, n = 5). Similarly, the FPF of the drug from both 1 % and 2 % leucine coated PCL microspheres increased with the increase in the carrier size (Fig. 9); however there was no significant difference in the FPF of SS amongst the two concentrations of leucine coatings suggesting that the FPF of SS is independent of the concentration of the leucine coatings (over the values studied of 1 % and 2 %, p > 0.05, n = 5).

From Figs. 8 and 9 it is seen that the FPF increases linearly with the particle size, d. A parameter that also increases linearly with d is the mass per unit area of the particles, given by ρd/6. A commonly measure parameter for particles is the specific surface area which is 6/ρd so the FPF scales inversely with specific surface area.

where, k has units of cm2/g and is the slope of the plots in Figs. 8 and 9.

This gives a simple way of tailoring the performance of the dispersion system, by working with the particles having the lowest possible specific surface area.

Influence of Inherent Carrier Size on Dispersion

It was observed that as the size of the carrier increased, there was a concurrent increase in the FPF of the drug. This occurs because of a potential difference in the mechanism in the way the drug detaches from the larger carriers as compared to the small sized carriers.

There are two major mechanisms which govern the detachment of drug from the carrier surface i.e. detachment by the flow stream (fluid forces) and detachment by impaction (mechanical forces) (29,34,35). When the flow stream has unobstructed path to access and remove the drug from the carrier surface, then the mechanism is called detachment by the flow stream (fluid forces). This mechanism occurs mostly on a relatively flat carrier surface with minimal asperities. Detachment by mechanical forces occurs when the collisions occurs between the carrier particles and the inhaler walls and in between the carrier particles. The geometry of the inhaler device has been reported to affect the extent of collisions occurring between the inhaler wall and the carrier particles. Collisions with the device or with other particles result in sudden acceleration of the large particles or agglomerates and these can be large enough to result in better drug dispersion. The DPI design parameters, which influence the effective dispersion of drug from the formulation include the geometry and the length of device mouthpiece, and the geometry and sizing of turbulence generating meshes (36,37). In this study a capsule based device, Rotahaler® has been used and it is well established that due to the design of this device the part of the capsule containing the drug powder experiences rotational motion in the airstream, which causes deagglomeration/dislodgement of particles after impacting on the turbulence grid for dispersion. The presence of the capsule in the Rotahaler was found to improve the FPF of drug by promoting the collision between the powder formulation and capsule (38). Thus the formulation containing large PCL microcarriers and SS particles might have experienced the collision and improved SS dispersion was observed.

Due to the collisions, there is a transfer of momentum which leads to the detachment of the drug from the surfaces. The momentum of any particle is dependent on the mass and the velocity of the carrier and as the larger particles will have greater mass there will be greater momentum transfer. The force of mechanical detachment will be directly proportional to the cube of carrier particle diameter (Force = Mass * Acceleration, Mass = Density * Volume and Volume = 4/3πr3). The larger particles will have greater mass, which will in turn lead to generation of dominant detachment forces due to high impaction. Hence as the magnitude of the detachment forces increases with the carrier size, there is more detachment of drugs from the carrier surface and consequently increase in the FPF of the drug. Therefore the larger carriers will increase the mechanical detachment forces due to the stronger particle-inhaler and particle-particle collisions (29) for the same flow velocity. This was further confirmed in a study by Concession et al. (39) who demonstrated the relationship between the impact forces and particle detachment. They found that as the diameter of the carrier particles (lactose or maltodextrin) decreased, greater magnitude of forces were required to separate the SS particles from the surface (39). From the SEM images (Figs. 6c, d, 7c and d), it has been seen that drug agglomerates have adhered to the large carriers probably due to increased interactions between drug particles on reduction in surface area. The drag forces encountered by the larger drug particles or drug-drug agglomerates adhered on the larger carriers in the turbulent air stream and particle-particle or particle-device wall collision might have contributed to significant detachment force (21,40), which in turn contributed to the better performance of the larger PCL carriers in terms of FPF as compared to their smaller counterparts. The larger drug particles or drug agglomerates may experience the strong drag force due to the differential velocity between the airflow and the higher mass of large carriers.

Although the surface free energy of different sizes PCL carriers was not determined, it can be assumed that the surface energy of carriers has an impact on the adhesional properties and the detachment of SS particles from the carrier, based on research on lactose particles (41). We are undertaking further studies using inverse gas chromatography to determine the effect of surface energy on FPF in PCL carriers. . The increase in surface energy results in higher adhesive forces between drug and carrier particles. As the particle size decreases, cohesive and frictional resistance both increase due to more points of contact arising from the increase in surface area-to-volume ratio (42). In addition, a large surface area with decreased particle size renders the particles subject to greater potential for charging and moisture uptake. Moreover, the strong van der Waals forces (43,44) between drugs and carriers influenced the drug detachment from the carrier surface and led to a decrease in drug dispersion from the smaller PCL microparticles. Hence all these factors might have contributed to the decreased detachment of the drug from the smaller carrier as compared to the larger carrier. Thus as the mechanical forces increased with the larger carrier particles, the role of the size of the carrier particles was confirmed in improving the dispersion performance of the drug from the carrier.

We found that increasing the size of PCL carrier increased the aerosol performance of the SS particles. The maximum particle size employed in this study was 150 μm and it is not known whether the particle size higher than 150 μm will further improve the drug delivery. Further work is being carried out on the use of carrier sizes greater than 150 μm to determine the optimum carrier size and the subsequent dispersion of SS from the carriers with increased sizes and the outcome is under the consideration for another publication. As the carrier mass continues to increase it will encounter reduced velocity due to its increasing mass which can hamper the drug dispersion. As a consequence, it is speculated that further increase in the size of the microspheres may inhibit the dispersion of drug from the carrier which requires further investigations.

Conclusion

The work presented here emphasized the importance of the inherent size of the spherical PCL carrier in the dispersion of the SS from the carrier surface in DPI formulations. A clear relationship between the carrier size and drug dispersion from the interactive mixtures was observed. The smaller size of the carrier resulted in lower FPF which was increased up to four-fold by increasing the carrier size. The SS dispersion from a number of formulations containing various sizes of PCL carriers mixed with a fixed amount (2.5%w/w) of SS was measured. As the size of the PCL carrier increased, the number of the particles decreased. Thus for a fixed mass of drug particles in a formulation, the mass of SS particles per unit area of PCL carriers is higher in formulations containing the larger size carriers compared with the formulation containing smaller sized PCL carriers. This leads to an increase in the mass of SS particles per unit area of larger carriers which produced higher FPF of SS. In addition, as the carrier size increased, there was an increased mechanical force, which resulted in efficient detachment of the SS particles from the carrier surfaces leading to significant increase in the FPF of SS.

Abbreviations

- d:

-

diameter

- DCM:

-

dichloromethane

- DPI:

-

dry powder inhaler

- ED:

-

emitted dose

- FPF:

-

fine particle fraction

- HPLC:

-

high performance liquid chromatography

- MgSt:

-

magnesium stearate

- MW :

-

molecular weight

- N:

-

particle number

- PCL:

-

polycaprolactone

- PVA:

-

polyvinyl alcohol

- RD:

-

recovered dose

- S1:

-

stage one

- S2:

-

stage two

- SEM:

-

scanning electron microscope

- SS:

-

salbutamol sulfate

- SX:

-

salmeterol xinafoate

- TSI:

-

twin stage impinger

- UV:

-

ultraviolet

- VMD:

-

volume median diameter

References

Hickey AJ, Concessio NM. Descriptors of irregular particle morphology and powder properties. Adv Drug Delivery Rev. 1997;26(1):29–40.

Young PM, Cocconi D, Colombo P, Bettini R, Price R, Steele DF, et al. Characterization of a surface modified dry powder inhalation carrier prepared by “particle smoothing”. J Pharm Pharmacol. 2002;54:1339–44.

Islam N, Stewart P, Larson I, Hartley P. Surface roughness contribution to the adhesion force distribution of salmeterol xinafoate on lactose carriers by atomic force microscopy. J Pharm Sci. 2005;94(7):1500–11.

Begat P, Price R, Harris H, Morton D, Staniforth J. The influence of force control agents on the cohesive-adhesive balance in dry powder inhaler formulations. KONA. 2005;23:109–21.

French DL, Edwards DA, Niven RW. The influence of formulation on emission, deaggregation and deposition of dry powders for inhalation. J Aerosol Sci. 1996;27(5):769–83.

Steckel H, Muller BW. In vitro evaluation of dry powder inhalers II: influence of carrier particle size and concentration on in vitro deposition. Int J Pharm. 1997;154(1):31–7.

Zeng XM, Martin GP, Marriott C, Pritchard J. The influence of carrier morphology on drug delivery by dry powder inhalers. Int J Pharm. 2000;200(1):93–106.

Karhu M, Kuikka J, Kauppinen T, Bergström K, Vidgren M. Pulmonary deposition of lactose carriers used in inhalation powders. Int J Pharm. 2000;196(1):95–103.

Kawashima Y, Serigano T, Hino T, Yamamoto H, Takeuchi H. Effect of surface morphology of carrier lactose on dry powder inhalation property of pranlukast hydrate. Int J Pharm. 1998;172(1–2):179–88.

Ganderton D. The generation of respirable clouds from coarse powder aggregates. J Biopharm Sci. 1992;3:101–5.

Lucas P, Anderson K, Potter UJ, Staniforth JN. Enhancement of small particle size dry powder aerosol formulations using an ultra low density additive. Pharm Res. 1999;16(10):1643–7.

Lucas P, Anderson K, Staniforth JN. Protein deposition from dry powder inhalers: fine particle multiplets as performance modifiers. Pharm Res. 1998;15(4):562–9.

Staniforth JN. Performance-modifying influences in dry powder inhalation systems. Aerosol Sci Technol. 1995;22(4):346–53.

Tee SK, Marriott C, Zeng XM, Martin GP. The use of different sugars as fine and coarse carriers for aerosolised salbutamol sulphate. Int J Pharm. 2000;208(1–2):111–23.

Byron P, Jashnani R, Germain S. Efficiency of aerosolization from dry powder blends of terbutaline sulfate and lactose NF with different particle size distribution. Pharm Res. 1990;7:S81.

Hamishehkar H, Emami J, Najafabadi AR, Gilani K, Minaiyan M, Mahdavi H, et al. Influence of carrier particle size, carrier ratio and addition of fine ternary particles on the dry powder inhalation performance of insulin-loaded PLGA microcapsules. Powder Technol. 2010;201(3):289–95.

Hassan MS, Lau R. Inhalation performance of pollen-shape carrier in dry powder formulation: effect of size and surface morphology. Int J Pharm. 2011;413(1–2):93–102.

Islam N, Stewart P, Larson I, Hartley P. Effect of carrier size on the dispersion of salmeterol xinafoate from interactive mixtures. J Pharm Sci. 2004;93(4):1030–8.

Islam N, Stewart P, Larson I, Hartley P. Lactose surface modification by decantation: are drug-fine lactose ratios the key to better dispersion of salmeterol xinafoate from lactose-interactive mixtures? Pharm Res. 2004;21(3):492–9.

Louey MD, Razia S, Stewart PJ. Influence of physico-chemical carrier properties on the in vitro aerosol deposition from interactive mixtures. Int J Pharm. 2003;252(1–2):87–98.

Ooi J, Traini D, Hoe S, Wong W, Young PM. Does carrier size matter? A fundamental study of drug aerosolisation from carrier based dry powder inhalation systems. Int J Pharm. 2011;413(1–2):1–9.

Podczeck F. The relationship between physical properties of lactose monohydrate and the aerodynamic behaviour of adhered drug particles. Int J Pharm. 1998;160(1):119–30.

Srichana T, Martin GP, Marriott C. On the relationship between drug and carrier deposition from dry powder inhalers in vitro. Int J Pharm. 1998;167(1–2):13–23.

Bell JH, Hartley PS, Cox JSG. Dry powder aerosols I: a new powder inhalation device. J Pharm Sci. 1971;60(10):1559–64.

Gilani K, Darbi M, Barghi M, Rafiee-Tehrani M. Influence of formulation variables and inhalation device on the deposition profiles of cromolyn sodium dry powder aerosols. Daru. 2004;12(3):123–30.

Kassem NM, Ho KKL, Ganderton D. The effect of air flow and carrier size on the characteristics of an inspirable cloud. J Pharm Pharmacol. 1989;41:14P.

Cline D, Dalby R. Predicting the quality of powders for inhalation from surface energy and area. Pharm Res. 2002;19(9):1274–7.

de Boer AH, Hagedoorn P, Gjaltema D, Goede J, Kussendrager KD, Frijlink HW. Air classifier technology (ACT) in dry powder inhalation Part 2. The effect of lactose carrier surface properties on the drug-to-carrier interaction in adhesive mixtures for inhalation. Int J Pharm. 2003;260(2):201–16.

Donovan MJ, Smyth HDC. Influence of size and surface roughness of large lactose carrier particles in dry powder inhaler formulations. Int J Pharm. 2010;402(1–2):1–9.

Byron P, Jashnani R, Germain S. Efficiency of aerosolization from dry powder blends of terbutaline sulfate and lactose NF with different particle size distribution. Pharm Res. 1980;7:S81.

Tuli RA, Dargaville TR, George GA, Islam N. Polycaprolactone microspheres as carriers for dry powder inhalers: Effect of surface coating on aerosolization of salbutamol sulfate. J Pharm Sci. 2012;101(2):733–45.

Wang S, Guo S. Disodium norcantharidate-loaded poly(ε-caprolactone) microspheres: II. Modification of morphology and release behavior. Int J Pharm. 2008;353(1–2):15–20.

Alway B, Sangchantra R, Stewart PJ. Modelling the dissolution of diazepam in lactose interactive mixtures. Int J Pharm. 1996;130(2):213–24.

de Boer AH, Hagedoorn P, Gjaltema D, Goede J, Frijlink HW. Air classifier technology (ACT) in dry powder inhalation: Part 1. Introduction of a novel force distribution concept (FDC) explaining the performance of a basic air classifier on adhesive mixtures. Int J Pharm. 2003;260(2):187–200.

Voss A, Finlay WH. Deagglomeration of dry powder pharmaceutical aerosols. Int J Pharm. 2002;248(1–2):39–50.

Coates M, Chan H-K, Fletcher D, Chiou H. Influence of mouthpiece geometry on the aerosol delivery performance of a dry powder inhaler. Pharm Res. 2007;24(8):1450–6.

Coates MS, Fletcher DF, Chan H-K, Raper JA. Effect of design on the performance of a dry powder inhaler using computational fluid dynamics. Part 1: grid structure and mouthpiece length. J Pharm Sci. 2004;93(11):2863–76.

Chew NYK, Chan H-K, Bagster DF, Mukhraiya J. Characterization of pharmaceutical powder inhalers: estimation of energy input for powder dispersion and effect of capsule device configuration. J Aerosol Sci. 2002;33(7):999–1008.

Concessio NM, VanOort MM, Knowles MR, Hickey AJ. Pharmaceutical dry powder aerosols: correlation of powder properties with dose delivery and implications for pharmacodynamic effect. Pharm Res. 1999;16(6):828–34.

Shur J, Harris H, Jones M, Kaerger J, Price R. The role of fines in the modification of the fluidization and dispersion mechanism within dry powder inhaler formulations. Pharm Res. 2008;25(7):1631–40.

Traini D, Young PM, Thielmann F, Acharya M. The influence of lactose pseudopolymorphic form on salbutamol sulfate-lactose interactions in DPI formulations. Drug Dev Ind Pharm. 2008;34(9):992–1001.

Hickey AJ, Mansour HM, Telko MJ, Xu Z, Smyth HDC, Mulder T, et al. Physical characterization of component particles included in dry powder inhalers. II. Dynamic characteristics. J Pharm Sci. 2007;96(5):1302–19.

Ibrahim TH, Burk TR, Etzler FM, Neuman RD. Direct adhesion measurements of pharmaceutical particles to gelatin capsule surfaces. J Adhes Sci Technol. 2000;14(10):1225–42.

Linsenbühler M, Wirth K-E. An innovative dry powder coating process in non-polar liquids producing tailor-made micro-particles. Powder Technol. 2005;158(1–3):3–20.

Acknowledgments AND DISCLOSURES

This work has been financially supported through a PhD studentship and Rinku Tuli would like to acknowledge the scholarship support provided by the Faculty of Science and Technology, Queensland University of Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tuli, R.A., George, G.A., Dargaville, T.R. et al. Studies on the Effect of the Size of Polycaprolactone Microspheres for the Dispersion of Salbutamol Sulfate from Dry Powder Inhaler Formulations. Pharm Res 29, 2445–2455 (2012). https://doi.org/10.1007/s11095-012-0772-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-012-0772-y