ABSTRACT

Purpose

To develop solid self-emulsifying drug delivery systems (SEDDS) for lipids using poloxamer 188 as both solidifying and emulsifying agents.

Methods

Mixtures of various lipids with poloxamer 188 and PEG 8000 were prepared at ~75°C. The molten mixtures, with and without dissolved drugs (fenofibrate and probucol), were then cooled to room temperature. When solids formed, they were characterized by powder XRD, DSC, microscopy using cross-polarization and confocal fluorescence techniques, dispersion test in water and particle size analysis of dispersions.

Results

When mixed with poloxamer 188 or PEG 8000, lipids consisting of monoesters of fatty acids with glycerol or propylene glycol formed solid systems, but not di- and tri-esters, which showed phase separation. Added to water, the solid systems containing poloxamer 188 started to disperse in water forming oil globules of 200–600 nm. No emulsification of lipids was observed from solids containing PEG 8000, indicating that the surfactant property of poloxamer 188 was responsible for emulsification. Powder XRD, DSC and microscopic examination revealed that poloxamer 188 and PEG 8000 maintained their crystallinity in solid systems, while the lipids were interspersed in between crystalline regions. The drug remained solubilized in the lipid phase.

Conclusions

A novel solid SEDDS is developed where the drug can be solubilized in liquid lipids and then the lipidic solution can be converted to solid mass by dispersing into the microstructure of poloxamer 188.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

The extensive application of combinatorial chemistry and high-throughput screening in the drug discovery process during the past 2 decades has made new molecular entities (NMEs) extremely insoluble in aqueous media (1). After oral administration, drugs must dissolve in gastrointestinal (GI) fluids prior to their absorption into the body (2). There has been a great interest in the pharmaceutical field on lipid-based drug delivery system (LBDDS) during past 10 to 15 years as they present poorly water-soluble drugs to the GI tract as solutions in lipids or in mixtures of lipids, surfactants and/or co-surfactants and facilitate formation of solubilized phases that promote absorption (3,4). Most of the LBDDS for poorly water-soluble drugs that were successfully developed into drug products have, however, been liquids. They include Neoral® (cyclosporine A; Novartis), Norvir® (ritonavir; Abbott), Agenerase® (amprenavir; GSK) and Fortovase® (saquinavir; Roche), all of which were developed as liquid solutions filled into soft gelatin capsules (5,6). Much of the research on LBDDS focused on solubility of active ingredients in lipids or lipid-like materials, ease of dispersion or emulsification of formulations in aqueous media, and particle size of dispersions or emulsions thus produced (4,7–12).

Lipid-based formulations for poorly water-soluble drugs are usually developed as liquids because most of the lipids and surfactants suitable for dissolving drugs exist as liquid at room temperature. They include (a) vegetable oils, predominantly containing unsaturated long-chain fatty acids, (b) glycerides and partial glycerides of medium chain and unsaturated long chain fatty acids, (c) polyacyl esters of medium chain fatty acids (e.g., propylene glycol (PG) esters), (d) polyoxylglycerides (macrogolglycerides) consisting of polyethylene glycol (PEG) esters of fatty acids (usually medium chain fatty acids or long-chain unsaturated fatty acids), and (e) ethoxylated lipids (e.g., Cremophor® EL, a PEG ester of ricinoleic acid derived from castor oil) (13). Hydrogenated vegetable oils as well as partial glycerides and esters of long-chain saturated fatty acids are not usually used for bioavailability enhancement as they exist as solids, which is not suitable for dissolving drugs. Even if drugs are dissolved by melting such lipids at elevated temperatures, the drugs may phase separate and crystallize out when the vehicles solidify at room temperature (14). Solid lipids are usually applied in the development of modified release dosage forms (13,15,16) or as lubricants in tablet formulations (17).

As the solid dosage forms are used more commonly because of their superior stability, lower cost of manufacture and better patient acceptability than liquid, various attempts for the development of solid lipid-based formulations have been reported in the literature (13,14,18,19). They include adsorption of liquids onto silicas and other porous carriers (20–25) and spray-drying of liquid formulations mixed with such carriers as sucrose (26), maltodextrin (27), dextran (28) and different polymeric materials (29). These approaches are, however, associated with various formulation development issues such as low drug loading (30), incomplete drug release (30), poor flow properties of powders (23), poor compactibility into tablets (31), and so forth. Much more research is needed to develop such solid formulations into viable alternative to liquids.

In 2009, Li et al. (32) reported the development of solid SEDDS where the solution of a poorly water-soluble drug in a liquid microemulsion preconcentrate consisting of the mixture of a lipid and a surfactant was converted into a solid form by incorporating it in a solid PEG system. The solid formulations thus prepared consisted of Capmul® PG8 (PG monocaprylate; ABITEC) or Capmul® MCM (glyceryl caprylocaprate; ABITEC) as lipids, Cremophor® EL (PEG-35 castor oil; BASF) as surfactant, and hydrophilic polymer PEG 3350 as solid system. The drug was dissolved in a melt of the mixture (65–70°C) and the solution was then filled into hard gelatin capsules. The solution inside the capsule solidified upon cooling below 55°C. The differential scanning calorimetric (DSC), scanning electron microscopic (SEM), confocal Raman microscopic (CRM) studies demonstrated that the solid was a two-phase system where clusters of crystalline PEG 3350 formed the solid structure (m.p. 55–60°C) and the liquid lipid-surfactant mixture dispersed in between crystalline PEG 3350 structures as a separate phase. The formulation exhibited excellent physical and chemical stability and was amenable to scale up for large-scale manufacturing. However, the study was limited to a small number of lipids where only PG monocaprylate and glyceryl caprylocaprate formed acceptable solids. It was not known what other lipids would solidify in the same manner. Moreover, only 30% of the composition was lipid, the remaining being liquid surfactant (30%) and solid PEG 3350 system (40%). Solid PEG 3350 did not participate in solubilizing drug and, as a result, the drug load in the formulation was low due to the lower lipid content as compared to a liquid system without PEG 3350. The only function of PEG 3350 had in the formulation was being the solidifying agent.

The present study has been undertaken to determine whether PEG 3350 can be replaced with another solid system that can serve as both solidifying and emulsifying agents. This will allow increasing the lipid content and consequently the drug load in the formulation as no separate liquid surfactant (e.g., Cremophor® EL) will be needed and the liquid phase in the formulation will consist of lipid only. Poloxamer 188, which is a block copolymer with the poly(ethylene oxide)-poly(propylene oxide)-poly(ethylene oxide) (PEO-PPO-PEO) backbone (average mol wt = 8500; m.p = 54°C) was selected as the solidifying cum emulsifying agent as it has structural similarities with solid PEGs that contain poly(ethylene oxide) backbone. Poloxamers are approved by the FDA for oral, intravenous, ophthalmic, subcutaneous, and topical preparations (33). Due to their surface active properties, poloxamers have been widely used as solid dispersion carriers to improve solubility and dissolution rate of poorly water soluble drugs (34–37). In addition to changing the solidifying agent, a wide range of liquid lipids was studied to determine whether they could be immobilized in a solid system for the development of solid dosage forms or not. For the present study, we have selected poloxamer 188 as the solidifying agent as its average molecular weight of 8500 is comparable to that of PEG 8000 (mol wt = 8000) and its hydrophilicity and HLB value (HLB = 29) are suitable to form oil-in-water emulsion (38).

MATERIALS AND METHODS

Materials

Poloxamer 188 (Pluronic® F68 NF), PEG 8000, and Cremophor® EL were received from BASF Corp., Tarrytown, NJ, USA. Capryol® PGMC, Labrafac® PG, Labrafil® M 2125 CS and Labrafil® M 1944 CS, Labrasol®, Maisine®35-1, and Peceol® were obtained from Gattefosse, Corp., Paramus, NJ, USA. Capmul® MCM NF, Capmul® PG-8 NF, Capmul® PG-12 EP/NF, Capmul® PG-2L EP/NF , and Captex® 355 EP/NF were supplied by ABITEC Corp., Columbus, OH, USA. Almost all the lipids are mixtures of multiple components; structures of their primary components are given in Fig. 1 and further descriptions of their compositions are given in footnotes of Table I. Although only triglycerides have traditionally been known as lipids, all materials listed in Table I are considered to be lipids for the purpose of the present investigation. This is also in agreement with the classification of lipids given by Jannin et al. (13) and Cannon and Long (39). Fenofibrate and probucol were purchased from Sigma-Aldrich® (St. Louis, MO, USA). Nile red, a fluorescence probe for lipids, was purchased from MP Biomedicals, LLC, Solon, OH, USA. All other chemicals and reagents are of analytical grade or better.

Preparation of Solid Systems

Preliminary studies were conducted to determine whether poloxamer 188 is comparable to PEG 8000 in solidifying liquid lipids and surfactants and to identify what lipids can be solidified by using these polymers. For this purpose, 1:1 mixture of each lipid or liquid surfactant listed in Table I as well as several vegetable oils (e.g., olive oil, sesame oil and peanut oil) was prepared with poloxamer 188 or PEG 8000. All lipids and surfactants used were liquid at a room temperature. The two components of a mixture (total weight: 5 g) were weighed into a scintillation vial and melted on a hot plate until it formed clear solution. Though the melting points of poloxamer 188 and PEG 8000 are 54°C and 60°C, respectively, mixtures were heated at 70–75°C to assure complete melting and uniformity of the sample. All samples were vortex mixed for ∼5 min in the molten state to obtain homogeneous mixing of the components. Samples were then allowed to solidify at room temperature and stored for at least 48 h before analysis. As one of the major objectives of this study was to increase lipid loading in the solid system, the mixtures of lipids and poloxamer 188 that formed solids at ratios of 1:1 were further evaluated for their ability to solidify at other ratios of poloxamer 188 to lipids (1:4, 1:3, 3:7, 2:3, 3:2 and 7:3 w/w).

Characterization of Solid Systems

Physicochemical properties of all solid forms of poloxamer-lipid and PEG-lipid mixtures prepared were characterized by powder X-ray diffractometry and differential scanning calorimetry. Selected poloxamer-lipid mixtures were also examined microscopically for their microstructures.

Powder X-ray Diffractometry (Powder XRD)

Powder XRD analysis of neat poloxamer 188 and PEG 8000 alone as well as their solid mixtures with various lipids was performed at room temperature using an X-ray diffractometer (XRD-6000, Shimadzu, Kyoto, Japan). The diffraction patterns were measured with a voltage of 40 kV and a current of 30 mA over a 2θ range of 10–70° using a step size of 0.02° at a scan speed of 4°/min. Samples that did not solidify and remained semisolid at room temperature were not analyzed by XRD. The XRD intensities were compared by measuring the approximate peak intensity at 2θ = 23.5° for both poloxamer 188 and PEG 8000.

Differential Scanning Calorimetry (DSC)

The thermal characteristics of pure carriers (poloxamer 188 and PEG 8000) and solid mixtures with lipids were determined using a differential scanning calorimetry (Pyris Diamond, Perkin-Elmer DSC-7, California, USA). Samples of 3 to 5 mg were weighed accurately and sealed into aluminum pans. All samples were held at initial temperature for 5 min and then heated from 25 to 80°C with a heating rate of 5°C/min under an extra dry nitrogen gas purge (20 ml/min).

Microscopical Examination of Solid Systems

Samples were analyzed microscopically using an optical microscope fitted with cross-polarizer (Nikon Microscope Eclipse 50i 55i, Morrell Instrument Co., Inc., Melville, NY, USA) and confocal fluorescence microscope (Leica Microsystems Inc., Exton, PA, USA) with 514–543 nm excitation, 528–608 nm emission wavelength and bandpass filter of DD458–514 nm. For fluorescence microscopic analysis, Nile red, a fluorescence probe for lipid, was dissolved in a lipid (Capmul® PG-8 NF), and the solution was then mixed with poloxamer 188 by raising the temperature to 70°C. A drop of the mixture was placed on the glass slide, covered with glass cover slip and sealed with nail polish. For solidification of samples, two sets of slides were prepared. The first set was solidified immediately upon exposure to ambient temperature. The second set was allowed to cool down in oven (Sheldon Manufacturing, Inc, Cornelius, OR, USA) at controlled temperature from 60 to 25°C at the rate of 0.1°C/min. Photographs were captured using Nikon digital camera (DS 5000, Nikon Inc., Melville, NY, USA) for optical microscopy using cross-polarized light with magnification of 100 ×.

Solubility Study

Lipids forming solid systems with poloxamer 188 or PEG 8000 in the ratio of 1:1 were selected for the solubility study. Solubility studies were conducted by placing an excess amount of fenofibrate or probucol in a 25 ml of volumetric flask containing approximately 5–7 g of vehicles. The mixture was then shaken using a wrist action shaker (BURRELL Wrist Action Shaker, BURRELL Scientific, Pittsburgh, PA, USA) in a water bath at 25°C for 24 h. The shaking time of 24 h was set because preliminary experiments showed that the solutions reached equilibrium within 12 h and there was no further change in concentration when shaking was continued for 24 h and longer. The supernatant was withdrawn, filtered through 0.45-μm polypropylene membrane filter (VWR® International, Radnor, PA, USA) and diluted with acetonitrile for HPLC analysis. In addition to fenofibrate, the solubility of probucol was determined in two lipids, glyceryl caprylocaprate and PG monocaprylate, as well as in their 1:1 and 2:1 mixture, where aliquots were diluted with methanol prior to HPLC analysis.

HPLC Analysis

The HPLC analysis system consisted of a quaternary pump, an autosampler and a diode array detector (HP1100 series, Agilent Technologies, Wilmington, DE). The chromatographic column was C8 Waters XBridge column (3.5 μm, 4.6 mm × 150 mm). For analysis of fenofibrate, the mobile phase used was a mixture of acetonitrile and distilled water (80:20 v/v), while for probucol, it was a mixture of methanol and distilled water (95:5 v/v). In both cases, the flow rate of the mobile phase was 1 ml/min. Fenofibrate and probucol concentrations were measured at λmax of 288 nm and 243 nm, respectively, at 25°C.

Drug Loading in Solid Systems

Fenofibrate and probucol were used as model drugs. They were first dissolved in the lipid vehicle by mild heating and vortexing. The solutions were then mixed with molten poloxamer 188 at 70–75°C. The primary purpose of the preparation of drug-loaded formulations was to investigate drug release (dispersion) from the formulations. Therefore, no attempt was made to maximize drug loading in various formulations based on solubility of drugs in different lipids. The drug loading was kept 2% w/w for all solid systems containing 1:1 ratio of poloxamer 188 to lipids. In case of 2:3 and 3:7 ratios of poloxamer 188 to glyceryl caprylocaprate, drug loading was 2.4 and 2.8% w/w, respectively. In case of probucol, the drug loading was in the range of 3.3 to 3.6% w/w. The solid formulations were analyzed after storage at room temperature for at least 24 h.

Dispersion Test

To simulate the degree and efficiency of emulsification of lipids in GI fluids after oral administration of the solid systems developed, the dispersion test was conducted by using the USP apparatus II (paddle method; Distek Inc., NJ, USA) at 50 RPM and 37°C with 250 ml of distilled water as the dispersion medium. Since aqueous solubilities of the drugs, fenofibrate and probucol, were pH-independent and all lipids and solid systems were non-ionic, distilled water was used as the dispersion medium. It is, however, recognized that a solid dosage form after oral administration encounters an acidic environment in the stomach. Preliminary studies in this investigation as well as results of a previous study in our laboratory showed that there were no differences in the results of dispersion tests if 0.01 N HCl was used instead of distilled water (40). A volume of 250 ml was selected for the dispersion test to mimic the gastric fluid volume as per the Biopharmaceutical Classification System (41) after oral administration of solid dosage unit. Approximately 1 g of the formulation was directly added to the dispersion vessel using weighing boats. To evaluate the effect of drug loading, if any, on emulsification properties of solid systems, controls without drugs were also subjected to dispersion test. Thus, the dispersion test for a particular formulation was conducted six times, three with drug and three without drug. Both drug concentration and particle size of dispersion fluids were analyzed for formulations with drugs, while only particle sizes of oil globules were measured for drug-free systems.

Aliquots from dispersion vessels were withdrawn at 5, 10, 15, 30, 45, 60, 90, 120, and 180 min time points. Drug concentrations were determined by HPLC analysis after appropriate dilution, where aliquots without filtration were used as there was the potential that lipids could be retained partly on filters depending on particle size of globules formed. Particle sizes were measured without any dilution by Delsa Nano C Particle Analyzer (Beckman Coulter Inc., CA, USA).

To investigate any potential for crystallization of drugs during dispersion testing, aliquots of dispersion fluids collected at the end of tests were centrifuged at 6,000 RPM (Eppendorf 5804R Centrifuge, NY, USA) at 25°C.

RESULTS AND DISCUSSION

Physical Evaluation of Solid Systems

The physical mixture of each lipid with either poloxamer 188 or PEG 8000 at 1:1 ratio was first examined visually, according to the method of Ping et al. (32), for the formation of uniform solid system without any apparent phase separation or stratification. The 1:1 ratio was used as the initial acceptance criteria for solid lipid-based formulation that it should contain at least 50% w/w lipid. To ensure adequate solidification, the visual observation was performed after 2 days of storage at room temperature. Table I lists various lipids that formed solid systems with poloxamer 188 or PEG 8000 at 1:1 ratio. It also lists those lipids that did not form acceptable solid systems or showed phase separation. In addition to the lipids listed in Table I, several vegetable oils (e.g., olive oil, sesame oil and peanut oil) were also tested; however, none of them formed solid systems with either poloxamer 188 or PEG 8000.

As mentioned earlier, Fig. 1 gives the structures of primary components of the lipids used in the present study. However, almost all the lipids contain multiple components. As described in the footnotes of Table I, a lipid containing primarily a monoglyceride may also contain di- and tri-glycerides at lesser concentrations. A lipid may also be a mixture having multiple fatty acid chain lengths. By looking at the compositions of lipids, it becomes apparent that lipids having high proportions (>50% w/w) of monoglycerides or monoesters in their composition formed uniform, hard solid masses with poloxamer 188 and PEG 8000, while lipids containing relatively higher proportions of di- and tri-glycerides or propylene glycol diesters did not form solid masses (Table I). For example, glyceryl caprylocaprate (Capmul® MCM NF) containing 60% monoglyceride and 35% diglyceride formed a solid mass with poloxamer 188 or PEG 8000 at 1:1 ratio, whereas glyceryl dicaprylate that contained 83% diglyceride and <17% monoglyceride did not form a uniform solid mass. Cremophor® EL and Labrasol®, which are also monoesters of fatty acids, formed hard, uniform, solid systems with poloxamer 188 and PEG 8000. Both Cremophor® EL and Labrasol® are considered to be surfactants rather than lipids in the development of lipid-based formulations because of their high HLB values than other lipids due the presence of relatively long PEG moieties in their structures. It was also noted that lipids containing long chain fatty acid (C18) esters like glyceryl monooleate (Peceol®), glyceryl monolinoleate (Maisine®35-1) and PEG-35 castor oil (Cremophor® EL) formed comparatively harder solid masses than those with medium chain fatty acid (C8 and C10) esters of the same backbones. Between poloxamer 188 and PEG 8000, the later formed harder solid masses as compared to the former, possibly because of the higher melting point of PEG 8000.

Comparison of Poloxamer 188 and PEG 8000 as Solidifying Agent

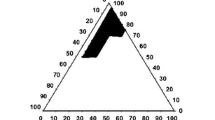

For lipids and surfactants that formed solid masses at 1:1 ratios with poloxamer 188 and PEG 8000, additional mixtures were prepared with poloxamer 188 or PEG 8000 contents ranging from 70% w/w (30% w/w lipid) to 20% w/w (80% w/w lipid). The powder XRD patterns of such mixtures of one representative lipid, glyceryl caprylocaprate (Capmul® MCM NF), with poloxamer 188 and PEG 8000 are shown, respectively, in Fig. 2a and b. Neat poloxamer 188 showed characteristic crystalline sharp peak at 2θ = 19.25° and 23.5° (pattern a in Fig. 2a) and, similarly, PEG 8000, showed crystalline peak at 2θ = 19° and 23.5° (pattern b in Fig. 2b). As the concentration of lipid in the formulation increased, the peak heights of both poloxamer 188 and PEG 8000 decreased. However, distinct XRD peaks in Fig. 2a and b can be observed at lipid content as high as 75% and 80% w/w, respectively, indicating that both poloxamer 188 and PEG 8000 serve as solidifying agents for high lipid concentrations in formulations.

In addition to comparing solidifying abilities of poloxamer 188 and PEG 8000, preliminary studies were also conducted to determine how these two materials serve as emulsifying agents. While the lipid started to disperse from the poloxamer 188 formulation within one minute, no such dispersion was observed from the PEG 8000 formulation, where the solid floated as particles without the release or dispersion of lipid. These results indicated that poloxamer 188 can serve as both solidifying and emulsifying agents at the same time. On the other hand, PEG 8000 served as the solidifying agent only. Previously, Ping et al. (32) observed drug release from a PEG-based formulation, because they also incorporated a surfactant in it.

Following initial studies demonstrating comparability of the two solidifying agents used and superiority of poloxamer 188 over PEG 8000 as the emulsifying agent, more in-depth characterization was conducted for poloxamer 188 formulations only.

Characterization of Solid Systems

Powder X-ray Diffractometry (Powder XRD)

As mentioned earlier, all lipids and surfactants listed in the left hand side of column of Table I formed solid systems with poloxamer 188. These mixtures also showed characteristic XRD peaks with lipid contents as high as 70 to 80% w/w (Fig. 2). In addition to XRD patterns of the poloxamer 188-glyceryl caprylocaprate mixture in Fig. 2, the powder XRD patterns of formulations containing three other lipids having different chemical structures and different fatty acid chain lengths are shown in Fig. 3. These lipids are PG monocaprylate (Fig. 3a), a PG ester of C8-fatty acid, PG monolaurate (Fig. 3b), a PG ester of C12-fatty acid, and glyceryl monooleate (Fig. 3c), a monoglyceride C18-fatty acid. Similarly, PEG monoesters of medium chain and long-chain fatty acids (Labrasol® and Cremophor® EL, respectively) also showed characteristic sharp peaks up to 80% w/w concentration in solid formulations. These results showed that all lipid monoesters formed solid systems with poloxamer 188 irrespective of their chemical structures and fatty acid chain length.

Powder XRD patterns of solid systems containing different concentrations of (a) PG monocaprylate (Capmul® PG-8 NF), (b) PG monolaurate (Capmul® PG-12 EP/NF) and (c) glyceryl monooleate (Peceol®) in lipid-poloxamer 188 mixtures. Lipid concentrations: (a) 0%, (b) 30%, (c) 40%, (d) 50%, (e) 60%, (f) 70%, (g) 75%, (h) 80%.

The decrease in intensities of powder XRD (2θ = 19.25° and 23.5°) with decreasing concentrations of poloxamer in various lipid-surfactant mixtures are tabulated in Table II. They showed linear relationships (r2 ≥ 0.90) between% poloxamer 188 and peak intensities of the X-ray diffraction (Table II). It indicates that poloxamer 188 and PEG 8000 remain in the same crystalline structure as that of pure poloxamer 188 and PEG 8000. This observation confirmed that the decrease in peak intensity of X-ray pattern in various systems was due to the decrease in concentration of carriers and not due to any change in their physical forms. In some cases, broadening of the peak was observed due to high lipid content in the systems.

It may be observed in Table II that two PG esters, one containing >90% w/w PG monoester (Capmul® PG-8 NF ) and the other containing 63–70% w/w PG monoester (Capryol® PGMC), formed solid masses with poloxamer 188. Several other monoesters also contained relatively small portions of diesters. Therefore, the XRD analysis shows that the solid systems can accommodate a certain portions of diesters along with monoesters.

To determine whether the presence of drug would have any impact on crystallinity of solid systems, powder XRD patterns of selected mixtures were recorded with and without the presence of fenofibrate or probucol (2% w/w). In none of the cases, any change in the XRD pattern due to the presence of drug was observed. In a few cases, the fenofibrate or probucol content was increased up to 6% w/w and yet the XRD patterns with and without drugs remained essentially similar and there were no drug peaks, which indicated that the drugs were solubilized in the lipid phase and did not interfere with the crystallinity of solid poloxamer 188. In several cases, the powder XRD analysis was repeated after storage of samples for 2–3 months and no change in XRD patterns was observed, indicating long term stability of solid systems.

Differential Scanning Calorimetry (DSC)

The results of the DSC study confirmed the crystallinity of lipid-poloxamer 188 and lipid-PEG 8000 mixtures observed by XRD analysis. The DSC scans of mixtures of one medium chain monoester (PG monolaurate; Capmul® PG-12) and one long chain monoglyceride (glyceryl monolinoleate; Maisine®35-1) are shown, respectively, in Figs. 4 and 5 as representative examples of the effect of decrease in poloxamer 188 content and the corresponding increase in lipid contents on onset, peak and enthalpy of DSC endotherms. Table III gives values for these endotherm parameters for all combinations studied. The melting points of pure poloxamer 188 and PEG 8000 were observed at 53.9°C (onset 52.5°C) and 62.6°C (onset 59.6°C), respectively. As shown in Figs. 4 and 5 as well as in Table III, there was decrease in onsets of melting endotherms of poloxamer 188 due to the addition of lipids. This was expected as lipids serve as solutes (or impurities) in poloxamer 188, thereby reducing its melting point. The reduction in the height of melting peaks could be the result of both lowering of poloxamer 188 content and the broadening of melting endotherms. The most important DSC parameter was the enthalpy, which in all cases decreased almost linearly with the decrease in poloxamer content and corresponding increase in lipid content (Table III), thus demonstrating that the presence of lipids did not have any significant influence on the crystallinity of poloxamer 188. These results are in agreement with previous studies with PEG 3350 where PEG-Capmul® PG8-Cremophore® EL (32) and PEG-Tween 80 (42) mixtures were used.

DSC scans of lipid-poloxamer 188 mixtures were also recorded with fenofibrate and probucol loads ranging from 2 to 6% w/w. No difference from the DSC scans of corresponding drug-free systems was observed (scans not shown). There were also no endotherms corresponding to melting points of fenofibrate and probucol (83° and 130°C, respectively). These results again indicate that the drugs remained dissolved in the lipid phase and their presence did not have any influence on crystallinity of poloxamer 188 present in the system.

Microscopical Examination of Solid Systems

There are several reports in the literature where it was observed that polymers like poloxamers, PEG, etc., formed crystalline spherulites after cooling their melts on glass microscopic slide (43–47). In the present investigation, poloxamer 188 and its mixtures with lipids and surfactants were examined microscopically under the cross-polarized light to determine the formation of spherulites as evident from their birefringence. Separately, poloxamer 188-lipid mixtures were also examined using confocal fluorescence microscopy, where a fluorescence dye was dissolved in the lipids to also visualize the non-crystalline regions of the mixtures.

Figure 6 shows microscopic images of neat poloxamer 188 and its 1:1 mixture with PG monocaprylate, where the images of the mixtures were captured under different experimental conditions (slow cooling, fast cooling and fluorescence). As shown in Fig. 6a, poloxamer 188 by itself forms birefringent spherulites without any dark zones, indicating crystallinity of the material and the absence of any visible amorphous zones. However, when neat poloxamer 188 was cooled slowly, there appeared to be relatively darker amorphous regions in between the crystalline spherulites (Fig. 6b). When poloxamer 188-lipid mixtures were cooled on glass slides, birefringent spherulites interspersed with dark amorphous regions were observed. It was also observed that the rate of cooling had an impact on the nature of spherulites formed. This was considered important because when the molten mixture was placed as a thin layer on the glass slide, it solidified in <5 min. However, the material took 3–4 h to solidify in a glass vial. For this reason, the microscopic examination was also performed by cooling the material from > 60°C to room temperature (~25°C) slowly over a period of 4 h. When the molten poloxamer-lipid mixture was cooled slowly, the spherulites were larger and more well-defined (Fig. 6d), while the spherulites were smaller and crowded when the material was cooled fast as there was a larger number of crystallization nuclei (Fig. 6c). It has been reported in the literature that the size of the spherulite depends on the number of nuclei from which the growth begins (47). Nonetheless, whether the structures were cooled slowly or fast, there were distinct crystalline (spherulites) and amorphous regions, the later being more well-defined in case of slow cooling. The confocal fluorescence microscopic image in Fig. 6e indicates that the amorphous region on the slide consists of the lipid present in the mixture as the dissolved fluorescent dye was visible only in the amorphous phase (shown in red). Thus, the spherulites of poloxamer 188 (shown white) and the amorphous lipids coexist in the solid mass with the drug (in this case, a dye) being dissolved in the lipids.

Photomicrographs (magnification: 100 ×) obtained from cross-polarization optical microscopy (a–d) and confocal fluorescence microscopy (e): (a) neat poloxamer 188 with immediate cooling to room temperature; (b) neat poloxamer 188 with slow cooling to room temperature (0.1°C/min); (c) poloxamer 188/PG monocaprylate mixture (1:1) with immediate cooling to room temperature; (d) poloxamer 188/PG monocaprylate mixture (1:1) with slow cooling to room temperature; (e) poloxamer 188/PG monocaprylate mixture (1:1) with immediate cooling, where red fluorescence indicates lipid phase while white patterns indicate crystalline spherulites of poloxamer 188.

Solubility Study

Results of solubility studies of fenofibrate and probucol in different lipids and surfactants used for the preparation of solid formulations are given in Table IV. Chemically, fenofibrate is a neutral molecule without any ionization in the GI pH range of 1 to 8 and, similarly, probucol is also a neutral compound without any ionizable group. Fenofibrate has a reported aqueous solubility of less than 3 μg/ml and a high logP (octanol/water partition coefficient) of 4.6 (48). Probucol is even more water-insoluble with a concentration of 0.002–0.005 μg/ml (49) and logP of 11 (50). Although, as reported by Rane and Anderson (51), the prediction of drug solubility in lipids is difficult, several trends emerge from the results presented in Table IV. Fenofibrate showed higher solubility in the monoglyceride of medium chain fatty acids (glyceryl caprylocaprate) than in the monoglyceride of long chain fatty acids (glyceryl monooleate and glyceryl monolinoleate). Similarly, PG monocaprylate showed higher fenofibrate solubility that that in PG monolaurate, which has a longer fatty acid chain length (C8 vs. C12). Between glyceryl monoesters and PG monoesters, the PG monoesters had higher drug solubility than that in the glyceryl monoesters; this was true for both fenofibrate and probucol. As mentioned earlier, two PG monocaprylate from two manufacturers were used in the present investigation, where Capryol® PGMC had higher diester content than Capmul® PG-8 NF. However, the fenofibrate solubility in both was essentially similar. Assuming that poloxamer 188 in the solidified systems does not participate in solubilizing drugs, the drug load in a poloxamer 188-lipid solid dosage form may be calculated based on drug solubility in the lipid component of the formulation. In the present investigation, drug concentrations below 80% of solubilities in lipids were used. No crystallization of drug in any of the formulations was observed even when the systems were stored in the refrigerator at ~8°C. It is possible that a higher drug load could be used if the concentration in lipid was increased to >80% of drug solubility. The stability of such formulations, however, has to be investigated in different formulations on a case by case basis.

The highest solubility of fenofibrate or probucol observed in Table IV is ~126 mg/g. Thus, a 7:3 mixture of lipid to poloxamer 188 could be obtained with 8.8% w/w drug loading if the saturated solutions of particular lipids were used, and the drug load would be 7.1% w/w if concentrations of drug in the lipids were 80% of its saturation solubility. The drug load will be lower when the drug solubility in the lipids is lower. Thus, one of the limiting factors in development of solid SEDDS, like all lipid-based formulations, is the solubility of drugs in lipids used.

Dispersion Test

The solid lipid-based drug delivery systems containing poloxamer 188 began dispersion immediately after their addition to 250 ml of an aqueous medium and they dispersed completely in <60 min. Fig. 7 gives the comparative dispersion profiles of two medium chain (glyceryl caprylocaprate, PG monocaprylate) and two long chain (glyceryl monooleate, glyceryl monolinoleate) monoesters having 1:1 ratio of lipid to poloxamer 188. The drug loading was kept constant at 2% w/w of the system. More than 80% drug release was observed within 45 min in case of systems containing glyceryl caprylocaprate with the formation of translucent microemulsion/emulsion in the dispersion fluids. When the medium chain monoglyceride was replaced by long chain lipids, Peceol® and Maisine®35-1, the drug release was still about 80% within 45–60 min of time period, but they formed milky white opaque emulsions. In all three cases, almost 90% of drug dispersed within 2 h. In contrast, propylene glycol based monoester (PG monocaprylate) showed the drug dispersion up to 65–70% in 2 h. It was observed that an oil layer separated from the aqueous medium was floating on the surface of dispersion fluid. This might be the reason of the low drug concentration in the dispersion medium. Similar results were also observed with studies where PG monolaurate was used as the lipid component (data not shown). The reason for the difference in behavior between PG monoester and glyceryl monoester is not clear from the present study. This could be related to the difference in lipophilicity of the two lipids; the PG monocaprylate is more lipophilic as it has one less –OH group in the propylene glycol backbone. Long chain monoglycerides like glyceryl monooleate and glyceryl monolinoleate formed milky white emulsion with higher particle size as compared to medium chain monoglycerides like glyceryl caprylocaprate. This observation is consistent with earlier reports in the literature, where it was observed that the globule size increases with the increase in fatty acid chain length (8).

The particle sizes of dispersed lipid globules corresponding to the profiles in the Fig. 7 are given in Table V. Particle sizes were determined for formulations without and with (2% w/w) drug (fenofibrate). There was no significant effect of the presence of drug on lipid particles. Among the lipids, only glyceryl caprylocaprate produced particles in the microemulsion range (<200 nm) in the dispersion fluids. In contrast, PG monocaprylate, a monoester of medium chain fatty acid, and the long chain fatty acid monoesters glyceryl monooleate and glyceryl monolinoleate formed milky white emulsions with particle sizes in the range of 300 to 700 nm. Although the microemulsion was not produced by all lipids from 1:1 mixtures with poloxamer 188, the particles were still low in the submicron range (<700 nm). If any digestion of lipids is involved in the release of drug from the fine lipid globules, it is expected that the drug will remain very finely dispersed and will redissolve rapidly. Although the dispersion of PG monocaprylate was incomplete due to partial phase separation (floating at the surface of dispersion fluid), this may not be a major issue in vivo, because, as pointed out by Pouton (11), further solubilization or emulsification will occur in presence of bile salts and other surface active agents.

Effect of Lipid-Poloxamer 188 Ratio

Figure 7 and Table V give comparative effects of lipid type on their dispersion from 1:1 lipid-poloxamer 188 mixtures. Studies were then conducted to determine what effects the lipid to poloxamer ratio will have on the dispersion of formulations and the particle size of lipid globules formed in aqueous media. Figure 8 shows dispersion profiles of fenofibrate from mixtures of glyceryl caprylocaprate (Capmul® MCM NF) with poloxamer 188 at different ratios. The results showed that at least 50% w/w poloxamer 188 was necessary for the complete dispersion of lipid; the dispersion was progressively lower when lipid content in the formulation was increased to 60 and 70% w/w.

As shown in Table VI, there was also no effect of the presence of drug on the particle size of lipid from any of the mixtures used in Fig. 8. There was no precipitation of drug during the dispersion test. The size of the lipid particles, however, decreased with the increase in poloxamer 188 content (Table VI). Such a decrease in particle size may be the result of more surfactant being available in aqueous media during dispersion testing to stabilize the oil-water interface (52).

Effect of Mixing Two Lipids

It is shown in Table V that glyceryl caprylocaprate formed microemulsion in aqueous media from its 1:1 mixture with poloxamer 188, while PG monocaprylate formed emulsion with particle size ~ 3 times higher. In addition, the dispersion of PG monocaprylate in aqueous media was incomplete (Fig. 7). In contrast, both the model drugs, fenofibrate and probucol, had much higher solubility in PG monocaprylate than that in glyceryl ester; for probucol, the solubility was 2.5 times higher (Table IV). It was, therefore, of interest to determine what impact of combining the two lipids will have on drug solubility, drug dispersion and particle sizes of lipid globules formed. Using probucol, it was demonstrated that the drug solubility in glyceryl caprylocaprate increased greatly when PG monocaprylate was mixed with it at 2:1 and 1:1 ratios (Table IV). Further, almost complete (>80%) dispersion of drug was obtained from the mixed lipids (Fig. 9) in contrast to the dispersion of PG monocaprylate alone (Fig. 7). Further, the particle size of the mixed lipids in the dispersion fluid was within the microemulsion range (<200 nm) (Table VII). Thus, the drug load in the formulations may be increased and the microemulsion after dispersion of formulations in GI fluids may be obtained when PG monocaprylate is mixed with glyceryl caprylocaprate.

Possible Mechanism of Lipid Entrapment by Solid System

Polyethylene glycols and polyethylene oxides are semicrystalline in nature and contain significant amorphous zones along with their crystalline domains (42,53,54). Being structurally similar to PEG, poloxamer 188 may also contain similar amorphous zones. It was suggested earlier that certain polar lipids and surfactants, such as polysorbate 80 (42), Capmul® PG-8 (32), Cremophor® EL (32) and monoolein (55) may be incorporated in the amorphous region of the solid PEG. By confocal Raman microscopic analysis study, Ping et al. (32) demonstrated that Capmul® PG-8 was interspersed as a separate liquid phase within the solid matrix of PEG 3350 and the drug remained dissolved in the lipid phase (32). The results of the present investigation with both PEG 8000 and poloxamer 188 are in agreement with this mechanism of lipid entrapment. Distinct crystalline and amorphous zones of lipid-poloxamer mixture are visible in Fig. 6(c, d, and e), where the lipid is present in the amorphous zone. By using a schematic diagram of PEG structures, Morris et al. (42) proposed that chains of PEG protrude from the crystalline zone to the amorphous zone and such polymeric chains were responsible for immobilizing polysorbate 80 within PEG-polysorbate solid mixtures. Similarly, all the poloxamer 188 in Fig. 6 may not exist as crystalline spherulites and a certain fraction may extend from the crystalline zone into the amorphous zone, which may be responsible for stabilizing lipids within the system.

Only the monoesters formed homogeneous solid masses in combination with poloxamer 188. When di- and tri-esters were used in place of monoesters, poloxamer 188 solidified from molten mixture at the bottom of vials used and the lipid produced a separate phase at the top of it. The difference between entrapment of monoesters and di-or tri-esters may possibly be explained by observations made in the present study with respect to miscibility of lipids with poloxamer 188 at elevated temperature. In the molten state at 70–75°C, it was observed that the di- and tri-esters were not fully miscible with poloxamer 188, and, for this reason, they were mixed by vortexing before cooling. On the other hand, the monoglycerides and PG monoesters were fully miscible. Thus, when the homogeneous mixtures of poloxamer 188 and monoesters were cooled to room temperature, poloxamer188 solidified and the monoesters remained trapped within the microstructure. On the other hand, when the miscibility between poloxamer 188 and the lipids (di- and tri-glycerides) was low, it is possible that no such entrapment of lipids occurred. Tejwani et al. (56) observed by using various liquid polyethylene glycols and polysorbate 80 that the two components were miscible at high temperatures and they phase separated once cooled to room temperature. Further studies are needed to elucidate the mechanism of why certain lipids are more miscible with poloxamer 188 than the others.

CONCLUSIONS

Solid self-emulsifying drug delivery system was successfully prepared using poloxamer 188 as solidifying agent and thus the need for a liquid surfactant could be avoided or minimized and the lipid content could be increased. The drug may be incorporated in solid systems as solutions in lipids. We demonstrated that the lipids containing higher proportion of monoesters in their composition were able to form solid systems with poloxamer 188. Further, it was confirmed by DSC, powder XRD and microscopic studies that poloxamer 188 retained its crystalline structures in the system and the lipid was interspersed in between crystalline structures as a separate phase. The PG monoesters demonstrated higher drug solubility than the glyceryl monoesters. The combination of PG monoesters with glyceryl monoester resulted into the formation of microemulsion which was not possible by PG monoester alone. Thus, this report presents a novel drug delivery system where the drug can be solubilized in liquid lipids and then the lipidic solutions can be hardened into solid mass by dispersing into the microstructure of solid poloxamer 188. Depending on the structure of lipids, microemulsions could be obtained after dispersion of solid mixtures.

REFERENCES

Lipinski CA, Lombardo F, Dominy BW, Feeney PJ. Experimental and computational approaches to estimate solubility and permeability in drug discovery and development settings. Adv Drug Deliv Rev. 2001;46(1–3):3–26.

Hörter D, Dressman J. Influence of physicochemical properties on dissolution of drugs in the gastrointestinal tract. Adv Drug Deliv Rev. 2001;46(1–3):75–87.

Humberstone AJ, Charman WN. Lipid-based vehicles for the oral delivery of poorly water soluble drugs. Adv Drug Deliv Rev. 1997;25(1):103–28.

Porter CJH, Pouton CW, Cuine JF, Charman WN. Enhancing intestinal drug solubilisation using lipid-based delivery systems. Adv Drug Deliv Rev. 2008;60(6):673–91.

Gursoy RN, Benita S. Self-emulsifying drug delivery systems (SEDDS) for improved oral delivery of lipophilic drugs: drug delivery and drug efficacy. Biomed Pharmacother. 2004;58(3):173–82.

Strickly RG. Currently marketed oral lipid-based dosage forms: drug products and excipients. In: Hauss D, editor. Lipid-based formulations for oral drug delivery: enhancing bioavailability of poorly water-soluble drugs. New York: Informa Healthcare; 2007. p. 1–31.

Shah NH, Carvajal MT, Patel CI, Infeld MH, Malick AW. Self-emulsifying drug delivery systems (SEDDS) with polyglycolyzed glycerides for improving in vitro dissolution and oral absorption of lipophilic drugs. Int J Pharm. 1994;106(1):15–23.

Bachynsky MO, Shah NH, Patel CI, Malick AW. Factors affecting the efficiency of a self-emulsifying oral delivery system. Drug Dev Ind Pharm. 1997;23(8):809–16.

Pouton CW. Formulation of self-emulsifying drug delivery systems. Adv Drug Deliv Rev. 1997;25(1):47–58.

Pouton CW. Lipid formulations for oral administration of drugs: non-emulsifying, self-emulsifying and ‘self-microemulsifying’ drug delivery systems. Eur J Pharm Sci. 2000;11:S93–8.

Pouton CW. Formulation of poorly water-soluble drugs for oral administration: physicochemical and physiological issues and the lipid formulation classification system. Eur J Pharm Sci. 2006;29(3–4):278–87.

Hauss DJ. Oral lipid-based formulations. Adv Drug Deliv Rev. 2007;59(7):667–76.

Jannin V, Musakhanian J, Marchaud D. Approaches for the development of solid and semi-solid lipid-based formulations. Adv Drug Deliv Rev. 2008;60(6):734–46.

Vasanthavada M, Serajuddin ATM. Lipid-based self-emulsifying solid dispersions. In: Hauss D, editor. Lipid-based formulations for oral drug delivery: enhancing bioavailability of poorly water soluble drugs. New York: Informa Healthcare; 2007. p. 149–84.

Savolainen M, Khoo C, Glad H, Dahlqvist C, Juppo AM. Evaluation of controlled-release polar lipid microparticles. Int J Pharm. 2002;244(1–2):151–61.

Desai D, Kothari S, Chen W, Wang J, Huang M, Sharma L. Fatty acid and water–soluble polymer–based controlled release drug delivery system. J Pharm Sci. 2011;100(5):1900–12.

Aoshima H, Miyagisnima A, Nozawa Y, Sadzuka Y, Sonobe T. Glycerin fatty acid esters as a new lubricant of tablets. Int J Pharm. 2005;293(1–2):25–34.

Tang B, Cheng G, Gu JC, Xu CH. Development of solid self-emulsifying drug delivery systems: preparation techniques and dosage forms. Drug Discov Today. 2008;13(13–14):606–12.

Cole ET, Cadé D, Benameur H. Challenges and opportunities in the encapsulation of liquid and semi-solid formulations into capsules for oral administration. Adv Drug Deliv Rev. 2008;60(6):747–56.

Ito Y, Kusawake T, Ishida M, Tawa R, Shibata N, Takada K. Oral solid gentamicin preparation using emulsifier and adsorbent. J Control Release. 2005;105(1–2):23–31.

Patil P, Paradkar A. Porous polystyrene beads as carriers for self-emulsifying system containing loratadine. AAPS PharmSciTech. 2006;7(1):E1–7.

Abdalla A, Klein S, Mäder K. A new self-emulsifying drug delivery system (SEDDS) for poorly soluble drugs: characterization, dissolution, in vitro digestion and incorporation into solid pellets. Eur J Pharm Sci. 2008;35(5):457–64.

Agarwal V, Siddiqui A, Ali H, Nazzal S. Dissolution and powder flow characterization of solid self-emulsified drug delivery system (SEDDS). Int J Pharm. 2009;366(1–2):44–52.

Wang Z, Sun J, Wang Y, Liu X, Liu Y, Fu Q, Meng P, He Z. Solid self-emulsifying nitrendipine pellets: preparation and in vitro/in vivo evaluation. Int J Pharm. 2010;383(1–2):1–6.

Tan A, Davey AK, Prestidge CA. Silica-Lipid Hybrid (SLH) versus non-lipid formulations for optimising the dose-dependent oral absorption of celecoxib. Pharm Res. 2011;28(9):2273–87.

Hansen T, Holm P, Schultz K. Process characteristics and compaction of spray-dried emulsions containing a drug dissolved in lipid. Int J Pharm. 2004;287(1–2):55–66.

Dollo G, Le Corre P, Guérin A, Chevanne F, Burgot JL, Leverge R. Spray-dried redispersible oil-in-water emulsion to improve oral bioavailability of poorly soluble drugs. Eur J Pharm Sci. 2003;19(4):273–80.

Yi T, Wan J, Xu H, Yang X. A new solid self-microemulsifying formulation prepared by spray-drying to improve the oral bioavailability of poorly water soluble drugs. Eur J Pharm Biopharm. 2008;70(2):439–44.

Nazzal S, Nutan M, Palamakula A, Shah R, Zaghloul AA, Khan MA. Optimization of a self-nanoemulsified tablet dosage form of Ubiquinone using response surface methodology: effect of formulation ingredients. Int J Pharm. 2002;240(1–2):103–14.

Nazzal S, Khan MA. Controlled release of a self-emulsifying formulation from a tablet dosage form: Stability assessment and optimization of some processing parameters. Int J Pharm. 2006;315(1–2):110–21.

Nazzal S, Zaghloul AA, Khan MA. Effect of Extragranular Microcrystalline Cellulose on compaction, surface roughness, and in vitro dissolution of a self-nanoemulsified solid dosage forms of ubiquinone. Pharm Tech. 2002;26:86–98.

Li P, Hynes SR, Haefele TF, Pudipeddi M, Royce AE, Serajuddin ATM. Development of clinical dosage forms for a poorly water–soluble drug II: formulation and characterization of a novel solid microemulsion preconcentrate system for oral delivery of a poorly water–soluble drug. J Pharm Sci. 2009;98(5):1750–64.

Margulis-Goshen K, Kamyshny A, Magdassi S. Applications of surfactants in pharmaceutical dosage forms. In: Zoller U, editor. Handbook of detergents, part E: applications. Boca Raton: CRC; 2008. p. 455–66.

Vippagunta SR, Maul KA, Tallavajhala S, Grant DJW. Solid-state characterization of nifedipine solid dispersions. Int J Pharm. 2002;236(1–2):111–23.

Chen Y, Zhang GGZ, Neilly J, Marsh K, Mawhinney D, Sanzgiri YD. Enhancing the bioavailability of ABT-963 using solid dispersion containing Pluronic F-68. Int J Pharm. 2004;286(1–2):69–80.

Brüsewitz C, Schendler A, Funke A, Wagner T, Lipp R. Novel poloxamer-based nanoemulsions to enhance the intestinal absorption of active compounds. Int J Pharm. 2007;329(1–2):173–81.

Fernandez-Tarrio M, Yañez F, Immesoete K, Alvarez-Lorenzo C, Concheiro A. Pluronic and Tetronic copolymers with polyglycolyzed oils as self-emulsifying drug delivery systems. AAPS PharmSciTech. 2008;9(2):471–9.

Rowe RC, Sheskey PJ, Weller PJ. Handbook of pharmaceutical excipients. London: Pharmaceutical; 2006. p. 447–50.

Cannon JB, Long MA. Emulsions, microemulsions, and lipid-based drug delivery systems for drug solubilization and delivery-Part II: Oral applications. In: Liu R, editor. Water-insoluble drug formulation. Boca Raton: CRC; 2008. p. 227–53.

Prajapati HN, Dalrymple DM, Serajuddin ATM. A comparative evaluation of mono, di and triglyceride of medium chain fatty acids by lipid/surfactant/water phase diagram, solubility determination and dispersion testing for application in pharmaceutical dosage form development. Pharm Res. 2012;29(1):285–305.

Amidon GL, Lennernäs H, Shah VP, Crison JR. A theoretical basis for a biopharmaceutic drug classification: the correlation of in vitro drug product dissolution and in vivo bioavailability. Pharm Res. 1995;12(3):413–20.

Morris KR, Knipp GT, Serajuddin ATM. Structural properties of polyethylene glycol—polysorbate 80 mixture, a solid dispersion vehicle. J Pharm Sci. 1992;81(12):1185–8.

Law TK, Whateley TL, Florence AT. Some chemically modified poloxamer hydrogels: preparation, morphology and swelling properties. Int J Pharm. 1984;21(3):277–87.

Ginés JM, Arias MJ, Moyano JR, Sánchez-Soto PJ. Thermal investigation of crystallization of polyethylene glycols in solid dispersions containing oxazepam. Int J Pharm. 1996;143(2):247–53.

Hosier IL, Bassett DC, Vaughan AS. Spherulitic growth and cellulation in dilute blends of monodisperse long n-alkanes. Macromolecules. 2000;33:8781–90.

Gránásy L, Pusztai T, Tegze G, Warren JA, Douglas JF. Growth and form of spherulites. Phys Rev E. 2005;72(1):011605.

Billmeyer Jr FW, Ceil PH, van der Weg KR. Growth and observation of spherulites in polyethylene: a high polymer demonstration. J Chem Educ. 1960;37(9):460–1.

Mohsin K, Long MA, Pouton CW. Design of lipid–based formulations for oral administration of poorly water–soluble drugs: precipitation of drug after dispersion of formulations in aqueous solution. J Pharm Sci. 2009;98(10):3582–95.

Yagi N, Terashima Y, Kenmotsu H, Sekikawa H, Takada M. Dissolution behavior of probucol from solid dispersion systems of probucol-polyvinylpyrrolidone. Chem Pharm Bull. 1996;44(1):241–4.

Nielsen FS, Gibault E, Ljusberg-Wahren H, Arleth L, Pedersen JS, Müllertz A. Characterization of prototype self–nanoemulsifying formulations of lipophilic compounds. J Pharm Sci. 2007;96(4):876–92.

Rane SS, Anderson BD. What determines drug solubility in lipid vehicles: is it predictable? Adv Drug Deliv Rev. 2008;60(6):638–56.

Kommuru TR, Gurley B, Khan MA, Reddy IK. Self-emulsifying drug delivery systems (SEDDS) of coenzyme Q10: formulation development and bioavailability assessment. Int J Pharm. 2001;212(2):233–46.

Craig D. Polyethyelene glycols and drug release. Drug Dev Ind Pharm. 1990;16(17):2501–26.

Craig DQM. A review of thermal methods used for the analysis of the crystal form, solution thermodynamics and glass transition behaviour of polyethylene glycols. Thermochim Acta. 1995;248:189–203.

Mahlin D, Ridell A, Frenning G, Engström S. Solid-state characterization of PEG 4000/monoolein mixtures. Macromolecules. 2004;37(7):2665–7.

Tejwani RW, Joshi HN, Varia SA, Serajuddin A. Study of phase behavior of poly (ethylene glycol)–polysorbate 80 and poly (ethylene glycol)–polysorbate 80–water mixtures. J Pharm Sci. 2000;89(7):946–50.

ACKNOWLEDGMENTS & DISCLOSURES

The authors thank ABITEC Corp., 501 W 1st Avenue, Columbus, OH 43215, USA for a research grant that partially supported this project. They also thank Mr. Louis E. Bryan from the department of Biological Sciences, St. John’s University, for his assistance in confocal fluorescence microscopic analysis of samples.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shah, A.V., Serajuddin, A.T.M. Development of Solid Self-Emulsifying Drug Delivery System (SEDDS) I: Use of Poloxamer 188 as Both Solidifying and Emulsifying Agent for Lipids. Pharm Res 29, 2817–2832 (2012). https://doi.org/10.1007/s11095-012-0704-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-012-0704-x