Abstract

Purpose

To compare the physical stability of amorphous molecular level solid dispersions of nifedipine and felodipine, in the presence of poly(vinylpyrrolidone) (PVP) and small amounts of moisture.

Methods

Thin amorphous films of nifedipine and felodipine and amorphous molecular level solid dispersions with PVP were stored at various relative humidities (RH) and the nucleation rate was measured. The amount of water sorbed at each RH was measured using isothermal vapor sorption and glass transition temperatures (T g) were determined using differential scanning calorimetry. The solubility of each compound in methyl pyrrolidone was measured as a function of water content.

Results

Nifedipine crystallizes more easily than felodipine at any given polymer concentration and in the presence of moisture. The glass transition temperatures of each compound, alone and in the presence of PVP, are statistically equivalent at any given water content. The nifedipine systems are significantly more hygroscopic than the corresponding felodipine systems.

Conclusions

Variations in the physical stability of the two compounds could not be explained by differences in T g. However, the relative physical stability is consistent with differences in the degree of supersaturation of each drug in the solid dispersion, treating the polymer and water as a co-solvent system for each drug compound.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Water may associate with pharmaceutical solids by several processes including adsorption onto surfaces, capillary condensation into very small pores, formation of hydrates, deliquescence, and through absorption into amorphous materials (1). Amorphous materials have an increased hygroscopicity relative to their crystalline counterparts since water can be absorbed into their internal structure in addition to being adsorbed at the surface (1,2). Following the absorption of water, the glass transition temperature is reduced and the systems are described as being plasticized (3). Reducing the glass transition temperature effectively increases the molecular mobility at room temperature (4–8). This increased molecular mobility may facilitate crystallization as shown for indomethacin (9) and lamotrigine mesylate (10). One common approach to decrease the rate of crystallization with the aim of maintaining a stable amorphous form over the shelf life of the material is to add polymers of high glass transition temperature (11–22). However, these polymers are most often more hygroscopic than the amorphous drug with which they are mixed thereby increasing the potential for water sorption from the environment. This increased water sorption will in turn lead to a reduced glass transition temperature and increased molecular mobility relative to the dry amorphous molecular level solid dispersion. Thus, there is a competing effect between the increased glass transition temperature imparted by the high molecular weight additive and the increased hygroscopicity due to the addition of the polymer.

From a thermodynamic perspective, the stability of a crystallizable component in the amorphous molecular level solid dispersion can also be described in terms of its chemical potential. As shown in Eq. 1, the difference between the chemical potential of the compound in a supersaturated solution, μ1, and the compound at the solubility limit, μ0, can be described as the degree of supersaturation (23,24), σ, and provides the thermodynamic driving force for crystallization (25) with R equal to the universal gas constant and T the absolute temperature.

A miscible polymer acts to reduce the chemical potential of a drug thereby reducing the thermodynamic driving force for crystallization (25). However, if the polymer used to formulate the amorphous molecular level solid dispersions increases the overall hygroscopicity of the system, the increased water content could increase the chemical potential of a hydrophobic drug in the dispersion thereby increasing the degree of supersaturation and the thermodynamic driving force for crystallization. So, again there is a competing effect between adding a polymer and increasing the hygroscopicity of the system—this time thermodynamic in nature. Since it is virtually impossible to formulate amorphous systems with zero moisture content, it is important to investigate the influence of moisture on the physical stability of amorphous molecular level solid dispersions. In this study, the nucleation rates of two structural analogues, nifedipine and felodipine, formulated as amorphous solid dispersions with the hydrophilic polymer, poly(vinylpyrrolidone) (PVP), have been investigated as a function of storage relative humidity (RH).

MATERIALS

Felodipine was a generous gift from AstraZeneca, Södertälje, Sweden, and nifedipine was obtained from Hawkins, Inc, Minneapolis, MN, USA. Poly(vinylpyrrolidone) K29/32 (PVP) and acetone were purchased from Sigma-Aldrich Co., St. Louis, MO, USA. Dichloromethane and ethanol were obtained from Mallinckrodt Baker, Inc., Paris, KY, USA and Aaper Alcohol and Chemical Co., Shelbyville, KY, USA, respectively.

METHODS

Preparation of Spin-Coated Films on Glass Substrates

Spin-coating was performed using a KW-4A spin-coater (Chemat Technology Inc., Northridge, CA, USA) inside a glovebox at a relative humidity of less than 10%. Nifedipine or felodipine and PVP K29/32 were dissolved together in a suitable solvent; 50:50 wt% dichloromethane/ethanol or acetone. A small drop of the solution was then placed on a clean, rotating glass microscope coverslip and the resulting film was heated to 90°C for several minutes to remove remaining volatiles. The resulting optically transparent film was immediately placed in a desiccator over a salt solution or phosphorous pentoxide.

Controlled Relative Humidity Storage Conditions

Materials were stored at various relative humidities using desiccators and saturated salt solutions (26) of lithium chloride (11%RH), potassium acetate (22%RH), magnesium chloride (33%RH), potassium carbonate (43%RH), magnesium nitrate (53%RH), sodium bromide (58%RH), sodium nitrite (64%RH), and sodium chloride (75%RH). Samples quoted as 0%RH were stored over phosphorous pentoxide.

Evaluation of Nucleation Rate with Optical Microscopic Observation

Samples were removed from the desiccators at each time point and the nucleation site number density was determined using an Olympus BHS polarized light microscope at 10×–50× magnification (Olympus Co., Tokyo, Japan). A total of 12 different sections of the film were analyzed for each of the triplicate samples at each time point. The site number density per unit volume was calculated from the site number density per unit area and the depth of field of the appropriate lens (27). The depth of field (D tot) as a function of the wavelength of the light used (λ = 550 nm) and the numerical aperture (NA) of the lens is given in Eq. 2 (28).

Where n is the refractive index of the medium (n air = 1.000), e is the smallest distance that can be resolved by a detector (e = 14 μm) and M is lateral magnification. For example, based on these calculations, D tot was 0.0144 mm for the 10× objective. The corresponding nucleation rate was determined by taking the slope of the site number density per unit volume as a function of time and is quoted in units of #/m3/s.

In some cases preferential nucleation and growth appeared at the periphery of the films; these sites were not included in the analysis.

Preparation of Bulk Amorphous Materials

Amorphous felodipine and nifedipine were prepared for thermal analysis by in situ melting and cooling of the crystalline material in the differential scanning calorimeter (DSC). Amorphous molecular level dispersions of the drugs and the polymer were prepared by solvent evaporation. PVP K29/32 was dried over phosphorous pentoxide for no less than 1 week, mixed with nifedipine or felodipine in a glovebox, and then dissolved in 100% ethanol. The solvent was then removed using a rotary evaporator apparatus (Brinkman Instruments, Westbury, NY, USA). The samples were placed under vacuum for at least 12 h prior to DSC or vapor sorption experiments.

Vapor Sorption Isotherms

Water uptake of pure amorphous nifedipine and felodipine and amorphous molecular level solid dispersions containing PVP were measured using a symmetrical gravimetric analyzer (SGA-100; VTI corporation, Hialeah, FL, USA) at 25°C. Bulk samples prepared as described above were heated to just above the melting temperature of the drug to ensure that no crystalline material remained and gently ground in a glovebox at relative humidity less than 10%. Ten to fifteen milligrams of sample were then loaded into the gravimetric analyzer, dried for 3 h at 25°C under nitrogen, and subsequently exposed to a relative humidity of 5, 15, 25, 35, 45, 55, 65, and 75%RH in separate experiments. The samples were left at each RH until a plateau in the weight gain profile was reached; about 600 min for the pure amorphous drugs and about 1,000 min for the amorphous molecular level solid dispersions. Reported vapor sorption isotherms are those values recorded at the plateau of each individual experiment at each RH.

Glass Transition Temperature

The glass transition temperature (T g) was measured using a TA 2920 Modulated DSC equipped with a refrigerated cooling accessory (TA Instruments, New Castle, DE, USA). Operating in standard mode, the instrument was calibrated for temperature using benzophenone (Sigma-Aldrich Inc., St. Louis MO, USA) and indium (Perkin-Elmer Corporation, Norwalk, CT, USA) and the enthalpic response was calibrated using indium. Nitrogen, 45 ml/min, served as the purge gas and reference and sample pans were matched for weight to within 0.01 mg.

Bulk samples prepared as described above were heated to just above the melting temperature of the drug to ensure that no crystalline material remained and gently ground in a glovebox at a relative humidity less than 10%. Samples of 4–6 mg were weighed into open DSC sample pans and then placed in desiccators at 0, 11, 22, 33, 43, 53, 64, and 75%RH. After a plateau in water uptake was reached, as indicated by the timescale for plateau as measured by the vapor sorption experiments, the samples were removed, immediately hermetically sealed, and placed in the DSC, cooled to −20°C and then heated to just above the melting temperature of the drug at 10°C/min. No ice melt was observed indicating that the water did not form crystals during the cooling process and was intimately associated with the dispersion.

Solubility Measurements

The solubility of nifedipine and felodipine in 1-methyl-2-pyrrolidone was measured using a Cary 50 UV-Vis Spectrophotometer (Varian Inc., Palo Alto, CA). An excess of crystalline material was added to a capped jacketed glass vessel containing 1-methyl-2-pyrrolidone maintained at 25°C for at least 24 h under vigorous stirring and in the absence of light. The mother liquor was decanted, centrifuged using an Eppendorf Centrifuge 5451C (Eppendorf AG, Germany), and filtered using a 0.2 μm Nalgene SFCA syringe filter (Nalgene Company, Rochester, NY). Samples were diluted with ethanol and compared to a standard concentration curve.

RESULTS

Nucleation Rate

Figure 1 shows the nucleation rate of nifedipine and felodipine at 0, 11, 33, 58 and 75% RH as a function of PVP concentration (wt%). For all systems, nifedipine shows a higher rate of nucleation than felodipine at any given polymer concentration and relative humidity. For both nifedipine and felodipine systems at 0%RH, the nucleation rate decreases dramatically with the addition of only 7% PVP followed by a less dramatic decrease in nucleation rate upon subsequent increases in PVP as described previously (22,29). As the relative humidity is increased, the initial decrease in nucleation rate with the addition of 7% PVP is less dramatic. At 75%RH, the effect is even less pronounced and the nucleation rate decreases according to a log linear relationship over the entire polymer concentration range. Finally, it is noted that at any given polymer concentration, the nucleation rate of the nifedipine systems is more sensitive to increased relative humidity than the corresponding felodipine systems. For instance, for the nifedipine dispersion containing 7% PVP, the nucleation rate increases by a factor of about 400 when comparing the dry dispersion to the dispersion stored at 75%RH. The corresponding felodipine system with 7% PVP shows an increase in nucleation rate by a factor of about 100. A comparison between the two amorphous molecular level solid dispersions containing 25% PVP also shows that nifedipine has a greater sensitivity to increased relative humidity. For this polymer concentration, it is interesting to note that the increase in nucleation rate with increasing relative humidity persists in the nifedipine system whereas the increase in nucleation rate becomes less significant in the case of felodipine. In other words, the difference between the nucleation rate of felodipine at 75%RH and 0%RH is greater at low polymer concentration than it is at high polymer concentration whereas the difference in nucleation rate for the corresponding nifedipine systems is less dependent on polymer concentration.

Nucleation rates of nifedipine (a) and felodipine (b) as a function of PVP concentration measured at 25°C using optical microscopy at 0% RH (open triangle), 11% RH (filled square), 33% RH (open diamond), 58% RH (filled circle), and 75% RH (open square). Error bars represent one standard deviation, n = 3.

Figure 2 shows the nucleation rate of nifedipine and felodipine systems as a function of relative humidity. This figure clearly shows how the nucleation rate of each system increases as a function of storage RH. The pure compounds show a similar extent of increase in nucleation rate as a function of RH. However, the nifedipine solid dispersions show a greater increase in nucleation rate as a function of RH than the corresponding felodipine solid dispersions. Consider the nucleation rate of nifedipine dispersed with 25% PVP as compared to the nucleation rate of felodipine dispersed with 25% PVP. The nifedipine system shows an increase in nucleation rate from about 2,000/m3/s (0%RH) to 400,000/m3/s (75%RH) while the corresponding felodipine system shows an increase from roughly 300/m3/s (0%RH) to 2,000/m3/s (75%RH).

Nucleation rate as a function of storage relative humidity: nifedipine with PVP (a) and felodipine with PVP (b). Symbols represent values of samples which contain 0% (open circle), 7% (filled circle), 10 % (open triangle), 15% (filled triangle), 20% (open square) and 25% (filled square) PVP. Error bars represent one standard deviation, n = 3.

The water sorption in nifedipine, felodipine, and PVP from 5–75%RH at 10% intervals was measured and, as expected, the amount of sorbed water increases with increasing relative humidity. At any given relative humidity, nifedipine sorbs more water than felodipine, as shown in Fig. 3. Consistent with literature reports (30,31), PVP takes up a significant amount of water since it is a very hygroscopic polymer (data not shown). The water sorption of nifedipine and felodipine systems prepared as amorphous molecular level solid dispersions with 10 and 25% PVP were also measured and the data are shown in Fig. 3. Consistent with the pure materials, for a given polymer concentration, the nifedipine systems sorb more water than the corresponding felodipine systems at each relative humidity. It was also noted that the amorphous molecular level solid dispersions took significantly more time to “equilibrate” at any given relative humidity when compared to the pure drugs (roughly 1,000 vs 600 min, data not shown).

Using the data presented in Fig. 3, selected nucleation rates are shown as a function of water content (Fig. 4). The most dramatic conclusion that can be drawn from these data is that the nucleation rate is less sensitive to water content when the concentration of polymer is increased. Specifically, larger increases in water content are necessary to increase the nucleation rate at higher polymer concentrations than at relatively lower polymer concentrations. Furthermore, as discussed above, for a given water content, most nifedipine systems crystallize more easily than the corresponding felodipine systems and the difference in the rate of nucleation between the two compounds is exaggerated as the polymer concentration is increased.

Thermal Analysis

It is expected that the glass transition temperature of these systems will be depressed in the presence of moisture (3) thereby increasing the molecular mobility of the compounds (4–8) which presumably decreases the activation energy for crystallization. The glass transition temperatures of nifedipine, felodipine, and amorphous molecular level solid dispersions containing 10% and 25% PVP by weight are presented in Fig. 5 as a function of relative humidity. From these data it is clear that storage at increased relative humidity decreases the glass transition temperature for both drug compounds alone and in the presence of PVP. Furthermore, the glass transition temperature at high relative humidity is similar in all systems. That is, the T g is depressed even further in systems containing PVP than in the pure drug systems. This observation is consistent with the fact that amorphous molecular level solid dispersions with higher concentration of PVP are more hygroscopic. At this point it is useful to note that the glass transition temperatures of each nifedipine and felodipine system as a function of relative humidity are statistically equivalent with the exception of the two pure systems in which nifedipine shows a lower T g than felodipine at a relative humidity greater than 54%.

When viewing the data in terms of water content, as shown in Fig. 6, it is clear that the T g is reduced to a greater extent in the pure drug systems than in the drug-polymer systems for a given amount of sorbed water. For instance, it takes a much larger amount of water to depress the T g by 10°C in the amorphous molecular level solid dispersions than it does in the pure amorphous drugs. This result suggests that water is a more effective plasticizer for the drug alone than it is in the solid dispersions. It is further noted that when comparing the two systems at any given polymer concentration, the glass transition temperature of each as a function of water content are statistically equivalent.

Figure 7 compares the nucleation rates of nifedipine and felodipine as a function of the difference between the glass transition temperature and the temperature at which nucleation was measured. It is clear from these data that the difference in nucleation rate between the two compounds for a given system is independent of the difference between the glass transition temperature and the crystallization temperature. Specifically, with the exception of a few data points for the pure compounds, nifedipine shows a higher rate of nucleation than the corresponding felodipine systems at a given T g − T. Clearly, the difference between the crystallization rates of these systems is not explained exclusively by the difference between the glass transition temperature and the nucleation temperature.

As expected, the nucleation rate decreases with increasing T g − T for nifedipine, felodipine, and amorphous molecular level solid dispersions of nifedipine and felodipine with PVP. For instance, pure felodipine shows about 1 order of magnitude reduction in nucleation rate in going from a T g − T of 8 to a T g − T of 21. With the addition of 10 wt% PVP, felodipine shows about 2 orders of magnitude reduction in nucleation rate in going from a T g − T of 7 to a T g − T of 23. Finally, with the addition of 25 wt% PVP, felodipine shows about 1 order of magnitude difference in nucleation rate in going from a T g − T of 3 to a T g − T of 23. Nifedipine also shows a reduction in nucleation rate with increasing T g − T. Pure nifedipine shows 1 order of magnitude reduction, nifedipine with 10 wt% PVP shows 2 orders of magnitude reduction, and nifedipine with 25 wt% PVP shows 2 orders of magnitude reduction over the range of T g − T values studied for each system, respectively. Moreover, it is interesting to note that for a given T g − T there is also a dramatic reduction in nucleation rate with increasing polymer concentration. Consider the nucleation rate of felodipine alone and in the presence of PVP at T g − T = 15°C. With the addition of 10% PVP, there is an order of magnitude reduction in nucleation rate and with the addition of 25% PVP, there is two orders of magnitude reduction in the nucleation rate. Therefore, it is clear that the glass transition temperature alone does not describe the behavior of these systems.

DISCUSSION

Competing Factors—Increased Polymer Content and Accompanying Increased Water Content

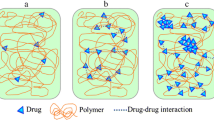

Crystallization from the amorphous form has been extensively studied in the pharmaceutical arena (27,32–38). The addition of a miscible polymer to an amorphous drug to form a single-phase amorphous molecular level solid dispersion has been shown to enhance the physical stability of the system (14–16,18,20,39). Although the addition of a hydrophilic polymer may also increase the hygroscopicity of the amorphous form and the balance between these two competing factors is of critical interest, there has been little work to understand the relative importance of increased polymer concentration and the accompanying increased water content. Specifically, there is a competing effect of decreased molecular mobility due to increased polymer content and increased molecular mobility due to increased hygroscopicity. Furthermore, miscible polymers will reduce the chemical potential of the amorphous drug, thereby decreasing the thermodynamic driving force (degree of supersaturation) for crystallization (25) and this may act as an additional stabilizing mechanism. However, as mentioned previously, the addition of water soluble polymers increases the overall hygroscopicity of the amorphous molecular level solid dispersion and the effect of absorbed moisture on the chemical potential of the drug needs to be considered. Borrowing a term from solution theory, water can be thought of as an “anti-solvent” for the hydrophobic drug in the hydrophilic polymer since it may act to increase the chemical potential of the drug in the dispersion relative to the chemical potential in the dry dispersion. For the nifedipine and felodipine systems presented in this work, it is clear that the benefits of the polymer outweigh the drawbacks of increased water content as shown in Figs 1, 2, and 4. The discussion that follows will explore the kinetic and thermodynamic changes resulting from the presence of a small amount of water (<6% for the systems studied here) in amorphous molecular level solid dispersions of nifedipine and felodipine with PVP.

Kinetics of Crystallization

Although the kinetics are likely to be complex in the presence of both a polymer and water, and little work has been performed to study the mechanism of such effects, the influence of the polymer on the kinetics of crystallization is well known. For instance, the presence of the polymer has been shown to increase the activation energy for crystallization (29) and also potentially act as a physical barrier to crystallization (22) in the absence of moisture. Presumably, it will impart a similar effect in the presence of a given amount of water. Moreover, the mobility may be reduced by coupling molecular motions through molecular interactions (40).

One common metric used to understand the activation energy associated with crystallization (that is the mobility barrier to crystallization) is the glass transition temperature. Several studies have shown that the crystallization tendency decreases as one cools to temperatures below the glass transition temperature (22,29,35,37). Although this parameter serves as an important indicator of crystallization tendency, it has been argued that modes of molecular mobility not reflected by the T g must also be considered (20,41). For example, the molecular mobility, as measured by DSC, of several binary systems have been reported to be reduced relative to the molecular mobility of the pure drug despite having a similar glass transition temperature (29,42). Furthermore, based on the data shown here, it is clear that for a given T − T g, the nucleation rate can vary by several orders of magnitude as seen by comparing the data shown in Fig. 7. Therefore, the glass transition temperature does not provide a complete description of the reduced rate of nucleation of nifedipine and felodipine in the presence of polymer and water.

Furthermore, the differences in the crystallization tendency between the two compounds cannot be explained by differences in the glass transition temperature or the difference between the glass transition temperature and the nucleation temperature (also shown in Fig. 7). Clearly, for a given T g − T, the nucleation rate of nifedipine is consistently higher than for the corresponding felodipine amorphous molecular level solid dispersions. The exception is for the pure drugs where the nucleation rates are quite similar when the T g − T approaches values below 15°C. Therefore, one must conclude that other factors are dictating the relative physical stability of the two compounds. One notable difference is in the relative stability of the pure amorphous materials. It has been noted previously that the thermodynamic driving force for crystallization of the two compounds may contribute to the relative physical stability of each. In other words, the driving force for crystallization or the degree of supersaturation for nifedipine is larger than for the corresponding felodipine system both alone and in the presence of a given amount of PVP (25,29). However, this problem is complicated by the presence of water. Since the glass transition temperature does not explain the relative stability of these two compounds, it is useful to consider the thermodynamic consequences of adding small amounts of water to these amorphous molecular level solid dispersions.

Thermodynamic Consequences of Water Addition

The thermodynamic driving force for crystallization of amorphous nifedipine is greater than that of amorphous felodipine. This has been attributed to the larger enthalpic driving force for crystallization of nifedipine (29). Furthermore, the solubility limit of nifedipine in PVP was estimated to be lower than the corresponding felodipine system (25). This estimation is consistent with the measured solubility of each compound in a low molecular weight analog of PVP; methyl pyrrolidone. Specifically, the mole fraction solubility of nifedipine and felodipine in methyl pyrrolidone is 0.05 (±0.01) and 0.10 (±0.02), respectively. The solubility of a crystal in a liquid is given by Eq. 3.

This equation highlights the two component parts which contribute to the overall solubility of a compound in a solvent. The first term represents the energy required to break the crystal lattice and includes the enthalpy of fusion, ΔH fus, and the melting temperature, T M. The second term in the equation is the activity coefficient, γ, which represents the heat of mixing and any non-idealities in the entropy of mixing. An activity coefficient which is larger than 1 would occur with endothermic mixing and an activity coefficient which is less than 1 would result from exothermic mixing if the mixing entropy is ideal.

Both compounds give an activity coefficient of less than 1; the activity coefficient associated with a saturated solution of nifedipine in methyl pyrrolidone is 0.09 (±0.01), while the activity coefficient of felodipine in methyl pyrrolidone at its solubility limit is 0.30 (±0.05). Therefore, the lower mole fraction solubility of nifedipine can be attributed to the higher enthalpy of fusion and the higher melting temperature (nifedipine has a higher intrinsic tendency to crystallize). This is highlighted in Fig. 8 which shows the contribution of the crystal lattice energy (first term in Eq. 3) and the activity coefficient (second term in Eq. 3) to the overall solubility of nifedipine and felodipine in methyl pyrrolidone. Based on these data it would be expected that, at any given drug loading, and in the absence of water, the supersaturation and thus the thermodynamic driving force for crystallization of nifedipine should be larger than for felodipine due to the higher lattice energy associated with nifedipine (29).

The introduction of water further complicates the thermodynamics of the system. However, a consideration of the solubility of nifedipine and felodipine in methyl pyrrolidone, water, and co-solvent systems will provide some insight into the thermodynamics of the ternary systems studied here. The mole fraction solubility of nifedipine in water, 2.6 × 10−6 (±4.2 × 10−7), is higher than that of felodipine in water, 1.3 × 10−7 (±1.7 × 10−8). The corresponding activity coefficients in water are 1.89 × 103 (±3.03 × 102) for nifedipine and 2.43 × 105 (±3.37 × 104) for felodipine. These large and positive activity coefficients suggest strongly endothermic mixing (Fig. 8). Thus assuming a close to ideal entropy of mixing, it can be concluded that both compounds show exothermic mixing with methyl pyrrolidone (higher than ideal solubility) and endothermic mixing with water (lower than ideal solubility). Moreover, felodipine shows a higher solubility in methyl pyrrolidone due to its weaker lattice energy (first term in Eq. 3) while nifedipine shows a higher solubility in water due to its lower activity coefficient in water (second term in Eq. 3). The effect of water content on the solubility is further highlighted by Fig. 9 which shows that the solubility in the co-solvent system follows an approximately log-linear relationship for both nifedipine (logS = −0.04 × (wt% water) − 0.89, R 2 = 0.96) and felodipine (logS = −0.06 × (wt% water) − 0.56, R 2 = 0.98)—typical of many co-solvent systems (43). Based on these data, water is a stronger anti-solvent for felodipine than it is for nifedipine since felodipine shows a larger negative slope as a function of water content. Assuming that a similar “solubility” relationship exists in the solid dispersions, water is expected to be a stronger anti-solvent for felodipine than it is for nifedipine for any given amorphous molecular level solid dispersion of the same concentration of drug in PVP.

The consequences of this are two-fold; first, for a given amount of water, the relative increase in driving force for crystallization of felodipine will be larger than for the same nifedipine system, and second, felodipine, having a larger activity coefficient in water, should sorb less water (consistent with Fig. 3) at any particular relative humidity. The relative importance of these two competing effects is now explored and can explain—in part—the differences in crystallization tendency between the two compounds as shown in Figs 1, 2 and 4. Consider that nifedipine and felodipine are estimated to have the same solubility in the co-solvent system at a water content of about 25 wt%. In other words, for a given concentration of drug (whereby the concentration is higher than the thermodynamic solubility), the degree of supersaturation in a co-solvent containing about 25 wt% water will be the same for both nifedipine and felodipine. This concentration of water is higher than any concentration present in the systems studied here (as explained below). It can be seen from Fig. 9, that below 25 wt% water, nifedipine has a lower solubility than felodipine. Therefore, for any given ratio of drug to polymer, it would be expected that nifedipine has a larger extent of supersaturation. Furthermore, despite the fact that water is a stronger anti-solvent for felodipine, nifedipine sorbs more water at any particular relative humidity over all polymer and water concentrations studied here. Based on the thermodynamics alone, one would expect nifedipine to crystallize more easily—consistent with the observations shown in Figs 1, 2 and 4.

Next, it is useful to further consider the co-solvent concentration of the various amorphous molecular level solid dispersions. It was noted that the nucleation rate of the amorphous dispersions is less sensitive to water content as the concentration of polymer is increased. There are two explanations for this behavior. First, the addition of water may alter the kinetics of crystallization as described in the previous section. Second, from a thermodynamic standpoint, the degree of supersaturation should increase with increasing water content for a given polymer concentration. Alternatively, the degree of supersaturation must decrease with increasing polymer concentration for a given water content. Therefore, it is useful to consider the combined effect of increased polymer concentration and increased water content. This can be accomplished by considering the degree of supersaturation in the polymer/water co-solvent system. Specifically, as shown in Fig. 10, at a given relative humidity, although dispersions with higher polymer concentration sorb more water overall (see Fig. 3), the polymer/water “co-solvent” concentration may not remain as rich in water. To illustrate this point consider the difference between the amorphous molecular level solid dispersion of nifedipine with 10% PVP and 25% PVP at 75% relative humidity. The 10% dispersion contains 23 wt% water in the polymer/water co-solvent system (3 wt% water divided by 3 wt% water + 10 wt% PVP) while the 25% PVP dispersion contains only 18 wt% water in the polymer/water co-solvent system (5.5 wt% water divided by 5.5 wt% water + 25 wt% PVP). Therefore, the degree of supersaturation of nifedipine is greater in the 10% PVP dispersion than for the 25% dispersion—not only because there is less polymer to solubilize the drug but also because the equilibrium solubility is lower due to the higher relative concentration of water. Consider now the amorphous molecular level solid dispersions of felodipine with PVP. Although not as exaggerated as the nifedipine example, the amorphous molecular level solid dispersions of felodipine with 10 wt% PVP have a water/PVP co-solvent concentration which contains a higher relative concentration of water than the corresponding felodipine dispersion with 25% PVP. Therefore, as in the nifedipine systems, the degree of supersaturation of felodipine is greater in the 10% PVP dispersion than for the 25% dispersion not only because there is less polymer to solubilize the drug but also because the equilibrium solubility is lower due to the slightly higher concentration of water in the co-solvent system.

Based on the data presented above, it can be concluded that the relative physical stability of these two systems is not described by the differences in the glass transition temperature. However, it is reasoned that the supersaturation of the nifedipine systems is consistently higher than the corresponding supersaturation for the equivalent felodipine systems for two reasons. First, the dispersions studied herein are all supersaturated with respect to the estimated solubility in PVP (25). Second, although water acts as a stronger anti-solvent for the felodipine systems than for the nifedipine systems, the felodipine systems sorb less water. Therefore, the increase in the degree of supersaturation upon introduction of water is greater for the nifedipine systems than for the felodipine systems. This can be seen from Fig. 10 which shows that the PVP/water co-solvent systems are richer in water for the nifedipine systems than they are for the corresponding felodipine systems.

CONCLUSIONS

Nifedipine crystallizes more easily than felodipine in amorphous molecular level solid dispersions stored at various relative humidities. The relative crystallization tendency of the two compounds could not be explained by the glass transition temperature since at a given T g − T, nifedipine always crystallized more easily than the corresponding felodipine systems. The difference in crystallization tendency between these two systems was explained by the differences in the degree of supersaturation. Specifically, for a given polymer concentration, nifedipine exhibits a higher supersaturation than the felodipine systems. Furthermore, water acts as a strong anti-solvent for both nifedipine and felodipine in the amorphous molecular level solid dispersions. Nifedipine, however, takes up more water and therefore the supersaturation is increased to a greater extent than for the felodipine systems. In short, when considering the relative physical stability of amorphous molecular level solid dispersions, although the properties of the amorphous form are important, they do not completely describe physical stability. For the systems studied here, a consideration of the thermodynamic driving force for crystallization in terms of the overall supersaturation provides insight into the relative stability. Future work should include application of theories used for understanding crystallization from solution to these meta-stable amorphous materials. Furthermore, the activation energies associated with nucleation and the modes of molecular mobility providing rate limiting steps to nucleation deserve attention.

References

G. Zografi. States of water associated with solids. Drug Dev. Ind. Pharm. 14:1905–1926 (1988).

C. Ahlneck, and G. Zografi. The molecular-basis of moisture effects on the physical and chemical-stability of drugs in the solid-state. Int. J. Pharm. 62:87–95 (1990).

B. C. Hancock, and G. Zografi. The relationship between the glass-transition temperature and the water-content of amorphous pharmaceutical solids. Pharm. Res. 11:471–477 (1994).

B. Borde, H. Bizot, G. Vigier, and A. Buleon. Calorimetric analysis of the structural relaxation in partially hydrated amorphous polysaccharides. I. Glass transition and fragility. Carbohydr. Polym. 48:83–96 (2002).

S. P. Duddu, and T. D. Sokoloski. Dielectric analysis in the characterization of amorphous pharmaceutical solids .1. Molecular mobility in poly(vinylpyrrolidone) water-systems in the glassy state. J. Pharm. Sci. 84:773–776 (1995).

H. Hu, and C. T. Sun. The equivalence of moisture and temperature in physical aging of polymeric composites. J. Compos. Mater. 37:913–928 (2003).

D. P. Miller, and D. Lechuga-Ballesteros. Rapid assessment of the structural relaxation behavior of amorphous pharmaceutical solids: Effect of residual water on molecular mobility. Pharm. Res. 23:2291–2305 (2006).

S. Yoshioka, Y. Aso, and S. Kojima. Temperature- and glass transition temperature-dependence of bimolecular reaction rates in lyophilized formulations described by the Adam–Gibbs–Vogel equation. J. Pharm. Sci. 93:1062–1069 (2004).

V. Andronis, M. Yoshioka, and G. Zografi. Effects of sorbed water on the crystallization of indomethacin from the amorphous state. J. Pharm. Sci. 86:346–351 (1997).

E. Schmitt, C. W. Davis, and S. T. Long. Moisture-dependent crystallization of amorphous lamotrigine mesylate. J. Pharm. Sci. 85:1215–1219 (1996).

W. L. Chiou, and S. Riegelman. Pharmaceutical applications of solid dispersion systems. J. Pharm. Sci. 60:1281–1302 (1971).

J. L. Ford. The current status of solid dispersions. Pharm. Acta Helv. 61:69–88 (1986).

A. T. M. Serajuddin. Solid dispersion of poorly water-soluble drugs: Early promises, subsequent problems, and recent breakthroughs. J. Pharm. Sci. 88:1058–1066 (1999).

T. Miyazaki, S. Yoshioka, Y. Aso, and S. Kojima. Ability of polyvinylpyrrolidone and polyacrylic acid to inhibit the crystallization of amorphous acetaminophen. J. Pharm. Sci. 93:2710–2717 (2004).

G. Van den Mooter, M. Wuyts, N. Blaton, R. Busson, P. Grobet, P. Augustijns, and R. Kinget. Physical stabilisation of amorphous ketoconazole in solid dispersions with polyvinylpyrrolidone K25. Eur. J. Pharm. Sci. 12:261–269 (2001).

K. Khougaz, and S. D. Clas. Crystallization inhibition in solid dispersions of MK-0591 and poly(vinylpyrrolidone) polymers. J. Pharm. Sci. 89:1325–1334 (2000).

V. Tantishaiyakul, N. Kaewnopparat, and S. Ingkatawornwong. Properties of solid dispersions of piroxicam in polyvinylpyrrolidone K-30. Int. J. Pharm. 143:59–66 (1996).

K. J. Crowley, and G. Zografi. The effect of low concentrations of molecularly dispersed poly(vinylpyrrolidone) on indomethacin crystallization from the amorphous state. Pharm. Res. 20:1417–1422 (2003).

T. Matsumoto, and G. Zografi. Physical properties of solid molecular dispersions of indomethacin with poly(vinylpyrrolidone) and poly(vinylpyrrolidone-co-vinylacetate) in relation to indomethacin crystallization. Pharm. Res. 16:1722–1728 (1999).

M. Yoshioka, B. C. Hancock, and G. Zografi. Inhibition of indomethacin crystallization in poly(Vinylpyrrolidone) coprecipitates. J. Pharm. Sci. 84:983–986 (1995).

N. M. Najib, M. A. Elhinnawi, and M. S. Suleiman. Physicochemical characterization of ibuprofen polyvinylpyrrolidone dispersions. Int. J. Pharm. 45:139–144 (1988).

H. Konno, and L. S. Taylor. Influence of different polymers on the crystallization tendency of molecularly dispersed amorphous felodipine. J. Pharm. Sci. 95:2692–2705 (2006).

J. W. Mullin. Crystallization, Reed Educational and Professional Publishing Ltd, Oxford, 2001.

N. Rodriguez-Hornedo, and D. Murphy. Significance of controlling crystallization mechanisms and kinetics in pharmaceutical systems. J. Pharm. Sci. 88:651–660 (1999).

P. J. Marsac, S. L. Shamblin, and L. S. Taylor. Theoretical and practical approaches for prediction of drug-polymer miscibility and solubility. Pharm. Res. 23:2417–2426 (2006).

A. Wexler, and S. Hasegawa. Relative humidity-temperature relationships of some saturated salt solutions in the temperature range 0-degree to 50-degrees-C. J. res. Natl. Bur. Stand. 53:19–26 (1954).

V. Andronis, and G. Zografi. Crystal nucleation and growth of indomethacin polymorphs from the amorphous state. J. Non-Cryst. Solids. 271:236–248 (2000).

S. Inoue, and R. Oldenbourg. Microscopes, McGraw-Hill, New York, 1995.

P. J. Marsac, H. Konno, and L. S. Taylor. A comparison of the physical stability of amorphous felodipine and nifedipine systems. Pharm. Res. 23:2306–2316 (2006).

C. A. Oksanen, and G. Zografi. The relationship between the glass-transition temperature and water-vapor absorption by poly(vinylpyrrolidone). Pharm. Res. 7:654–657 (1990).

Y. Y. Tan, and G. Challa. Glass-transition temperature of poly(N-Vinyl Pyrrolidone) and effect of water. Polymer. 17:739–740 (1976).

D. L. Zhou, E. A. Schmitt, G. G. Zhang, D. Law, S. Vyazovkin, C. A. Wight, and D. J. W. Grant. Crystallization kinetics of amorphous nifedipine studied by model-fitting and model-free approaches. J. Pharm. Sci. 92:1779–1792 (2003).

D. L. Zhou, G. G. Z. Zhang, D. Law, D. J. W. Grant, and E. A. Schmitt. Physical stability of amorphous pharmaceuticals: Importance of configurational thermodynamic quantities and molecular mobility. J. Pharm. Sci. 91:1863–1872 (2002).

Y. Aso, S. Yoshioka, and S. Kojima. Explanation of the crystallization rate of amorphous nifedipine and phenobarbital from their molecular mobility as measured by C-13 nuclear magnetic resonance relaxation time and the relaxation time obtained from the heating rate dependence of the glass transition temperature. J. Pharm. Sci. 90:798–806 (2001).

Y. Aso, S. Yoshioka, and S. Kojima. Relationship between the crystallization rates of amorphous nifedipine, phenobarbital, and flopropione, and their molecular mobility as measured by their enthalpy relaxation and H-1 NMR relaxation times. J. Pharm. Sci. 89:408–416 (2000).

S. D. Clas, M. Cotton, E. Moran, S. Spagnoli, G. Zografi, and E. B. Vadas. Assessment of the physical stability of lyophilized MK-0591 by differential scanning calorimetry. Thermochim. Acta. 288:83–96 (1996).

M. Yoshioka, B. C. Hancock, and G. Zografi. Crystallization of indomethacin from the amorphous state below and above its glass-transition temperature. J. Pharm. Sci. 83:1700–1705 (1994).

K. R. Morris, U. J. Griesser, C. J. Eckhardt, and J. G. Stowell. Theoretical approaches to physical transformations of active pharmaceutical ingredients during manufacturing processes. Adv. Drug Deliv. Rev. 48:91–114 (2001).

N. Hirasawa, S. Ishise, H. Miyata, and K. Danjo. An attempt to stabilize nilvadipine solid dispersion by the use of ternary systems. Drug Dev. Ind. Pharm. 29:997–1004 (2003).

Y. Aso, S. Yoshioka, J. Zhang, and G. Zografi. Effect of water on the molecular mobility of sucrose and poly(vinylpyrrolidone) in a colyophilized formulation as measured by 13C-NMR relaxation time. Chem. Pharm. Bull. 50:822–826 (2002).

G. P. Johari, S. Kim, and R. M. Shanker. Dielectric studies of molecular motions in amorphous solid and ultraviscous acetaminophen. J. Pharm. Sci. 94:2207–2223 (2005).

S. L. Shamblin, and G. Zografi. Enthalpy relaxation in binary amorphous mixtures containing sucrose. Pharm. Res. 15:1828–1834 (1998).

S. H. Yalkowsky. Solubility and solubilization in aqueous media, Oxford University Press, New York, 1999.

Acknowledgements

This work was supported in part by a fellowship from Merck Research Laboratories. Professors George Zografi, Rodolfo Pinal, Ken Morris, and Steve Byrn are acknowledged for their support. AstraZeneca is thanked for financial support. The PhRMA Foundation is acknowledged for a pre-doctoral fellowship to PJM. LST thanks AFPE/AACP for a New Investigator Award. HK acknowledges Astellas Pharma Inc. for granting him a leave of absence to undertake this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Marsac, P.J., Konno, H., Rumondor, A.C.F. et al. Recrystallization of Nifedipine and Felodipine from Amorphous Molecular Level Solid Dispersions Containing Poly(vinylpyrrolidone) and Sorbed Water. Pharm Res 25, 647–656 (2008). https://doi.org/10.1007/s11095-007-9420-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-007-9420-3