Abstract

Purpose

Crystallization of drugs formulated in the amorphous form may lead to reduced apparent solubility, decreased rate of dissolution and bioavailability and compromise the physical integrity of the solid dosage form. The purpose of this work was to develop thermodynamic approaches, both practical and theoretical, that will yield a better understanding of which factors are most important for determining the ability of polymers to stabilize amorphous active pharmaceutical ingredients (API).

Materials and Methods

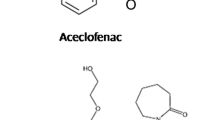

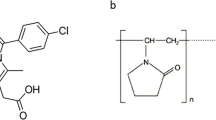

Lattice based solution models were used to examine miscibility criteria in API-polymer blends. Different methods were used to estimate the Flory‐Huggins interaction parameter for model API-polymer systems consisting of felodipine or nifedipine with poly(vinylpyrrolidone) (PVP). These were melting point depression and determination of solubility parameters using group contribution theory. The temperature and enthalpy of fusion of crystalline API alone and the fusion temperature of the API in the presence of the polymer were measured by differential scanning calorimetry. The resultant thermal data were used to estimate the reduced driving force for crystallization and the solubility of the API in the polymer.

Results

Flory‐Huggins theory predicts that, for typical API-polymer systems, the entropy of mixing is always favorable and should be relatively constant. Due to the favorable entropy of mixing, miscibility can still be achieved in systems with a certain extent of unfavorable enthalpic interactions. For the model systems, interaction parameters derived from melting point depression were negative indicating that mixing was exothermic. Using these interaction parameters and Flory‐Huggins theory, miscibility was predicted for all compositions, in agreement with experimental data. A model was developed to estimate the solubility of the API in the polymer. The estimated solubility of the model APIs in PVP is low suggesting that kinetic rather than thermodynamic stabilization plays a significant role in inhibiting crystallization.

Conclusions

The thermodynamics of API-polymer systems can be modeled using solution based theories. Such models can contribute towards providing an understanding of the compatibility between API and polymer and the mechanisms of physical stabilization in such systems.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The solubility of small molecules in polymeric systems has long been of interest in the design of pharmaceutical dosage forms. Amorphous molecular level dispersions of active pharmaceutical ingredients (APIs) in polymeric matrices are one example of such a system. Other examples include transdermal systems and polymer matrix tablets, where the flux will in part be a function of the equilibrium solubility. Design and control of the release profiles from these systems would benefit from a simple method to estimate the thermodynamic activity in these and other dosage forms and devices of pharmaceutical importance.

Amorphous molecular level solid dispersions have been the subject of numerous publications because the crystallization of low Tg amorphous APIs over pharmaceutically relevant time scales can be prevented by incorporating a polymeric crystallization inhibitor. There has been much debate in the pharmaceutical literature about mechanisms involved in the physical stabilization of such systems (1–13) and no consensus has been reached, although it is generally considered that achieving miscibility is important. Herein, the term miscibility is used to refer to the formation of a single phase amorphous system through liquid–liquid mixing where one liquid is an amorphous polymer and the other liquid is an amorphous API (clearly this is an oversimplification for systems below the glass transition temperature since these are non-equilibrium). Molecular level mixing can be achieved either by dissolution of each component in a mutual solvent followed by solvent removal or by directly mixing the two liquids (14). The latter method is normally accomplished by melting the crystalline API and mixing the melt with the amorphous polymer using a technique such as melt extrusion. In order to form a one-phase mixture during the preparation stage, the two liquids have to be thermodynamically miscible. Because the system is perturbed during the preparation stage, the system must re-equilibrate at the post-processing conditions and may remain a single phase or become metastable/unstable. Thermodynamics dictate that metastable/unstable systems will tend to phase separate but due to slow dynamics, the blend may be sufficiently kinetically stable for the intended use.

Achieving miscibility can be considered important for two major reasons. Firstly, in order to modify the physical stability of the API, molecular level mixing with the polymer is desirable, thereby altering the local environment of the API. If the two components are immiscible, the properties of the pure amorphous solid will largely dominate the crystallization behavior of the mixture (although there may be modification at interface regions) and effects of the polymer on physical stability will be limited (1,15). Secondly, it is important to recognize that the chemical potential of the API will be lowered through mixing with a polymer. Reducing the chemical potential will alter the thermodynamic driving force for crystallization.

Although lattice-based solution models are well known, there has been little progress in their application to understanding thermodynamics of mixing in systems of pharmaceutical relevance. This is in part due to the uncertainty in the relative contributions of enthalpy and entropy to the process, which is in turn due to the difficulties in obtaining reliable thermodynamic data. Therefore, the objective of this study was to investigate if lattice-based solution models could be applied to API-polymer systems to predict miscibility and estimate relevant thermodynamic parameters. The specific application in this study was to use this information to better understand stabilization mechanisms for amorphous API-polymer systems, however, such a method obviously has much broader utility. A theoretical framework was developed to connect API-polymer miscibility to API solubility in a polymer. The dihydropyridine calcium channel blockers, nifedipine and felodipine, and the amorphous polymer, poly(vinylpyrrolidone) (PVP), were used as the model systems.

Materials and Methods

Materials

Felodipine was a generous gift from AstraZeneca, Södertälje, Sweden, and nifedipine was obtained from Hawkins, Inc, Minneapolis, MN, USA. Benzophenone, poly(vinylpyrrolidone) (PVP), and 1-methyl-2-pyrrolidone were purchased from Sigma–Aldrich Co., St. Louis, MO, USA. Indium was obtained from the Perkin–Elmer Corporation, Norwalk, CT, USA. Ethanol was obtained from Aaper Alcohol and Chemical Co., Shelbyville, KY, USA.

Methods

Melting Point Depression

All materials used for melting point depression experiments were composed of particles in the range 45–75μm and were dried over phosphorous pentoxide for at least one week prior to mixing. Physical mixtures were prepared by geometric mixing at concentrations of 5, 10, 15, 20, and 25wt.% PVP K12 for nifedipine systems and 5, 10, 15, 17.5, 20, 22.5, and 25wt.% PVP K12 for felodipine systems. Two to three samples were prepared at each concentration. The melting temperature of the nifedipine and felodipine in the presence of PVP K12 was measured with a TA 2920 Modulated DSC equipped with a refrigerated cooling accessory (TA Instruments, New Castle, DE, USA) at a scan rate of 1°C/min. The instrument was calibrated in standard mode for temperature using indium and benzophenone while the enthalpic response was calibrated using indium. Nitrogen, 45ml/min, served as the purge gas. The reference and sample pans were matched by weight to within 0.01mg. The onset of melting was taken as the extrapolated onset of the bulk melting endotherm and it was found that the melting point decreased linearly with increasing concentration of PVP K12 over the concentration range from 0 to 25wt.% PVP K12.

Solubility Measurement

The solubility of nifedipine and felodipine in 1-methyl-2-pyrrolidone was measured using a Cary 50 UV–Vis Spectrophotometer (Varian Inc., Palo Alto, CA). An excess of crystalline material was added to a capped jacketed glass vessel containing 1-methyl-2-pyrrolidone maintained at 25°C for at least 24h under vigorous stirring and in the absence of light. The mother liquor was decanted, centrifuged using an Eppendorf Centrifuge 5451C (Eppendorf AG, Germany), and filtered using a 0.2μm Nalgene SFCA syringe filter (Nalgene Company, Rochester, NY). Samples were diluted with ethanol and compared to a standard concentration curve.

Solubility Parameter Estimation

Solubility parameters were estimated according to the method outlined by Fedors (16). Specifically, fragment or group contributions to the energy of vaporization were summed and divided by the sum of the molar volumes of each fragment/group. The solubility parameter was then calculated as the square-root of the ratio of the energy of vaporization to that of the molar volume.

Flory–Huggins Modeling

The volume fraction of the drug and the polymer were calculated by dividing the weight fraction by the true density of the amorphous material. True densities were experimentally determined using an Accupyc 1330 helium picnometer (Micromeritics, Norcross, GA). The Flory–Huggins interaction parameter was estimated using two different methods; from solubility parameters and melting point depression, as described in more detail elsewhere. For both cases, the lattice volume was defined as being equal to the molecular volume of the drug.

Table I shows the molecular weight, density, and calculated molecular volumes used to calculate the free energy of mixing.

Solubility Estimations

The solubility of nifedipine and felodipine in methyl pyrrolidone was estimated using the interaction parameter calculated from melting point depression results and assuming ideal entropy of mixing. Specifically, it was assumed that the Flory–Huggins interaction parameter estimated from melting point depression with PVP K12 was equal to the interaction parameter between the drug and the small molecular weight analog (i.e., methyl pyrrolidone). The increased entropy in the drug/methyl pyrrolidone mixture relative to the drug/polymer system was estimated by assuming that the entropy of mixing methyl pyrrolidone with nifedipine and felodipine was ideal. The activity coefficient of the drug in methyl pyrrolidone and the activity coefficient in the solubility equation were then solved simultaneously to give the mole fraction of drug in the presence of methyl pyrrolidone. Values used in calculations are summarized in Table I.

Results and Discussion

Solution Theories Applicable to API-Polymer Systems

Predicting miscibility at a particular temperature and pressure requires knowledge of both (a) the sign and magnitude of the free energy of mixing and (b) the composition dependence of the free energy of mixing. Several solution theories of varying complexity have been developed to describe the change in free energy when mixing two species (17). When describing the mixing of a large molecular weight component and a small molecular weight component the solution models for small molecules and solvents are inappropriate and the free energy of the mixture is more accurately described in terms of the volume fraction of the material rather than the mole fraction (18). This is because the entropy of mixing for large molecular weight materials is significantly reduced due to the reduction in the number of possible configurations of the two components of the binary mixture. Flory–Huggins (FH) lattice theory was developed for polymer–solvent systems to take molecular size into account when predicting the entropy of mixing. Although the limitations Flory–Huggins lattice theory have been documented (18–20) and more advanced descriptions of the free energy of mixing have been developed by (21,22), it is still considered an excellent starting point to understand polymer thermodynamics (19). Consider a large molecular weight polymer mixed with a small molecular weight solvent. Flory–Huggins theory defines a hypothetical “lattice” in space. The size of each position in the lattice may be described by the molecular volume of the solvent molecule or any other convenient volume. Each component of the mixture will occupy several adjacent positions in the lattice and the number of lattice positions required to accommodate each component is then equal to the ratio of the molecular volume of each component to that of the lattice cell. If the amorphous drug is considered to behave similarly to a solvent, then the Flory–Huggins model can be applied to describe the thermodynamics of API-polymer systems. Following this logic and after the addition of the Flory–Huggins interaction parameter, χ to account for the enthalpy of mixing, the free energy of mixing for an API-polymer system, ΔG M, is described by Eq. (1).

Here, n drug is the number of moles of drug, n polymer is the number of moles of polymer, Φ drug is the volume fraction of the drug, Φ polymer is the volume fraction of the polymer, R is the gas constant, and T is the absolute temperature. Application of Eq. (1) to API-polymer systems enables evaluation of the relative contributions of entropy and enthalpy to the mixing free energy.

Entropy of Mixing: Importance of Molecular Size

Using Eq. (1) (with χ = 0), the entropy of mixing as a function of composition curves were predicted for several nifedipine-PVP systems, varying the molecular weight of the polymer from 2,500 (K12) to 1,250,000 (K90). In addition, simulations were carried out for nifedipine mixed with the low molecular weight analogue of PVP, methyl pyrrolidone. Results are shown in Fig. 1. It is clear that the entropy of mixing for nifedipine-polymer systems is much less favorable than for nifedipine-methyl pyrrolidone. This is because the configurational entropy of the polymer is significantly reduced due to the connectivity of the repeat units. In contrast, the effect of different molecular weight grades of polymer on mixing thermodynamics is much less marked. Indeed, for any “typical” API (MW ranging from 200 to 600) and any typical polymer (MW between 10,000 and 1,500,000), the magnitude of the entropy contribution towards the free energy term is predicted to be relatively constant. This observation leads to the inference that the magnitude of the enthalpic interactions in each of the pure amorphous components (the cohesive interactions), relative to the enthalpic interactions in the blend (adhesive interactions) will essentially determine if the system is miscible. The relative strength of these interactions will depend on the chemistry of the API and polymer. Therefore if immiscibility is observed, a change to a chemically different polymer is more likely to induce miscibility than a switch to lower molecular weight grade.

Enthalpy of Mixing: Importance of Intermolecular Interactions

The origin of adhesive and cohesive interactions can be broken down into the familiar interactions which differ in strength and directionality (i.e., van der Waals forces such as London dispersion, Keesom, and Debye interactions, hydrogen bonding interactions, charge transfer complexation, and ionic interactions). The effect of the enthalpic interactions on miscibility can be considered in the framework of Flory–Huggins lattice theory. Specifically, enthalpic interactions are reflected in the interaction parameter since this term describes the relative strength of cohesive and adhesive interactions. χ has an entropic component and can also vary with temperature and composition (18,23,24).

Negative interaction parameters describe systems which exhibit strong and numerous adhesive interactions which favor miscibility, whereas positive interaction parameters characterize systems exhibiting stronger cohesive interactions. Figure 2 shows simulations predicting how the free energy of mixing versus composition profiles for nifedipine-PVP K29/32 blends would be expected to vary with the interaction parameter. It is clear that for large positive interaction parameters, the free energy of mixing is positive predicting immiscibility. For small values of the interaction parameter, the free energy of mixing is negative and shows a concave dependence on composition with only one minimum, indicating miscibility. Based on the simulations shown in Fig. 2, it is estimated that for the nifedipine-PVP system, an interaction parameter of approximately 0.6 or less would be required for miscibility to occur over the entire composition range (note that the critical value of the interaction parameter (χ crit) depends on how the size of the lattice is defined and will therefore be system specific). Based on the simulations shown in Fig. 2, it can be inferred that that some degree of unfavorable enthalpic interactions can be tolerated while still achieving miscibility (due to the favorable contribution from the mixing entropy), albeit less than would be tolerated for mixtures of small molecules (20).

At this point it is apparent that, with knowledge of the interaction parameter, an estimation of the mixing behavior of any API-polymer systems can be obtained at a particular temperature using Flory–Huggins theory. It is also clear that, for an API-polymer system, it is the energetic interactions between species, reflected in the magnitude and sign of the interaction parameter that will determine if miscibility is achieved.

Estimating the Interaction Parameter

Having established the importance of the interaction parameter, methods which enable estimation of this value for API-polymer systems are now considered. For polymer–solvent systems, the interaction parameter has been estimated using several methods such as vapor pressure reduction, inverse gas chromatography, osmotic pressure, and melting point depression (18,19). Unfortunately, most of the aforementioned experimental techniques are not applicable to API-polymer blends because of their viscous and non-volatile character. Two methods will now be considered that might be applicable to API-polymer systems: 1) a priori estimates using solubility parameters and 2) melting point depression.

Solubility Parameter Approach

Solubility parameter differences have been advocated as a method to predict miscibility in pharmaceutical systems (25–27). Furthermore, the interaction parameter can be estimated from solubility parameters, δ as shown in Eq. (2):

where V site is the volume of the hypothetical lattice.

Using solubility parameters determined from group contribution theory as described above, interaction parameters of 0.5 and 2.0 were calculated for felodipine-PVP and nifedipine-PVP systems, respectively, using Eq. (2). These positive values predict that mixing is endothermic and further suggest, based on the simulations shown in Fig. 2, that the nifedipine-PVP system would be immiscible. These predictions are in conflict with experimental results which have shown that felodipine and nifedipine are in fact both miscible with PVP over all concentrations (28). These discrepancies most likely arise from the inappropriate use of solubility parameters for systems that contain specific interactions (21). Extensive specific hydrogen bonding interactions between nifedipine and PVP have been demonstrated (28). The relationship shown in Eq. (2) stems from assuming that enthalpic interactions between unlike species are equal to the geometric mean of the enthalpic interactions between like species (17). This assumption is reasonable for systems containing van der Waals type interactions, but not for systems with specific directional interactions. Since many APIs and pharmaceutical polymers are known to form specific interactions (2,7,8,29), solubility parameter estimates of the interaction parameter are likely to be inaccurate for such systems.

Melting Point Depression Approach

The interaction parameters have been determined from melting point depression for both polymer–polymer blends when one polymer crystallizes and the other remains amorphous (30) and for polymer–solvent systems where the melting point depression of the polymer in the presence of the solvent is measured (18,31,32). However, the use of this approach to estimate the interaction parameter in API-polymer systems has not been reported. This is both a result of the need to extend the concept through rational assumption to API-polymer systems as well as the lack of method development essential to generate the requisite data.

Extending equations presented in the literature for polymer–solvent systems (33) to crystalline API-polymer systems, the melting point depression of the drug can be related to the interaction parameter as follows:

Where \( T^{{{\text{mix}}}}_{{\text{M}}} \) is the melting temperature of the drug in the presence of the polymer, \(T^{{{\text{pure}}}}_{M} \) is the melting temperature of the drug in the absence of the polymer, ΔH fus is the heat of fusion of the pure drug, and m is the ratio of the volume of the polymer to that of the lattice site (defined here by the volume of the drug), and the other terms are as described previously. The application of Eq. (3) to pharmaceutical systems requires that the drug and polymer are chemically stable over the temperature range of interest and that there is sufficient physical interaction between the components for the melting point depression to be manifested.

The extent of melting point depression of crystalline nifedipine and felodipine in the presence of PVP was used together with Eq. (3) to estimate the interaction parameter. Melting point depression is well documented phenomenon for APIs mixed with polyethylene glycol (PEG) using differential scanning calorimetry (DSC) to determine fusion temperatures (34–36). For these systems, melting point depression is usually kinetically favorable because of the low melting point of the polymer which is around 60°C. Hence at the melting temperature of the API, the polymer is molten and therefore, the drug can easily interact and equilibrate with the polymer in the liquid state. However, initial experiments with nifedipine or felodipine mixed with PVP K29/30 and analyzed at a scan rate of 10°C min−1 showed essentially no melting point depression (data not shown). This is most likely due to a lack of physical interaction resulting from the high glass transition of the polymer (168°C). As a consequence, the polymer is not very “liquid-like” at the melting point of nifedipine (171°C) or felodipine (142°C) leading to unfavorable kinetics for forming a mixture of polymer with molten API. Such experimental artifacts are well recognized for polymer–polymer systems (30). After method optimization which involved reducing the scan rate and controlling particle size, substantial melting point depression was observed for nifedipine or felodipine mixed with PVP K12 which has a Tg of 100°C (37) and results are shown in Fig. 3. The extent of melting point depression seen for the drug–polymer mixtures was similar to that observed for crystalline polymers and solvents (32).

Estimation of the interaction parameters from melting point depression data required rearrangement of Eq. (3). Specifically, a plot of \( {\left( {1 \mathord{\left/ {\vphantom {1 {T^{{{\text{mix}}}}_{{\text{M}}} - 1 \mathord{\left/ {\vphantom {1 {T^{{{\text{pure}}}}_{{\text{M}}} }}} \right. \kern-\nulldelimiterspace} {T^{{{\text{pure}}}}_{{\text{M}}} }}}} \right. \kern-\nulldelimiterspace} {T^{{{\text{mix}}}}_{{\text{M}}} - 1 \mathord{\left/ {\vphantom {1 {T^{{{\text{pure}}}}_{{\text{M}}} }}} \right. \kern-\nulldelimiterspace} {T^{{{\text{pure}}}}_{{\text{M}}} }}} \right)} * {\left( {{\Delta H_{{{\text{fus}}}} } \mathord{\left/ {\vphantom {{\Delta H_{{{\text{fus}}}} } { - R}}} \right. \kern-\nulldelimiterspace} { - R}} \right)} - \ln {\left( {\Phi _{{{\text{drug}}}} } \right)} - {\left( {{1 - 1} \mathord{\left/ {\vphantom {{1 - 1} m}} \right. \kern-\nulldelimiterspace} m} \right)}\Phi _{{{\text{polymer}}}} \quad {\text{vs}}{\text{.}}\quad \Phi ^{2}_{{{\text{polymer}}}} \), as shown in Fig. 4a, yielded a linear relationship at low polymer weight fractions with a slope equal to χ. For the concentration range 0–0.25, r 2 values of 0.99 and 0.92 were obtained for nifedipine and felodipine, respectively, however at higher concentrations, linearity was lost. The absence of linearity across the entire concentration range most likely reflects the well known composition dependence of the interaction parameter (18) as well as the increasingly unfavorable kinetics of drug–polymer interaction as the melting point is depressed closer to the glass transition temperature of the polymer. The resultant values of χ, using only data for the concentration range 0–0.25 volume fraction polymer, were −3.8 and −4.2 for nifedipine-PVP and felodipine-PVP, respectively. It should be further noted that Eq. (3) provides an estimate of the interaction parameter at temperatures close to the melting point of the API.

Plot used to calculate the interaction parameter for the nifedipine-PVP system based on Eq. (3). See text for more details. r 2 was 0.99. (a) Extrapolated onset of melting point for nifedipine as a function of the volume fraction of PVP K12 measured at a heating rate of 1°C/min (Black Triangle) compared with predicted extents of melting point depression for interaction parameters of −3.8, 0.0 and 2.0.(b).

In contrast to the immiscibility predicted for nifedipine-PVP using a solubility parameter derived χ, the melting point derived interaction parameter of −3.8 predicts miscibility, (see Fig. 2) consistent with experimental observations (28). In order to provide an indication of the sensitivity of χ to the extent of melting point depression, Fig. 4b shows the predictions of Eq. (3) for various values of the interaction parameter for the nifedipine-PVP system. With an interaction parameter of zero (athermal mixing), melting point depression would be anticipated to be very small, and results from the mixing entropy which is small for a drug–polymer system as shown in Fig. 1. For a value of 2.0 (solubility parameter estimate), the results are not physically meaningful, since elevation of the melting point is predicted. Finally, the fit of the estimated value of −3.8 to the experimental data is shown. Based on Eq. (3), the extent of melting point depression observed is certainly consistent with a negative value of the interaction parameter and an exothermic heat of mixing. Clearly the ability to estimate a realistic value of χ is critical to using Flory‐Huggins theory to describe mixing thermodynamics in API-polymer systems and our results suggest that the melting point depression method can be applied to obtain reasonable values.

Driving Force for Crystallization from Amorphous Molecular Level Solid Dispersions

The free energy change of crystallization for the pure amorphous API at any particular temperature above Tg can be estimated from the enthalpy of fusion and the melting temperature of the pure material using the Hoffman relationship shown in Eq. (4) where it is assumed that the enthalpy difference between the crystalline and supercooled liquid phases varies linearly with temperature (38). This equation has been found to adequately predict the free energy change for crystallization of felodipine and nifedipine (28).

The driving force for crystallization of an API must of course be considered in the system of interest. If the API and the polymer form a miscible amorphous system, the chemical potential of the API is reduced relative to that of the pure amorphous API. Therefore, the thermodynamic driving force for crystallization of an API in a polymer must be reduced relative to the driving force for the pure amorphous drug. The reduction in chemical potential results from the increased entropy in a mixture. Additionally, if the strength and/or extent of enthalpic interactions are greater in the mixture than the sum of the interactions in the pure components, API activity is further reduced.

Melting point depression is a manifestation of the reduced thermodynamic activity of the drug in the presence of the polymer relative to the activity of the pure amorphous drug as was shown in Eq. (3). This phenomenon arises because the chemical potential of the drug in the solid and liquid phase must be identical at the melting point. Hence the drug in the amorphous molecular level solid dispersion will have a chemical potential equal to that of the crystalline drug at a lower temperature than the fusion temperature of the pure drug and depression of the melting point results.

A modified version of the Hoffman equation (Eq. 4) can be used to estimate the reduction in thermodynamic driving force for crystallization from melting point depression data (38). Here we apply this approach to an API molecularly dispersed in a polymer. The reduced driving force for crystallization of amorphous nifedipine in the presence of PVP is shown in Fig. 5 as estimated from the Hoffman equation using the melting point depression data shown in Fig. 3. It should be noted that the reduction in thermodynamic driving force for crystallization is most likely underestimated because of the problems associated with obtaining equilibrium melting point depression values at high polymer concentrations as discussed above. Even so, it is apparent that these predictions do not forecast a large reduction in the driving force for crystallization, particularly when extrapolated to lower temperatures. In fact, the difference in ΔG ν for pure amorphous nifedipine and the solid dispersion with 40% PVP is less than the difference in ΔG ν between nifedipine and felodipine (28). Pure nifedipine and felodipine both have much faster nucleation rates than solid dispersions containing even small amounts of polymer (28). Thus, as demonstrated here quantitatively for the first time, it can be concluded that the reduction in the thermodynamic driving force for crystallization seems unlikely to account for the observed reduction in crystallization tendency in a solid dispersion suggesting that kinetic and/or interfacial energy factors are of great importance.

Development and Application of a Thermodynamic Model to Estimate API Solubility in Glassy Polymer

For a typical API-polymer amorphous molecular level dispersion, the starting form of the API used to manufacture to the dispersion is a crystalline solid. Whereas miscibility describes the tendency of the supercooled liquid/glassy form of the API to mix with a polymer, solubility refers to the ability of the polymer to act as a “solvent” and dissolve a crystalline API. Appearance of crystalline API in a solid dispersion following manufacturing or storage does not necessarily imply that the two liquids are immiscible. Crystalline API can also be explained if the solubility limit has been exceeded and conditions were favorable for crystallization. It is therefore of interest to better understand factors that govern the “solubility” of a crystalline API in a polymer. In addition, if the solubility of the API in the polymer can be measured or estimated, then the degree of supersaturation, which is a measure of the driving force for crystallization can be evaluated. Although methods have been reported for the measurement of API solubility in a polymer with a low glass transition temperature (39), the extent of API solubility in solid dispersions formed with high Tg polymers has not been established. In this section, a new model is developed to estimate the solubility of an API in a polymeric matrix.

The solubility of a crystalline material in a typical low molecular weight solvent is given by Eq. (5).

Where γ drug is the activity coefficient and x drug is the mole fraction. Non-idealities in mixing are reflected by γ drug. If it is assumed that the polymer can assume the role of a solvent, then Eq. (5) can be used to describe the solubility of a crystalline API in a polymeric matrix. Applying Flory‐Huggins lattice theory, for an API-polymer system, the activity coefficient of the API can be described by Eq. (6).

From Eq. (6), it can be seen that the value of the activity coefficient will be influenced by the nature of the interactions in the system as reflected by the interaction parameter as well as the disparity in molecular size between the two components. For predicting solubility in systems where there is minimal difference in molecular size (e.g., for predicting the solubility of API in a low molecular weight solvent), ideal mixing entropy can be assumed and hence the activity coefficient only reflects the partial molal heat of mixing supercooled liquid solute with solvent as reflected by the interaction parameter. Hence in Eq. (6), if ideal mixing entropy is assumed, the first two terms on the right hand side of the equation are equal to zero.

The solubility of nifedipine and felodipine in PVP was estimated using the χ parameter obtained from melting point depression and simultaneously solving Eqs. (5) and (6). The predicted solubilities are shown in Table II. In an attempt to verify the validity of this method, the solubility of nifedipine and felodipine was measured in methyl pyrrolidone. Specifically, it was assumed that the interaction parameter as measured from melting point depression of nifedipine and felodipine in PVP could be extended to estimate the interaction parameter in the methyl pyrrolidone systems. Next, the increased entropy of mixing nifedipine and felodipine with methyl pyrrolidone relative to mixing with PVP (Fig. 1) was accounted for by assuming ideal mixing entropy. The predicted solubility of nifedipine and felodipine in methyl pyrrolidone is listed in Table II along with the measured solubility. It is apparent that the predicted solubility in methyl pyrrolidone is in good agreement with the experimentally determined solubility. The similarity of the two values indicates that the interaction parameter calculated for both drug–PVP systems from the melting point depression method described above is a reasonable estimate. For comparison, the solubility predicted for nifedipine in methyl pyrrolidone using an interaction parameter of 0.5 is also shown in Table II. This value is more than an order of magnitude smaller than the experimentally determined value and serves to demonstrate the sensitivity of the solubility estimation to the value of χ. Having confirmed that a reasonable estimate of the interaction parameter has been determined, the solubility of nifedipine and felodipine in PVP can be estimated. It can be seen from Table II that the solubility of nifedipine in PVP is predicted to be less than that in methyl pyrrolidone. This difference arises from the reduced entropic contribution to the mixing free energy in the former system. Hence, attempts to estimate the “solubility” of an API in a polymer by measuring solubility in a low molecular weight analogue of the polymer (40) need to be corrected accordingly to avoid overestimating the solubility. Similar solubility estimates and measured solubilities are shown for felodipine in Table II.

It apparent from Eqs. (5), (6) that the solubility of an API in a polymer will be a function of its melting temperature and heat of fusion as well as the sign of the mixing enthalpy as reflected in the interaction parameter. APIs with a high heat or temperature of fusion will therefore be less soluble in a polymer. This is apparent from comparing data for nifedipine and felodipine where it can be seen that the lower melting, lower heat of fusion felodipine is predicted to have a greater solubility in the polymer than nifedipine. The effect of fusion properties on solubility of small molecules in conventional solvents has been discussed in detail previously (41), but these factors have not been considered for API-polymer systems. In addition, if the enthalpy of mixing is positive, then the solubility will be reduced. Therefore, high melting point/high enthalpy of fusion compounds which do not have substantial interactions with the polymer will display very low solubility. Conversely, a negative enthalpy of mixing (and FH interaction parameter) will increase solubility.

From a practical standpoint, this analysis informs us that since the solubility of an API in a polymer is likely to be strong function of the melting point, higher melting point substances will most likely be harder to stabilize since they will be more supersaturated. The results shown in Table II also suggest that API solubility in polymers is sufficiently low, even for systems which interact favorably with the polymer such that the drug will be supersaturated for most practical formulations. For example, with nifedipine, the formulation would have to consist of more than 90% polymer to ensure that no drug would crystallize based on a thermodynamic stabilization. Such a high ratio of polymer to drug would only be feasible for very low dose formulations. The solubility analysis also suggests that the physical stabilization of APIs in amorphous molecular level solid dispersions is largely due to altering the kinetics of the systems.

Conclusions

When considering the mixing of API with polymers for the purposes of making stable amorphous molecular dispersions, lattice-based solution models predict a relatively constant mixing entropy. This suggests that the focus for understanding miscibility in these systems should be on the relative balance between adhesive and cohesive interactions. A method has been developed to estimate the Flory‐Huggins interaction parameter for drug–polymer systems which subsequently enables modeling of the thermodynamic properties of such systems. Depending on the degree of interaction between the two components, and hence the enthalpy of mixing, the chemical potential of the API in the mixture can be higher or lower than the chemical potential of the crystalline drug, and therefore above or below its solubility limit in a polymeric matrix. A model for estimating drug solubility in a polymer was developed. This solubility limit is predicted to be relatively low for the majority of API-polymer systems, hence most APIs will be supersaturated and tend to crystallize. Inhibition of API crystallization in solid dispersions can therefore be attributed predominantly to a kinetic stabilization. In summary, it is concluded that achieving molecular level miscibility with the polymer is of critical importance to enable alteration of the molecular level environment of the API which leads to altered thermodynamics and more importantly dynamics.

References

D. Law, S. L. Krill, E. A. Schmitt, J. J. Fort, Y. H. Qiu, W. L. Wang, and W. R. Porter. Physicochemical considerations in the preparation of amorphous ritonavir-poly(ethylene glycol) 8000 solid dispersions. J. Pharm. Sci. 90:1015–1025 (2001).

L. S. Taylor and G. Zografi. Spectroscopic characterization of interactions between PVP and indomethacin in amorphous molecular dispersions. Pharm. Res. 14:1691–1698 (1997).

D. Law, E. A. Schmitt, K. C. Marsh, E. A. Everitt, W. L. Wang, J. J. Fort, S. L. Krill, and Y. H. Qiu. Ritonavir-PEG 8000 amorphous solid dispersions: In vitro and in vivo evaluations. J. Pharm. Sci. 93:563–570 (2004).

T. Miyazaki, S. Yoshioka, Y. Aso, and S. Kojima. Ability of polyvinylpyrrolidone and polyacrylic acid to inhibit the crystallization of amorphous acetaminophen. J. Pharm. Sci. 93:2710–2717 (2004).

I. Weuts, D. Kempen, A. Decorte, G. Verreck, J. Peeters, M. Brewster, and G. Van den Mooter. Phase behaviour analysis of solid dispersions of loperamide and two structurally related compounds with the polymers PVP-K30 and PVP-VA64. Eur. J. Pharm. Sci. 22:375–385 (2004).

G. Van den Mooter, M. Wuyts, N. Blaton, R. Busson, P. Grobet, P. Augustijns, and R. Kinget. Physical stabilisation of amorphous ketoconazole in solid dispersions with polyvinylpyrrolidone K25. Eur. J. Pharm. Sci. 12:261–269 (2001).

K. Khougaz and S. D. Clas. Crystallization inhibition in solid dispersions of MK-0591 and poly(vinylpyrrolidone) polymers. J. Pharm. Sci. 89:1325–1334 (2000).

V. Tantishaiyakul, N. Kaewnopparat, and S. Ingkatawornwong. Properties of solid dispersions of piroxicam in polyvinylpyrrolidone K-30. Int. J. Pharm. 143:59–66 (1996).

H. Suzuki and H. Sunada. Influence of water-soluble polymers on the dissolution of nifedipine solid dispersions with combined carriers. Chem. Pharm. Bull. 46:482–487 (1998).

S. Sethia and E. Squillante. Solid dispersion of carbamazepine in PVPK30 by conventional solvent evaporation and supercritical methods. Int. J. Pharm. 272:1–10 (2004).

E. Broman, C. Khoo, and L. S. Taylor. A comparison of alternative polymer excipients and processing methods for making solid dispersions of a poorly water soluble drug. Int. J. Pharm. 222:139–151 (2001).

K. J. Crowley and G. Zografi. The effect of low concentrations of molecularly dispersed poly(vinylpyrrolidone) on indomethacin crystallization from the amorphous state. Pharm. Res. 20:1417–1422 (2003).

M. Fujii, J. Hasegawa, H. Kitajima, and M. Matsumoto. The solid dispersion of benzodiazepins with phosphatidylcholine–the effect of substituents of benzodiazepins on the formation of solid dispersions. Chem. Pharm. Bull. 39:3013–3017 (1991).

W. L. Chiou and S. Riegelma. Pharmaceutical applications of solid dispersion systems. J. Pharm. Sci. 60:1281–1302 (1971).

K. Six, C. Leuner, J. Dressman, G. Verreck, J. Peeters, N. Blaton, P. Augustijns, R. Kinget, and G. Van den Mooter. Thermal properties of hot-stage extrudates of itraconazole and eudragit E100–phase separation and polymorphism. J. Therm. Anal. Calorim. 68:591–601 (2002).

R. F. Fedors. Method for estimating both solubility parameters and molar volumes of liquids. Polym. Eng. Sci. 14:147–154 (1974).

J. H. Hildebrand and R. L. Scott. Solubility of Nonelectrolytes. Reinhold, New York, 1950.

P. J. Flory. Principles of Polymer Chemistry. Cornell University Press, Ithaca, 1953.

R. J. Young and P. A. Lovell. Introduction to Polymers. Nelson Thornes, Cheltenham, United Kingdom, 1991.

M. Rubinstein and Ralph H. Colby. Polymer Physics. Oxford University Press, New York, 2003.

P. C. Painter, J. F. Graf, and M. M. Coleman. Effect of hydrogen-bonding on the enthalpy of mixing and the composition dependence of the glass-transition temperature in polymer blends. Macromolecules 24:5630–5638 (1991).

M. M. Coleman, John F. Graf, and Paul C. Painter. Specific Interactions and the Miscibility of Polymer Blends. Technomic, Lancaster, Pennsylvania, 1991.

M. J. Newing. Thermodynamic studies of silicones in benzene solution. Trans. Faraday Soc. 46:613–620 (1950).

C. E. H. Bawn, R. F. J. Freeman, and A. R. Kamaliddin. High polymer solutions.1. Vapour pressure of polystyrene solutions. Trans. Faraday Soc. 46:677–684 (1950).

D. J. Greenhalgh, A. C. Williams, P. Timmins, and P. York. Solubility parameters as predictors of miscibility in solid dispersions. J. Pharm. Sci. 88:1182–1190 (1999).

B. C. Hancock, P. York, and R. C. Rowe. The use of solubility parameters in pharmaceutical dosage form design. Int. J. Pharm. 148:1–21 (1997).

A. Forster, J. Hempenstall, I. Tucker, and T. Rades. Selection of excipients for melt extrusion with two poorly water-soluble drugs by solubility parameter calculation and thermal analysis. Int. J. Pharm. 226:147–161 (2001).

P. J. Marsac, H. Konno, and L. S. Taylor. A comparison of the physical stability of amorphous felodipine and nifedipine systems. Pharm. Res. (in this issue) (2006).

X. L. C. Tang, M. J. Pikal, and L. S. Taylor. A spectroscopic investigation of hydrogen bond patterns in crystalline and amorphous phases in dihydropyridine calcium channel blockers. Pharm. Res. 19:477–483 (2002).

T. Nishi and T. T. Wang. Melting-point depression and kinetic effects of cooling on crystallization in poly(vinylidene fluoride) poly(methyl methacrylate) mixtures. Macromolecules 8:909–915 (1975).

E. Meaurio, E. Zuza, and J. R. Sarasua. Miscibility and specific interactions in blends of poly(L-lactide) with poly(vinylphenol). Macromolecules 38:1207–1215 (2005).

L. Mandelkern. Crystallization of Polymers. McGraw-Hill, New York, 1964.

Y. Hoei, K. Yamaura, and S. Matsuzawa. A lattice treatment of crystalline solvent-amorphous polymer mixtures on melting-point depression. J. Phys. Chem. 96:10584–10586 (1992).

R. Kaur, D. J. W. Grant, and T. Eaves. Comparison of polyethylene-glycol and polyoxyethylene stearate as excipients for solid dispersion-systems of griseofulvin and tolbutamide.1. Phase-equilibria. J. Pharm. Sci. 69:1317–1321 (1980).

S. E. Bartsch and U. J. Griesser. Physicochemical properties of the binary system glibenclamide and polyethylene glycol 4000. J. Therm. Anal. Calorim. 77:555–569 (2004).

C. Anastasiadou, S. Henry, B. Legendre, C. Souleau, and D. Duchene. Solid dispersions‐comparison of prepared melts and coprecipitates of diazepam and polyoxyethylene glycol-4000. Drug Dev. Ind. Pharm. 9:103–115 (1983).

L. S. Taylor, F. W. Langkilde, and G. Zografi. Fourier transform Raman spectroscopic study of the interaction of water vapor with amorphous polymers. J. Pharm. Sci. 90:888–901 (2001).

J. D. Hoffman. Thermodynamic driving force in nucleation and growth processes. J. Chem. Phys. 29:1192–1193 (1958).

B. R. Jasti, B. Berner, S. L. Zhou, and X. L. Li. A novel method for determination of drug solubility in polymeric matrices. J. Pharm. Sci. 93:2135–2141 (2004).

J. Breitenbach. Melt extrusion: from process to drug delivery technology. Eur. J. Pharm. Biopharm. 54:107–117 (2002).

S. H. Yalkowsky. Solubility and Solubilization in Aqueous Media. Oxford University Press, New York, 1999, pp. 49–80.

Acknowledgments

Alfred Rumondor is thanked for providing experimental solubility values. The PhRMA Foundation is acknowledged for a pre-doctoral fellowship to PJM. LST thanks AFPE/AACP for a New Investigator Award. AstraZeneca is thanked for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Marsac, P.J., Shamblin, S.L. & Taylor, L.S. Theoretical and Practical Approaches for Prediction of Drug–Polymer Miscibility and Solubility. Pharm Res 23, 2417–2426 (2006). https://doi.org/10.1007/s11095-006-9063-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-006-9063-9