Abstract

The synthesis of ammonia has been studied in methane-nitrogen plasmas using a micro-gap discharge under an environmentally friendly condition. The effects of some parameters such as the specific input energy, the discharge gap, the volume ratio of CH4/N2, the residence time, and the gas temperature on the yield of NH3 and conversion rate of CH4 are discussed in the paper. The results show that the highest yield of NH3 is 8000 ppm for a residence time of 1.6 s. In addition, the yield and generating rate of H2 are 9.1% (v/v) and 1879.8 μmol/min, respectively. Therefore, the micro-gap discharge is an efficient method for NH3 synthesis and H2 generation from CH4.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Ammonia (NH3), as an important chemical product, can be used to produce ammonium fertilizer, such as carbamide ammonium nitrate and ammonium bicarbonate. Hydrogen (H2) is definitely a green energy source, and hydrogen based fuel-cell technology has been investigated extensively to develop fuel cell vehicles and cogeneration system. Methane is the major constituent of natural gas. Activation of saturated hydrocarbons and especially methane is difficult due to the high dissociation energy of C–H bonds. The direct synthesis of NH3 using CH4 rather than H2 by non-equilibrium plasma at atmospheric pressure is of great importance.

A number of studies on plasma synthesis of ammonia have been carried out by radio frequency (=13.56 MHz) or microwave (=2540 MHz) discharge at low pressure. In 1994, Oumghar, Legrand et al. [1–3] investigated the conversion of CH4 by N2 or air microwave plasma, as well as kinetic mechanism of CH4 conversion. C2 hydrocarbons (C2H2, C2H4, C2H6) and trace amount of HCN, NH3 were obtained, and the methane conversion rate was 80% within the power range of 350~650 W. Some studies [4, 5] reported that ammonia molecules would be formed by the reaction between NHx radicals and hydrogen atoms. In some cases, catalysts were placed in the discharge or afterglow region, or on the cold trap wall in order to enhance the ammonia yield [5–8]. Tanaka et al. [7, 8] studied the synthesis of ammonia in N2-H2 plasmas by microwave or radio frequency discharge at a pressure of 650 Pa (5 Torr) with catalysts of iron and molybdenum wires of 100 pieces. The yields of NH3 and N2H4 were only 1.5 mmol/g and 2.5 μmol/g, respectively, with a residence time of 2 h and power input of 180 W. The main drawback of low pressure plasmas is low energy efficiency and low yields of NH3.

H2 generation from water, methane, and methanol was investigated in a ferroelectric pellet packed-bed reactor (FPR) and a silent-discharge-type reactor (SDR) by Kabashima et al. [9] in 2003. The H2-generation rate with FPR was 54 μmol/min in ambient Ar. Suid et al. [10] have reported water splitting by a dielectric barrier discharge (DBD) plasma reactor, of which the inner electrode was an Au-coated copper rod. The highest H2-generating rate was 3.4 μmol/min in ambient Ar.

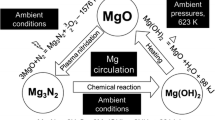

In previous studies performed by the author, the NH3 synthesis in N2–H2 plasmas was carried out using the combined surface discharge and DC (direct current) discharge [11]. NH3 yield was 5000 ppm with MgO catalyst. Subsequently, the concentration of NH3 reached 12500 ppm by the micro-gap DBD without any catalyst [12, 13]. In this paper, the synthesis of NH3 by N2-CH4 plasmas was performed. The yield of NH3 was 8000 ppm for a residence time of 1.6 s. The whole process was carried out under atmospheric pressure without any catalyst, which is an environmentally friendly condition in line with Green Chemistry Principle [14, 15].

Plasma Processes of Micro-Gap Discharge

Comparison of Main Parameters between Several Kinds of Gas Discharges

The comparison of main parameters between several kinds of gas discharges is shown in Fig. 1. At high pressure (≥105 Pa), the main gas discharges are the high-voltage corona, pulse corona, general DBD, and our micro-gap discharge. Strong and weak ionization zones are separated by the line which is defined by the following parameters: the electric field intensity Eg, 100 kV/cm; the electron density in discharge path Ne, 1014/cm3; the average electron energy Te, 10 eV; and the fractional active volume (δ, %), 1%. The main parameters of our micro-gap discharge, which falls in the strong ionization zone, are much higher than that of other gas discharges; in particular the fractional active volume is about 2%. The fractional active volume refers to the volume ratio of the volume of all ionization discharge paths to that of micro-gap. Plasma chemistry reactions take place in the ionization discharge paths. The increase of the fractional active volume leads to more discharge paths, resulting in greater whole electron density in the micro gap. Therefore, our micro-gap discharge is an efficient method for the conversion of CH4 into NH3.

Excited Dissociation, Direct Ionization of CH4 and Formation of H2

The dissociative potential of C–H bond of CH4 is less than 4.6 eV. The excited methane S1 (9.6 and 10.4 eV) and S2 (11.7 eV),which are formed by the electron-methane collisions, are so unstable that rapidly dissociate into radicals such as CH3, CH2, CH, C. The plasma reactions are as follows [1–3]:

Direct Ionizations of CH4 are as follows [12]:

Te in our micro-gap discharge is ≥10 eV, which means a lot of electrons have the energy ≥9.6 eV. In this study, the above plasma reactions might be dominant reactions for H2 generation as well as the formations of CH4, CH3, CH2, CH radicals and CH4 +, CH3 +, CH2 + ions.

Dissociation and Ionization of N2 Molecule [16]

Plasma Processes of NH3 Synthesis

The CH4, CH3 etc. react with N2 +, N+, N(4S) to form the NH radicals as follows [1, 2]. Ion reactions (20) with high rate constant are the major reactions.

NH radicals, which are considered as the ammonia precursors, are formed by the reactions of N2 + with H2, H. Also N atoms adhered to the wall react with hydrogen to form NH radicals [1, 2, 12].

Synthesis of NH3 molecule [12]

The N2 + ion is the major activated particle to form the NH radical and leads to NH3. As for the micro-gap discharge, a lot of electrons have the energy ≥15.6 eV (ionization potential of N2). Therefore, the micro-gap discharge is an efficient plasma method for the synthesis of NH3 at atmospheric pressure.

Experiment

Experimental Setup

The experimental setup for synthesis of NH3 using the micro-gap discharge is shown in Fig. 2. The plasma reactor 3 is rectangular, of which the dimension is 260 mm (length) × 130 mm (width) × 35 mm (thickness). The thin dielectric layers of α-AL2O3 are attached to both sides of discharge electrodes, of which the dimension is 175 mm (length) × 80 mm (width) × 0.3 mm (thickness). The discharge gap is 0.47 mm or 0.64 mm. The dielectric constant and the electric insulation intensity are 10 and 350 kV/cm, respectively. With this thin dielectric layer, strong streamer discharge can be obtained in the micro-gap.

Schematic diagram for the synthesis of NH3 by CH4–N2 plasmas Note: 1. Gas flow meter; 2. Gas mixing system; 3. Plasma reactor; 4. Earthing electrode 5. Discharge electrode; 6. Dielectric layers; 7. NH3 analyzer; 8. Glass for Liquid fuel; 9. Gas chromatograph; 10. Discharge gap; 11. Power supply; 12. Insulator 13. Oscillograph; 14. Electrostatic voltage meter

Measurement System

The CH4–N2 gas mixture with a purity of 99.98% is fed into the reactor. The gas flow rate and mixing ratio are adjusted by the mass-flow controller 4000 Series Gas Mixing System (Environics INC in USA). The yield of ammonia is monitored on-line by GXH-105 Type Infrared Analyzer. The feed and product of gaseous hydrocarbons are analyzed with a gas chromatograph of GC-102 or HP4890 equipped with a thermal conductivity detector (TCD) and a flame ionization detector (FID). The relative standard deviation (RSD) is <0.5% based on the five times measurement of one sample.

The self-made power supply is applied to the discharge electrodes, leading to a continuous strong streamer discharge, of which the main parameters are as follows: the discharge power, 240 W; the applied frequency, 10 kHz; the pulse width, 40 μs. The electric parameters are measured using HV-60 High Voltage Probe (Iwatsu, Japan), SS-240 Pulse Current Probe (Iwatsu, Japan), TDS-3032B Oscilloscope (Tektronix, USA), Model HC-F1000L Frequency Meter (Hong Chong Electronic Co. Ltd) and Q3-V Electrostatic Voltage Meter (Beijing Electric Meter Factory, China).

Evaluation of System Performance

In order to evaluate the energy efficiencies for methane conversion, the specific input energy (SIE, electrical input energy to unit volume of gas), defined in Eq. 1, is used. The discharge power is measured using the method of charge-voltage figure [17, 18], which can efficiently eliminate the measure error caused by discharge gap that was equal to a capacitor. Equations 2–3 indicate the calculation methods for generation rate and conversion rate of CH4. The volume per mol in our experiments is 24.2 L/mol with a temperature of 22°C and an atmospheric pressure.

Experimental Results

Analysis of Gaseous Products for the Conversion of CH4

The experiments were carried out at 22°C, 105 Pa, without any catalyst. The mixed gases of CH4/N2=3:1 (v/v) were fed into the reactor at a flow rate of 0.5 L/min. The specific input energy (SIE) is 29.2 kJ/L with a discharge power of 243.6 W. The discharge gap width of the plasma reactor is 0.47 mm. The yields of gaseous products in Table 1 were analyzed with a GC-102 gas chromatograph by Institute of Guang Ming Chemical Engineering. The standard gases of hydrocarbons, NH3 and H2 were injected into the Chromatogram to calibrate their peak values.

As shown in Table 1, hydrocarbons (≤C4) such as ethane (C2H6), ethylene (C2H4), acetylene (C2H2), propane (C3H8), propylene (C3H6), butane (i-C4H10, n-C4H10) are produced by electron collision reaction and recombination reaction. The yield and generation rate of hydrocarbons are of the following relationship C2H6 > C3H8 > C2H2 > C2H4 > i-C4H10, n-C4H10 > C3H6. 10.13% of the residual is not identified, which is possibly to be gaseous hydrocarbon (≥C5). The conversion rate of CH4 is 4752 μmol/min.

With the electron-methane collisions, large numbers of H2 are produced by exited dissociation and direct ionization of CH4. The yield and generation rate of H2 are 9.1% (v/v) and 1879.8 μmol/min, respectively. These data show that the micro-gap discharge is a promising method to obtain high H2-generating rate in the absence of catalyst.

The NH3 is synthesized by atmospheric plasma in ambient N2 and CH4. The yield of synthesized NH3 is 8000 ppm equal to 0.42 mmol/g for a residence time of 1.6 s. The yield of NH3 would be1.89 × 103 mmol/g if the gas residence time was 2 h. However, the yield of NH3 was only 1.5 mmol/g for a residence time of 2 h by Tanaka et al. [7, 8].

Effect of the Specific Input Energy on the Concentration of Synthesized NH3 and Conversion Rate of CH4

As shown in Fig. 3, the SIE has a vital effect on the concentration of synthesized NH3 and the conversion rate of CH4. The greater the SIE is, the more molecules of CH4, N2 are ionized into activated particles, thus enhancing synthesis of NH3. When the SIE changes in the range of 5.38–29.2 kJ/L, the NH3 concentration increases from 3600 ppm to 7000 ppm, meanwhile CH4 conversion rate increases from 47.3% to 59.0%. The trend slows after the point where SIE is 29.2 kJ/L. When the SIE is 35 kJ/L, the highest CH4 conversion rate of 60.0% is obtained, accordingly the highest NH3 concentration is 7400 ppm. However SIE is not further increased due to the possibility of dielectric layer breakdown, in addition, high SIE is also unsuitable for synthesis of NH3 from energy consumption perspective.

Effect of the Volume Ratio of CH4 to N2 on the Concentration of Synthesized NH3 and Conversion Rate of CH4

As shown in Fig. 4, the volume ratio of CH4/N2 has a strong effect on the concentration of NH3, and the optimum volume ratio is 3:1, where the concentration of NH3 and the conversion rate of CH4 reach 7000 ppm and 59%, respectively. When the volume ratio of CH4/N2 is in the range of 0.25~3, the two values increase with the volume ratio. When the ratio of CH4/N2 exceeds 3, the concentration of NH3 remains constant at 7000 ppm, and the conversion rate of CH4 decreases with the increase of the volume ratio. The optimum ratio of CH4/N2 3:1 is the same as that of conventional NH3 synthesis process.

Effects of the Residence Time and Discharge Gap on the Concentration of Synthesized NH3

As shown in Fig. 5, curve 1 (0.47 mm) and curve 2 (0.64 mm) for the different discharge gaps have almost the same trend. The concentration of NH3 increases with the residence time in the range of 0.5–2.25 s. The residence time is much shorter than that of NH3 synthesis by Tanaka et al. [4, 5], because more CH4 and N2 are ionized and dissociated in our micro-gap discharge.

The discharge gap has a great effect on the concentration of NH3. When the residence time is 1.65 s, the concentration of NH3 is 6930 ppm for a discharge gap of 0.64 mm, 8000 ppm for a discharge gap of 0.47 mm with a 1070 ppm increase. With the same residence time, the SIE for the discharge gap of 0.47 mm is higher than that of 0.64 mm, so that higher concentration of NH3 is obtained with the gap of 0.47 mm. In addition, when the discharge gap becomes narrow, the fractional active volume is correspondingly increased, resulting in the increase of high-energy electron density. As a result, more molecules of CH4 and N2 are ionized and dissociated to produce N2 +, NH, CH4, CH3·radicals for the synthesis of NH3.

Effect of the Gas Temperature on the Concentration of Synthesized NH3 and Conversion Rate of CH4

Even though the feed gas isn’t heated, its temperature can go up to about 70–80 °C owing to the micro-gap discharge. As shown in Fig. 6, the concentration of NH3 increases with the gas temperature in the range of 14.9~137.3 °C. When the gas temperature exceeds 137.3 °C, the concentration of NH3 is almost constant at 7000 ppm. The gas temperature has light effect on the conversion rate of CH4, which is almost constant at 60%. The activation energy of gas molecules increase with the gas temperature so that more CH4 and N2 are ionized and dissociated for the synthesis of NH3. However, high temperature isn’t necessary for synthesis of NH3, and high temperature leads to electrodes breakdown and reactor destruction.

Conclusions

The conversion of CH4 into NH3 is investigated using the micro-gap discharge plasma. The whole reaction processes is carried out under the conditions of normal temperature and pressure without any catalyst, which is an environmentally friendly condition in accordance with Green Chemistry Principle. The results show that:

-

1)

Analysis of gas ingredient shows that the main products of CH4/N2 discharge plasma are NH3, H2 and hydrocarbons (≤C4) such as C2H6, C2H4, C2H2, C3H8, C3H6, i-C4H10, n-C4H10. The yield and generation rates of hydrocarbons (≤C4) are of the following relationship C2H6 > C3H8 > C2H2 > C2H4 > i-C4H10, n-C4H10 > C3H6.

-

2)

The synthesis of NH3 is realized using CH4/N2 micro-gap discharge at an atmospheric pressure. The yield of NH3 is 8000 ppm for a residence time of 1.6 s, and 1.89 × 103 mmol/g if the residence time was 2 h.

-

3)

The micro-gap gas discharge is a promising method for high H2 generation rate in the absence of catalyst. The yield and generation rate of H2 are 9.1% (v/v) and 1879.8 μmol/min, respectively.

References

Oumghar A, Legrand JC, Diamy AM (1994) A kinetic study of methane conversion by a dinitrogen microwave plasma. Plasma Chem Plasma Process 14(3):229–249

Oumghar A, Legrand JC, Diamy AM, Turillon N (1995) Methane conversion by an air microwave plasma. Plasma Chem Plasma Process 15(1):87–107

Legrand JC, Diamy AM, Hrach R, Oumghar A (1999) Mechanisms of methane decomposition in nitrogen afterglow plasma. Vacuum 52:27–32

Uyama H, Matsumoto O (1989) Synthesis of ammonia in high-frequency discharge. Plasma Chem Plasma Process 9(1):13–24

Amorim J, Baravian G, Ricard A (1995) Production of N, H, and NH active species in N2–H2 dc flowing discharges. Plasma Chem Plasma Process 15(4):721–731

Sugiyama K, Akazawa K, Oshima M et al. (1986) Ammonia synthesis by means of plasma over MgO catalyst. Plasma Chem Plasma Process 6(2):179–193

Uyama H, Nakamura T, Tanaka S, Matsumoto O (1993) Catalytic effect of iron wires on the syntheses of ammonia and hydrazine in a radio-frequency discharge. Plasma Chem Plasma Process 13(1):117–131

Tanaka S, Uyama H, Matsumoto O (1994) Synergistic effects of catalysts and plasmas on the synthesis of ammonia and hydrazine. Plasma Chem Plasma Process 14(4):491–505

Kabashima H, Einaga H, Futamura S (2003) Hydrogen generation from water, methane, and methanol with nonthermal plasma. IEEE Trans Ind Appl 39(2):340–345

Chen X, Marquez M, Rozak J, Marun C, Luo J, Suib SL, Hayashi Y, Matsumoto H (1998) H2O splitting in tubular plasma reactor. J Catal 178:372–377

Bai MD, Bai XY, Zhang ZT (2000) Synthesis of ammonia in a strong electric field discharge at ambient pressure. Plasma Chem Plasma Process 20(4):511–520

Bai MD, Zhang ZT, Bai XY, Wang N (2003) Plasma synthesis of ammonia with a microgap dielectric barrier discharge at ambient pressure. IEEE Trans Plasma Sci 31(6):1285–1291

Bai XY, Zhang ZT, Han H, Bai MD (2002) Research situation and progress of non-equilibrium plasma chemistry. Chinese Sci Bull 47(7):529–530

Horton B (1999) Green chemistry puts down roots. Nature 400(19):797–799

Leitner W (2000) Green chemistry: designed to dissolve. Nature 405(11):129–130

Yoon SF, Tan KH, Rusli H, Ahn J (2002) Modeling and analysis of hydrogen-methane plasma in electron cyclotron resonance chemical vapor deposition of diamond-like carbon. J Appl Phys 91(1):40–47

D3382-95 Standard test method for measurement of energy and integrated charge transfer due to partial discharge (Corona) using bridge techniques. In: 2001 Book of Standards, Vol. 10.02

Zhang ZT, Xian YZ, Bai MD, Zhao YH, Dong KB (2003) Electrical characterization of dielectric barrier discharge plasma using the charge-voltage figure. J Physics (in Chinese) 32(7):458–462

Author information

Authors and Affiliations

Corresponding author

Additional information

Project of National Major Foundation Research from Science and Technology Ministry of China (2004CCA06300).

Support Plans of National New Century Excellent Youth of China (NCET-04-0286, -05-0398).

Rights and permissions

About this article

Cite this article

Bai, M., Zhang, Z., Bai, M. et al. Synthesis of Ammonia Using CH4/N2 Plasmas Based on Micro-Gap Discharge under Environmentally Friendly Condition. Plasma Chem Plasma Process 28, 405–414 (2008). https://doi.org/10.1007/s11090-008-9132-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-008-9132-4