Abstract

The application of optimization methods and algorithms to energy management is crucial when trying to find instantaneous compromises between various energy sources that can provide the power required by a powertrain. Because of the complexity of both the problem and the system structure, it is difficult to determine the optimal strategy in real time (on-line and using the onboard computer). This article tackles the problem of optimizing the power provided by various sources available to meet the power demand from the driver whilst minimizing the total hydrogen consumption during a journey. The real challenge is to find an energy management law applicable in real time on any power profile. This paper presents two new energy management methods: off-line “Dynamic Programming with Improved Constraints (DPIC)” and a real-time optimized decision-maker based on a two-levels optimized Fuzzy Logic (Fuzzy Switching of Fuzzy Rules—FSFR). DPIC produces better results than the classical discrete dynamic programming with state-of-the-art constraints, in terms of execution time and hydrogen consumption. FSFR is a real time energy management algorithm based on fuzzy rules learnt on specific profiles and real-time fuzzy switching of these fuzzy rules. Both methods are evaluated on different types of real world profiles (urban, road and highway profiles), to assess and confirm their effectiveness.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The development of Hybrid Electric Vehicles (HEV) has started since the year 1900 with the beginning of the design of such cars. In 2011, more than 4.5 million hybrid vehicles have been sold worldwide. This increase is mainly due to the increase of the human population in the world from 1.7 billion people in 1900 to 7 billion people in 2011 (Chan 2002). Before the last decade there was no crisis in fossil fuels and the HEV diffusion was limited by the technology of electrical energy storage. Now, taking into account the eco-design, sustainable development and the price of oil, HEV promotion is a necessity to maintain or increase ones market shares. The name Hybrid Vehicle refers to the use of at least two different energy sources for the propulsion of the vehicles. Often, an internal combustion engine is used as the primary source for propulsion, mechanically coupled to the second source (batteries and electrical motor are commonly used in such called parallel structure), such as for the Toyota Prius II (Cheng et al. 2011). Such Hybrid Vehicles (Chan 2007; Burke 2007) are a good compromise because they are using existant manufacturing processes based on thermic engines. Due to the inflexibility of the actual power grid, the full Electric Vehicle using only batteries or capacitors is not yet feasible (Su et al. 2011) due to possible grid-overload when charging billions of EV. Another promising main energy source is the Fuel Cell, which is considered as the best energy source that reduces fuel consumption and the CO2 emission von Ellis et al. (2001), Rajashekara (2005). Fuel Cell System (FCS) cars are considered nature-friendly and already commercialized under well known brands such as Toyota (Aso et al. 2007). Since the onboard FCS does not deliver high power and because the energy generated during braking should be recovered for later reuse, it is necessary to add a reversible source of energy (Storage Element), generally an electro-chemical battery or super-capacitors (Chau et al. 1999; Thounthong et al. 2006). The SE is used as an assistant in peak power and recovers braking energy for a later reuse, allowing an optimization step dealing with the optimal splitting between both sources (Destraz et al. 2004). This paper is thus focused on HEV composed of a Fuel Cell System and Supercapacitors adding their electrical energy to feed the electrical moto-propulsion group (called serial structure). Combining such architecture shown on Fig. 1 with smart power management reduces considerably the fuel consumption (Wang and Li 2010) . The hybrid vehicle support of the work in this paper operates with two different power sources: a Fuel Cell System and a super-capacitor as SE. The biggest problem of using this hybridization is how to use optimally the different sources in order to minimize the global cost of hydrogen consumption for any mission. Hence the need to integrate an Energy Management System. A non-exhaustive list of methods and approaches existing in the literature of powers management is given in Desai and Williamson (2009).

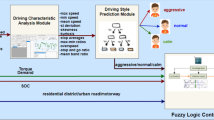

Energy Management Strategies are divided into two classes depending on the knowledge of the profile: if all road sections are known in advance, then, it is possible to use off-line strategies for global optimization; otherwise real-time management strategies are required (Hankache et al. 2008; Caux et al. 2010a,b; Neffati et al. 2011). Classical discrete Dynamic Programming, referred to as DP, is used as a reference off-line method, because it is the most popular method used in the literature for solving off-line optimization problems keeping computation time and data volume feasible onboard (O’Keefe and Markel 2006; Yu et al. 2009; Hofman et al. 2007; Sinoquet et al. 2009; Malaize and Tona 2011; Koot et al. 2005). The mathematical constraints formulation is significantly improved in this paper. The second real time energy management strategy proposed here is based on a system of fuzzy inference rules optimized through a Genetic Algorithm (G.A.). The G.A. optimizes the parameters of the fuzzy membership function and generates specific rules for each profile that characterize the relationship between the input and the output variable (Lombardi et al. 2006). The original method proposed develop a fuzzy switching of the fuzzy rules in real time. Such strategy is applicable to any unknown profile.

The paper is organized as follows: Section 2 presents the problem formulation of HEV energy management. Section 3 describes an energy management strategy off-line based on the Dynamic Programming and the Dynamic programming with Improved Constraints (DPIC). Section 4 focusses on a real-time energy management strategy based on Fuzzy Switching for Fuzzy Rules. Finally, Sect. 5 presents the results on different driving cycles by applying the different methods.

2 Problem description

The hybrid system under consideration has two energy sources, as illustrated on Fig. 1: a Fuel Cell Stack and a Storage Element (super-capacitor). It derives from a hybrid full electric vehicle classified as hybridization series. The FCS is the main energy source used to produce electricity from hydrogen. Usually it provides the electricity needed for the traction whereas the SE can recover the energy generated during braking phases, or from the FCS itself, for a later reuse.

The goal is to minimize the overall cost of hydrogen consumption for a given vehicle that follows a given profile of power demand, by optimizing the distribution of power between the two sources under several constraints: availability of the two sources (power and energy limits), performance (varying efficiency curves) and State of Charge (SOC) of the super-capacitator.

The design of the power sources is outside the scope of this paper. The optimization problem considered here is done on a pre-defined system whose characteristics are summarized in Table 1.

2.1 Fuel cell system (FCS)

A Fuel Cell System (FCS) is a device that transforms chemical energy into electrical energy from a chemical reaction between the hydrogen contained in a storage tank in the first side and oxygen on the other side. It is considered as the primary source. There is no pollutant emission, only water is generated if pressure, gaz flow and heat are locally controlled. The main feature of the controlled FCS is the efficiency curve taken experimentally as a non-linear function of the power delivered by the FCS (see Fig. 2). The optimization criterion is the minimization of the hydrogen consumption cost during a mission, with the aim of increasing its autonomy whilst respecting all its constraints (design and internal control fixing efficiency curves, minimum and maximum deliverable power).

2.2 Storage element system (SE)

A Storage Element (SE) is needed to follow high accelerations of a few seconds that cannot be provided by the main source (which otherwise would be over-dimensioned). To fulfill this requirement, a super-capacitor is more suitable than a battery, because it presents a higher dynamic to quickly deliver the power during a short period of time (Lu et al. 2007). It also has an almost constant efficiency coefficient. Let the State Of Charge SOC(t) be the amount of energy contained in the SE at instant-time t. SOCmin and SOCmax are respectively the minimum and the maximum amount of energy that the SE can contain. Generally the Storage Element can only be used between 25 % and 100 % of its energy capacity (Tallner and Lannetoft 2005).

If the SE supplies power to the powertrain system (discharge) then P SE>0 and \(\dot{x}(t) < 0\) (x represents State Of Charge). Otherwise, if the SE absorbs the power recovered by the braking (recharge) then P SE<0 and \(\dot{x}(t) > 0\). Therefore, equation (1) is always valid.

2.3 Powertrain system

The powertrain is responsible for the traction in the HEV. The system consumes the electrical energy provided by both sources. If the power of this moto-propulsion-group is positive then the system is in traction, if it is negative then the vehicle is in braking. At the end, if the power demand is zero then the vehicle is stopped.

2.4 Power demand profile

Energy optimization can be performed once the following elements have been identified: the profile of the power demand corresponding to the journey of the vehicle, the loss characteristic of the SE, and the efficiency of the FCS. Three profiles provided by INRETS/IFSTTAR (National Institut on Science and Technology in Transport) are used in this paper: the path of an Electric Vehicle in Urban environments, a Road mission (fluent traffic) and a Highway mission (Neffati et al. 2011).

3 Off-line strategy

Assuming that the mission is known in advance, it is possible to apply an off-line global optimization algorithm. The goal is to compute the lower consumption cost reachable, that can later be used as a reference when trying to evaluate the global performance of the vehicle achievable with the real time optimization approaches.

3.1 Problem formulation

The problem is formulated as a non-linear problem with non-linear constraints as follows:

-

Decision variables \(\divideontimes\, P_{\mathrm{FC}_{i}} =\) instantaneous power generated by the FCS at time i, \(P_{\mathrm{FC}_{i}} \geq0\) \(\divideontimes\, P_{\mathrm{SE}_{i}} =\) instantaneous power generated (\(P_{\mathrm{SE}_{i}} \geq0\)) or stored (\(P_{\mathrm{SE}_{i}} \leq0\)) by the SE at time i ⋇ SOC i = State Of Charge at time i (the following percentage is used \(x_{i} = \frac{\mathrm{SOC}_{i}}{\mathrm{SOC}_{\max}}\))

-

Bounds

$$ \begin{array}{c} \forall i \in[1,\ldots,n], \quad P_{\mathrm{FCmin}} \leq P_{\mathrm{FC}_i} \leq P_{\mathrm{FCmax}}\\ \forall i \in[1,\ldots,n], \quad P_{\mathrm{SEmin}} \leq P_{\mathrm{SE}_i} \leq P_{\mathrm{SEmax}} \end{array} $$(2) -

Objective function: Minimize the total energy consumed by the fuel cell

$$ \min\, F(P_{\mathrm{FC}})= \min\sum_{i=1}^{n}f(P_{\mathrm{FC}_i}) $$(3)⊛ Definition of the function \(f(P_{\mathrm{FC}_{i}})\)

$$ f(P_{\mathrm{FC}_i})=\frac{P_{\mathrm{FC}_i}}{\rho(P_{\mathrm{FC}_i})} $$(4)where ρ is the efficiency function of the fuel cell. Since the data is obtained experimentally, there are two ways to represent this function: as a continuous function per piece or polynomial function of degree three or greater according to the superposition of the function with the experimental curve.

-

Constraints ⊛ Meet the power demand at each instant time

$$ \begin{array}{c} \forall i \in[1,\ldots,n], \quad P_{\mathrm{FC}_i} +P_{\mathrm{SE}_i} = P_r (i) \end{array} $$(5)⊛ Initial state of charge equal to final state of charge:

$$ \sum_{i=1}^{n}[P_{\mathrm{SE}_i} +\tilde{\rho}(P_{\mathrm{SE}_i})]=0 $$(6)

where \(\tilde{\rho}(P_{\mathrm{SE}_{i}})\) is the energy losses function of the SE. With this condition, the SE ends with a state of charge equal to its initial state of charge, allowing the vehicle to restart the mission in the same condition as often as requested. In this case, it reuses all the amount of energy recovered from braking. If the energy level is not imposed to the SE at the end of the profile, then the equation becomes:

⊛ Bounds on the variation of the state of charge:

The classical discrete dynamic programming is applied to solve this problem.

3.2 Dynamic programming (DP)

In the energy management literature, the most popular method used is Dynamic Programming (Bonnans et al. 2004; Won et al. 2005; Lin et al. 2003). It is based for the discrete form, on a recurrence relation allowing for the computation of the cost of hydrogen consumption.

Classical formulations of the global optimization problem are usually based on a state equation (10) and consist in finding a command that brings the system from the predefined initial state to a desired final state with a minimized cost criterion (11) while respecting constraints (12). In the HEV case, the state corresponds to the energy evolution in the SE; these evolution imposes the complementary FCS solicitation thus fuel consumption and constraints classically applied during a mission are (5) and (6).

State equation:

Cost criterion to be minimized:

Constraints:

where

-

x(t) represents the system State Of Charge, which in the HEV case corresponds to the SOC of the SE

-

u(t) represents the command variable, which in the HEV case corresponds to the power from the FCS

-

γ represents the criterion cost, which in the HEV case corresponds to the hydrogen consumption

When the time horizon is discretized, the state equation can be written with equation (13). Then, an admissible command u(k) at each step k moves the system from state x(k) to another state x(k+1). Such move has a cost γ(x(k),u(k),k) and by definition, an admissible command corresponds to a trajectory of the state variable x satisfying all the constraints (12). The set of feasible trajectories is the validity domain. The total cost is equal to the sum of all movement costs between the initial and the final time step.

Starting from a known initial state x(0)=SOC0, the goal is to find an admissible command sequence u(1),u(2),…,u(N), where N is the number of discrete time steps, that minimizes the total cost of the mission described in (14).

The application of DP requires a fully discretized validity domain. A profile of the power demand must be discretized in function of time (“horizontal discretization of the validity domain”) Δt=(t N −t 0)/N, not only because the power repartition decisions are computed onboard but also to take into account the fact that it is not possible in practice to have instantaneous variations of the power delivered by the sources (because of a voltage equilibrium control in the SE and an internal control fluid dynamic in the FCS). Therefore, an additional discretization of the energy levels of the SE (“vertical discretization of the validity domain”) is necessary before DP can be applied, usually ΔSOC=(SOCmax−SOCmin)/M, where M is the number of energy steps chosen. The value of M should not be small (no accuracy on the resulting optimization solution) and not too large so as not to overload the onboard computer.

A summary of DP is given in Algorithm 1, where:

-

(i)

\(\operatorname{Cost}(j,k)\) is the optimal cost to go from a SOC value of j at time k to the predefined final SOC N at time N,

-

(ii)

E k is the vector of all feasible (in the validity domain) SOC values at instant k and

-

(iii)

\(\operatorname{CommandSeq}(j,k)\) is the command u(k) related to the cost \(\operatorname{Cost}(j,k)\). Note that if \(\operatorname{Cost}'(k,j,p)\) is the cost of moving from state j at time k to state p at time k+1, then DP consists in the backward computation (from the end to the beginning) of a shortest path from a predefined starting-node to the desired ending-node, on a graph where:

-

each node corresponds to a couple (time_step, SOC_level)

-

the starting node corresponds to time step 0 and the initial SOC level; the ending node corresponds to time step N and the desired final SOC

-

an arc (i,j) exists only if it is possible to move from node i to node j in a single time step; the cost associated to such arc (i,j) is the fuel consumption necessary to perform the move from node i to node j

-

3.3 Main weaknesses identified in DP

3.3.1 Recovery of energy braking

The main idea of using a reversible source is to recover braking energy for later use. Hence a reduction of the energy consumption cost. However, contrary to the common assumption, imposing that braking energy has to be recovered and reused may lead to worst solutions. In fact in such case the power tend to be delivered by the SE to ensure that it is discharged before the end, lowering the use of FCS to lower efficiency points and a greater Hydrogen consumption.

Figure 3 illustrates an example, on a 15 seconds profile, where P r is power requested (or power demand), P SE and P FC are the power provided by respectively the SE and the FCS. In the first case, when retrieving braking energy, the cost of the mission is equal to 37 kWs. In the second case, no braking energy is recovered and the cost is reduced to 32 kWs. Another example can be generated by considering a vehicle descending a downward path. In this case, the amount of braking energy is greater than the amount of traction, therefore there is no feasible solution that allows to recover all of the braking energy.

As a consequence, the equality constraint P r =P FC+P SE, should be replaced with the inequality P r ≤P FC+P SE. This means that during braking, the recovery of all or part of the energy generated is authorized but not mandatory. Unrecovered braking energy can be simply dissipated as in mechanical heat and as having no effect on the optimization.

3.3.2 Final state of charge of the SE

To facilitate comparisons between different algorithms and to be able to repeat the same cycles in the same conditions, Rousseau et al. (2008) and Serrao et al. (2011) proposed to impose an equality between the initial (at instant-time t 0) and the final (at instant-time t N ) state of the SE. However, for some instances, this means that the vehicle had to “burn” excess energy towards the end of the profile to return the energy level to its initial state. As a solution, we propose to forbid the driver to return the SE at the end with less energy than the quantity he had at the beginning of the profile, but to allow the final energy level to be higher than at start (but with no special reward for the additional energy). In a DP algorithm, this corresponds to opening the validity domain and allowing the final SOC element to vary in an interval, instead of being reduced to a single point (see example Fig. 4).

3.3.3 Penalties due to SE discretization

Figure 5 illustrates an example where the braking energy is greater than the traction energy which should lead to a cost of zero. DP produces a solution which uses the FCS and therefore has a cost strictly positive. Basically, since the power levels have been discretized, the system tends to respond too strongly to demands that are not exact multiples of the discretization step. This flaw has been handled when designing the following proposed algorithms.

To summarize, DP produces good results in the literature, even better than the fuzzy logic and optimal control. However, there is an increasing need for a new and more efficient approach to find better solutions in terms of total cost as well as computation time taking into account specific constraints in HEV energy management and sampling DP form used in ship onboard computer.

3.4 Dynamic programming with improved constraints (DPIC)

The goal of DPIC is to get only the amount of energy that would not deteriorate the quality of the final solution. As a consequence, the constraint (5) is relaxed for all instant times k∈[1,…,N]:

The idea is to get less energy from braking and provide a little more than the required energy if it leads the FCS to a better point on the efficiency curve (thus a better solution). So at each instant k∈[1,…,N], ε(k) must be calculated in order to avoid the wasted energy done by the constraint equation (5) and explained in the Sect. 3.3.1.

In terms of implementation, it consists in modifying the costs of arcs on the (time step, SOC level)-graph on which the shortest path is computed. Indeed, \(\operatorname{Cost}'(k,j,p)\) is now equal to the minimum cost among all costs of movements that can move the system from energy level j to any energy level p′ with 0≤p′−p≤ discretization step. The excess electrical energy (surplus quantity =p′−p) can be dissipated as heat (in resistances present in the braking system) or reused at home.

3.5 Intermediate results

3.5.1 Multi-objective optimization

An open validity domain is established by fixing only the initial or the final SOC value and authorizing the variation of the other in an interval, so that a multi-objective optimization (cost vs initial or final SOC value) is obtained in a single run of DP. Time and energy discretization defined are input variables,set here, taking into account the onboard computer limitation, to 1 kWh for the energy step and 1s for time step. Note that in the case of multi-start, the final SOC is 900 kWs and in the case of multi-end, the initial SOC is 900 kWs (arbitrarily chosen in the middle of [SOCmin SOCmax]. Figure 6 shows that the cost of hydrogen consumption and the initial or final SOC are connected through two affine functions. Each of the two lines inclined to the left represents a multi-start SOC with a final fixed SOC depending on the minimum cost corresponding to each starting point. It should be noticed that each point on the line represents an optimal solution obtained (best fuel cost achieved vs the corresponding starting SOC). These two straight lines are parallel and show that the benefit of DPIC versus DP is constant (1130 kWs). The figure also shows the characteristics that the SE should have (such as minimum and maximum SOC achievable). In this example, the smallest possible final SOC, by absorbing all the energy from braking is 691 kWs, therefore it is impossible to return with an empty SE at the end of the mission.

3.5.2 Intersection energy

If the initial SOC is fixed to SOC(x 0), the application of DP recursively from the initial SOC to finals SOC shows that it is possible to connect all the possible final states of charge to the initial SOC with an optimal consumption cost path. Similarly, when the final SOC is fixed to SOC(x N ), the application of DP recursively from the final SOC to initial states of charge shows that, as illustrated on Fig. 7 it is possible to connect any feasible initial state of charge with the final SOC through an optimal consumption cost path.

The interest in recording all solutions is the possibility to find alternatives if a disturbance occurred on the system or if there was a posterior decision change about the desired final state of charge. To do this, finding an intersection with another path that leads to the desired state of charge is necessary. Figure 8 shows that from a single intersection point between two solutions, four paths are obtained, so it is possible to change the path with an easily quantifiable consumption cost.

4 On-line strategy

The Energy Management Strategy (EMS) using Dynamic Programming provides a benchmark regarding the maximum potential fuel savings. A real-time EMS using DP is hampered by two restrictions. First, an a priori knowledge is needed about the power demand along the entire driving cycle. Second, calculations from DP over a lengthy driving cycle are computationally demanding (Yu et al. 2009; O’Keefe and Markel 2006). To overcome both problems, this paper proposes an on-line EMS based on a fuzzy logic decision system (Caux et al. 2010a; Neffati et al. 2011).

4.1 Fuzzy energy management

The fuzzy logic rules are used to identify the instantaneous power output to be supplied by FCS using two input variables: the SOC and the power required. The fuzzy inference system is characterized by rules that are already have been already turned by a Genetic Algorithm (Fig. 9). GA is used to optimize the choice of the parameters of the fuzzy membership functions and generate these specific rules for each profile that characterize the relationship that should be enforced between the input and the output variables (Neffati et al. 2011). Once the optimal rules have been identified off-line, the fuzzy decision can be used in the EMS without prior knowledge of the journey. When applying a rule on the profile on which it was optimized, better results are obtained. And if another rule is applied the consumption degrades. The consumption obtained by applying a single rule for each profile is shown in Table 2.

Several characteristics and various power classes can be found in a power profile. In this context, a method is proposed to optimally switch between different set of optimal rules that involves manipulating the fuzzy rules according to the required power via a segmentation method (Neffati et al. 2011). The switching rules is a program that uses the average power as an indicator, then it computes the average power of segments to give each segment an index, this index will be used later in the optimization algorithm to choose the optimal rule to be used from the existing rules. This indicator can be seen as a prediction to help the decision.

In order to establish a method of EMS in real time and in the case of an unknown profile, the decision on the choice of the best rule should now be made in real time.

4.2 Real-time fuzzy switching of fuzzy rules FSFR

Instead of using pattern recognition or clustering approach, a fuzzy switching decision is sought. The second fuzzy decision system proposed is used to characterize in real time the power required to identify the best fuzzy rule management to use for each power demand. The membership functions and the universes of discourse of each variable of the fuzzy switching rules are shown in Fig. 10. The second fuzzy system for switching fuzzy (Fig. 10(a)) uses two input variables: the power demand in real time at the moment i, and a prediction factor which contains the average of three previous power demand (Fig. 10(b)).

The output variable of the system is the best decision of the fuzzy rule (Rule 1 (R.1), Rule 2 (R.2), Rule 3 (R.3)) to be applied for the power demand at this moment i. The universe of discourse of each variable is divided into three classes, the power required and the prediction factor are characterized by “low”, “average” and “high”. The output variable of fuzzy switching system takes three decisions “Rule 1 of the urban profile”, “Rule 2 of the road profile” and “Rule 3 of the highway profile”. All parameters of the fuzzy controller were optimized using genetic algorithm in order to have a complete energy management in real time based on the fuzzy switching of fuzzy rules (Fig. 11(b)). The choice of the output variable and more precisely the identification of the best fuzzy rule to be used after, depends on the input parameters which are formulated as a description language using the fuzzification to the output variable. The linguistic description of the inference system adopted in this fuzzy decision is as follows:

If P r is “Low” | and index is | “Low” | then use a “R. 1” |

If P r is “Average” | and index is | “Low” | then use a “R. 1” |

If P r is “High” | and index is | “Low” | then use a “R. 2” |

If P r is “Low” | and index is | “Average” | then use a “R. 1” |

If P r is “Average” | and index is | “Average” | then use a “R. 2” |

If P r is “High” | and index is | “Average” | then use a “R. 3” |

If P r is “Low” | and index is | “High” | then use a “R. 2” |

If P r is “Average” | and index is | “High” | then use a “R. 3” |

If P r is “High” | and index is | “High” | then use a “R. 3” |

Note that the power supplied by the FCS, is in terms of two input parameters, the required power on one hand and the SOC of the SE on the other. If the rules were mixed together, the power supplied would risk to not be optimal, because at every moment, each rule i makes a different calculation of the value of their output, which explains why an error (P r ≠P FC+P SE) appears in this method of fuzzy switching if the rules are mixed.

In order to solve the problem of energy errors (P r not satisfied), an adjustment was made in the optimization algorithm, corresponding to the cases where the power supplied by FCS should be calculated by two fuzzy rules at the same time. The correction highlights the need to always use a single fuzzy rule “Urban or Road or Highway”. Improving the fuzzy inference system requires an adjustment phase and an improvement of its parameters. For this purpose, the genetic algorithm is again used to optimize the choice of the parameters of the fuzzy decision switching to finally obtain a complete system of energy management in real time. This system is called FSFR.

The results show that EMS based on FSFR has improved energy consumption compared to the application of one rule that has been optimized using another profile. This finding leads us to note that if the fuzzy switching algorithm is applied on any unknown profile, the results will still be very near to the optimal consumption with zero error of energy.

5 Results and comparisons

Four instances are used. The upper bounds are obtained by assuming that the storage element is not used, as if the vehicle was not hybrid. Dynamic Programming provides good solutions, better than this upper bound, but DPIC produces even better solutions in the case of off-line computation and the Fuzzy Logic in the case of the on-line management.

For Urban profile and off-line strategy, the improvement of DP over the upper bound is small (9 %) compared to the improvement obtained with DPIC (nearly 60 %). Therefore we can conclude that for the off-line strategy, the use of DPIC gives always better result compared to the use of the Fuel Cell alone or compared to the classical DP constraints.

For the Highway profile, there is less braking energy than in Urban profile and consequently there is less energy recoverable for reuse, thus there is no great effect of the use of a EMS on the overall consumption both in the on-line or off-line strategy as shown in Fig. 12(c). The improvement is not very large compared to the use of the fuel cell alone and represents a maximum of 15 %.

On the Road profile, the instantaneous consumption using FSFR is equal to consumption using DPIC until 60 % of the mission (see Fig. 12(b)), and from this point the DPIC solution converges to a better solution.

The improvement obtained by applying the FSFR method is given in Table 3. The gain is significant for the four profiles, compared to the off-line method DP (Fig. 12 and Table 3). Recall that the dynamic algorithm must respect the state-of-the-art constraints expression and that have been called into question in Sect. 3 of this paper, such as recovery of all braking energy and the equality constraint on initial and final SOC. So the algorithm is sometimes in critical situations, where it is forced to operate the FCS in points that are characterized by low efficiency in order to meet these constraints. On the contrary, the FSFR is more flexible. The originality of a fuzzy rule is to provide a better consumption, within the limits of charge, so as to bring the fuel cell to work in points that are characterized by better efficiency while remaining within the limits (Fig. 12). The fuzzy rules allow, during the profile, to not recover energy braking if necessary, avoiding low fuel cell efficiency. If the SE is empty at the end, reloading it after the journey is more efficient (even if the FCS system is used to reload the SE, the vehicle is stopped and it is possible to use the FCS at its maximum efficiency point).

Figure 13 shows that the energy variation of the SE is important from a strategy to another, but the variation of the hydrogen consumption cost is not so important. That shows the numerous possibilities to vary the space energy in the storage element without losing too much hydrogen (difficult optimization problem). More specifically, in Fig. 13(a), regarding the use of the fuzzy logic, it appears that using the Charge-sustaining mode is relevant at the end of mission.

The distribution of operating points of the FCS for each proposed approach of EMS explains the improvements achieved compared to DP. In the case of Urban profile, 70 % of the points which are characterized by low efficiency when applying DP have been cancelled by the application of the DPIC or FSFR, this reflects the 60 % improvement by DPIC and the 42 % improvement by FSFR. This observation leads to the conclusion that these methods proposed steer towards the usage of FCS at a better efficiency level both in an off-line and anon-line context.

6 Conclusion

As in the literature, the hybridization (the addition of a storage element to a primal power source leading to a multi-source of power) has a positive effect on the cost of consumption, regardless of the method or tool used for energy management. To apply dynamic programming, the energy contained in the storage element has to be discretized. As a result, this discretization has a negative effect, especially the penalty incurred by the Fuel Cell System if the energy discretization step is different from the braking or demanded power. To counter that, Dynamic Programming with Improved Constraints is able to provide a little more energy than required if the limit of the required power is lower than a specified power. Moreover an improved mathematical model was defined to better manage the energy recovery and store only the necessary quantity to minimize the criterion. Energy Management Strategy in real time based on fuzzy rules was also applied. This approach has been improved by the methods of segmentation and a fuzzy switching layer. The energy management strategy based on Fuzzy Switching of Fuzzy Rules (FSFR) has been tested on different profiles. This method takes into account the evolution of the state of charge of the storage element at each time, leading the fuel cell to operate at its best efficiency point. The results show that if the designed method of fuzzy switching is applied in real time on any unknown profile, it will deliver near-optimal results, better than the consumption obtained with the DP. Such controller is not time consuming and physical experiments can now start. Future works also include extensions on the energy management for more than two sources.

References

Aso S, Kizaki M, Nonobe Y (2007) Development of fuel cell hybrid vehicles in TOYOTA. In: Power conversion, Conference-Nagoya, PCC’07, pp 1606–1611

Bonnans J, Guilbaud T, Ketfi-Cherif A, Von Wissel D, Sagastizábal C, Zidani H (2004) Parametric optimization of hybrid car engines. Optim Eng 5(4):395–415

Burke AF (2007) Batteries and ultracapacitors for electric, hybrid, and fuel cell vehicles. Proc IEEE 95(4):806–820

Caux S, Hankache W, Fadel M, Hissel D (2010a) On-line fuzzy energy management for hybrid fuel cell systems. Int J Hydrog Energy 35(5):2134–2143

Caux S, Hankache W, Fadel M, Hissel D (2010b) PEM fuel cell model suitable for energy optimization purposes. Energy Convers Manag 51(2):320–328

Chan CC (2002) The state of the art of electric and hybrid vehicles. Proc IEEE 90(2):247–275

Chan CC (2007) The state of the art of electric, hybrid, and fuel cell vehicles. Proc IEEE 95(4):704–718

Chau KT, Wong YS, Chan CC (1999) An overview of energy sources for electric vehicles. Energy Convers Manag 40(10):1021–1039

Cheng Y, Trigui R, Espanet C, Bouscayrol A, Cui S (2011) Specifications and design of a PM electric variable transmission for Toyota Prius II. IEEE Trans Veh Technol 60(9):4106–4114

Desai C, Williamson SS (2009) Comparative study of hybrid electric vehicle control strategies for improved drivetrain efficiency analysis. In: Electrical power & energy conference (EPEC), pp 1–6

Destraz B, Barrade P, Rufer A (2004) Power assistance for diesel-electric locomotives with supercapacitive energy storage. In: IEEE 35th Annual Power Electronics Specialists Conference PESC, vol 1, pp 677–682

Ellis MW, von Spakovsky MR, Nelson DJ (2001) Fuel cell systems: efficient, flexible energy conversion for the 21st century. Proc IEEE 89(12):1808–1818

Hankache W, Caux S, Fadel M, Hissel D (2008) Real time fuzzy energy management of fuel cell and ultracapacitor powertrains. In: Fundamentals and developments of fuel cell (FDFC), Nancy, France

Hofman T, Steinbuch M, van Druten R, Serrarens A (2007) Rule-based energy management strategies for hybrid vehicles. Int J Electr Hybrid Veh 1(1):71–94

Koot M, Kessels J, deJager B, Heemels W, vandenBosch P, Steinbuch M (2005) Energy management strategies for vehicular electric power systems. IEEE Trans Veh Technol 54(3):771–782

Lin C, Peng H, Grizzle J, Kang J (2003) Power management strategy for a parallel hybrid electric truck. IEEE Trans Control Syst Technol 11(6):839–849

Lombardi G, Mengali G, Beux F (2006) A hybrid genetic based optimization procedure for aircraft conceptual analysis. Optim Eng 7(2):151–171

Lu R, Zhu C, Tian L, Wang Q (2007) Super-capacitor stacks management system with dynamic equalization techniques. IEEE Trans Magn 43(1):254–258

Malaize J, Tona P (2011) Optimization-based control design for hybrid energy storage systems in electric vehicles. In: IEEE Vehicle power and propulsion conference (VPPC), pp 1–7

Neffati A, Caux S, Fadel M (2011) Local versus global optimization in multi source energy management. In: Fundamentals and developments of fuel cell (Conference–FDFC), Grenoble, France

O’Keefe M, Markel A (2006) Dynamic programming applied to investigate energy management strategies for a plug-in hev. Tech Rep, National Renewable Energy Laboratory

Rajashekara K (2005) Hybrid fuel-cell strategies for clean power generation. IEEE Trans Ind Appl 41(3):682–689

Rousseau G, Sinoquet D, Sciarretta A, Milhau Y (2008) Design optimization and optimal control for hybrid vehicles. In: International conference on engineering optimization (EngOpt), Rio de Janeiro, Brazil

Serrao L, Onori S, Rizzoni G (2011) A comparative analysis of energy management strategies for hybrid electric vehicles. J Dyn Syst Measur Control 133(3)

Sinoquet D, Rousseau G, Milhau Y (2009) Design optimization and optimal control for hybrid vehicles. Optim Eng 12(1–2):199–213

Su W, Rahimi Eichi H, Zeng W, Chow M (2011) A survey on the electrification of transportation in a smart grid environment. IEEE Trans Indust Inf 99

Tallner C, Lannetoft S (2005) Batteries or supercapacitors as energy storage in HEVs?

Thounthong P, Raël S, Davat B, Sadli I (2006) A control strategy of fuel cell/battery hybrid power source for electric vehicle applications. In: 37th IEEE Power electronics specialists conference (PESC), pp 1–7

Wang L, Li H (2010) Maximum fuel economy-oriented power management design for a fuel cell vehicle using battery and ultracapacitor. IEEE Trans Ind Appl 46(3):1011–1020

Won J, Langari R, Ehsani M (2005) An energy management and charge sustaining strategy for a parallel hybrid vehicle with CVT. IEEE Trans Control Syst Technol 13(2):313–320

Yu YB, Wang QN, Min HT, Wang PY, Hao CG (2009) Control strategy optimization using dynamic programming method for synergic electric system on hybrid electric vehicle. Nat Sci 1(3):222–228

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guemri, M., Neffati, A., Caux, S. et al. Management of distributed power in hybrid vehicles based on D.P. or Fuzzy Logic. Optim Eng 15, 993–1012 (2014). https://doi.org/10.1007/s11081-013-9235-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11081-013-9235-5