Abstract

Creep failure behavior of rock is the focus of research on rock rheology and affects the stability and safety of slopes and underground structure. Based on continuous damage mechanics and the physical damage mechanism, double variables of time-dependent damages are defined here to further investigate the creep behaviors of rock. A new viscoelastic-plastic damage element and residual strength correction factor are first introduced to construct a novel double damage factor for the creep constitutive model. Furthermore, three-dimensional creep equations are derived for considering the yield criterion, plastic potential function, and flow law. Finally, the experimental data and the Burgers model have conducted a series of validations on the proposed model. Results show that the model proposed here can accurately capture the creep characteristics of rock, especially in simulating accelerated creep. The proposed model is more advantageous than the Burgers model and provides some reference for practical engineering design and safety monitoring.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Nowadays, it is well known that the rheological properties of rock materials contribute to the safety of buildings and slopes (Zhao et al. 2017; Xu et al. 2019; Cao et al. 2020). The essential purpose of rock rheology research is to analyze the actual mechanical properties of rock mass and the relationship between mechanical properties and rock structure, i.e., to establish the constitutive equation of rock. The creep fracture or creep failure of rock has time effects. Many scholars have made in-depth studies on the creep properties of stones, and a series of valuable results have been obtained (Chaboche 1982; Zhong and Ma 1987; Kachanov 1993; Wong et al. 2006; Jiang et al. 2013; Wu et al. 2020; Li et al. 2021).

As we know, the creep model of rock mainly includes two categories of mechanical models and physical models (Cao et al. 2020; Li et al. 2021). Mechanical models are widely used due to their easy understanding and clear physical mechanics concepts. However, it has difficulty to characterize nonlinear deformation properties (Liu et al. 2020). Physical models establish the rheological constitutive relations from the perspective of solid-state physics. They can consider the effects of physical and chemical properties inside materials, crystal and crystal boundary defects on the rheological properties. Unluckily, the development of the two kinds of models is relatively independent, there is lack of effective bridging and transition methods between them because the question of an organic combination between them has not yet been substantively resolved (Xue and Zhang 2015) in recent years, the introduction of damage mechanics provides a way to solve this problem.

Previous studies have shown that correctly defining the damage variable is essential for constructing the damage creep models. Since the concept of continuous damage was proposed (Kachanov 1958), the damage variable has been defined from various perspectives and approaches. The familiar theoretical bases of the definition can be divided into three categories. One is the effective bearing area, earlier, Chaboche (1982) pointed out that material damage mainly represents a reduction in the effective bearing area at a macro level. Then, based on the concept, Kachanov (1993) obtained the time-dependent damage variable by considering the stress and material properties. Another is the so-called geometric damage theory, which focuses on the quantitative relation between the mesoscopic cracks and the damage, such representative damage variables can be found in Grady (1980), Chen and Taylor(1985), and Yang (1996). The last is the statistical damage theory. Tang and Kaiser (1998) proposed that the cumulative seismic damage calculated by the simulated event rate can be used as the damage parameter to describe the damage evolution mechanism. Wong et al. (2006) postulated that the statistics of damage properties follow the Weibull distribution with time parameters at the grain scale. To accurately study some dynamic mechanical behaviors of rock, such as accelerated creep behavior, time as an essential parameter is further coupled into the damage variable (Jiang et al. 2013; Wang et al. 2014, 2017; Liu et al. 2017; Wu et al. 2020; Yan et al. 2020).

It is observed that these researches introduce a single damage variable into the damage evolution equation for changing physical constants into nonlinear variables. In light of the above discussion, there are two main ideas for dealing with the coupling behavior of time and damage in mechanical models. One is to convert some physical constants into equivalent variables based on the concept of effective bearing area, and the other is to directly reduce the values of physical constants based on the damage deterioration characteristics of materials. However, in these damage creep models mentioned above, only one of the two is adopted. That is, only a single time-dependent damage variable is used to capture the nonlinear characteristics for accelerated damage creep behavior of rock under different mechanical and physical mechanisms. As a result, these models have some shortcomings in theory and need further research.

In addition, according to the experiments on the total stress–strain relationship of the rock, there is still a particular residual strength after the failure of the rock (Xu et al. 2018; Zhu et al. 2019). The residual strength should be incorporated into the time-dependent damage variable, which can improve the rigor of the damage creep model. Still, there are few studies on the residual strength in creep constitutive models of rock.

Another problem, the current consensus is that the accelerated creep characteristics of rock are mainly related to the deterioration of the properties of elastic modulus and viscosity coefficient. Previous studies of the static damage model of rock also show that it is not adequate to describe three-dimensional isotropic damage only by a single damage scalar. Two independent damage scalars are needed (Fares 1993; Kachanov 1993; Gao et al. 1996). Although many damage creep models exist, the damaging effect on elastic modulus and viscosity coefficient is rarely considered simultaneously.

This paper aims to introduce a new viscoelasto-plastic damage element considering double time-dependent damage variables. The damage correction coefficient is firstly utilized to improve the time-dependent damage variable. Then, a one-dimensional damage creep model is obtained using a constitutive differential equation with double damage scalars. To better accord with the engineering practice, considering the failure criterion and the flow law, the three-dimensional creep damage constitutive equation of rock is further derived. Finally, experimental data and the Burgers model are used to verify and analyze the proposed constitutive model. For the safe design and construction of slopes and underground structures, this study can provide a theoretical reference and can better guarantee the stability and safety of the projects.

2 Establishment of the damage viscoelastic-plastic creep model

2.1 Definition of double time-dependent damage variables

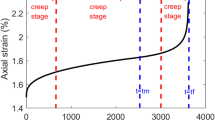

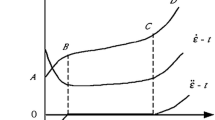

The typical creep curve of rocks consists of three stages, transient creep, steady creep, and accelerated creep, as shown in Fig. 1. When the loading stress level is lower than the long-term strength of the rock, the internal damage of rock material has little influence on creep, and the creep curve of the stone only includes the transient and steady stages. On the contrary, the damage will occur to the rock and result in a faster rate of rock deformation, and then rock creep will enter the accelerated stage.

In general, the initial two stages can be accurately described by the traditional Burgers model, as shown in Fig. 2, and the corresponding constitutive differential equation can be written as Eq. (1) (Chen et al. 2017)

where \(\dot{\sigma }\) and \(\ddot{\sigma }\) represent the first and second derivatives of stress to time, respectively. \(\dot{\varepsilon }\) and \(\ddot{\varepsilon }\) represent the first and second derivatives of strain versus time, respectively. E1 is the elastic modulus of the elastic body. η3 is the viscosity coefficient of the viscous body. E2 and η2 are the elastic modulus and viscosity coefficient of the viscous body, respectively. By solving Eq. (1), the one-dimensional creep equation of the Burgers model can be obtained as

where ε is the total strain of the Burgers model. σ is the stress inside the rock. t is the cumulative loading time, and the meanings of other parameter symbols are the same as above.

Compared to the initial two stages of rock creep, the third stage, i.e. the acceleration stage of creep, has nonlinear characteristics. Existing studies (Kachanov 1958, 1993; Chaboche 1982; Fares 1993) have shown that the evolution and development of internal mseo-cracks under external load will be produced along with the stress–strain change process of rock. These mesoscopic defects will slowly evolve to macro performance deterioration, eventually leading to rock destruction. So the damage variables are defined here from two aspects of macroscopic and mesoscopic.

Firstly, from the macroscopic point of view, under the external force, dislocation creep and diffusion creep both lead to the generation of mesoscopic cracks and holes, as time goes on, these accumulated defects will lead to a reduction in effective bearing area, which in turn leads to an increase in effective stress. Herein, concerning the concept of effective stress proposed by Kachanov (1992, 2007), the expression of time-dependent damage variable D1 relating to effective stress is given as

where \(\dot{D}_{1}\) represents the first derivative of the damage variable with respect to time. C and n are material parameters.

According to the principle of strain equivalence (Lemaitre 1990), the stress–strain relation with damage is given as

where σ represents the effective stress; σ* denotes the apparent stress; E is the elastic modulus, and ε is the strain. Equation (4) can be combined and rewritten into the following formula

It should be noted that D1 only reflects the impact of damage on the stress of rock, but does not involve the impact on elastic modulus. Then, by observing Eq. (5), it can be found that when the damage approaches the maximum value, D1= 1, the effective stress approaches infinity. As seen in the introduction, existing experiments have shown that residual strength remains after rock failure. Therefore, the residual strength correction factor δ is introduced here to resolve this conflict (Yuan et al. 2019), and the corresponding model is

where σr represents the residual strength; σc is the long-term strength.

Substitute Eq. (6) into Eq. (3), then Eq. (3) can be written as

Through integrating Eq. (7), the following expression can be obtained as

where A is the integration constant, to solve Eq. (8), the boundary conditions are introduced as follows:

Substitute Eq. (9) into Eq. (8), the functional expression of initial time tf when creep failure occurs can be given as:

By combining Eqs. (7) and (10) with suitable integration and arrangements, the time-dependent damage variable D1 considering residual strength can be obtained as

Crystal is a kind of polycrystalline structured material. Its defect is the root of the weakness of the mechanical properties from the mesoscopic point of view. In the mechanical model of rock creep, the elastic modulus and the viscosity coefficient are critical physical parameters that reflect a rock's ability to resist deformation under the action of external forces. As far as stones are concerned, the dislocation slip of crystals is an essential factor affecting these two physical parameters. Previous studies have shown that the existence of dislocations causes the surrounding atoms to be disturbed and disarranged, thus causing lattice distortion or local strain. Considering macroscopic continuity, such strain will lead to distortion of the stress field and accumulation of strain energy (Liu 1994).

Based on the above analysis, it is assumed that the constant accumulation of stress field energy will accelerate the lattice distortion or local strain over time. This physical assumption is reflected in phenomenology as the elastic modulus and viscosity coefficient deterioration with time. In general, the damage properties inside the rock are close to the power function of time (Yang et al. 1999), so the suggestion of Hou et al. (2019) is adopted, a time-dependent damage variable relating to elastic modulus and viscosity coefficient can be given as

where D2 is the time-dependent damage variable relating to elastic modulus and viscosity coefficient, 0 < D2 < 1; a is an unstable constant related to the internal properties of the material.

2.2 A new element of time-dependent damage

Continuum damage mechanics is introduced here to more appropriately describe the nonlinear characteristic of the accelerated creep from the perspectives of effective area and internal structure damage, and put forward a new element of viscoelastic-plastic damage. Elastic modulus and viscosity coefficient in this new element are both transformed into unstable constants by time-dependent damage variables. The concrete form of the damaged mechanical element is depicted in Fig. 3. The physical meanings of D1 and D2 are the same as above.

Through the principle of effective stress (Kachanov 1992, 2007), the constitutive relation of the damaged viscous body in Fig. 3 can be expressed in Eq. (13).

where εv and η4 represent the strain and viscosity coefficient of the damaged viscous body in Fig. 3.

Substitute Eq. (11) into Eq. (13), and by integration, the one-dimensional creep equation of the damaged viscous body is obtained as

For the deterioration of rock physical properties in the stress field, for the simplicity of computation and applicability of the formula, take the traditional approach here. The time-dependent damage variable D2 is directly introduced into the viscosity coefficient, then the final one-dimensional creep equation of the damaged viscous body can be written as

Duo to the damage elastic body and damage viscous body are in series in Fig. 3. According to the superposition principle, the creep equation of the damaged viscoelastic body in Fig. 3 in a one-dimensional stress state is given as

where εve represents the strain of the damaged viscoelasto body, and E4 is the elastic modulus of the damaged elastic body.

As is known to all, plastic deformation occurs only when the stress level of rock exceeds the long-term strength σs, so σ should be replaced by σ–σs. Then, the final creep equation of the damaged viscoelasto-plastic body is as

where εvep represents the whole strain of the damaged viscoelasto-plastic body.

2.3 The one-dimensional creep equation of the creep model presented

Since the Burgers model can well capture the characteristics of the initial two stages of rock creep, which can be connected in series with the proposed element of viscoelastic-plastic damage to establish a new damage creep model as shown in Fig. 4.

The proposed creep damage model in Fig. 4 is subdivided into four parts: elastic body, viscous body, viscoelastic body, and damaged viscoelasto-plastic body. Thus, the one-dimensional creep equation obtained according to the superposition principle is written as

2.4 The three-dimensional creep equation of the creep model presented

The actual rock mass is in a complex stress environment, so it is necessary to establish the three-dimensional creep equation further. Before derivation, some assumptions should be made as follows:

-

(1)

The rock is isotropic material, and the damage law in all directions is consistent.

-

(2)

Damage occurs only during the accelerated creep phase.

-

(3)

The damage time and creep time are consistent in the accelerated creep stage.

Suppose that the total strain of the proposed creep model is \(\varepsilon_{ij}^{t}\), the strain of the elastic body is \(\varepsilon_{ij}^\text{e}\), the strain of the viscous body is \(\varepsilon_{ij}^{{\text{v}}}\), the strain of the viscoelastic body is \(\varepsilon_{ij}^{{{\text{ve}}}}\), and the strain of the damaged viscoelasto-plastic body is \(\varepsilon_{ij}^{{{\text{vep}}}}\). According to the superposition principle, the total strain \(\varepsilon_{ij}^{t}\) can be expressed as

For elastic materials, the total stress tensor \(\sigma_{ij}\) and the total strain tensor \(\varepsilon_{ij}\) at any point in the interior are composed of two parts; the specific relationship is as follows

where δijσm denotes the spherical tensor of stress. Sij is the deviatoric tensor of stress. δijεm is the spherical tensor of strain. eij is the deviatoric tensor of strain, and δij is Kronecker delta.

According to the generalized Hooke's law, the three-dimensional constitutive relation of elastic materials is

where K is the bulk modulus; G is the shear modulus.

Combined with Eqs. (20) and (21), the three-dimensional creep equations of the elastic body, viscous body, and viscoelastic body can be derived. We have

where K1 and G1 are the bulk and shear modulus of the elastic body, respectively; G2 is the shear modulus of the viscoelastic body.

The three-dimensional creep constitutive relation of rock caused by friction sheet in the damaged viscoelasto-plastic body is related to the yield criterion and plastic potential function and the flow law. To sum up, the three-dimensional creep equation of the damaged viscoelasto-plastic body can be written as

with

where G4 is the shear modulus of viscoelasto-plastic body. F is the yield function. F0 is the initial value of the yield function, which is generally 1 for simplification of calculation; Q is the plastic potential function. \(\Phi \left( {\frac{F}{{F_{0} }}} \right)\) is the form of power function. In general, the value of the power exponential is 1. In addition, the correlative flow rule is used, which is F = Q.

At room temperature or below, the deviatoric strain is the main effect on rock creep, while the spherical strain plays a secondary role. Herein, Mises yield function is adopted, and its form is as

where J2 is the second invariant of deviatoric stress.

In the conventional triaxial creep experiment of rock (σ1 ≥ σ2 = σ3), when the accelerated creep of rock begins, the stress should satisfy the following conditions:

where σm is the mean spherical stress; S11 is the axial deviatoric stress.

By combining Eqs. (21)–(26), the three-dimensional creep equation of rock can be obtained as

3 Validations of model

3.1 Parameter identification

Parameter identification is mainly divided into one-dimensional state and three-dimensional state. Before the nonlinear fitting of parameters, it is necessary to determine some parameters that do not need fitting and can be easily obtained through experimental curves.

In Eq. (18), the instantaneous elasticity modulus E1 can be determined by the stress–strain relationship curve, i.e.

where ε1 is the instantaneous elasticity strain when t = 0, which can be obtained from the creep curve. In addition, according to the characteristics of transition creep, we have

where ε' is the strain value at the intersection of the extension line of the stable creep curve and the longitudinal axis, E2 can be determined. And finally, \(\eta_{3}\) can be determined by the slope of the steady creep curve.

In Eq. (27), G1 and K1 are shear modulus and bulk modulus, respectively, which the following formulas can determine

where E is the instantaneous elasticity modulus.

After completing the above work, other undetermined parameters must be determined by nonlinear fitting algorithm. As is known to all, statistical fitting of nonlinear creep models and experimental data is a challenging task, and the scientific selection of initial parameters is significant. To avoid improper initial values of parameters resulting in complex convergence of calculation, the Levenberg–Marquardt method and the Universal-Global-Optimization method are combined to determine the other parameters in Eqs. (18) and (27).

3.2 Verification of one-dimensional creep equation

The experimental data used for parameter identification in the one-dimensional creep equation is chosen from Okubo et al. (1991), the parameters of the creep model listed in Table 1 are determined by the above method, and the contrastive analysis of the creep calculation curve and experimental data are illustrated in Fig. 5.

Comparison between the Burgers model and the proposed model for Kawazu tuff rock from Okubo et al. (1991)

It can be seen in Fig. 5 that in a one-dimensional stress state, the model proposed here can fully capture the creep mechanical behavior of rock. In addition, since the experimental curve of Kawazu tuff rock under static load is relatively smooth, the error between the theoretical curve and the experimental point is tiny, in contrast, the traditional Burgers model has some shortcomings in describing the accelerated creep stage, and the fitting effect is poor. On the whole, the proposed damage creep model can accurately describe the characteristics of three phases of rock creep, which verifies the rationality of the proposed model.

3.3 Verification of three-dimensional creep equation

To further demonstrate the applicability of the presented creep model, other three kinds of rock (Jiang et al. 2013; Qui et al. 2003; Zhong and Ma 1987) are utilized to verify the proposed model. Otherwise, the comparison between the proposed model and Burgers model in three-dimensional stress state is continued as with a one-dimensional stress state. However, it can be observed from Eq. (2), and Fig. 5 that the Burgers model can only describe the linear growth of creep. To illustrate it more intuitively, the Burgers model of Wanzhou sandstone from Jiang et al. (2013) and Changshan salt rock from Qui et al. (2003) is established, respectively. The corresponding parameters of the three kinds of rock are determined as above. The physical parameters are listed in Tables 2 and 3, and the contrastive analyses of creep calculation curves and experimental data are depicted in Figs. 6, 7, and 8.

Comparison between the Burgers model and the proposed model for Wanzhou sandstone from Jiang et al. (2013)

Comparison between the Burgers model and the proposed model for Changshan salt rock from Qui et al. (2003)

Comparison between experimental date and computational solution of sandy shale rock from Zhong and Ma (1987)

It is worth discussing that, as seen in Table 2, the same physical parameter of different rocks differs significantly. For example, although Wanzhou sandstone and Sandy shale rock are both sandstone in nature, most of the physical parameter values of sandy shale rock are greater than Wanzhou sandstone. There are two possible reasons for this phenomenon. One is that the inner structure of sandstone may be various microscopic compositions due to different times of formation and environments. Another possibility is the problem of stability of the optimization algorithm.

From Figs. 6, 7, 8, it can be seen that the proposed damage creep model with double time-dependent damage variables could accurately simulate the three creep stages of rock in a three-dimensional stress state. Besides, no matter which stress state of confining pressure is low, medium, or high, the creep failure behaviors of rock can be well described by the model. Figures 6 and 7 show that the ability of the Burgers model to describe the accelerated creep behavior of rock in the three-dimensional stress state is still rather rough and weaker than the creep model with two damage factors proposed here.

The damage viscoelastic-plastic element is the crucial part of the presented model, and the variation rules of η4 and G4 under different confining pressures are studied, as shown in Figs. 7 and 8, given the experimental data of sandy shale rock, is relatively sufficient, which can better illustrate the problem, so take it for example. According to Figs. 9, 10 for sandy shale rock, it is observed that η4 decreases with the increment of confining pressure, while G4 declines with the increase of confining pressure.

4 Conclusions

Double time-dependent damage variables are discussed here based on the rock's effective stress and mesoscopic physical damage mechanism. A new element of viscoelastic-plastic damage was further constructed with the combination of residual strength. The final damage creep model and three-dimensional creep equations are derived and verified by experimental data and the Burgers model, and sound fitting effects are obtained.

-

(1)

Combined with the damage mechanism of the rock's internal structure, double time-dependent damage variables are defined to set up a nonlinear creep model with residual strength. The case study indicates that the model proposed here is more comprehensive and rigorous relative to conventional Burgers model.

-

(2)

The proposed model's and three-dimensional damage creep equations are derived, and related model parameters identification methods are also given. Furthermore, four groups of experimental data are used for verification. The results show that the proposed creep model with better description can reflect the creep characteristics in the whole stage well compared with the traditional Burgers model.

-

(3)

According to the fitting data analysis of sandy shale rock, when the presented model identifies the parameters, the viscosity coefficient increases in the element of viscoelasto-plastic damage, and the elastic modulus decreases with the rise in deviator stress.

Although the presented model provides a helpful way to accurately capture the creep characteristics of the given rocks with limited experimental data, more experimental data are needed to verify the applicability. And to facilitate the engineering application of practical problems, how to incorporate the model presented here into the existing commercial software is still required to be studied in future.

Abbreviations

- \(\dot{\sigma }\) :

-

First derivative of stress with respect to time

- \(\ddot{\sigma }\) :

-

Second derivative of stress with respect to time

- E 1 :

-

Elastic modulus of an elastic body

- η 3 :

-

Viscosity coefficient of a viscous body

- E 2 :

-

Elastic modulus of a viscous body

- η 2 :

-

Viscosity coefficient of the viscous body

- ε :

-

Total strain in the Burgers model

- σ :

-

Stress

- t :

-

Cumulative loading time

- D 1 :

-

Time-dependent damage variable relating to effective bearing area

- \(\dot{D}_{1}\) :

-

First derivative of damage variable with respect to time

- C :

-

Material parameters

- n :

-

Material parameters

- σ*:

-

Apparent stress

- σ r :

-

Residual strength

- σ c :

-

Long-term strength

- δ :

-

The residual strength correction factor

- t f :

-

Initial time when creep failure occurs

- D 2 :

-

Time-dependent damage variable relating to elastic modulus and viscosity coefficient

- a :

-

Unstable constant related to the internal properties of the material

- ε v :

-

One-dimensional strain of the damaged viscous body

- η 4 :

-

Viscosity coefficient of the damaged viscous body

- ε ve :

-

One-dimensional strain of the damaged viscoelasto body

- E 4 :

-

Elastic modulus of the damaged elastic body

- ε vep :

-

One-dimensional strain of the damaged viscoelasto-plastic body

- \(\varepsilon_{ij}^{t}\) :

-

Three-dimensional total strain of the proposed creep model

- \(\varepsilon_{ij}^\text{e}\) :

-

Three-dimensional strain of the elastic body

- \(\varepsilon_{ij}^\text{v}\) :

-

Three-dimensional the strain of the viscous body

- \(\varepsilon_{ij}^{{{\text{ve}}}}\) :

-

Three-dimensional the strain of the viscoelastic body

- \(\varepsilon_{ij}^{{{\text{vep}}}}\) :

-

Three-dimensional and the strain of the damaged viscoelasto-plastic body

- \(\sigma_{ij}\) :

-

Total stress tensor

- \(\varepsilon_{ij}\) :

-

Total strain tensor

- δ ij σ m :

-

Spherical tensor of stress

- S ij :

-

Deviatoric tensor of stress

- δ ij ε m :

-

Spherical tensor of strain

- e ij :

-

Deviatoric tensor of strain

- δ ij :

-

Kronecker delta

- K 1 :

-

The bulk modulus of the elastic body

- G 1 :

-

Bulk modulus and shear modulus of the elastic body

- G 2 :

-

Shear modulus of the viscoelastic body

- G 4 :

-

Shear modulus of viscoelasto-plastic body

- F :

-

Yield function

- F 0 :

-

Initial value of the yield function

- Q :

-

Plastic potential function

- \(\Phi \left( {\frac{F}{{F_{0} }}} \right)\) :

-

The form of power function

- J 2 :

-

Second invariant of deviatoric stress

- σ m :

-

Mean spherical stress

- S 11 :

-

Axial deviatoric stress

References

Cao WG, Chen K, Tan X et al (2020) A novel damage-based creep model considering the complete creep process and multiple stress levels. Comput Geotech 124:1–9. https://doi.org/10.1016/j.compgeo.2020.103599

Chaboche J (1982) Lifetime prediction and cumulative damage under high-temperature condition, symp. On Low-Cycle Fatigue and Life predication, Firminy, France, ASTM STP770, 1982

Chen LW, Li SJ, Zhang KX, Liu YX (2017) Secondary development and application of the N-P-T creep model based on FLAC(3D). Arab J Geosci 10:508

Chen EP, Taylor LM (1985) Fracture of brittle rock under dynamic loading condition. Sandia: SAND-84–2583c Sandia National Laboratories

Fares N (1993) Effective stiffness of cracked elastic 3-D solids. Int J Fract 62:149–162. https://doi.org/10.1007/BF00035159

Gao YQ, Zheng QS, Yu SW (1996) Double scalar formulation of isotropic elastic damage. Acta Mech Sin 28(5):542–549 (in Chinese)

Grady DL, Kipp ML (1980) Continuum modeling of explosive fracture in oil shale. Int J Rock Mech Min Sci 17:145–147

Hou RB, Zhang K, Jiang T et al (2019) A Nonlinear creep damage coupled model for rock considering the effect of Initial damage. Rock Mech Rock Eng 52:1275–1285. https://doi.org/10.1007/s00603-018-1626-7

Jiang QH, Qi YJ, Wang ZJ et al (2013) An extended Nishihara model for the description of three stages of sandstone creep. Geophys J Int 193:841–854. https://doi.org/10.1093/gji/ggt028

Kachanov M (1958) On the time to failure during creep. Izv.AN SSSR 8:26–31

Kachanov M (1992) Effective elastic properties of cracked solids: critical review of basic concepts. Appl Mech Rev 45:304–335

Kachanov M (1993) On the effective moduli of solids with cavities and cracks. Int J Fract 59:17–21. https://doi.org/10.1007/BF00035159

Kachanov M (2007) On the effective elastic properties of cracked solids-Editor’s comments. Int J Fract 146:295–299. https://doi.org/10.1007/s10704-007-9170-6

Lemaitre J, Chaboche JL (1990) Mechanics of solid materials. Cambridge University Press, Cambridge

Li AR, Deng H, Zhang HJ (2021) Developing a two-step improved damage creep constitutive model based on soft rock saturation-loss cycle triaxial creep. Nat Hazards 108:2265–2281. https://doi.org/10.1007/s11069-021-04779-6

Liu X (1994) Introduction to rock rheology. China Geological Publishing House, Beijing

Liu HZ, Xie HQ, He JD et al (2017) Nonlinear creep damage constitutive model for soft rocks. Mech Time-Depend Mater 21:73–96. https://doi.org/10.1007/s11043-016-9319-7

Liu WB, Zhang SG (2020) An improved unsteady creep model based on the time dependent mechanical parameters. Mech Adv Mater Struct 28:1838–1848. https://doi.org/10.1080/15376494.2020.1712624

Okubo S, Nishimatsu Y, Fukui K (1991) Complete creep curves under uniaxial compression. Int J Rock Mech Min Sci Geomech Abstr 28(1):77–82. https://doi.org/10.1016/0148-9062(91)93235-x

Qui XD, Jiang YD, Yan ZL (2003) Creep damage failure of rock salt. J Chongqing Univ 26(5):106–109 (in Chinese)

Tang CA, Kaiser PK (1998) Numerical simulation of cumulative damage and seismic energy release during brittle rock failure-part I: fundamentals. Int J Rock Mech Min Sci 35(2):113–121

Wang GJ, Zhang L, Zhang YW (2014) Experimental investigations of the creep–damage–rupture behaviour of rock salt. Int J Rock Mech Min Sci 66:181–187. https://doi.org/10.1016/j.ijrmms.2013.12.013

Wang QY, Zhu WC, Xu T et al (2017) Numerical simulation of sock sreep behavior with a damage-based constitutive law. Int J Geomech 17:1–14. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000707

Wong TF, Robina HC, Chau KT et al (2006) Microcrack statistics, Weibull distribution and micromechanical modeling of compressive failure in rock. Mech Mater 38(7):664–668

Wu F, Gao RB, Zou QL et al (2020) Long-term strength determination and nonlinear creep damage constitutive model of salt rock based on multistage creep test: implications for underground natural gas storage in salt cavern. Energy Sci Eng 8:1592–1603. https://doi.org/10.1002/ese3.617

Xu XL, Gao F, Zhang ZZ (2018) Thermal damage constitutive model for rock considering damage threshold and residual strength. J Cent South Univ 25:2523–2536. https://doi.org/10.1007/s11771-018-3933-2

Xu G, He C, Yang Q et al (2019) Progressive failure process of secondary lining of a tunnel under creep effect of surrounding rock. Tunn Undergr Space Technol 90:76–78. https://doi.org/10.1016/j.tust.2019.04.024

Xue XH, Zhang WH (2015) Mechanics of seepage damage in rock and soil. Sichuan University, Chengdu

Yan Q, Guo QF, Ren FH et al (2020) Modified Nishihara model and experimental verification of deep rock mass under the water-rock interaction. Int J Rock Mech Min Sci 128:1–10. https://doi.org/10.1016/j.ijrmms.2020.104250

Yang RA (1996) New constitutive model for blast damage. Int J Rock Mech Min Sci 33(3):245–254. https://doi.org/10.1016/j.mechmat.2005.12.002

Yang CH, Daemen JJK, Yin JH (1999) Experimental investigation of creep behavior of salt rock. Int J Rock Mech Min Sci 36:233–242. https://doi.org/10.1016/S0148-9062(98)00187-9

Yuan C, Zhang HM, Meng XZ et al (2019) Discussion of constitutive relation of rocks based on correction factor. Coal Sci Technol 47:177–182 (in Chinese)

Zhao Y, Wang Y, Wang W et al (2017) Modeling of non-linear rheological behavior of hard rock using triaxial rheological experiment. Int J Rock Mech Min Sci 93:66–75. https://doi.org/10.1016/j.ijrmms.2017.01.004

Zhong SY, Ma MJ (1987) An approach to creep failure regularity of weak rock. J Central South Inst Min 18(5):495–500 (in Chinese)

Zhu LJ, Xu XL, Cao XJ et al (2019) Statistical constitutive model of thermal damage for deep rock considering initial compaction stage and residual strength. Math Probl Eng 2019:1–10. https://doi.org/10.1155/2019/9035396

Acknowledgements

Financial support partially provided by the National Natural Sciences Foundation of China (No. 41172274) is gratefully acknowledged.

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work, there is no professional or other personal interest of any nature or kind in any product, service and/or company that could be construed as influencing the position presented in, or the review of, the manuscript entitled "A three-dimensional nonlinear rock damage creep model with double damage factors and residual strength."

Ethical approval

I certify that this manuscript is original and has not been published and will not be submitted elsewhere for publication while being considered by Natural Hazards. And the study is not split up into several parts to increase the quantity of submissions and submitted to various journals or to one journal over time. No data have been fabricated or manipulated (including images) to support your conclusions. No data, text, or theories by others are presented as if they were our own.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, X., Wang, M. & Shen, F. A three-dimensional nonlinear rock damage creep model with double damage factors and residual strength. Nat Hazards 115, 2205–2222 (2023). https://doi.org/10.1007/s11069-022-05634-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11069-022-05634-y