Abstract

Subsidence plays a significant role on safety of the mine surface constructions above the underground faces, extraction efficiency, and environment. The prediction of ground surface movements is an important challenge in mining sciences. Subsidence can occur as a result of removing rock in an underground mine. The surface constructions safety to resist subsidence in underground mining depends on mine topography, location, and type of them. The aim of this paper is to investigate the subsidence possibility in an underground mine by establishing the fuzzy membership function. The used subsidence estimation method was based on fuzzy theory. In this regard, using the several α-cuts, the subsidence in definite panel is defined as a fuzzy form. Finally, to show the application of the defined approach in the prediction of an underground mining subsidence based on fuzzy set theory, it was applied for the Tabas coal mine subsidence prediction which located in South Khorasan province of Iran. Results show that the mining area is in an unstable state by considering the critical-factor of safety = 0.75.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Coal is one of the most important sources of energy in the world. According to the federal Institute for Geosciences and Natural Resources (BGR), there are 1052 billion tons of coal reserves left in the world which equal to 134.5 years of global coal output in 2013 (Reddish and Whittaker 2012). In this regard, the world needs much more coal for future energy which drives to more underground mining. Mining exploitation using room and pillar, longwall and caving methods will result in subsidence. This phenomenon can cause safety and environmental problems accompany with damage to surface structures.

Many studies on predicting ground subsidence due to coal mining have been conducted in the UK, Europe, China, South Africa, Australia, and the USA. In the 1820s, Belgian engineers started a systematic study of mine subsidence because of surface damage to structures (New South Wales Coal Association 1989). Until the early 1900s, most studies were conducted in Europe and the UK, where subsidence research continues to the present. The Subsidence Engineer’s Handbook, a landmark publication produced in the UK by the National Coal Board (1965), became the basis for studies associated with longwall subsidence in the USA (Bauer 2008).

Several prediction methods have been developed for subsidence prediction in underground mines such as empirical prediction methods which based on the correlation of measured data with the geometric parameters of the excavations, influential function methods which based on assumptions to simplify the calculations, mathematical–physical model prediction methods which based on roof behavior of subsidence or numerical. In recent years, various approximate methods have been developed for prediction of mining subsidence which theory of fuzzy mathematics is one of the methods has been applied to analyze the problems of displacement and deformations of rock mass due to underground mining (Wenxiu 1987; Liao 1993a, b; Li 1989, 1998, 2003a, b; Li and Mei 2003; Li et al. 2006, 2007, 2010).

In this paper, the application of the fuzzy probability measures to analysis of the mining subsidence due to the longwall underground mining is described.

2 Fuzzy operations and mine subsidence function

For a long time, it has been recognized that an exact description of many real life in physical situations may be virtually impossible. This is due to the high degree of imprecision involved in real world situations. Zadeh, in his seminal papers, proposed fuzzy set theory as the means for quantifying the inherent fuzziness that is present in ill-posed problems (which by many accounts are the majority of the real-life problems in decision making). Fuzziness is a type of imprecision which may be associated with sets in which there is no sharp transition from membership to non-membership (Triantaphyllou 2000).

The most critical step in any application of the fuzzy set theory is to effectively estimate the pertinent data (i.e., the membership values). Although this is a fundamental problem, there is not a unique way of determining membership values in a fuzzy set. This is mainly due to the way different researchers perceive this problem. Most of the decision making in the physical world takes place in a situation in which the pertinent data and the sequences of possible actions are not precisely known. Therefore, it is very important to adopt fuzzy data to express such situations in decision-making problems (Triantaphyllou 2000).

The main goal of all mine subsidence prediction methods is to find an accurate assessment of mining effects on surface structures and ground conditions. Most of the studies on developing such prediction methods have been based on coal mining situations. Of particular importance here has been the fact that seams of uniform thickness and relatively large horizontal and regular extent of extraction have provided the basis on which prediction methods could be satisfactorily developed. Efforts have been made in many coal mining countries to develop mining subsidence prediction techniques, and generally, the starting point has been to ensure that the pre-calculation method follows closely the phenomenon as observed in practice. There are many publications dealing with predicting mining subsidence, some covering theoretical concepts, while others resort to applying observed surface behavior in the form of empirical prediction models (Triantaphyllou 2000).

As it mentioned above, several estimation methods have been developed for maximum subsidence prediction in underground mines such as empirical prediction methods, influential function, and mathematical–physical model prediction. In this study by using Eq. 1, the possibility of maximum subsidence occurrence with use of fuzzy theory technique with regard to several certain and uncertain parameters survived (Triantaphyllou 2000):

where parameters are defined as \(S_{\hbox{max} }\) maximum subsidence; \(m\) seam thickness; \(a\) overburden coefficient and \(\alpha\) dip of the seam.

In a theoretical point of view, the subsidence occurs when the stope extraction is reached to critical dimensions. Situ study shows that subsidence factor depends on the properties of the overburden rock and system of ceiling support. The roof is a function of the layer properties, and it can be expressed by the following equation (Triantaphyllou 2000):

\(P\) is the ratio of the upper classes and properties to be mixed or combined show and reflect the overall condition of the properties of the stone and the upper layers according to the thickness and properties of each of the classes in hanging wall account. The following formula to calculate \(P\) is introduced (Triantaphyllou 2000):

In this case, \(N\) is the number of classes in hanging wall mineral and hi is the thickness of each of the upper floors. \(Q\) index for different stones according to their hardness and resistance and also the extent of their participation in the development of the session depends on the surface. \(Q\) value can be due to an axial compressive strength of rock obtained according to Table 1 (Bräuner 1973).

The subsidence condition based on fuzzy set interpretation is shown in Fig. 1.

Description of subsidence condition by using interpretation of FOS fuzzy set (Liao 1993a)

3 Parvade coal mine (Tabas coal region)

Tabas coal mine of Iran is considered as a case study in this research. This mine is the largest and, uniquely, fully mechanized coal mine in Iran located in the central part of Iran in South Khorasan province and situated 75 km from southern Tabas city. The mine area is a part of the Tabas-Kerman coalfield. A large volume of the coal reserve and appropriate geometry of coal seams in Tabas have created suitable conditions for application of the longwall mining method. Tabas coal deposit includes three mineable seams (C1, B1, and B2). Tabas region is one of the most important coal regions in Iran that contains three areas named Parvade, Mazino, and Nayband. The area of this region is about 30,000 square kilometers (Parvade area is 1200 square km), and it is the biggest coal reserve in Iran. The height of this area is 850 meters above the sea level. The total probable anthracite reserve in the Parvade region is approximately 1.2 billion tons. Furthermore, the minable reserve suitable for underground production is 28 million tons in the Parvade1 (Hosseini 2016). Figure 2 shows these areas on the local map.

Three areas in Tabas coal mine region (Hosseini 2016)

4 Fuzzy analysis of Tabas coal mine subsidence

The C1 seam is the most important coal seam in Tabas and is mined using a mechanized longwall retreat mining method. The thickness of the coal seam ranges from 1.5 to 2.2 m. The overburden depth alters from 100 to 500 m with an average value of 350 m is considered as the overburden depth in model calculations. The width of the panels ranges from 200 to 220 m (average 210 m), and the length of the panels is about 1000 m (Hosseini 2016). The mining parameters of Tabas mine regions and mechanized longwall mine (C1 seam) are given in Tables 2 and 3, respectively.

The Subsidence Engineer’s Handbook (SEH) empirical design procedure for determining the maximum value of subsidence in flat seams was shown that the extraction width-to-depth (w/h) ratio is a major controlling parameter and the result is expressed as a function of the extracted seam height. A basic assumption made here in extending this design procedure to steep seams is that maximum subsidence will also be a function of the cosine of the angle of seam inclination so that the subsidence is given by Eq. (3). The permitted subsidence in different circumstances is shown in Table 4.

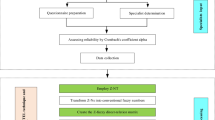

By considering the value of Table 1 for each input parameter and by using of statistical distribution, the fuzzy numbers of m and Cosα are plotted as shown in Figs. 3 and 4, respectively.

After defining the fuzzy sets for input parameters, with creating the α-cuts, the upper and lower limits for each cut are determined, as shown in Table 5.

Next, the \(S_{\hbox{max} }\) based on the performance maximum subsidence function for each \(\alpha - {\text{cuts}}\) is calculated. By considering the combination of upper and lower limits of m and Cosα, four \(S_{\hbox{max} }\) are obtained for each α-cuts.

As it is shown in Table 6, upper and lower limits of \(S_{\hbox{max} }\) are calculated as 1.809 and 1.469, respectively. However, the upper and lower limits of \(S_{\hbox{max} }\) for all α-cuts are given in Table 7, and accordingly, the fuzzy number of \(S_{\hbox{max} }\) is also plotted as shown in Fig. 5.

After defining the \(S_{\hbox{max} }\) sets for input parameters, with creating the α-cuts, the upper and lower limits for each cut are determined, as shown in Table 7. Finally, the \(S_{\hbox{max} }\) based on the performance function (Eq. 1) for each α-cut is calculated. By considering the combination of upper and lower limits obtained for each α-cut and the critical-FOS = 0.75, the mining surface area is in unstable state.

5 Conclusions

In this paper, by applying the concept of fuzzy probability theory, maximum subsidence has been analyzed by establishing a fuzzy membership function. Whereas the fuzzy theory defines a range of numbers for each parameter, the undesired performance probability of uncertainties is decreased.

-

The results show that the uncertainty in input parameters of the subsidence problem can significantly effect on the calculations.

-

However, by considering the upper and lower limits in fuzzy definition of each parameter, the uncertainty is reduced.

-

The evaluation of subsidence by using of fuzzy possibility theory, the realistic concept of subsidence is provided.

-

Considering the critical-FOS = 0.75, the mining area on surface is unstable and it is expected that buildings and rigid pipelines expose to risk of damage.

References

Bauer RA (2008) Planned coal mine subsidence in Illinois: a public information booklet. Illinois State Geological Survey, Department of Natural Resources

Bräuner G (1973) Subsidence due to underground mining: (in two parts). Ground movements and mining damage. US Department of the Interior, Bureau of Mines

Hosseini N (2016) Calculation of periodic roof weighting interval in longwall mining. HampaDanesh Co. Project Final Report, Iran

Li W (1989) Fuzzy models for estimation of surface ground subsidence. In: Proceedings of international symposium on environmental geotechnology, 2nd Envo, USA. 1:317–328

Li WX (1998) Applications of fuzzy mathematics in mining and geotechnical engineering. The Press of Metallurgy Industry, Beijing

Li W (2003a) Fuzzy mathematical method for analysis of movement of Yichang phosphate body. Ind Miner Process 32(4):19–21

Li W (2003b) Fuzzy models of analysis for rock mass displacements due to underground mining in mountain areas. Math Pract Theory 33(2):26–30

Li WX, Mei SH (2003) Fuzzy mathematical method of prediction and analysis on rock mass displacements and instability due to underground mining under river valley. Chin J Rock Mech Eng 20(1):2289–2293

Li W, Mei S, Zai S, Zhao S, Liang X (2006) Fuzzy models for analysis of rock mass displacements due to underground mining in mountainous areas. Int J Rock Mech Min Sci 43(4):503–511

Li WX, Dai LF, Hou XB, Lei W (2007) Fuzzy genetic programming method for analysis of ground movements due to underground mining. Int J Rock Mech Min Sci 44(6):954–961

Li WX, Liu L, Dai LF (2010) Fuzzy probability measures (FPM) based non-symmetric membership function: engineering examples of ground subsidence due to underground mining. Eng Appl Artif Intell 23(3):420–431

Liao CP (1993a) Fuzzy influence function method for calculating mine subsidence in a horizontal seam. Geotech Geol Eng 11(4):235–247

Liao CP (1993b) Fuzzy influence function method for calculating mine subsidence in a horizontal seam. Geotech Geol Eng 11(4):235–247

Rankin W (1988) Ground movements resulting from urban tunnelling: predictions and effects. Eng. Geol 5(1):79–92

Reddish DJ, Whittaker BN (2012) Subsidence: occurrence, prediction and control, vol 56. Elsevier, Amsterdam

Triantaphyllou E (2000) Multi-criteria decision making methods. In: Multi-criteria decision making methods: a comparative study. Springer, Boston, pp. 5–21

Wenxiu L (1987) Fuzzy probability analysis for displacement of rock mass. Sci China Ser B-Chem Biol Agric Med Earth Sci 30(10):1109–1120

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hosseini Alaee, N., Mozafari, A., Mirzaee, M. et al. Fuzzy evaluation method for the identification of subsidence susceptibility in an underground mine (case study in Tabas coal mine of Iran). Nat Hazards 99, 797–806 (2019). https://doi.org/10.1007/s11069-019-03774-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11069-019-03774-2