Abstract

In North China coal basin, there is an accident: the water which comes from Ordovician system aquifer (O2) discharges into underground coal mines. The coal mining operations would be seriously threatened by this kind of accident. In order to solve this problem, the characteristics of various exploration methods have been discussed. A comprehensive approach involving hydrogeological analysis, geophysical prospecting, hydrogeological drilling, and hydrogeological field test was proposed to explore the groundwater recharge channel. A typical North China coal mine, Siwan coal mine, was taken as an example. The groundwater recharge channel on F8 fault was precisely explored and plugged. After the curtain grouting, the water discharge rate per unit of drawdown was dropped from 12.0 to 7.0 m3/(h m), and the water yield in coal mine was reduced by 600 m3/h. A much safer condition can be provided for Siwan coal mine, avoiding the waste of water resource.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

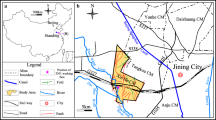

In China, approximately 70 % of all identified coal resources have been deposited in the North China coal basins (Gao and Lin 1985). It is bordered by the Yinshan-Yanshan Mountains to the north, the Qinling-Dabieshan Mountains to the south, the Liupanshan Mountains to the west, and the Bohai Sea to the east (Fig. 1). The area of the coal basin is about 1,664,000 km2 (Wu and Wang 2006). The coal deposits were mainly formed in the Carboniferous and Permian periods (Han and Yang 1984). In this coal basin, one of the most serious safety issues is the accident of water bursting, i.e., groundwater from water filling aquifer would burst into the underground coal mines.

There are five major groups of water filling aquifers. They are porous aquifer group in the Quaternary system, porous aquifer group in the Neogene system, sandstone aquifers in the Permian system, thin-bedded limestone aquifers in the Carboniferous system, and the carbonate rock aquifer in the Ordovician system (O2), wherein there are 11 layers of thin-bedded limestone aquifers. Those aquifers are sequentially named L1 through L11, from the bottom to the top. The thin-bedded limestone aquifers and the sandstone aquifer are direct water filling aquifers in the North China coal basins (Wu and Jin 1995; Wu and Wang 2006).

In normal situations, it is generally considered that the discharge capacity in direct water filling aquifers is weak. However, if these aquifers combine with underlying O2, a stronger water discharge capacity can be formed and observed. Then, the safety of coal mining can be seriously threatened. Many accidents indicate that the structures, such as faults, fractures, and karst collapse columns, play a very important role in causing the inflow of O2 water into the coal mine (Fang et al. 2011). For the no. 5 coal mine in Hebi coal mining district, there is a hydraulic connection between L8 and O2 by a small fault. L8 water burst into the coal mines has led to a catastrophic water bursting accident in 1971. In the no. 2 coal mine of Hebi coal mining district, there is also a hydraulic connection between the L2 and O2; the maximum water yield of L2 was 169 m3/h in 1980.

Concerning this issue, plenty of researches have been carried out. These studies mainly focus on the analysis about the mechanisms on water bursting (Burazer et al. 2010; Giustiniani et al. 2009; Van Paridon and Brandimarte 2012), the coal mine water inflow forecast (Dou et al. 2011; Hatherly 2013), water bursting source identification (Dou et al. 2011; Huang and Chen 2012), and water disaster prevention and control (Gao and Lin 1985; Ma 2005; Pu et al. 2001; Zhao and Wu 2005). A series of mature techniques have been gradually developed to manage the water bursting. The main techniques are drainage of water, reinforcing of floor, and curtain grouting. Drainage is an effective method to diminish water inrush risk in coal mine. It is more appropriate to be applied in areas with relatively simple hydrogeological conditions or the aquifer with thin-bedded limestone. Reinforcing of floor is aimed to improve pressure resistance ability of the floor by filling the fractures on the thin-bedded limestone aquifers. Curtain grouting is intended to plug the water recharge channels by a grouting agent. This method is suitable for the areas which are affected by the O2 water. Thus, it has a wide range of applications in the North China coal basins. The key point of curtain grouting is confirming the recharge channel.

Nowadays, there are many approaches for exploring recharge channels. Various methods have enjoyed special advantages and disadvantages. It is difficult to accurately explore the recharge channels with a single method. In order to improve and explore the accuracy, a comprehensive approach which includes hydrogeological analysis, geophysical prospecting, hydrogeological drilling, and hydrogeological field test is applied to explore the groundwater recharge channel. In this paper, a coal mine, Siwan coal mine, with complex hydrogeological conditions was chosen as an example. The comprehensive approach was applied in this coal mine to verify its effectiveness. Based on the exploration results, the recharge channel was plugged.

Methodology study

A series of mature techniques have been gradually developed to explore the recharge channel of water bursting. The main approaches are hydrogeological analysis, geophysical prospecting, hydrogeological drilling, hydrogeological field test, numerical simulation, and so on.

Hydrogeological analysis is one of the most fundamental methods in hydrogeological study. According to the basic geological data, the recharge, flow pathway, and discharge of groundwater can be identified. What is more, the most critical factor in water hazard treatment is to identify the water source and flow pathway. Any effective method in order to successfully and efficiently solve groundwater inrush is followed by detailed regional and local hydrogeological analysis (Sui et al. 2011). Thus, hydrogeological analysis is an effective method to determine the groundwater recharge channel.

The geophysical prospecting methods include transient electromagnetic detection, 3D seismic surveys, and so on. In China, the earliest research on transient electromagnetic method has started since 1970s. It has been widely applied in the hydrogeological investigation of mining regions to ensure the safety in production (Danielsen et al. 2003; Liu et al. 2005). Now, it has become a vital geophysical approach for accident control in coal mines (Han et al. 2011). The water-inrushing structures can be rapidly and accurately detected with transient electromagnetic method. It is able to save time for emergency rescue after flooding accident in coal mines. However, there are still some limits in the application of transient electromagnetic method, such as the interference of complex terrain, more man-made conductor, and various ore body characteristics. The precision of detection results is affected by all these factors.

3D seismic surveys have wide applications such as characterizing a multilayered confined aquifer system (Giustiniani et al. 2009), tracing the water supply source (Burazer et al. 2010), providing extremely useful information on faulting, mapping coal seam, mapping lithological features, evaluating geotechnical characteristics, assessing the rock mass response to mining, detection of voids, locating trapped miners, and guiding the drills and mining equipment (Hatherly 2013). A recent application of 3D seismic survey shows examples of lithological interpretation and trace attributes to assist with fault interpretations (Van Paridon and Brandimarte 2012). Zhao has provided examples of 3D seismic survey results in China and the relevant applications (Zhao and Wu 2005). Despite equipment has small size and high resolution, 3D surveys still have been considered as an expensive exploration tool. Problems can arise if the geological setting is unfavorable or adverse.

Hydrogeological field test is an important method to explore the hydrogeological conditions. It contains dewatering test, pumping test, tracer test, water injection test, and so on. The dewatering test is a vital method for evaluating the characteristics of water-rich aquifer, determining the hydrogeological parameters, and forecasting water inflow in coal mine (Zhang and Li 2009). In addition, under certain conditions, the connection between aquifers can also be judged. In China, the first application of dewatering test was in Doulishan coal mine of Hunan province in 1962. Followed by this case, the dewatering test was generalized progressively. Nowadays, this method is common, but it is still important for investigating coal mine hydrogeology condition (Ma 2005; Yin et al. 2012) and evaluating the feasibility of aquifer water discharge (Pan and Wang 2011). Besides, it is also a reliable basis for numerical simulation of groundwater (Li 2012). However, the application is rigorous in coal mine. The demand is higher for the dewatering capability in coal mines, and the results will also be affected by the amount of observation wells.

The tracer test is also a vital approach for estimating the hydraulic connection of groundwater. It has been widely applied to investigate the dam leakage (Jiang et al. 2012; Song et al. 2005; Wang and Pan 2010), karst channel interconnectivity (Cao et al. 1999; Meigs and Beauheim 2001; Thrailkill et al. 1991), groundwater pollution (Kogovšek and Šebela 2004; Lin et al. 2010), and groundwater recharge sources (Huang and Chen 2012; Lapworth et al. 2008). The efficiency of tracer test is determined by conditions of groundwater seepage field. According to the previous researches, it is reasonable to apply the tracer test during the dewatering test (Pan et al. 2014). The accelerated seepage field which resulted from dewatering test can promote the migration of tracer.

Numerical modeling provides an efficient method for clarifying the flow path, seasonal dynamics of groundwater, forecasting the water inflow of coal mine, and simulating the pathway formation of water bursting. However, the reliability estimates by models depend on the accuracy of the measures and hydraulic parameters (Liu et al. 2014; Sibanda et al. 2009).

Considering the advantages and disadvantages of various methods in exploring water recharge channel, some of these methods are combined. The combination of several methods can maximize the advantages.

Hydrogeological analysis is a method which can roughly clarify the recharge, flow pathway, and discharge of groundwater. Then, the location of water channel can be confirmed by geophysical prospecting (the transient electromagnetic detection and 3D seismic surveys), drilling exploration (hydrogeological drilling), hydrogeological field test (dewatering test), and other methods. Based on the hydrogeological conditions in the research area, as well as the budget, it can determine which method should be applied first or whether all the methods should be applied simultaneously.

After the exploration, the recharge channel is plugged. The injecting paste materials are aggregate, sodium silicate, and industrial salt. These materials are injected into the recharge channel or the aquifer by the borehole on or under the ground. The plugging effect should be evaluated after plugging. Generally, the techniques for evaluating grouting effect include analytical method, check-up hole method, geophysical prospecting method, dewatering test, and so on (Zhang and Li 2009; Zhang et al. 2006; Zhu et al. 2007). Which method should be chosen is decided by the hydrogeological settings and conditions.

In short, the process of detering and plugging groundwater recharge channel is divided into two subsections. They are exploration of the underground water recharge channel, plugging, and evaluation of the plugging effect. All the methods mentioned above can be flexible, selected, or combined. It depends on the hydrogeological conditions, equipment of coal mine, budget, and the specific characteristics of each method.

Case study

The hydrogeological settings

Hebi coal mining district is located at the piedmont plain of the Taihang Mountain in Henan province (Fig. 1). It is a part of the tectonic system of New China and Qinling Mountains. Major forms of geologic structures are faults. Folds are less developed, and the overall tendency is a monoclinic structure. The faults are mainly high-angle normal faults, which develop into three groups with the trends of E–W, NW–SE, and NE–SW.

The main strata are the Archean erathem, the Proterozoic erathem, the Paleozoic erathem, and the Cenozoic erathem. The Carboniferous and the Permian systems in the Paleozoic erathem are the primary coal measure strata, in which the coal seams of Da-mei and Xia-jia occurring in the Taiyuan and Shanxi formation are the mineable coal seam.

According to the lithology, thickness, water features, and burial conditions of the stratum, the main water inrush aquifers, from top to bottom, can be divided into five categories (Fig. 2). They are porous aquifer group in the Quaternary system, porous aquifer group in the Neogene system, sandstone aquifers in the Permian system, thin-bedded limestone aquifers in the Carboniferous system, and the carbonate rock aquifer in the Ordovician system. The main aquiclude is bauxitic mudstone in the Bengxi formation. The deposit thickness is 25–35 m.

The thin-bedded limestone aquifers in Carboniferous system and the carbonate rock aquifer in the Ordovician system are the main aquifers in this coal mining district. The main water filling aquifers of carboniferous system are L2 and L8 (Fig. 2). In this area, the average thickness of L2 is 7 m, with stable distribution. The thickness of L8 is 3–5 m. The spatial distribution and occurrence of groundwater are greatly varied. Since geological structure and groundwater recharge conditions in the districts are not favorable for karst development, large karst caves in the drilling cores of exploratory boreholes are seldom (Wu and Wang 2006). According to the data of pumping test, the water discharge rate per unit of drawdown is 0.002–2.619 L/(s m), and the permeability coefficient is 0.015–28.84 m/day in L2. The water discharge rate per unit of drawdown is 0.0015–0.532 L/(s m), and the permeability coefficient is 0.02–12.09 m/day in L8. There are limited outcrop areas in aquifers, neither recharge source. Thus, the L2 and L8 water is generally static reserves and easy to be drained.

The whole thickness of Є (the aquifer in Cambrian system) and O2 is more than 600 m, in which the thickness of O2 is about 400 m. The karst fissure is well-developed. According to the result of single borehole pumping test, the minimum value of the water discharge rate per unit of drawdown is 0.67 L/(s m), the maximum value is 83.91 L/(s m), and the average value is 14.02 L/(s m). In the area of Taihang Mountain, the O2 is widely outcropped. It accepts the recharge of precipitation infiltration. In addition, the groundwater recharge can be observed from Qi River leakage through the karst fissure. After accepting the recharge in mountain area, the groundwater flows to the piedmont from west to east and discharges by karst spring and coal mine drainage.

Until December 2009, there have been 392 times of water bursting accidents in Hebi coal mining district, in which O2 water bursting accidents have accounted for 10.7 %, L2 water bursting accidents have taken amount of 8.9 %, and the proportion of L8 water bursting accidents was 35.7 %. The maximum water yield in coal mine pit was 13,507 m3/h, and all the serious accidents were caused by the O2 water.

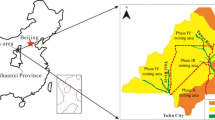

The Siwan coal mine is located in the northeast of the Hebi coal mining district (Fig. 1). It was reestablished in May 2002. The designed annual production capacity is 150,000 t. Because of the threats of water bursting, the annual production capacity cannot meet the demand. The primary mineable coal seam is Xia-jia which is located at the bottom of the Taiyuan formation (the Carboniferous system). Their total average thickness is 3 m. Its roof is L2 and floor is bauxitic mudstone in Bengxi formation. The O2 is about 30 m below the coal seam. In this coal mine, the fault strike of F9 fault (a normal fault) is 22° NE and the dip is ∠63° NW. It is the west boundary of Siwan coal mine (Fig. 3). The F8 fault is the east boundary and the fault strike is N–S with the dip of ∠63–70° W. Based on the hydrogeological analysis, the O2 and L2 are directly connected by this fault. It may be a water conductive fault. In order to reduce the deficit of water bursting and ensure mine safety, it is necessary to determine and plug the groundwater recharge channel.

Exploration of underground water recharge channel

Methods

Twenty-one underground dewatering boreholes were arranged in Siwan coal mine. There were manometers in two of these boreholes (Y1, Y2) for observing water level (water pressure). The rest boreholes were applied to drain L2 water. Moreover, there were four observation boreholes on the ground for observing the variation of water levels in the L2 (Fupin well, 194-L2-2) and O2 (192-O2-2, 105-O2-1).

The first dewatering test for unsteady flow was divided into three stages (Table 1). At the end of the third stage, all underground dewatering boreholes were turned off (Pan et al. 2007).

Along with the first dewatering test, the tracer test was implemented synchronously. In the research area, the background value of I− in groundwater was low, and it indicated stable chemical properties of groundwater. What is more, I− was harmless to the human body. In this test, potassium iodide (KI) was selected as the tracer to map the movement path of groundwater. The value of K+ was higher in background. Thus, the groundwater movement was analyzed according to I−. If the tracers were observed and received in the groundwater boreholes located on the other side of the F8 fault, it proved that the two aquifers (L2 and O2) will be connected by the fault. The potassium iodide was poured into 192-O2-2 boreholes half an hour before the dewatering test, and hydrochemical characteristics of the water in underground dewatering boreholes were first observed. In order to make sure tracers come into the aquifer as much as possible, it was pressed into the O2 karst aquifer by continually injecting water into boreholes before dewatering test. Groundwater in underground dewatering boreholes was sampled every 2 h. The water samples were measured at the central lab of the Institute of Resources & Environment, Henan Polytechnic University.

The second dewatering test was divided into two stages (Table 2). Except for the four previous observation boreholes, some new observation boreholes which drilled alone the F8 fault were also involved. They were three L2 water level observation boreholes (T2, T4, T5) and four O2 water level observation boreholes (T1, T3, 107-O2-1, LZ well). The interval of each borehole for T1 to T5 was 200 m. The water level of ground observation boreholes was observed by water level telemeters which were based on GSM handset module (YJSY(A), CCTEG Xi’An Research Institute, China).

The transient electromagnetic detection (PROTEM-67D, GEONICS, Canada) was carried out for two times. Based on the analysis of geological data, two parallel transient electromagnetic profile lines were plotted along F8 fault (Fig. 3). Additional eight profile lines were performed perpendicular to F8 fault at the two abnormal areas, respectively.

The results of first dewatering test and tracer test

The results show that there are the same change trends of water level in O2 observation boreholes on the east of F8 fault (192-O2-2) and the L2 boreholes on the west (194-L2-2, Fupin well, Y1 and Y2). The maximum drawdown in L2 is 73 m, and the maximum drawdown in O2 is 3.14 m (Table 1).

There is a significant declining trend which happens to the L2 water level in different observation boreholes (Fig. 4). The water level within 3 or 4 h decreases at the beginning of each stage. Then, it remains stable. It indicates that water-bearing space is limited in the L2; thus, the water is easy to drain. However, the drop of water level is hard to be sustained, because the water level will be stable after receiving enough recharge from other water resource.

For O2 water level, the variation trends are different in two boreholes. The water level in 192-O2-2 is synchronously declined with the L2 water. However, the decline is less than that of L2 water. Hence, the O2 at the east side of the fault is related to the L2 at the west side. Combining with hydrogeological conditions, the O2 water closes to the 192-O2-2 discharges to the L2 water. However, the variation of water level in 105-O2-1 is different. It steadily drops without periodic tendency. The 105-O2-1 is closed to 194-L2-2, and the distance between them is more than 35 m. However, the changes are totally different. Generally, there is aquiclude between O2 and L2; thus, they are not connected (Fig. 2). If the aquiclude is damaged, there will be a correlation. Because of the same change tendency, the fluctuation of water level in 192-O2-2 is affected by the changes of L2 water level at the other side of the fault, whereas the water level in 105-O2-1 and 194-L2-2 is irrelevant and the aquiclude between O2 and L2 at west side of F8 fault is unbroken. The changes of 105-O2-1 resulted from the changes of O2 water instead of L2 water. Thus, in the research area, it is the lateral hydraulic connection rather than vertical connection between the O2 and L2. As shown in the Fig. 4, it also observed that there is a sharp increase of L2 water level within 2 days after dewatering test. It indicates that the L2 water will be recharged by O2 water quickly.

During the tracer test, the tracer is captured 58 h later in underground dewatering boreholes (Fig. 5). The concentration peak is 0.26 mg/L which is 12 times higher than the background value. It means that there is a hydraulic connection between O2 and L2. The O2 water discharges to L2 through the F8 fault, and the discharge rate is fast.

The results of transient electromagnetic detection

The results of the first transient electromagnetic detection show that there are two low resistance anomaly areas (E1 and E2) alone the fault (Fig. 6a). The extent of E1 is bigger, and it should be the main recharge channel of F8 fault. The extent of E2 is shallow and limited. It is closed to the main shaft and the test accuracy may be seriously interfered by the ground electricity supply facilities and transportation railway. The detection results of E1 area are more accurate, and it can be an important groundwater recharge channel.

The results of the second dewatering test

The drawdown is different in different borehole. In L2, the minimum value is 28.42 m (T2) and the maximum value is 64.0 m (Y1). In O2, the minimum value is 2.72 m (192-O2-2) and the maximum value is 0.04 m (LZ well).

As shown in Fig. 7, the general trends of water level are similar in five boreholes which present the variation of L2 water. The water level in T2 is lowest and the recovery rate is faster. The distance between the observation borehole and underground dewatering boreholes is an important influence factor. Underground dewatering area is located at the middle point between T2 and T4. The variation rate of the two boreholes should be the same. However, the fact is not the case. The water level value of T2 is higher than the Fupin well. The Fupin well is further away from dewatering area. These phenomena prove that the T2 borehole should be more close to the recharge channels, and it can be quickly refilled with the discharge of O2 water.

The variation tendencies of the water level in other six boreholes (O2) are different (Fig. 8). The water level in 105-O2-1, T3, and LZ well generally remains stable. There is a sharp decline of water level in T1, 107-O2-1, and 192-O2-2, in which the water level in 192-O2-2 drops faster with wider fluctuations. It indicates that the O2 water in T1, 107-O2-1, and 192-O2-2 is affected by the variations of L2 water on the other side of the fault. It concludes that the recharge channel of F8 fault should be delimited by 192-O2-2, 107-O2-1, and underground dewatering boreholes. From the results of second dewatering test, it shows that the recharge channel is located between T1 and T4, and the priority areas are T2 to T4.

The result is also confirmed by the drilling data. The minor faults and karst are well-developed in the cores of T2, T3, and T4. The coal seam in T3 is missing; stratigraphic sequence is confusing because of the broken rocks. The karst fissure and small karst caves prove that karst collapse column has happened in this area. There is no anomaly in T5 and the aquiclude is complete. The main recharge channel may have existed in the area between T2 and T4. This area is potential to be the positions of recharge channels.

Plugging and evaluation the plugging effect

Considering the above conclusion, the recharge channels should be in the area among T1 to T4. The region E1 and the region T3 nearby are included in this area. Fifteen grouting boreholes are distributed between T1 and T4. The grouting was performed in stages. The variation of water level in T2 is the lowest. Therefore, the first batch of grouting was concentrated near the T2 region, which was also the area of E1. There were six grouting boreholes (from Z1 to Z5 and T2) in this batch.

Then, the simple dewatering test and the second transient electromagnetic detection were carried out. The results show that the apparent resistivity increases in the center of E1 after the batch of the first grouting (Fig. 6b). However, the plugging effects are not favorable, and the water level changes in 192-O2-2 are not apparent. After the first grouting, the E1 is divided into two parts. And a new low resistance anomaly area appeared nearby the E1. A new channel has appeared at E3 which results from the hydraulic pressure (Fig. 3).

The second batch of grouting is mainly concentrated at the E3, and some grouting boreholes were added at E1. In this batch, there were seven grouting boreholes (Z6–Z9, Z11, Z13, and T4). After this step, the water level of O2 increases by 0.5–0.8 m at 192-O2-2 and L2 water level drops by 3–5 m. The results of the fourth dewatering test show that the water discharge rate per unit of drawdown reduces from 12.0 to 7.9 m3/(h m).

In order to optimize the results, Z10 and Z12 were arranged on both sides of the Z11. The fifth dewatering test shows that the water level of L2 is decreased, while the O2 is increased (Table 3). Taking the water level in Y1 as an example, the water yield is significantly varied (Fig. 9). After the second batch of grouting, the dewatering quantity declines significantly compared with the stage before grouting. After the whole grouting, it also declines but much less significantly. The water discharge rate per unit of drawdown is reduced from 12.0 to 7.0 m3/(h m), with the decreasing amplitude of 42 %. The results show that main recharge channels are plugged.

Siwan coal mine has almost been shut down due to the serious threats of water bursting. After grouting, the production is recovered and the annual production of raw coal has reached 180,000 t. The total investment for grouting project was 6 million yuan. The water yield in coal mine pit was reduced by 600 m3/h. A drainage cost of 10 million yuan could be saved in each year, as well as abundant water resource.

Conclusion

There may be an unexpected and catastrophic increase of water discharge from O2 aquifer into underground coal mine in North China coal basin. It is a critical hydrogeological issue for mining safety, and it is also a complicated problem in mining hydrogeology. The main water recharge channel is the fault. The effective approaches for decreasing the occurrence of water disasters are to detect and plug the groundwater recharge channel. Generally, it is difficult to determine the location of recharge channel in mining area just by single method. If the investigation result was inaccurate, the following curtain grouting will be a waste of money and manpower. Considering the advantages and disadvantages of various methods in exploring water recharge channel, some of these methods are combined. The combination of several methods can maximize the advantages.

In this study, a typical coal mine, Siwan coal mine, which is seriously affected by O2 has been taken as the example. For this typical area, a comprehensive approach is designed. The groundwater recharge channel on F8 fault was precisely explored by hydrogeological analysis, dewatering test and tracer test, and transient electromagnetic detection. After the exploration, the recharge channel is plugged. The plugging effect was evaluated by transient electromagnetic detection and dewatering test. The results show that the water discharge rate per unit of drawdown is dropped from 12.0 to 7.0 m3/(h m), and the water yield in coal mine is reduced by 600 m3/h. The results proved the feasibility and effectiveness of the comprehensive approach. It provides safer mining conditions for Siwan coal mine. The waste of water resource can also be avoided and abundant water storage would be saved in groundwater reservoir. This comprehensive approach provides a frame of reference for determining and plugging those recharge channels that may lead to the water bursting in North China coal basin.

References

Burazer M, Žitko V, Radaković D, Parezanović M (2010) Using geophysical methods to define the attitude and extension of water-bearing strata in the Miocene sediments of the Pannonian Basin. J Appl Geophys 72:242–253

Cao H, Cowart JB, Osmond JK (1999) Uranium and strontium isotopic geochemistry of karst waters, Leon Sinks Geological Area, Leon County, Florida. Cave Karst Sci 26(3):101–106

Danielsen JE, Auken E, Jørgensen F, Søndergaard V, Sørensen KI (2003) The application of the transient electromagnetic method in hydrogeophysical surveys. J Appl Geophys 53:181–198

Dou H, Ma Z, Cao H, Liu F, Hu W, Li T (2011) Application of isotopic and hydro-geochemical methods in identifying sources of mine inrushing water. Min Sci Technol (China) 21:319–323

Fang X, Fu Y, Hua J, Wu T (2011) Modes and characteristics of karst groundwater system in north of China. J Hefei Univ Technol 34(2):286–291

Gao H, Lin Z (1985) Regional characteristics of mine-hydrogeological conditions of coal deposits in China. Hydrogeol Engg Geol 12:14–17

Giustiniani M, Accaino F, Picotti S, Tinivella U (2009) 3D seismic data for shallow aquifers characterisation. J Appl Geophys 68:394–403

Han D, Yang Q (1984) Coal geology of China, 2nd edn. Publishing House of China Coal Industry, Beijing

Han D, Li D, Shi X (2011) Effect of application of transient electromagnetic method in detection of water-inrushing structures in coal mines. Procedia Earth Planet Sci 3:455–462

Hatherly P (2013) Overview on the application of geophysics in coal mining. Int J Coal Geol 114:74–84

Huang P, Chen J (2012) Recharge sources and hydrogeochemical evolution of groundwater in the coal-mining district of Jiaozuo, China. Hydrogeol J 20:739–754

Jiang C, Lin J, Qin S, Li S, Duan Q (2012) Experiment on dam leakage detection with magnetic resonance sounding. J Jilin Univ 42(3):858–863

Kogovšek J, Šebela S (2004) Water tracing through the vadose zone above Postojnska Jama, Slovenia. Environ Geol 45(7):992–1001

Lapworth DJ, Gooddy D, Butcher A, Morris B (2008) Tracing groundwater flow and sources of organic carbon in sandstone aquifers using fluorescence properties of dissolved organic matter (DOM). Appl Geochem 23(12):3384–3390

Li X (2012) Evaluation of mine shaft water discharge prediction based on underground dewatering test. Coal Geol China 24(10):26–30

Lin Y, Wang G, Pan G (2010) A study of groundwater pollution mechanism by using stable isotopes and hydrochemistry. China Rural Water Hydropower 5:01–04

Liu S, Liu Z, Jang Z (2005) Application of TEM in hydrogeological prospecting of mining district. J China Univ Min Technol 34(4):414–417

Liu Y, Yamanaka T, Zhou X, Tian F, Ma W (2014) Combined use of tracer approach and numerical simulation to estimate groundwater recharge in an alluvial aquifer system: a case study of Nasunogahara area, central Japan. J Hydrol 519:833–847

Ma P (2005) Aquifer hydrogeological testing studies aimed at floor water bursting prevention. [J] Coal Geol China 17:61–64

Meigs LC, Beauheim RL (2001) Tracer tests in a fractured dolomite: 1. Experimental design and observed tracer recoveries. Water Resour Res 37:1113–1128

Pan G, Wang P (2011) The feasibility study on Cambrian limestone water discharging based on large dewatering test of group holes. J Henan Polytech Univ 30:674–678

Pan G, Xuan J, Yue B, Liu Z (2007) The large dewatering test and tracing experiment based on GSM water level remote sensing system. J Henan Polytech Univ 26:153–155

Pan G, Wu Y, Lin Y (2014) The evaluation and exploration of the coal mine water bursting accident. China coal industry publishing house, Beijing

Pu C, Zhang X, Yin W, Qu X (2001) Inundation in the North-China type coalfields and the status quo of its protection. Geol Rev 47:405–410

Sibanda T, Nonner JC, Uhlenbrook S (2009) Comparison of groundwater recharge estimation methods for the semi-arid Nyamandhlovu area, Zimbabwe. Hydrogeol J 17:1427–1441

Song S-H, Song Y, Kwon B-D (2005) Application of hydrogeological and geophysical methods to delineate leakage pathways in an earth fill dam. Explor Geophys 36(1):92–96

Sui W, Liu J, Yang S, Chen Z, Hu Y (2011) Hydrogeological analysis and salvage of a deep coalmine after a groundwater inrush. Environ Earth Sci 62:735–749

Thrailkill J, Sullivan SB, Gouzie DR (1991) Flow parameters in a shallow conduit-flow carbonate aquifer, Inner Bluegrass Karst Region, Kentucky, USA. J Hydrol 129:87–108

Van Paridon H, Brandimarte F (2012) Interburden mapping using 3D seismic attributes at an underground coal mine, Bowen Basin, Queensland. ASEG Ext Abstr 2012:1–4

Wang X, Pan J (2010) Location detection of concentrated-leakage passages in dam by groundwater temperature. Chin J Geotech Eng 32(11):1800–1805

Wu Q, Jin Y (1995) Deciding system of preventing and curing mine water in Northern China Coalfield. Publishing House of Coal Industry, Beijing

Wu Q, Wang M (2006) Characterization of water bursting and discharge into underground mines with multilayered groundwater flow systems in the North China coal basin. Hydrogeol J 14:882–893

Yin H, Wei J, Guo J, Guan Y, Liu R, Hu D (2012) Research on water quality characteristics in the process of dewatering test for Ordovician limestone aquifer. Procedia Environ Sci 13:2146–2153

Zhang C, Li Z (2009) The analysis about characteristics of Xujiazhuang limestone water in Bucun coalmine and corresponding prevention and control measures. J Shandong Univ Sci Technol 28(6):51–55

Zhang M, Zhang W, Sun G (2006) Evaluation technique of grouting effect and its application to engineering. Chin J Rock Mech Eng 25(2):3909–3918

Zhao P, Wu X (2005) How seismic has helped to change coal mining in China. First Break 23:31–34

Zhu S, Wang F, Zeng X (2007) Groundwater blockage by grouting curtain in Dahongshan mine and its evaluation. Metal Mine 9:79–83

Acknowledgments

The data were based on the reports of projects presided by the authors. This study was financially supported by the Doctor Foundation of Henan Polytechnic University (No. B2012-034). We thank for the helpful suggestions of Baoxiang Yue, Zhaoxia Liu, and Guojun Chen. We also thank the workers of Siwan coal mine and students of Henan Polytechnic University for their hardwork in the experiments. The constructive suggestions of all referees and editors on this paper were appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, Y., Wu, Y., Pan, G. et al. Determining and plugging the groundwater recharge channel with comprehensive approach in Siwan coal mine, North China coal basin. Arab J Geosci 8, 6759–6770 (2015). https://doi.org/10.1007/s12517-014-1753-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12517-014-1753-8