Abstract

Formation of Rh–Pd–Pt solid-solution alloy nanoparticles (NPs) by femtosecond laser irradiation of aqueous solution in the presence of polyvinylpyrrolidone (PVP) or citrate as a stabilizer was studied. It was found that the addition of surfactant (PVP or citrate) significantly contributed to reduce the mean size of the particles to 3 nm for PVP and 10 nm for citrate, which was much smaller than that of the particles fabricated without any surfactants (20 nm), and improved the dispersion state as well as the colloidal stability. The solid-solution formation of the Rh–Pd–Pt alloy NPs was confirmed by the XRD results that the diffraction pattern was a single peak, which was found between the positions corresponding to each pure Rh, Pd, and Pt NPs. Moreover, all the elements were homogeneously distributed in every particle by STEM-EDS elemental mapping, strongly indicating the formation of homogeneous solid-solution alloy. Although the Rh–Pd–Pt alloy NPs fabricated with PVP was found to be Pt rich by EDS observation, the composition of NPs fabricated with citrate almost exactly preserved the feeding ratio of ions in the mixed solution. To our best knowledge, these results demonstrated for the first time, the formation of all-proportional solid-solution Rh–Pd–Pt alloy NPs with well size control.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Multimetallic nanoparticles (NPs) consisting of more than two elements with different kinds of nanostructures such as solid-solution, core–shell, and heterostructure have been increasing interest in many research and industrial areas due to their unique and improved catalytic, optical, electric, and magnetic properties compared with that of pure metal NPs (Habas et al. 2007; Zeng and Sun 2008; Toshima 2000; Tsuji et al. 2008; Major et al. 2009; Costi et al. 2010; Cortie and McDonagh 2011; Pan and Wai 2011). In particular, better catalytic activity is expected by a synergistic effect due to the modulation of band structure (Toshima et al. 2002; Zhang et al. 2004). Among multimetallic NPs, Rh-based alloy NPs attracted great attention due to the excellent catalytic activity and selectivity originated from an architectural configuration of metals, i.e., core–shell and alloy structure (Jiang and Xu 2011; Heck and Farrauto 1995; Alayoglu and Eichorn 2008; Renzas et al. 2011; Park et al. 2008, 2012). In spite of the remarkable catalytic activity, Rh-based alloy NPs are easily oxidized and aggregated at higher temperature (Dent et al. 2007). Moreover, Pt-based ternary alloy NPs attracted much attention for the application for electrocatalysis and fuel cell (Ferrando et al. 2008; Antolini et al. Antolini 2007a, b; Venkataraman et al. 2003; Wanjala et al. 2012, 2011). However, the metal elements in the alloy NPs were rapidly segregated to its oxide/hydroxide unless a subsequent reduction process at high temperature is applied (Antolini 2007a). Recently, the formation of ternary Rh–Pd–Pt alloy and complex of these elements have been reported using chemical reduction techniques (Hueso et al. 2013; Hung 2012). However, the control of composition and stability of alloy NPs, in spite of its significant importance for catalytic applications, has not been studied in detail.

On the other hand, a number of researches are dedicated to control the size of metal NPs to investigate size effects of NPs (Shalaev and Moskovits 1997; Wilcoxon et al. 1998; Steigerwald et al. 1988; Brugger et al. 1981; Mulvaney et al. 1991). Pileni and co-workers synthesized size-controlled metal NPs in reversed micelles by chemical reduction of metal ions in aqueous solution (Petit et al. 1993; Pileni 1997). These NPs showed high catalytic activity and stability in the hydrogenation of benzene. Co-reduction of metal salts in an aqueous solution by borohydrate yielded Au–Rh, Au–Pt, Pt–Rh, and Pd–Rh alloy NPs with tunable compositions in the presence of a variety of molecular and polymeric surface stabilizers at room temperature. However, the aggregation and coalescence of alloy NPs were frequently observed and supporting materials were needed to avoid the aggregation of NPs (Essinger-Hileman et al. 2011).

Apart from these chemical syntheses, Au, Ag, Pt, and Au–Pt alloy NPs were recently produced by nanosecond or femtosecond laser ablation of solid target in the presence of the dispersants to control the size and stability of NPs (Mafuné et al. 2000, 2003, 2001; Zhang et al. 2012). Although any reducing agents are not required in the liquid-phase pulsed laser ablation approach, a complicated process is usually applied for alloy formation especially due to the immiscible property. The development of facile and efficient method is thus desired to produce not only pure metal NPs but also alloy NPs with controlled composition, size, and dispersion state for many practical applications.

Recently, we demonstrated multimetallic Au–Ag, Au–Pt, Au–Ag–Pt, and Rh–Pd–Pt (Herbani et al. 2011; Nakamura et al. 2012; Herbani et al. 2012; Sarker et al. 2013) alloy NPs formation using femtosecond laser irradiation of mixed solutions of metallic ions without the use of reducing agents. Tightly focused femtosecond laser pulses in solutions can easily create an extremely high energetic field in laboratory scale. In such a high energetic field, solvated electrons and hydrogen radicals, which act as strong reducing agents to reduce metal ions to metal atoms, can be created through the optical decomposition of water molecules resulting in the NP formation (Pommeret et al. 2001). Using this technique, we had demonstrated the formation of Rh–Pd–Pt solid-solution alloy NPs, and confirmed that the composition of the fabricated alloy NPs precisely reflected the mixing ratio of the solutions. However, the particles’ size was not uniform and agglomeration of the fabricated NPs was observed (Sarker et al. 2014). Rh–Pd–Pt alloy NPs are well known as three-way catalyst for the purification of automobile exhausts such as CO, NO x , and hydrocarbon through oxidation and reduction processes. For the maximum catalytic performance, it is essential to precisely control the composition, the size, and size distribution of the fabricated alloy NPs.

In this study, we intend to fabricate the Rh–Pd–Pt solid-solution ternary alloy NPs with controllable composition, size, and dispersion state by femtosecond laser irradiation of aqueous solution of metallic ions by applying two surfactants, PVP and citrate. PVP is generally used as a stabilizing polymer as well as a reducing agent to synthesize the stable colloid of metal and alloy NPs. However, the reduction of the metal components is depending on their redox potentials (Toshima and Yonezawa 1998). On the other hand, citrate has a long history to synthesize metal NPs using Turkevich method (rapid injection of sodium citrate (SC) into a hot aqueous solution) (Turkevich et al. 1951). Following that, role of SC was modified as (i) reducing agent (Turkevich et al. 1953), (ii) capping agent (Ojea-Jimenez and Puntes 2009), and (iii) pH mediator (Xia et al. 2009) in chemical synthesis. Here in femtosecond laser irradiation, PVP and citrate are used as a capping agent. The alloy formation was confirmed through XRD and STEM-EDS analyses. In addition, the effect of PVP and citrate on the stabilization of the colloidal NPs was also discussed.

Experimental methods

Materials

Rhodium (III) chloride trihydrate (RhCl3·3H2O, 99.5 %), trisodium citrate dihydrate (C6H8O7), and polyvinylpyrrolidone [(C6H9NO) n , PVP; K10, molecular weight of approximately 10,000] were obtained from Wako Pure Chemical Industries Ltd. Palladium (II) chloride (PdCl2, 99.9 %) and hydrogen hexachloroplatinate (IV) hexahydrate (H2PtCl6·6H2O, 99.9 %) were purchased from Sigma Aldrich Co. All chemicals were used without further purification. All glasswares used in the study were carefully cleaned by acids, to remove almost of all impurities prior to experiment.

Synthesis of Rh–Pd–Pt ternary alloy NPs

Rh–Pd–Pt alloy NPs were synthesized using two kinds of dispersant. Initially, Rh, Pd, and Pt ion solutions were separately prepared by dissolving the powder of RhCl3·3H2O, PdCl2, and H2PtCl6.6H2O in ultrapure water at a concentration of 2.54 × 10−4 M, and then 10 wt% concentration of PVP or citrate was added to these aqueous solutions. Mixed solutions were prepared by mixing these solutions with the molar ratios of Rh:Pd:Pt = 1:1:1, 2:1:1, 1:2:1, and 1:1:2. Each solution is denoted by the molar ratio, i.e., Rh33Pd33Pt33, Rh50Pd25Pt25, Rh25Pd50Pt25, and Rh25Pd25Pt50 in this paper.

Laser irradiation was performed using a Ti:Sapphire femtosecond laser (Spitfire Pro, Spectra Physics Inc.), which generates 100 fs pulses with the averaged energy of 5.3 mJ at the wavelength of 800 nm and the repetition rate of 100 Hz. The beam was focused by an aspheric lens (focal length: 8 mm, numerical aperture (NA): 0.5) into 3 ml of metal ion solution filled in a 10 × 10 × 45 mm quartz cuvette. The estimated beam diameter was 175 μm by taking into account the spherical aberration of refractive index mismatch of the cuvette and the solution. The maximum peak intensity at the focus is expected to be of the order of 1014 W/cm2 assuming no energy loss in the sample solution and the optics employed in the experiment. Irradiation was conducted for 30 min at room temperature and atmospheric pressure.

Characterization

The optical absorption properties of metal colloids were characterized by UV–visible absorption spectroscopy ranging from 200 to 800 nm. The size, shape, and corresponding selected area electron diffraction (SAED) patterns of fabricated NPs were obtained by a transmission electron microscope (TEM; JEOL, JEM2000EXII, JEOL Ltd.) that was operated at an acceleration voltage of 200 kV. TEM samples were prepared by placing a few drops of irradiated colloids onto a carbon-coated copper microgrid (Microgrid type B, Okenshoji Co., Ltd.) and dried in vacuo at room temperature. The average size and size distribution of particles were determined by analyzing the particles using a particle counting software (ImageJ 1.46d) provided from National Institutes of Health (NIH). The zeta potential was measured to check the stability of a colloidal solution using a nanoparticle analyzer (SZ-100, HORIBA Ltd.). High-resolution TEM images were taken to confirm the crystalline nature of NPs with an FEI-TITAN X-FEG TEM (Hillsboro) in STEM mode operated at 300 kV. Energy-dispersive X-ray spectroscopy (EDS) analysis as well as STEM-EDS mapping was performed by the same instrument to measure the elemental composition and distribution of NPs. The crystalline structure of NPs was determined by powder X-ray diffraction (XRD, RINT-V, Rigaku Co.). A computerized diffractometer equipped with a Ni-filtered Cu Kα (λ = 0.15406 nm) X-ray source and a goniometer with a solid-state Ge detector was used to obtain XRD profiles by θ–2θ scan. The as-prepared particles suspended in solution were collected using a freeze drier and placed onto a single-crystal silicon substrate with no diffraction peak in the scan range of the XRD measurement. Electronic state of the element in fabricated NPs was analyzed by X-ray photoelectron spectroscopy (XPS, Shimadzu/KRATOS with Al Kα radiation; AXIS-165).

Results and discussions

Synthesis of Rh–Pd–Pt alloy NPs with PVP

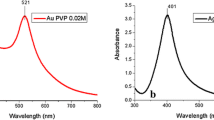

Figure 1 shows the UV–vis. absorption spectra of the solutions with PVP of different mixing ratios of Rh, Pd, and Pt ions (a) before and (b) after the laser irradiation. As it is illustrated in the spectra of the solution before irradiation (Fig. 1a), the absorption peaks around 250 nm are characteristics of metal to ligand charge transfer of Pt ions in solution (Chen et al. 2010; Long et al. 2010). After irradiation, the peaks completely disappeared in the spectra of all solutions (Fig. 1b), indicating that all metal ions in the solution were consumed and NPs were formed by 30 min laser irradiation.

The TEM images and corresponding size distributions of as-synthesized particles in the mixed solutions of Rh, Pd, and Pt ions for different feeding ratios are presented in Fig. 2. The mean particle size (d), standard deviation (σ), and coefficient of variation (CV) of the particles estimated from the TEM images are shown in the inset of the size distribution profile. Most of the particles were well dispersed and spherical in shape with a uniform size distribution. The mean diameter of the fabricated NPs obtained in Rh33Pd33Pt33, Rh50Pd25Pt25, Rh25Pd50Pt, and Rh25Pd25Pt50 solutions were 2.9 ± 0.9, 3.3 ± 1.3, 3.2 ± 0.9, and 3.2 ± 1.4 nm, respectively, and the coefficient of variation (CV) was less than 45 %. The SAED patterns of the fabricated NPs are shown in the inset of Fig. 2. The four major rings of the SAED patterns were identified as (111), (200), (220), and (311) planes for fcc crystal, and the interplanar spacings of NPs corresponding to 111 plane are summarized in Table 1. The interplanar spacings obtained from the SAED patterns were different from those estimated by Vegard’s law. This indicates that the composition of the fabricated particles are not agreed with the initial feeding ratio of the solutions, which will be much clear from XRD measurements as well as elemental composition evaluated through EDS measurement.

To assess the local structure, the fabricated particles were characterized by XRD for different feeding ratios of Rh, Pd, and Pt metal ions in the solutions as shown in Fig. 3. Each profile exhibited a characteristic single phase to fcc structure. The diffraction curve of (111) plane in every sample presented in Fig. 3b was a single peak indicating no phase segregation in the fabricated particles. However, it is clear that the peak positions were the same with that of the pure Pt and unchanged regardless of feeding ratio of Rh, Pd, and Pt ions. Therefore, all the fabricated particles in the solutions with different feeding ratios were Pt-rich alloy. The structural analysis followed by the X-ray diffraction peak of (111) is summarized in Table 2. There are no salient differences between the fabricated NPs in the solutions with different feeding ratios of ions.

HR-TEM was conducted to confirm crystal nature of the fabricated NPs. Figure 4 shows a typical HR-TEM image of NPs fabricated in Rh33Pd33Pt33 solution. The visible lattice fringes with grain boundaries illustrate polycrystalline nature of the fabricated NPs. The crystalline size of NPs calculated from Scherrer’s equation for full width at half maximum (FWHM) of a diffraction peak from (111) plane was smaller than of the particle size measured by TEM due to the polycrystalline nature with grain boundaries as observed in the HR-TEM image. Moreover, the shape of all the fabricated NPs was almost spherical, which is different from an angular shape commonly observed in conventional chemical methods. This indicates that the growth mechanism of NPs in the reaction is different from chemical reduction process.

Further, the elemental compositions of NPs were evaluated through EDS measurement and summarized in Table 3. The compositions of NPs showed high Pt ratios in all systems. Namely Pt-rich particles were formed in all the solutions irrespective of the initial feeding ratio of the ions. The deviation of the alloy composition was due to the reducing property of PVP in the NPs formation by laser irradiation of solution. Because the reduction potential of Pt is larger than that of Rh and Pd, Pt ions were preferably reduced in comparison with the other metal ions. In addition, a replacement reaction (Tsuji et al. 2012) was also simultaneously occured in the alloy formation. As a result, Rh and Pd ions were left behind in the reduction process in NP formation.

XPS measurement was performed to determine the chemical state of Rh, Pd, and Pt elements in the alloy NPs (see Fig. S1). For XPS measurements, the NPs were supported on an indium foil to avoid peak overlapping. The XPS peaks at 306.9 eV and 311.5 eV were assigned to the peaks of metallic state of Rh 3d 5/2 and Rh 3d 3/2, respectively (Christ 2000). In a similar fashion, the XPS peaks at 335.5 eV and 340.83 eV were assigned to the metallic state of Pd 3d 5/2 and Pd 3d 3/2, respectively. Furthermore, the XPS peaks at 74.5 eV and 71.3 eV were assigned to the Pt metallic state of Pt 4f 7/2 and Pt 4f 5/2 peaks, respectively (Christ 2000). These results demonstrate that Rh, Pd, and Pt in the alloy NPs were metallic.

Synthesis of Rh–Pd–Pt alloy NPs with citrate

The same irradiation experiment was performed by addition of citrate as a dispersant instead of PVP. The photo-absorption properties of Rh–Pd–Pt colloids with citrate were also characterized by UV–vis. absorption spectroscopy. Figure 5 shows UV–vis. absorption spectra of Rh–Pd–Pt mixed ion solutions with citrate as a stabilizer before and after the irradiation. In UV–vis. spectra of the solution before irradiation shown in Fig. 5a, the absorption peak appeared at 262 nm due to metal–ligand charge transfer, which is a characteristic of Pt ion in the solutions. The peak absorbance in the spectra became large depending on the feeding ratio of Pt ion in the same way observed in the mixed solution with PVP (Fig. 1a). However, the peaks disappeared after the irradiation indicating the reduction of ions and the formation of NPs by laser irradiation of solution.

Figure 6 depicts typical TEM images and corresponding size distributions of products obtained after 30 min irradiation of Rh–Pd–Pt systems (Rh33Pd33Pt33, Rh50Pd25Pt25, Rh25Pd50Pt25, and Rh25Pd25Pt50) with citrate. The size of NPs was 10.6 ± 1.9, 11.8 ± 2.4, 7.0 ± 1.8, and 10.4 ± 2.2 nm for Rh33Pd33Pt33, Rh50Pd25Pt25, Rh25Pd50Pt25, and Rh25Pd25Pt50, respectively, and the coefficient of variation was less than 26 % for all cases. Therefore, the NPs had a uniform size distribution and a good dispersion state. The mean size of fabricated NPs was larger than that with PVP due to the weak capping effect of citrate compared with PVP. The four major rings of the SAED patterns were identified as (111), (200), (220), and (311) planes of fcc crystal. To assess ternary alloy NPs formation, the interplanar spacing of NPs was obtained from the SAED pattern and compared with the theoretical value from Vegard’s law. The estimated interplanar spacings corresponding to 111 plane are summarized in Table 4. It is clearly seen that the interplanar spacings obtained from SAED patterns are agreed well with those estimated by Vegard’s law. This indicates that the fabricated particles are composition-controlled solid-solution alloy. For more detailed structural analysis of the fabricated NPs, XRD measurement was performed for all the samples. Figure 7a shows a set of XRD patterns of NPs prepared in the citrate-added solutions with different mixing ratios of Rh, Pd, and Pt ions. The XRD peaks of NPs were characteristic of fcc structure (Fig. 7a). The diffraction peak from (111) plane of every sample presented in Fig. 7b was a single peak indicating no phase segregation. Moreover, the peak shift was observed depending on the mixing ratio of Rh, Pd, and Pt ions in the solution. The open circles in Fig. 7b represent experimental data, while the solid lines are fitting curves of the experimental result. The structural analysis followed by the XRD peak of (111) plane for the particles is summarized in Table 5. The crystalline size of NPs calculated from Scherrer’s equation for (111) reflections showed that the mean crystalline size was below 10 nm. The lattice parameters obtained from (111) diffraction peaks for Rh33Pd33Pt33, Rh50Pd25Pt25, Rh25Pd50Pt25, and Rh25Pd25Pt50 were in the range of those of bulk Rh, Pd, and Pt and varied with the feeding ratio of ions in the solutions. Moreover, the lattice parameters obtained from XRD (3.876, 3.859, 3.878, and 3.891) showed a well match with that estimated by Vegard’s law (3.871, 3.854, 3.876, and 3.883). This strongly indicates that the fabricated particles were all-proportional solid-solution Rh–Pd–Pt alloy.

HR-TEM was also performed to confirm crystal nature of the fabricated NPs. Spherical-shaped polycrystalline particles with the mean particle size of 10 nm were observed in all the samples as shown in Fig. 8. Although some multiple twinned crystals and stacking faults were observed, no core–shell and phase segregation were observed. It is also noticed that the crystal size was smaller than the particles size due to the polycrystalline nature of the particles as observed in the HR-TEM images.

The averaged elemental compositions of citrate-capped ternary Rh–Pd–Pt NPs by EDS are given in Table 6. Compositions of fabricated alloy NPs were Rh29.3Pd34.9Pt35.8, Rh50.8Pd24.2Pt25, Rh27.8Pd48.6Pt23.6, and Rh25.6Pd31.1Pt43.3 in the Rh33Pd33Pt33, Rh50Pd25Pt25, Rh25Pd50Pt25, and Rh25Pd25Pt50 mixed ion solutions, respectively. This strongly demonstrates that the elemental compositions of NPs were comparable with the initial feeding ratios of mixed solutions strongly supporting the formation of all-proportional solid-solution ternary alloy formation. Moreover, the elemental distributions in alloy particles were confirmed by means of elemental mapping by STEM-EDS. Figure 9 shows the high-angle annular dark field (HAADF) and corresponding STEM-EDS mapping images for Rh–Pd–Pt systems. The formation of spherical particles was also confirmed in the HAADF images. Furthermore, the EDS elemental mappings for Rh–Pd–Pt alloy NPs with different compositions indicate a uniform elemental distribution of Rh, Pd, and Pt without phase segregation in the particles. It is also observed in the reconstructed images that no core–shell or phase-segregated structures existed in the alloy NPs. Therefore, the citrate-capped NPs fabricated by laser irradiation of mixed ion solutions were concluded to be all-proportional solid-solution alloy at least within few layers in atomic dimension with homogeneous distribution of individual component.

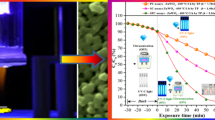

UV–vis. absorption spectra of Rh–Pd–Pt alloy particles and their stability

Typically, the stability of colloidal NPs depends on the applied surfactant and surface charge of NPs. Such surfactant dependence on the stability of NPs has been studied in the past years on the particle fabricated by liquid-phase laser ablation of solid target in the presence of SDS (Mafuné et al. 2000, 2003, 2001). In their works, the average particle size was reduced when the SDS concentration was increased. This surfactant concentration dependency on the particles size could be explained by NPs formation dynamics (Mafuné et al. 2000). In brief, metal atoms produced by laser irradiation in a solution aggregate to form nuclei, and this continues until the atoms are depleted for the formation of embryonic NPs. This growth continues slowly even after a laser shot, as the NPs diffuse through the solution and interact with other atoms or NPs to form larger clusters. The latter growth mechanism can be controlled by surfactant and was applied to the present experiment. The concentration effects of PVP and citrate on the size of NPs are summarized in Fig. 10. Mixed solution of Rh33Pd33Pt33 was applied in this experiment. The particle size remained in the range of 17–3 nm when the PVP concentration was varied from 2 to 10 wt% reflecting the strong affinity of PVP molecules on the surface of particles. However, as mentioned before, the composition of the fabricated alloy NPs varied from the initial feeding ratio of the mixed ion solutions. On the other hand, in case of citrate, though the particle size was in the range of 12–10 nm irrespective to the concentration of citrate (2–10 wt%) due to the relatively weak affinity in comparison to PVP, the composition of the fabricated alloy NPs was reflected the feeding ratio of the solution, and moreover, the particles become more dispersed and stable by increasing the citrate concentration. It is noted that the size of the NPs saturates at 10 nm for the concentration above 4 wt% and there was no significant change in the size of the NPs up to 10 wt% of citrate. This is due to the weak affinity of citrate to cap the NPs. However, the concentration of citrate was increased up to 10 % to find out optimum level of stability of the particles. It was found that by increasing the concentration of citrate the stability of the particles was increased and maximum stability was found to be 10 wt% concentration of citrate. Finally, the colloidal stability of Rh–Pd–Pt alloy NPs produced in aqueous solutions with PVP and citrate was investigated by means of the variation of absorption spectra of NPs measured periodically over 2 months under ambient condition. The time variation of UV–vis. photo-absorption spectra of the solutions for different ratios of Rh, Pd, and Pt metal ions with PVP or citrate was measured (see Fig. S2). The almost unchanged absorption spectra for Rh33Pd33Pt33 solutions with PVP and citrate indicate that the formed NPs were sufficiently stabilized by the addition of dispersant.

The exceptional stability probably stems from a strong promoting effect of adsorbed PVP molecules or citrate anions (possessing a free –COO– group) on the formation of electric double layers that envelop the surface of Rh–Pd–Pt alloy NPs, ensuring their mutual electrostatic repulsion, which prevents the formation of larger particles and/or aggregates in the aqueous solution. The stability of NPs in colloidal suspension is explained in terms of the surface electric charges of NPs, i.e., ζ-potential. Actually, the ζ-potential represents the electric potential difference between the charges of the species strongly adsorbed on the metal surface and those of the diffuse layer (with an opposite sign) in the dispersing medium. The electrostatic stability of Rh–Pd–Pt alloy NPs was evaluated by measuring the ζ-potential immediately after the particles synthesis. The ζ-potential of colloid without surfactant was below −30 mV. On the other hand, the ζ-potential of the PVP stabilized colloid ranged from −32 to −39 mV, whereas the citrate-stabilized colloid showed about −40 mV irrespective to the concentration. This is originated from the differences in the coordination fashion between citrate and PVP. Citrate anions coordinate to the metal surface by innersphere complexation of the carboxylate group. The higher concentration of citrate may affect metal−citrate bonding, i.e., more citrate ions able to bind to each metal NPs surface leading to increase the ζ potential. On the other hand, NPs are stabilized by PVP due to the electrostatic repulsion as well as the steric hindrance by the large PVP molecule. Accordingly, PVP-capped NPs are fine and have even or lower magnitude of ζ potentials than citrate-capped particles. It is predicted that, in case of lower concentration of surfactant, the particles are not sufficiently covered by surfactant molecules resulting in the precipitation after a couple of days.

Growth mechanism of Rh–Pd–Pt alloy NPs with different kind of surfactant

During laser irradiation, formation of bubbles seemed to be due to the decomposition of water molecules through laser-induced optical breakdown (Chin and Lagacé 1996). The formation of ternary Rh–Pd–Pt alloy NPs by intense laser irradiation of mixed aqueous solution of Rh, Pd, and Pt ions can be attributed to the generation of high energetic solvated electrons and hydrogen radicals during laser irradiation. Their energetic radicals are generated due to avalanche ionization and/or multiphoton absorption of water molecules (Pommeret et al. 2001). When energetic radicals meet metal ions, the ions will be reduced to zero valence atoms. The reduction process is as follows:

As a result, alloy formation occurs due to coalescence and collision among the atoms in the solution during laser irradiation. When the particles become several nanometers in size, most of the atoms generated by laser irradiation are consumed; the particles are capped by surfactants, and then the growth of particles is terminated. As a result, all-proportional solid-solution alloy formation is achieved in the citrate-added solutions. In the case of PVP-added solution, Pt-rich particles were fabricated irrespective to feeding ratio of ions. This can be explained as follows. The standard reduction potential of Pt2+, Pd2+, and Rh3+ (vs. SHE) varies in the following order: Pt2+/Pt0 (+1.20 eV), Pd2+/Pd0 (+0.915 eV), and Rh3+/Rh0 (+0.8 eV). As a consequence, Pt ions reduced faster than Pd and Rh. Therefore, one would expect to form a core–shell structure more likely than solid-solution alloy NPs. However, HR-TEM images as shown earlier indicate the solid-solution alloy formation. This is due to the fact that high-intensity laser pulse favors an efficient competition for reduction and thus alloy formation occurs within a short time (~hundreds of picosecond) and suppresses the metal segregation. Apart from reduction of Pt2+, Pd2+, and Rh3+ ions, the replacement reaction (Eqs. 4–6).) was also occured simultaneously in the presence of Rh0 and Pd0 (Tsuji et al. 2012). Therefore, some of the Rh and Pd atoms were consumed by Pt ions during the growth of NPs in PVP-added solution. Actually further investigation is necessary for complete understanding of replacement reaction. However, in the case of PVP-added solution, before the reduction process, the interaction of metal ion with stabilizing polymer formed a complex, i.e., polymer–metal ion complex (Toshima and Yonezawa 1998). Thereafter, the faster reduced metal atoms were captured in the metal atom complex. Therefore, unreacted metallic ions are coordinated on the PVP itself, and then the replacement reaction tends to take place among the NPs and the coordinated metallic ions on PVP molecules.

Moreover, the surface of formed NPs was covered by PVP at an early stage inhibiting the interaction with other atoms. Even though the above phenomena were applicable to citrate-capped particles, due to the weak capping effect, reaction rate differs from PVP-capped particles, as a result, interdiffusion among metal atoms occurred very promptly. Therefore, all-proportional solid-solution alloy was maintained.

All-proportional solid-solution ternary alloy NPs with nearly mono-dispersed size distribution and excellent stability were simply achieved by laser irradiation of mixed solution of ions with citrate. Properties of the fabricated NPs can be easily tuned not only by changing alloy composition but also by any kinds of supporting matrices. It is noted that the particles reported here are a promising candidate as an effective catalyst and its result will be reported in the near future.

Conclusion

In summary, we have demonstrated a viable approach to the synthesis of all-proportional solid-solution ternary alloy NPs based on the effective, non-equilibrium reaction of femtosecond laser irradiation of metallic ion solution. In particular, crystalline Rh–Pd–Pt alloy NPs with the effectively controlled size and composition of the NPs were achieved by the addition of citrate as a surfactant. Noble metal alloy NPs with tunable properties in size and composition are attractive for effective catalyst in desired reactions. The use of surfactant, which covers the particle surface immediately after the particle formation, promotes the improved size uniformity as well as the stability. The ability to easily produce crystalline ternary alloyed NPs under favorable conditions would be a suitable candidate for practical application whether as unsupported or supported catalysis.

Electronic Supplementary Material

Additional figures of XPS spectra and the time variation of UV–vis. photo-absorption spectra.

References

Alayoglu S, Eichorn B (2008) Rh–Pt bimetallic catalysts: synthesis, characterization, and catalysis of core–shell, alloy, and monometallic nanoparticles. J Am Chem Soc 130:17479–17486

Antolini E (2007a) Platinum-based ternary catalysts for low temperature fuel cells: Part I. Preparation methods and structural characteristics. Appl Catal B 74:324–336

Antolini E (2007b) Platinum-based ternary catalysts for low temperature fuel cells: Part II. Electrochemical properties. Appl Catal B 74:337–350

Brugger PA, Cuender P, Gratzel MJ (1981) Ultrafine and specific catalysts affording efficient hydrogen evolution from water under visible light illumination. J Am Chem Soc 103:2923–2927

Chen X, Xie J, Hu J, Feng X, Li A (2010) EDTA-directed self-assembly and enhanced catalytic properties of sphere-constructed platinum nanochains. J Phys D Appl Phys 43:115403

Chin SL, Lagacé S (1996) Generation of H2, O2, and H2O2 from water by the use of intense femtosecond laser pulses and the possibility of laser sterilization. Appl Opt 35:907–911

Christ BV (2000) Hand book of monochromatic XPS spectra. Wiley, New York

Cortie MB, McDonagh AM (2011) Synthesis and optical properties of hybrid and alloy plasmonic nanoparticles. Chem Rev 111:3713–3735

Costi R, Saunders AE, Banin U (2010) Colloidal hybrid nanostructures: a new type of functional materials. Angew Chem Int Ed 49:4878–4897

Dent AJ, Evans S, Fiddy G, Jyoti B, Newton MA, Tromp M (2007) Rhodium dispersion during NO/CO conversions. Angew Chem Int Ed 46:5356–5358

Essinger-Hileman E-R, DeCicco D, Bondi JF, Schaak RE (2011) Aqueous room-temperature synthesis of Au–Rh, Au–Pt, Pt–Rh, and Pd–Rh alloy nanoparticles: fully tunable compositions within the miscibility gaps. J Mater Chem 21:11599–11604

Ferrando R, Jellinek J, Johnston RL (2008) Nanoalloys: From theory to applications of alloy clusters and nanoparticles. Chem Rev 108:845–910

Habas SE, Lee H, Radmilovic V, Somorjai GA, Yang P (2007) Shaping binary metal nanocrystals through epitaxial seeded growth. Nat Mater 6:692–697

Heck RM, Farrauto RJ (1995) Catalytic air pollution control: commercial technology. Van Nostrand Reinhold, New York

Herbani Y, Nakamura T, Sato S (2011) Synthesis of near-monodispersed Au–Ag nanoalloys by high intensity laser irradiation of metal ions in hexane. J Phys Chem C 115:21592–21598

Herbani Y, Nakamura T, Sato S (2012) Synthesis of platinum-based binary and ternary alloy nanoparticles in intense laser field. J Coll Interface Sci 375:78–87

Hueso JL, Sebastián V, Mayoral A, Usón L, Arrueboab M, Santamarŕa J (2013) Beyond gold: rediscovering tetrakis-(hydroxymethyl)-phosphonium chloride (THPC) as an effective agent for the synthesis of ultra-small noble metal nanoparticles and Pt-containing nanoalloys. RSC Adv 3:10427–10433

Hung CM (2012) Complex PtPdRh nanoparticles: synthesis, characterization, and performance in the electrocatalytic oxidation of ammonia. Powder Technol 232:18–23

Jiang HL, Xu Q (2011) Recent progress in synergistic catalysis over heterometallic nanoparticles. J Mater Chem 21:13705–13725

Long NV, Chien ND, Hayakawa T, Hirata H, Lakshminarayana G, Nogami M (2010) The synthesis and characterization of platinum nanoparticles: a method of controlling the size and morphology. Nanotechnol 21:035605

Mafuné F, Kohno J, Takeda Y, Kondow T (2000) Structure and stability of silver nanoparticles in aqueous solution produced by laser ablation. J Phys Chem B 104:8334–8337

Mafuné F, Kohno J, Takeda Y, Kondow T (2001) Formation of gold nanoparticles by laser ablation in aqueous solution of surfactant. J Phys Chem B 105:5114–5120

Mafuné F, Kohno J, Takeda Y, Kondow T (2003) Formation of stable platinum nanoparticles by laser ablation in water. J Phys Chem B 107:4218–4223

Major KJ, De C, Obare SO (2009) Recent advances in the synthesis of plasmonic bimetallic nanoparticles. Plasmonics 4:61–78

Mulvaney P, Linnert T, Henglein A (1991) Surface chemistry of colloidal silver in aqueous solution: observations on chemisorption and reactivity. J Phys Chem 95:7843–7846

Nakamura T, Herbani Y, Sato S (2012) Fabrication of solid-solution gold–platinum nanoparticles with controllable compositions by high-intensity laser irradiation of solution. J Nanopart Res 14:785

Ojea-Jimenez I, Puntes V (2009) Instability of cationic gold nanoparticle bioconjugates: the role of citrate ions. J Am Chem Soc 132:5322

Pan HB, Wai CM (2011) Facile sonochemical synthesis of carbon nanotube-supported bimetallic Pt–Rh nanoparticles for room temperature hydrogenation of arenes. New J Chem 35:1649–1660

Park JY, Zhang Y, Grass M, Zhang T, Somorjai GA (2008) Tuning of catalytic CO oxidation by changing composition of Rh-Pt bimetallic nanoparticles. Nano Lett 8:673–677

Park JY, Zhang Y, Joo SH, Jung Y, Somorjai GA (2012) Size effect of RhPt bimetallic nanoparticles in catalytic activity of CO oxidation: role of surface segregation. Catal Today 181:133–137

Petit C, Lixon P, Pileni MP (1993) In situ synthesis of silver nanocluster in AOT reverse micelles. J Phys Chem 97:12974–12983

Pileni MP (1997) Nanosized particles made in colloidal assemblies. Langmuir 13:3266–3276

Pommeret S, Gobert F, Mostafavi M, Lampre I, Mialocq JC (2001) Femtochemistry of hydrated electron at decimolar concentration. J Phys Chem A 105:11400

Renzas JR, Huang W, Zhang Y, Grass ME, Huang DT, Alayoglu S, Butcher DR, Tao F, Liu Z, Somorjai GA (2011) Rh1−x Pd x nanoparticle composition dependence in CO oxidation by oxygen: catalytic activity enhancement in bimetallic systems. Phys Chem Chem Phys 13:2556–2562

Sarker MSI, Nakamura T, Herbani Y, Sato S (2013) Fabrication of Rh based solid solution bimetallic alloy nanoparticles with fully tunable composition through femtosecond laser irradiation in aqueous solution. Appl Phys A 110:145–152

Sarker MSI, Nakamura T, Sato S (2014) Composition-controlled ternary Rh–Pd–Pt solid-solution alloy nanoparticles by laser irradiation of mixed solution of metallic ions. J Mater Res 29:856–867

Shalaev VM, Moskovits M (1997) Nanostructured material. American Chemical Society, Washington, DC

Steigerwald ML, Alivisatos AP, Gibson JM, Harris TD, Kortan R, Muller AJ, Thayer AM, Duncan TM, Douglass DC, Brus LE (1988) Surface derivatization and isolation of semiconductor cluster molecules. J Am Chem Soc 110:3046–3050

Toshima N (2000) Core/shell-structured bimetallic nanocluster catalysts for visible-light-induced electron transfer. Pure Appl Chem 72:317–325

Toshima N, Yonezawa T (1998) Bimetallic nanoparticles–novel materials for chemical and physical applications. New J Chem 22:1179–1201

Toshima N, Shiraishi Y, Matsushita T, Mukai H, Hirakawa K (2002) Self-organization of metal nanoparticles and its application to syntheses of Pd/Ag/Rh trimetallic nanoparticles catalysts with triple core/shell structures. Int J Nanosci 1:397–401

Tsuji M, Nishio M, Jiang P, Miyamae N, Lim S, Matsumoto K, Ueyama D, Tang XL (2008) Role of chloride ions in the formation of Au@Ag core–shell nanocrystal structures by using a microwave–polyol method. Colloids Surf A 317:245–247

Tsuji S, Matsunaga M, Ishizaki T, Nonaka T (2012) Synthesis of Au–Cu-rich AuAg(AgCl)Cu alloy and Ag–Cu-rich AuAgCu@Cu core–shell and AuAgCu alloy nanoparticles using a polyol method. Cryst Eng Comm 14:3623–3632

Turkevich J, Stevenson PC, Hillier J (1951) A study of the nucleation and growth processes in the synthesis of colloidal gold. Discuss Faraday Soc 11:55

Turkevich J, Stevenson PC, Hillier J (1953) The formation of colloidal gold. J Phys Chem 57:670

Venkataraman R, Kunz HR, Fenton JM (2003) Development of new CO tolerant ternary anode catalysts for proton exchange membrane fuel cells. J Electrochem Soc 150:A278–A284

Wanjala BN, Fang B, Luo J, Chen YS, Yin J, Engehard MH, Loukrakpam R, Zhong CJ (2011) Correlation between atomic coordination structure and enhanced electrocatalytic activity for trimetallic alloy catalysts. J Am Chem Soc 133:12714–12727

Wanjala BN, Fang B, Loukrakpam R, Chen YS, Engelhard M, Luo J, Yin J, Yang LF, Shan SY, Zhong CJ (2012) Role of metal coordination structures in enhancement of electrocatalytic activity of ternary nanoalloys for oxygen reduction reaction. ACS Catal 2:795–806

Wilcoxon JP, Martin JE, Parsapour F, Wiedenman B, Kelley DF (1998) Photoluminescence from nanosize gold clusters. J Chem Phys 108:9137–9143

Xia H, Bai S, Hartmann JR, Wang D (2009) Synthesis of monodisperse quasi-spherical gold nanoparticles in water via silver (I)-assisted citrate reduction. Langmuir 26:3585

Zeng H, Sun S (2008) Syntheses, properties, and potential applications of multicomponent magnetic nanoparticles. Adv Funct Mater 18:391–400

Zhang X, Zhang F, Chan KY (2004) Preparation of Pt–Ru–Co trimetallic nanoparticles and their electrocatalytic properties. Catal Commun 5:749–753

Zhang J, Oko DN, Garbarino S, Imbeault R, Chaker M, Tavares AC, Guay D, Ma D (2012) Preparation of PtAu alloy colloids by laser ablation in solution and their characterization. J Phys Chem C 116:13413–13420

Acknowledgments

The authors would like to acknowledge Mr. Yuichiro Hayasaka for his kind assistance of EDS and HAADF-STEM EDS measurements.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sarker, M.S.I., Nakamura, T. & Sato, S. All-proportional solid-solution Rh–Pd–Pt alloy nanoparticles by femtosecond laser irradiation of aqueous solution with surfactant. J Nanopart Res 17, 259 (2015). https://doi.org/10.1007/s11051-015-3056-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-015-3056-8