Abstract

In the field of agriculture science, automatic visual inspection improves the commercial, quality and fertility of the country. It is very challenging to sort the fruit based on quality because of varieties of fruits available in the market. Human grades the fruit but it is inconsistent, stagnant, and expensive and influenced by the surrounding. Thus an effective system for grading of fruit is desired. In this paper, an automated fruit grading system is developed for apple to classify based on external quality. The different combination of several features are considered depending on the damages exposed on apple fruits. In this work, these features are considered as input to train Support Vector Machine (SVM). The classifier has been contemplated with two different database of apple: one having 100 color images out of which 24 are of apples with various defects and the other dataset having 112 color images out of which 56 are of apples with various defects. The system performance has been validated using k-fold cross validation technique by considering different values of k. The maximum accuracy 96.81% and 93.00% for two dataset respectively, achieved by the system is encouraging and is comparable with the state of art techniques.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Classifying a fruit is difficult and important task in supermarket and to govern its price cashier must know the category of a particular fruit. This problem is resolved by using barcodes for packaged products. However, some of the fruits cannot be packaged using barcodes and therefore each fruit can be assign by codes but this leads to error in pricing as well as tedious memorization of barcodes. One solution can be assigned by images and codes to the cashier, but flipping the booklet can be time consuming. Hence the classification of fruits using image processing and machine vision system is rapidly growing research area because it provides consequential amount of information about its attributes and the nature to maintain quality standard, reduces cost and deliver effective information at real time. Broadly, the fruit quality rely on exterior parameters: intensity, color, size, surface, shape appearance and interior parameters like acid and sugar contents but size and color is the most essential factor for sorting of fruits. From the past few years, distinct technique have been enhanced to grade and inspect the quality of fruits. Among all type of fruits, apples are one of the common fruits because the farming rate of apples with respect to all other fruits is more in India. The image processing based inspection of apple fruit is crucial for rising the agility of grading and excluding the human faults in the mechanism. In recent years in different fields [25, 35, 36, 40, 55] several effective solutions based on machine learning and computer vision have been proposed by researchers.

For this purpose Leemans et al. [32] introduced a method based on color information to detect defect using gaussian model on ‘golden delicious’ apples. Leemans et al. [33] introduced a method based on Bayesian classification process for defect segmentation on ‘Jonagold’ apples. Rennick et al. [45] compares five classifiers includes k-means, fuzzy c-means, k-nearest neighbor, multilayer perceptron and probabilistic neural network classifier on ‘Granny Smith’ apples. Yang [60] introduces a machine vision system for detection of defects on apples like patches. A flooding algorithm is used to segment dark patches then neural network approach is used. Leemans et al. [34] propose apple grading using quadratic discriminant analysis and neural network with multilayer perceptron. Kavdir and Guyer [26] use fuzzy logic for decision making support to grade apples by measuring the features using high tech sensors and machine vision. Blasco et al. [12] propose an apple grading using Bayesian discriminant analysis for segmentation while classifying the apples in batches and repeatability in blemish detection results in good performance. Kleynen et al. [29] proposed a method to select the best filters using quadratic discriminant analysis for detecting defects in ‘Jonagold’ apple fruit Unay and Gosselin [50] introduced an Artificial Neural Network (ANN) based automatic defect segmentation system for ‘Jonagold’ apples to eliminate false segmentation related to illumination artifacts.. Kleynen et al. [30] proposed a method for defect detection of ‘Jonagold’ apple based on Baye’s theorem using multi-spectral vision system. Leemans and Destain [31] proposed a method for defect detection of ‘Jonagold’ apple based on shape and texture feature extraction and linear discriminant classifier.

Unay and Gosselin [49] introduced ANN segmentation technique to grade apple fruit. Bennedsen et al. [7] reports a novel approach to locate the defects and eliminate other dark area based on rotating the ‘Pink Lady’ and ‘Ginger Gold’ apples. Xing et al. [59] report for detecting bruises on ‘Golden Delicious’ apples using principle component method, the wavebands were selected then moment thresholding was developed for classification. Xiaobo and Jiewen [57] uses near infrared machine vision and electronic nose system for detection of ‘Fuji’ apples. These three sensors are combined and uses ANN, multiple linear regression for grading of apples. Anderson et al. [2] introduce spatial frequency domain imaging for assessing the apple. They calculate scattering and absorption properties for bruise and non-bruise region. Bennedsen et al. [8] use infrared images to detect surface defects using multiple ANN and principle components at different wavelength and applying Weiner filter. Zhu et al. Zhu and Jiang [65] introduce apple quality inspection using gabor wavelet decomposition of NIR images with kernel Principle Component Analysis PCA for classification. Xiaobo et al. [58] propose a method based on genetic algorithm to grade ‘Fuji’ apples which shows more accurate result then capital SVM and BP-ANN. Vijayrekha Vijayarekha [53] introduced “multivariate image analysis” for defect detection of apples depending on decomposition from PCA. Wang et al. [54] proposed an apple grading using “vector median filter” with region growing segmentation and SVM.

Xiaobo et al. Xiabo et al. [56] developed an in-line detection of apple defect which is segmented using multi threshold. The defects include region of interest to grade the fruit. Radojevic et al. Radojević and Petrović [42] proposed a digital parameterization to measure size, shape and surface spottiness of apple fruit. Unay et al. [51] presents a novel method using machine vision for grading of apple fruit. The multi-spectral images are first segmented by minimal confusion matrix then geometric, statistical and textural features are extracted to classify the fruit. Moradi et al. [38] developed apple defect detection by using statistical histogram based Fuzzy c-means algorithm. Suresha et al. [48] proposed apple sorting using SVM classifier in which first RGB images to HSI then average red and green component are calculated for classification. Gopal et al. [21] presented the classifier based on probability density function on 187 apple fruits. Dubey and Jalal [16] detects and classify apples based on color and texture features using complete local binary patterns. Baranowski et al. [6] presented a method for early bruises detection in apples using thermal and hyperspectral imaging cameras by minimal noise fraction analysis of the apple fruit. Ghabousian and Shamsi [20] proposed a contour algorithm to segment the images. Arlimatti [4] proposed a window based method for grading the apples. Zhou et al. [64] developed a method of image fusion for apple surface quality detection. In this, images are collected by multi sensors and then fused by certain arithmetic system. Each image has improved operating factor. Khoje et al. [28] present a novel method for fruit grading based on discrete Curvelet Transform for feature extraction. Vani and Vinod [52] developed a non-destructive method to classify apple fruit using probabilistic neural network approach. Dubey and Jalal [17] used global Color Histogram, Color Coherence Vector, Local Binary Pattern (LBP) and CLBP, Zernike moment to grade the apples.

Khade et al. [27] proposed a defect segmentation based on texture feature using k-means clustering algorithm. Raihana and Sudha [44] presents a modified water shed segmentation method to detect the defected apple fruit using gray level covariance matrix based feature extraction. Ali and Thai [1] proposed a prototype of an automated fruit grading system to detect the defect of apple fruit. Moallem et al. [37] proposed a computer vision algorithm to grade ‘Golden delicious’ apple using multilayer perceptron neural network. Jawale and Deshmukh [23] proposed automatic evaluation of apple fruit disease using thermal camera and image processing bruises detection system. Bhargava and Bansal [9] reviewed various techniques for fruits and vegetables quality evaluation. Zhang et al. [62] presented a new deep learning-based method for removing haze from a single input image by estimating a transmission map via joint estimation of clear image detail. Yu et al. [61] presented a novel edge-based active contour model for medical image segmentation which guarantees the stability of the evolution curve and the accuracy of the numerical computation. Chen et al. [14] proposed a novel matting method based on full feature coverage sampling and accelerated traveling strategy to get good samples for robust sample-pair selection. Singh and Singh [47] presented a novel technique to grade apples by using different features like histogram of oriented gradients, Law’s Texture Energy, Gray level co-occurrence matrix and Tamura features. Bhargava and Bansal [10] proposed quality evaluation of mono and bi-colored apples with computer vision and multispectral imaging. Bhargava and Bansal [11] also presented an automatic grading and detection of multiple fruits by machine learning.

Among the literature surveyed for quality inspection of apple fruit using computer vision, researchers presented distinct methods that differ at quality categories taken, apple varieties tested, particular equipment used, imaging technique employed. As a result of this review, finding a commonly relevant basis to the bi-colored and mono-colored group, the used grading algorithm compare these works and conclude as followed: “Quality grading of apple fruit by machine vision is a burdensome task due to the variance of the problem. Thus, the research for a robust, generic and accurate grading system that works for all apple variations while respecting all norms of standards is still in progress” [51] .

The remaining paper is organized as: Section 2, describe computer vision algorithm that presented and build the apple fruit sorting system which includes explanation of image acquisition, segmentation, feature extraction and classification. We conferred the result of our experiments in Section 3, and the paper is concluded with research finding and feasible future work in Section 4.

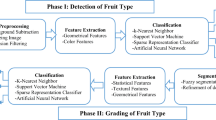

2 Proposed APPLE fruit grading system

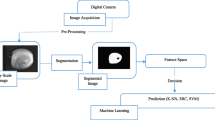

This section describes the apple fruit sorting system that we have built. In broad with increased expectation of high quality and safety in fruits, a computer vision based apple quality inspection system must achieve explicit segmentation and then perform correct grading of apples by extracting the statistical, textural, geometric features for classification by non-destructive method. Figure 1. shows the basic flow chart of the process.

2.1 Image acquisition

The first database (Set 1) is the ‘Golden Delicious’ apples consist of 100 images taken from EOS 550D digital camera acquire immense quality images with a size of 3456 × 2304 pixels and a resolution of 0.03 mm/pixel. An inspecting chamber (camera and lighting system) is created where samples are placed. The distance between camera and sample is 20 cm and are created by Blasco et al. [12]. The second dataset (Set 2) of 112 images of 40 apples (RGB color space) with different angle by Redmi Note 5 mobile phone with a size of 4000 X 3000 pixels. The distance between phone and apple is 1 m. The third dataset (Set 3) of 4359 images of fresh and rotten red delicious/ golden delicious/ granny smith apples are taken from kaggle.com created by Sriram Reddy Kalluri [24]. Dtataset used by our algorithm is shown in Table 1. Figure 2. shows some samples of database images used.

2.2 Segmentation

Image acquired by camera abide of various noises which degrade the appearance of image. Hence, it cannot assign convenient data for processing of image. So, enhancement of image is done by adjusting the image intensity value or color map. European commission marketing standard [3] for apples defines category for quality which requires defect information.

Therefore, it is necessary to specifically segment the defect which is ambiguous because size, type, texture and color vary for different defect. In this work, after preprocessing image segmentation is required for separating the area during the evaluation.

This division is done using different techniques: converting RGB image to grayscale image, “Otsu” strategy and k- means clustering. The k-means clustering detects the degraded part of apple and partition the intensity values into k number of regions by reducing the distance between corresponding regions and objects. The value of k is chosen by elbow method. Firstly, determine Within-Cluster-Sum of Squared Errors (WSS) for various values of k. Choose the k for which WSS becomes first start to diminish. Here, k = 3 is chosen as an elbow. Some of the segmented images are shown in Fig. 3 using Otsu’s and k-means clustering method.

2.3 Feature extraction

Segmentation results in definite unconnected objects with different shape and size. Each object handles separately or together for correct decision of fruit. Table 2 summarized the different combination of features extracted from the defective segmented area. Our experiment shows that 13 statistical & textural, 14 geometric features, Gabor wavelet and color coherence features are used for best performance in grading system.

2.3.1 Statistical features

The probability of first order measure observing the random gray pixels values are called statistical features which includes mean, standard deviation, variance, smoothness, RMS, inverse difference moment, kurtosis and skewness. These features do not take contingent relations of gray values into account.

2.3.2 Textural features

The probability of second order measure as pixel pairs are called textural features which includes contrast, correlation, energy, homogeneity and entropy. Pattern recognition widely uses geometric moment’s textural features. Another prominent group of textural features includes gray-level co-occurrence matrices (GLCM) [39, 43] which shows number of occurrences for gray level pairs as a square matrix. The GLCM features, inverse difference moment (IDM) is related to smoothness while variance and contrast are assessment of local variations. A GLCM is defined as a matrix (M X N) gray level image I, parameterized by an offset [22], defined as:

where I(p, q), gray level of image I at pixel (p, q).

2.3.3 Geometrical features

Also, features can be extracted for recognition depending on geometry of object. Nonetheless, defects of apple cannot have peculiar characteristics. Hence, we inked the geometric features that includes solidicity, area, and maximum length of area, eccentricity and perimeter listed in Table 3.

2.3.4 Gabor wavelet feature

Gabor wavelet is invented by Dennis Gabor using the complex function to minimize the product of its standard deviation in time and frequency domain. Mathematically,

The Fourier transform of Gabor Wavelet is also a Gabor Wavelet given by:

2.3.5 Discrete cosine transform (DCT)

DCT is a powerful transform to extract proper features. After applying DCT to entire image, some of the coefficients are selected to construct feature vectors. Most of the conventional approaches select coefficients in a zigzag manner or by zonal masking. The low frequency coefficients are discarded in order to compensate illumination variations.

2.4 Classification

The essential feature for fruit grading is classification. By using sufficient number of training samples, the grading is done. In this experiment, we use statistical classifier known as SVM. It is a type of learning system which uses hypothesis space in higher dimensional space of linear function which implements statistical learning theory. It consist of two parts: Linearly separable, Non-linear separable.

2.4.1 Linearly separable

SVM is used for grading purpose which is formerly proposed for 2-class problems. SVM is a supervised learning method which is based on minimization procedure of structural risk [13]. It calculates the hyper plane which separates the classes with maximum margin for binary values. For preventing the biased to sample order before being introduced to classifier, samples are randomly ordered. Assuming two training of hollow and solid dots, H is hyper plane optimized, H1 & H2 (support vectors) are samples whose distance is minimum.

To find a linear function, linear regression defined by

where ai is Lagrange multipler, b∗ is threshold, yi indicating the class to which point belongs.

SVM uses feature mapping where new space is separable which is done by kernel functions defined by:

2.4.2 Non-linearly separable

SVM uses non-seperable by introducing positive slack variables ξi, i = 1,2,…,l, in the constraints [15], which then become

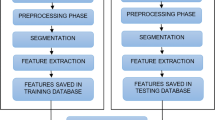

2.5 Evaluation

After extracting the different combination of features, the whole database is divided into two parts: Training set and testing set. The training set is used to train the system for classification, concurrently testing set is used to test the completion of classifier. The generation capability of the classifier are enhanced by using cross validation method on training dataset. This method generally employed to estimate the statistical applicability of the classifiers. It consist of four [41] types: Monte Carlo cross validation, Random subsampling, leave-one-out validation and k-fold cross validation. The k-fold cross validation is used because of its simplicity. In this method, K complementary subsets are partitioned from the dataset from which training is done for k-1 subset and validation is done by one subset. The whole process repeats K times by using every subset once for validation. The mean value of the results are computed for the final estimation. It can be observed that by using k-cross validation process all observations are used for both training and testing and each observation is used for validation exactly once. Figure 4 shows the simplified diagram of 5 –fold cross validation process.

The predication performances of the classifiers uses following measures: accuracy, sensitivity and specificity. Accuracy is calculated as all correct overall (true positive & negative) classifications. Sensitivity is also known as recall or true positive rate and is the probability of detection of undesirable objects which is correctly classified. Specificity is also known as true negative rate and is the probability of detecting the sound kernel correctly.

where TP, TN, FP and FN represent true positive, true negative, false positive and false negative of confusion matrix respectively.

3 Results and discussions

European commission marketing standard [3] for apples defines one reject and three acceptable quality category. Nonetheless, wide literature consist of healthy/defective grading due to adversity of collection of database and grading processes. In the pursuit of detection of best feature of apple two category sorting, we have inspected some statistical, textural and geometrical features while Support Vector Machine (SVM) is used for classification. The three dataset of apples are 100 Golden delicious (74 healthy, 26 defected) for Set 1 and 112 Normal (56 healthy, 56 defected) for Set 2 and 4359 (2017 healthy, 2342 defected) for Set 3 has trained with different combination (12/18/24/30) of features. Note that, each feature set selected consist of combination of statistical, textural and geometrical features. We implement fruit sorting with SVM using different kernel functions (linear, quadratic, polynomial, RBF, MLP) at a time as shown in Fig. 5.

It can be seen that by using different kernel function best performance is obtained when linear SVM is used among other kernel functions. Highest recognition rate for minimum combination (12 feature) with linear SVM for k = 10 are 72.00% (Set 1), 73.13% (Set 2) and 75.38% (Set 3). To improve the recognition rate more features are selected (18 feature) with linear SVM for k = 10 are 82.00% (Set 1), 79.16% (Set 2) and 79.38% (Set 3). To make system robust more features are combined (24 features) with linear SVM for k = 10 are 84.00% (Set 1), 87.91% (Set 2) and 86.23% (Set 3). Statistically, as examine increasing more features (30 feature) highest recognition rate achieved with linear SVM for k = 10 are 93.00% (Set 1), 96.81% (Set 2) and 95.41% (Set 3)as shown in Table 4. It can be observed that by selection of combination of features and increasing the number of features the accuracy increases. Also, using different kernel function best performance is obtained when combination of 30 features are incorporated. While increasing number of combination of features above 30 the accuracy rate is observed to be decreasing. Therefore the proposed combination of features are advantageous for two-category apple grading. It can be found that linear SVM is superior to all other kernel function and is best for apple recognition. Figure 6 displayed the results within each plot, SVM with different kernel function is taken at y-axis and accuracy rate obtained using the test images is represent at the x-axis. In each plot, it can be observed that the performance combination of all the features is far better than the performance of small set of features.

Sensitivity and specificity give an indication of how well the sound kernels were classified. As classification accuracy only indicates the presence of errors, one may prefer to describe the model in terms of sensitivity and specificity to better describe the models. The lower sensitivity and specificity indicates the classification errors and the higher values indicates the perfectly classified classes. The False Positive Rate (FPR) and False Negative Rate (FNR) were used to measure the errors done by method. The minimum and maximum value of FPR are 3.34% and 58.34% and of FNR are 12.51% and 65.00% respectively.

3.1 Comparison to other methods

Among different works popularized in the literature, few of them attains our attention because of apple fruit defect detection system as summarized in Table 5. Seng and Mirisaee [46] uses 55 apples fruit by extracting geometric features and classifying by KNN achieved 90.00% recognition rate. Ashok and Vinod [5] uses 65 apples images by extracting geometric features and classifying by PNN achieved 86.52% recognition rate. Moallem et al. [37] uses golden delicious apple database [12] consist of 120 (80 Healthy/ 40 Defected) apple color images which results in accuracy of 89.20% with 16 features. The proposed system also uses same database [13] but it consist of 100 (74 Healthy/ 26 Defected) which results in accuracy of 93.41% with 30 features. Both the database are downloaded from the same link but the researcher found 100 images instead of 120 (as mentioned by [37]). The obtained accuracy of the proposed system is compatible with Khan et al. (2019). However, there is an improvement of 3.91% from 92.90% to 96.81% is encouraging and satisfactory. Comparative analysis of the proposed system with other existing techniques shows improved and better accuracy with two different datasets. Hence, our approach contributes to improved recognition with cascaded features and a suitable classifier.

The accuracy obtained by the proposed system is better as compared to the available system. The system performance will be improved by taking more combination of features.

3.2 ROC curve

The receiver operating characteristic curve (ROC) analysis is a tool to classify the implication of the results contributed by classification and identification systems. The true positive, true negative, false positive and false negative and the various tuning parameters results in the outcome range for ROC. It is the plot of relation between true positive rate (TPR) and false positive rate (FPR). Figure 7 shows the ROC curve for our grading algorithm for k = 10 using linear function Set 1, Set 2 and Set 3.

4 Conclusion and future work

In this research, a computer vision based apple fruit grading and sorting is introduced. Firstly the area of fruit is extracted from background and is segmented by k-means clustering algorithm. After segmentation, defected region are extracted from multiple features which is fed to SVM for fruit grading by binary (healthy or defected) classification. Our apple fruit sorting results shows that different combination of different features acquired more accuracy compared to state of art. The maximum accuracy of 96.81% with 30 features and linear SVM classifier is encouraging and much better in comparison to another state of art technologies. Results showed that the proposed system with linear SVM classifier has better performance as compared to other kernels of SVM classifier.

Finally, the experimental results validations support the observations as follows: if features are less, one should prefer the combination of different features, improved recognition rate can be achieved with different features. However, the future work may further be improved by considering large number of apple images, different segmentation techniques, more significant features and combination of classifiers techniques. In the future, a more generalized and robust system with improved performance may be worked upon. The solution proposed in this work must be tested for multiple apple images to access its generality, robustness and accuracy and must be installed in a real life apple sorting environment. Also, the idea of the proposed system may be extended using convolution neural network [18, 19, 63].

References

Ali MAH, Thai KW (2017) Automatic fruit grading system. Int Symp Robot Manuf Autom

Anderson ER, You JS, Cuccia DJ, Tromberg BJ, Durkin AJ (2006) Spatial frequency domain imaging for quality assessment of apples. Quantum Electronics and Laser Science Conference

Anonymous (2004) Commission regulation (ec) no 85/2004 of 15 January 2004 on marketing standards for apples. Off J Eur Union L 13:3–18

Arlimatti S (2012) Window based method for automatic classification of apple fruit. Int J Eng Res Appl 2(4):1010–1013

Ashok V, Vinod DS (2014) Automatic quality evaluation of fruits using probabilistic neural network approach” in international conference on contemporary computing and informatics (IC3I) IEEE, pp 308–311

Baranowski P, Mazurek W, Wozniak J, Majewska U (2012) Detection of early bruises in apples using hyperspectral data and thermal imaging. J Food Eng 110:343–355

Bennedsen BS, Peterson DL, Tabb A (2005) Identifying defects in images of rotating apples. Comput Electron Agric 48:92–102

Bennedsen BS, Peterson DL, Tabb A (2007) Identifying apple surface defects using principle component analysis and artificial neural network. Am Soc Agric Biol Eng 50(6):2257–2265

Bhargava A, Bansal A (2018) Fruits and vegetables quality evaluation using computer vision: a review. J King Saud Univ Comput Inf Sci. https://doi.org/10.1016/j.jksuci.2018.06.002

Bhargava A, Bansal A (2019a) Quality evaluation of mono & bi-colored apples with computer vision and multispectral imaging. Multimed Tools Appl. https://doi.org/10.1007/s11042-019-08564-3

Bhargava A, Bansal A (2019b) Automatic detection and grading of multiple fruits by machine learning. Food Anal Methods. https://doi.org/10.1007/s12161-019-01690-6

Blasco J, Aleixos N, Molto E (2003) Machine vision system for automatic quality grading of fruit. Biosyst Eng 85(4):415–423

Burges (1998) A tutorial on support vector machines for pattern recognition. Data Min Knowl Disc 2:121–127

Chen X, He F, Yu H (2019) A matting method based on full feature coverage. Multimed Tools Appl 78(9):11173–11201

Cortes C, Vapnik V (1995) Support vector networks. Mach Learn 20:273–297

Dubey SR, Jalal AS (2012) Detection and classification of apple fruit diseases using complete local binary patterns. Int Conf Comput Commun Technol 12012

Dubey SR, Jalal AS (2015) Apple disease classification using color, texture and shape features from images. SIViP 10(5):819–826

Fan DP, Cheng MM, Liu JJ, Gao SH, Hou Q, Borji A (2018) Salient objects in clutter: bringing salient object detection to the foreground, 1–17

Fu K, Zhao Q, Gu IY, Yang J (2019) Deepside: A general deep framework for salient for salient object detection. Neurocomputing 356(2019):69–82

Ghabousian A, Shamsi H (2012) Segmentation of apple color images utilizing fuzzy clustering algorithms. Advances in Digital Multimedia

Gopal A, Subhasree R, Srinivasan VK (2012) Classification of color objects like fruits using probability density function. Int Conf Mach Vis Image Process 1–4

Haralick RM, Shanmugam K, Dinstein I (1973) Textural features for image classification. IEEE Trans Syst Man Cybern 3(6):610–621

Jawale D, Deshmukh M (2017) Real time bruise detection in apple fruits using thermal. Int Conf Commun Signal Process 1080–1085

Kalluri SR, Apple, Orange, Banana Images are retrieved January 15, 2018 from https://www.kaggle.com/sriramr/fruits-fresh-and-rotten-for-classification

Kang L, Fazhi H, Haiping Y, Xiao C (2017) A correlative classifiers approach based on particle filter and sample set for tracking occluded target. Appl Math A J Chin Univ 32(3):294–312

Kavdir I, Guyer DE (2003) Apple grading using fuzzy logic. Turk J Agric For 27:375–382

Khade S, Pandhare P, Navale S, Patil K, Gaikwad V (2016) Fruit quality evaluation using k-means clustering approach. Int J Adv Sci Eng Technol 4(2):27–31

Khoje SA, Bodhe SK, Adsul A (2013) Automated skin defect identification system for fruit grading based on discrete curvelet transform. Int J Eng Technol 5(4):3251–3256

Kleynen O, Leemans V, Destain MF (2003) Selection of the most efficient wavelength bands for 'jonagold' apple sorting. Postharvest Biol Technol 30(3):221.232

Kleynen O, Leemans V, Destain MF (2004) Development of a multi-spectral vision system for the detection of defects on apples. J Food Eng 69(1):41–49

Leemans V, Destain MF (2004) A real-time grading method of apples based on features extracted from defects. J Food Eng 61(1):81–89

Leemans V, Magein H, Destain M-F (1998) Defect segmentation on 'golden delicious' apples by using colour machine vision. Comput Electron Agric 20(2):117–130

Leemans V, Magein H, Destain M-F (1999) Defect segmentation on 'jonagold' apples using colour vision and a bayesian classification method. Comput Electron Agric 23(1):43.53

Leemans V, Magein H, Destain MF (2002) On-line fruit grading according to their external quality using machine vision. Biosyst Eng 83(4):397–404

Li K, He F, Yu H, Chen X (2018) A parallel and robust object tracking approach synthesizing adaptive Bayesian learning and improved incremental subspace learning. Front Comput Sci 13:1116–1135. https://doi.org/10.1007/s11704-018-6442-4

Lv X, He F, Yan X, Wu Y, Cheng Y (2019) Integrating selective undo of feature-based modeling operations for real-time collaborative CAD systems journal. Futur Gener Comput Syst. https://doi.org/10.1016/j.future.2019.05.021

Moallem P, Serajoddin A, Pourghassem H (2017) Computer vision based apple grading for golden delicious apples based on surface features. Inf Process Agric 4:33–40

Moradi G, Shamsi M, Sedaaghi MH, Moradi S (2011) Apple defect detection using statistical histogram based fuzzy C-means algorithm. Iramian Conf Mach Vis Image Process (2011)

Ou X, Pan W, Xiao P (2014) Vivo skin capacitive imaging analysis by using grey level co-occurrence matrix (GLCM). Int J Pharm 460(2):28–32

Pan Y, He F, Yu H (2019) A novel enhanced collaborative autoencoder with knowledge distillation for top-N recommender systems. Neuro Comput 332:137–148

Pereira AC, Reis MS, Saraiva PM, Marques JC (2011) Madeira wine ageing prediction based on different analytical techniques: UV–vis, GC-MS, HPLC-DAD. Chemom Intell Lab Syst 105(1):43–55

Radojević RL, Petrović DV (2011) Digital parameterization of apple fruit size, shape and surface spottiness. Afr J Agric Res 6(13):3131–3142

Raheja JL, Kumar S, Chaudhary A (2013) Fabric defect detection based on GLCM and Gabor filter: a comparison. Opt – Int J Light Electron Opt 124(23):6469–6474

Raihana A, Sudha R (2016) AFDGA: defect detection and classification of apple fruit images using the modified watershed segmentation method. Int J Sci Technol Eng 3(6):75–85

Rennick G, Attikiouzel Y, Zaknich A (1999) Machine grading and blemish detection in apples. Int Symp Signal Proces Appl 567(570)

Seng WC, Mirisaee SH (2009) A new method for fruits recognition system. Int Conf Electr Eng Inf 130–134

Singh S, Singh NP (2019) Machine learning based classification of good and rotten apple. Recent Trends Commun Comput Electr 377–386

Suresha M, Shilp NA, Sommy B (2012) Apples grading based on SVM Classifier. Int J Comput Appl 0975–8878.

Unay and Gosselin (2005) Artificial neural network-based segmentation and apple grading by machine vision. Int Conf Image Process

Unay D & Gosselin B (2004) A stem-end/calyx recognition system based on pattern recognition for ‘Jonagold’ Apples, Tech. Rep., TCTS labs., Facult’e Polytechnique de Mons

Unay D, Gosselin B, Kelynan D, Leemans V, Destain M, Debeir O (2011) Automatic grading of bi-colored apples by multispectral machine vision. Comput Electron Agric 75:204–212

Vani A, Vinod DS (2014) Automatic quality evaluation of fruits using probabilistic neural network approach. Int Conf Contemp Comput Inf (IC3I) 308-31

Vijayarekha K (2008) Multivariate image analysis for defect identification of apple fruit image. Annu Conf IEEE Ind Electron 1499–1503

Wang J, Zhao D, Ji W (2009) Application of support vector machine to apple recognition using in apple harvesting robot. IEEE Int Conf Inf Autom

Wu Y, He F, Zhang D, Li X (2018) Service-oriented feature-based data exchange for cloud-based design and manufacturing. IEEE Trans Serv Comput 11(2):341–353

Xiabo Z, Jie-Wen Z, Youxiao L, Holmes M (2010) Inline detection of apple defects using three color cameras system. Comput Electron Agric 70:129–134

Xiaobo Z, Jiewen Z (2005) Apple quality assessment by fusion three sensors. Sensors IEEE 389–392

Xiaobo Z, Jiewen Z, Yanxiao L (2007) Apple color grading based on organization feature parameters. Pattern Recogn Lett 28:2046–2053

Xing J, Bravo C, Jancsok PT, Ramon H, Baerdemacker JD (2005) Detecting bruises on Golden delicious apples using hyperspectral imaging with multiple wavebands. Biosyst Eng 90(1):27–36

Yang Q (1995) Automatic detection of patch-like defects on apples. Image Process Its Appl 529.533

Yu H, He F, Pan Y (2019) A novel segmentation model for medical images with intensity inhomogeneity based on adaptive perturbation. Multimed Tools Appl 78(9):11779–11798

Zhang S, He F, Ren W, Yao J (2018) Joint learning of image detail and transmission map for single image dehazing. Vis Comput 36:305–316. https://doi.org/10.1007/s00371-018-1612-9

Zhao JX, Liu JJ, Fan DP, Cao Y, Yang JF, Cheng MM (2019) EGNet: Edge Guidance Network for Salient Object Detection. IEEE Int Conf Comput Vis (ICCV) 1–10

Zhou J, Yin H, Liu J, Fan L (2012) Method of image fusion for apple surface quality detection. Int Conf Autom Control Artif Intell

Zhu B, Jiang L (2007) Gabor feature-based apple quality inspection using kernel principal component analysis. Elsevier

Funding

This research did not receive any specific grant from funding agencies in the public, commercial or not-for profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants performed by any of the authors.

Informed consent

Not applicable.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bhargava, A., Bansal, A. Machine learning based quality evaluation of mono-colored apples. Multimed Tools Appl 79, 22989–23006 (2020). https://doi.org/10.1007/s11042-020-09036-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11042-020-09036-9