Abstract

With increasing design reuse in modern products, accurate and efficient 3D CAD model retrieval methods are required. To improve retrieval capability, a 3D shape comparison method is often utilized. In this method, the shapes of 3D CAD models in a database are compared with the shape given by a user. Meanwhile, for rapid generation of query models, a freehand sketch-based modeling method is adopted for retrieval systems. This method creates a low-level-of-detail (low-LOD) 3D CAD model with abbreviated exterior shapes. On the other hand, the target 3D CAD model in the database is a high-LOD 3D CAD model including detailed shapes of a product or components of a product. Considering different LODs of query and target models, we propose a new 3D CAD model retrieval method consisting of a 3D CAD model simplification system and a shape distribution-based shape comparison engine that compares multi-resolution models in a database to improve retrieval accuracy using a query model with simple shape. Experiment is conducted on 64 LOD models generated from 8 test cases and 8 query models generated by freehand sketch-based modelling method. Result shows a 200 % improvement on retrieval success rate for lower LOD models (100 %) compared with source models (50 %). Moreover, the proposed method has an advantage on efficiency, due to the simple calculation method and short computation time.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

With improvements in computing power, modeling, and visualization technology, three-dimensional (3D) computer-aided design (CAD) models have become widely used in industry for product design, engineering simulation, and virtual prototyping. Thus, an enormous number of 3D CAD models is being created nowadays and is managed in information management systems with model databases.

Generally, 60 % of designer time is consumed in finding relevant existing information in the product design process [16]. Moreover, 80 % of new designs nowadays are created by reusing existing designs or by minor modification of existing designs [6]. Therefore, a method for 3D CAD model retrieval from databases is required in the design process or for business-to-business activities using the designer’s intention as query information.

The objective of 3D CAD model retrieval is to return the most similar 3D CAD model by comparing the given search conditions from the user with 3D CAD models in a database. The basic 3D CAD model retrieval method is text-based retrieval, which calculates similarity using pre-defined evaluation metrics that include the name, number, and/or annotation information assigned to each model in the database. However, this method is not applicable for models that have no ancillary information described and may return inaccurate results if naming, numbering, or annotation conventions are different between the database and the user’s knowledge. Similar with image/video retrieval or indexing researches such as [27], features extracted from the data can be exploited to retrieve or classify the query data. Thus, to improve retrieval capability, a 3D shape is often adopted to compare the shapes of 3D CAD models in a database with the shape given by a user in order to obtain the similarity of available 3D models [26].

In a 3D CAD model retrieval system involving 3D shapes, information given by the user for retrieval can be either an existing 3D CAD model that has a similar shape to that of the retrieval target model in the database or a 3D CAD model designed by the user using a simple authoring tool contained mainly in the retrieval system. One of the most convenient and rapid 3D CAD model generation methods for retrieval is the freehand 2D-sketch-based modeling method. In freehand 2D-sketch-based modeling, the user first creates a freehand 2D sketch using pen or mouse input and a 3D model is generated based on this sketch. 3D modeling operations are mapped from the user’s gestures as given by a pen or mouse device.

The 3D CAD model generated by the freehand 2D sketch-based modeling method is usually a low-level-of-detail (low-LOD) part model that only has approximated exterior shapes [2]. On the other hand, the target 3D CAD model in the database is a model resulting from detailed design, and is therefore a high-LOD 3D CAD model including detailed shapes of a product or components of a product. Moreover, assembly models may exist outside of part models, having an assembly relationship between components and the internal structure of a product. Thus, to increase accuracy of retrieval results, differences between the query model and 3D CAD models in database in terms of LOD and type of 3D CAD model should be considered.

In this research, we propose a 3D CAD model retrieval system with a shape distribution-based shape comparison method to address the abovementioned problems by considering LOD differences. In our approach, a simplification operation is applied to existing 3D CAD models in the database to generate shapes that have lowered LOD and whose interior structures have been removed. Afterward, a shape distribution-based comparison method is applied to calculate a quantitative similarity measure for a query model generated by the freehand 2D sketch-based modeling method and 3D CAD models in the database. As a result, the source 3D CAD model in the database that results in the highest similarity is returned as the final retrieval result. Retrieval success rate is improved by 200 % for lower LOD models compared with source models. Moreover, the proposed method has an advantage on efficiency, due to the simple calculation method and short computation time.

This paper is organized as follows. In section 2, we review existing 3D shape comparison, freehand sketch modeling, and 3D CAD simplification approaches. The proposed 3D CAD model retrieval system is introduced, which assumes that the query model has a low LOD as generated from the freehand 2D sketch-based modeling method and that 3D CAD models in the database have a high LOD. A 3D CAD model retrieval experiment and its result using the proposed system is introduced in section 4, followed by conclusions and future works in section 5.

2 Related research

2.1 3D shape comparison

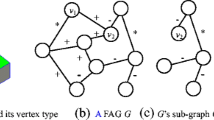

In order for a comparison to be made, each 3D model has to be identified using a shape descriptor that provides a compact overall description of a 3D shape. Similarity comparison methods can classify shapes into six categories according to the data used to generate the shape descriptor. These are global-feature-based, manufacturing-feature-recognition-based, graph-based, 3D-object-recognition-based, product-information-based, and histogram-based methods [9]. Paquet et al. [20] proposed a compact way of representing the coarse shape, scale, and composition properties of an object for 3D shape matching. Ramesh et al. [23] presented a machining-feature-based similarity comparison method for the retrieval of mechanical parts. El-Mehalawi and Miller [4] developed a representation scheme that created an attribute graph to compare CAD models of engineering parts. Horn [8] reported that extended Gaussian images (EGI) are useful for representing the shapes of surfaces, and are therefore appropriate for use in object recognition. Rodríguez and Egenhofer [24] developed a method for semantic similarity measurements that was conducted at two levels, measuring the similarities between elements themselves and measuring the similarities of the neighborhoods of elements. Osada et al. [19] presented a method that represents the signature of an object as a shape distribution for comparison of 3D mesh models. Ohbuchi et al. [18] enhanced the method proposed by Osada et al. by introducing angle-distance and absolute angle-distance histograms, which are calculated based on the D2 shape function.

2.2 Freehand 2D sketch-based modeling

There are two main approaches in reconstructing 3D models from freehand 2D sketches [3, 10]: gestural modeling and reconstructional modeling. The difference between these approaches is in how the intent of a given designer is interpreted. In gestural modeling, a 2D sketch is interpreted based on the user’s behaviors whereas in reconstructional modeling, a 2D sketch is interpreted without regard to user behavior. Features and detailed descriptions for a variety of freehand 2D sketch modeling methods are found in [1]. The gestural modeling method builds 3D data by mapping the gestures of an input pen to modeling operations. Reconstructional modeling views a 2D sketch as the projected image of a 3D shape and reconstructs 3D data via a geometric reconstructional algorithm. The modeling procedure in a gestural modeling system is explicitly known since the system interprets each input stroke and generates a 3D shape corresponding to it [2]. On the other hand, the modeling procedure of the reconstructional modeling system is ambiguous because the system interprets an entire set of input strokes at once and generates the resulting 3D shape.

In 3D CAD model retrieval researches based on 2D sketch input [17, 21, 22], 2D views are generated by projecting 3D CAD models stored in a database and the 2D views are compared with a 2D sketch input from a user without gestural or reconstructional modeling process. In [21], silhouette view is generated from 3D CAD models stored in a database and is compared with a 2D sketch input from a user. Followed by [21], a method [22] to improve retrieval accuracy is proposed by combining similarities measured using different levels of detail 2D views (contour level, silhouette level and drawing level) generated from 3D CAD models stored in a database. In [17], an efficient 2D view generation method is proposed by considering drawing habits of users. Therefore, performance of 3D CAD model retrieval using a pen-based 2D sketch input given by a user was improved. Since 2D view is a projected image of 3D shapes 2D view-based methods have disadvantages on possibility of instability in comparison result depending on the direction of projection and on possibility of loss of meaningful 3D shape information for retrieval. On the other hand, 2D view-based method is efficient since minimal query information (2D sketch) is sufficient for retrieval.

2.3 3D CAD model simplification

Many studies related to simplification of 3D CAD models can be classified into one of the following three methods, according to the type of 3D CAD model used: polygon-based [7, 25], boundary-representation-based (B-rep-based) [5, 12], and feature-based methods [11, 13–15]. The polygon-based method is mainly used in computer graphics. It simplifies models by reducing the number of triangles used to represent the shape in a mesh. Mesh simplification methods show good results when applied to regular, dense meshes used in computer graphics. However, meshes generated from CAD models are not typically regular and dense. Therefore, the characteristics of the original shape can be distorted when mesh simplification is applied to CAD models. The B-rep-based method simplifies shapes by using their topological information, and can be classified into two methods. In the dimensional reduction method, thin solids are transformed into faces or long solids such as cylinders are transformed into edges. In the feature suppression method, shapes are simplified by suppressing features that do not significantly affect engineering analysis (such as rounds, fillets, or holes). In the feature-based method, shapes are simplified by incrementally suppressing low-importance features in CAD models. The level of importance of a feature depends on the purpose of the CAD model. While feature suppression in B-rep simplification can be applied only to limited features detected by an individual recognition algorithm, feature suppression in feature-based simplification can be applied to any feature. As a result, the LOD of CAD models can be controlled.

3 Proposed method

3.1 Retrieval system overview

As summarized in [26], in the general framework of a 3D model retrieval system, comparison of 3D models is performed using descriptors of shapes to measure the quantitative similarity of models from the difference of descriptors. As we introduced in section 2.1, various methods are studied as to how to define descriptors of shapes and how to measure their similarity.

The overall diagram of the proposed 3D CAD model retrieval system is illustrated in Fig. 1, including a 3D CAD model retrieval engine and a 3D CAD model simplification system. The main idea of proposed system is application of a shape distribution-based similarity measuring method proposed in [18] along with calculation of multiple descriptors of source models in the 3D CAD model database from multi-resolution models (MRM) generated using the 3D CAD simplification method. The result is increased retrieval accuracy for a queried model designed using a freehand sketch-based modeling system.

At first, the user designs a rough 3D model using the freehand sketch-based modeling method that can be used as a query model for 3D CAD model retrieval. Note that, owing to the similarity measuring method we selected, the proposed method does not restrict the query model to be a feature-based model or a B-rep model. Therefore, a surface representation is sufficient for use as the query model and we assume the query model is a mesh model, which is widely used for surface representation in various fields.

The main characteristic of the freehand sketch-based model is that the resulting shape is relatively simple owing to the limited sketch input method and gesture-based feature modeling. Limitation of sketch input and gesture-based feature modeling is required, on the other hand, for rapid model generation and user convenience. Then the shape characteristics of the generated query model are recorded as descriptors. The detailed method of calculation of descriptors from the query model and the comparison method for descriptors will be introduced in Section 3.2, which is related closely to our 3D CAD model retrieval engine.

On the other hand, the 3D CAD model database includes existing designs, which we call source models. Contrary to the query model, source models are feature-based models or B-rep models. Surface information, which is required by the similarity measuring method, can be extracted from these models. The main characteristic of a source model is that it has a highly detailed shape. Naturally, a source model in the database is a final design or design alternative that should include detailed shapes so that it can be used in the manufacturing process. Therefore, we can estimate that the query models from the freehand sketch-based modeling system and source models in the 3D CAD model database are different in terms of the LOD of their shapes.

In the proposed method, the key concept utilizes the obvious fact that a query model designed by the user must have “simplified” shapes compared with the designated model. Generally, the objective of a 3D CAD model retrieval system is to retrieve an existing design in a short time with low user effort, which leads to a query model simplified as much as possible. Therefore, a query model that has detailed shapes is rare and meaningless in the context of a retrieval system. Our assumption is that, if we simplify source models in a database, the results will converge to shapes more similar to the query model compared with the source models.

Our proposed method generates multi-resolution models, and therefore multiple descriptors from source models, in a 3D CAD model database. This is based on research [14] that proposed a simplification method for 3D CAD models that reflects simplification criteria observed in industrial practice. In the retrieval process, the descriptor of a query model is compared with multiple descriptors for each source model, and the source model that shows the highest similarity measured is delivered to the user as the retrieval result.

3.2 Shape distribution-based comparison method

As we reviewed in Section 2.1, there are various studies on shape comparison; we selected 2D shape distribution methods as proposed in [18]. The selected method generates uniform point samples from a 3D surface and calculate distances and angles of sampled point pairs to create 2D descriptors from a probability distribution function. The similarity of two 3D models can be quantitatively calculated from the distance between two descriptors.

This method has the advantage of applicability to various 3D model databases in that it requires only low-level geometry information. Furthermore, the method is translation-, rotation-, and in case of adopting normalization, scale-invariant, and the calculation is simple for descriptor creation and comparison. Therefore, result similarity can be obtained in a relatively short time. Due to the abovementioned advantages, we decided that the 2D shape distribution-based comparison method is suitable for our proposed 3D CAD model retrieval system.

The overall process of shape distribution-based shape comparison is illustrated in Fig. 2. At first, a uniform point set S is generated from the 3D surface of a 3D model. Additionally, while generating each element in the point set S, normal vectors corresponding to each point can be obtained, and we define them as the set of normals N. Usually, normals can be obtained easily for a surface model (in our case, a mesh model), and a simple cross product can be adopted to estimate a normal if it does not exist. If the existing normals are flipped, similarity can still be measured reliably if we define a proper shape function. After obtaining S and N, we repeat the sampling loop that picks point pairs from S and corresponding normal vector pairs from N M times (where M is a user-defined parameter), and then calculate a shape function called the absolute angle distance (AAD).

The AAD shape function, as shown in Fig. 3, is a tuple of Euclidean distance between two points in 3D space denoted by D and the absolute angle between two normal vectors denoted by θ, which can be transformed into the dot product of two vectors for simple calculation. Therefore, we obtain M values of AAD; then, by counting the frequency of distance and angle values in the AAD set divided by specific interval length, a 2D probability distribution function can be created as a descriptor of the 3D model.

When comparing two descriptors, different distance metrics can be considered; in our research, the simple and intuitive Minkowski L1 norm is applied. In [18, 19], the differences between various distance metrics are covered in detail. The process shown in Fig. 2 is applied to both the query model and to models in the database, and the 3D CAD model retrieval engine is responsible for calculating result similarity measures between descriptors and concluding which is the most similar source model in the database. Descriptors for multi-resolution models can be pre-generated offline for efficient retrieval. Therefore, in the online mode, generation of descriptors for the query model as well as distance calculations between descriptors are conducted.

3.3 Feature-based simplification method

The main techniques for the simplification of a 3D CAD model are evaluation metrics and simplification operations [13]. Evaluation metrics are used to calculate the quantitative importance of each element in a 3D CAD model in order to determine whether an element should be maintained or removed based on its importance. Simplification operations are used to remove the selected element and fill up the void caused by the removal. For feature-based 3D CAD models, feature rearrangement and removal algorithm [15] are used as simplification operations.

Feature-based simplification method calculates importance of each feature comprising a 3D CAD model, receives a desired LOD from a user, and removes features with lower importance value to meet the desired LOD. To select the features to be suppressed, evaluation metrics are used for calculating the quantitative importance of each feature by judging all characteristics of each feature according to the simplification criteria. The evaluation metrics proposed by Kwon et al. [27] were adopted in the proposed method for calculating feature importance. Equation (1) shows the evaluation metrics.

Where

where

where

FIi is the importance of the i-th feature. The positive term \( {\mathrm{P}}_{\mathrm{i}} \) adds 1 to the features to be retained otherwise it adds 0. The conditional term \( {\mathrm{C}}_{\mathrm{i}} \) assigns a value between 0 and 1 to the features that fall into the conditional criteria. For this, the weighting factors for each criterion x (wx) should be determined if there are more than one criterion. The negative term \( {\mathrm{N}}_{\mathrm{i}} \) multiplies −1 to the features to be removed, otherwise 1.

The features fall into one of three ranges based on Equation (1): features that must be maintained (\( {FI}_{\mathrm{i}}>1\Big) \), features to be conditionally simplified (\( 0<{FI}_{\mathrm{i}}\le 1\Big) \), and features that must be removed (\( {FI}_{\mathrm{i}}<0\Big) \). Consequently, it allows all the features to be progressively simplified by their relative importance.

4 Implementation and experiments

4.1 Test cases

To validate the proposed method, we conducted similarity-measuring experiments on test cases. We selected eight 3D CAD models as test cases: an air compressor, ANC101, blower cover, butterfly valve, control valve, engine block 1, 2 and pump. The shapes of the selected models are shown in Fig. 4. These models were designed in CATIA V5, a commercial mechanical 3D CAD system.

Multi-resolution models with different LOD are generated for each test model using the parametric feature-based 3D simplification method in our proposed system. The generated models that have the lowest LOD are denoted by LOD 30 and those with the highest are denoted by LOD 100; these have exactly the same shape as the source models, and the LOD interval between multi-resolution models is 10. Therefore, 8 models are generated for each test case. As shown in Fig. 5, where the example is the control valve, parametric features are removed during generation of low-LOD models, leading to alteration of detailed shapes. In our observations on these test cases, hole features, extruded cut features, and fillet features are often removed in low-LOD models.

After generation of multi-resolution models, we converted them into mesh models that represent shapes as vertices and triangles. As mentioned before, a mesh model has 3D surface information only, without topology or design history.

Finally, eight 3D models were designed using a freehand sketch-based modeling system. Models were designed using simple sketch- and gesture-based input without advanced modeling commands such as curve or fillet features. By eliminating advanced modeling commands, the shapes of these models are different from the source models in that they are simpler. All the models used in the experiments are shown in Fig. 6. Models in the leftmost column are from the freehand sketch-based modeling system, and in the rest of the columns are multi-resolution models from LOD 100 to LOD 30 (from left to right). Additionally in the case of blower cover, engine block 2 and pump, a 3D model generated from freehand 2D sketch-based modeling has different position and orientation. Therefore, we expected to observe the pose-invariant characteristic of shape distribution-based comparison method when unaligned 3D CAD models and query models are compared to each other.

4.2 Validation of the shape comparison method

As described in Section 3.2, the shape comparison method we chose starts from generating a point set from the surface of a model and then calculates distances and measures angles in the point set to create a 2D distribution. The difference between two 2D shape descriptors produces a quantitative similarity between models. In this experiment, a point set with 10,000 elements and a corresponding normal vector set are generated for each model illustrated in Section 4.1. During descriptor generation, distance and angle interval was divided into 64 and 8 bines to construct a histogram. The bin intervals for distance are defined adaptively using maximum distance found on corresponding models for scale-invariant similarity measures. Therefore, if two models have similar shapes, the resulting similarity measured can be high regardless of the scale difference.

The primary experiment was conducted for multi-resolution models in 8 test cases to validate the robustness of the comparison method. Obviously, multi-resolution models of a single source model have smaller differences in shape compared to other source models, and we expect that the comparison method should conclude a higher similarity between multi-resolution versions of the same model if the method is robust. The results are shown in Fig. 7 as a similarity matrix image. Each column and row index represents a single model and the value of each element in the matrix is assigned as a result of the similarity value measured between two models, corresponding to each column and row index. In Fig. 7, each element in the matrix is illustrated using a grid and higher similarity is indicated by a brighter color while lower similarity appears in a darker color. From the figure, multi-resolution models from the same test case have high similarities with brighter colors while models from different test cases have low similarities with darker colors.

Table 1 shows summarized results from Fig. 7 by averaging values for each test case. Again, the similarity of the same test case is higher than the similarity between different test cases; thus, the comparison method’s validity is proven.

4.3 Experiment results and discussion

The same comparison experiment was conducted on query models designed by the freehand sketch-based modeling method between multi-resolution models. As we described, query model shapes are different from those of the designated source models depending on the experiment and the qualitative decisions of the user. However, they share common characteristics of shape simplicity for efficient retrieval, and the same characteristics can be observed in our test query model as those designed using the modeler. In this section, we introduce results and analysis for the experiment conducted to validate the proposed multiple-descriptor approach with the shape distribution-based similarity-measuring method.

The experimental results depicted with a graph are shown in Figs. 8 and 9. Figure 8 shows similarity evaluated between query model and simplified models with different LODs for air compressor, ANC101, block cover and engine block 2. Figure 9 shows evaluated similarity of butterfly valve, control valve, engine block 1 and pump. In Figs. 8 and 9, the x-axis indicates level of detail of 3D CAD models, and the y-axis indicates similarity measure where a lower value is located on a higher position since a lower value means a higher similarity. Since the measured similarity value range is diverse according to the test case, we adaptively scaled the range of y-axis.

Figure 8 shows test cases where query models generated by freehand 2D sketch-based modeling resulted in the highest similarity to the designated test cases in the entire LOD 30 ~ 100 interval. On the other hand, for the other four test cases (butterfly valve, control valve, engine block 1 and pump), query models did not show the highest similarity to the designated test cases when query models were compared with LOD 100 models of their corresponding test cases, as shown in Fig. 9. However, all 8 query models showed the highest similarity to the designated test cases when query models were compared with LOD 30 models of their corresponding test cases, as shown in Fig. 10. The result implies that similarities become higher when low LOD models are used for each test case on comparison because a 3D model generated from freehand 3D sketch-based modeling by a user contains simple 3D shape in nature. Overall success rate is monotonically increased from 50 % for source models (LOD 100) to 100 % for LOD 30 models. Therefore, retrieval success rate is improved by 200 %.

Retrieval performance changes according to the levels of detail are illustrated in Fig. 11 with precision-recall curve. Higher precision and recall value indicates better retrieval performance. In Fig. 11, lower LOD interval (LOD 60 ~ 30) shows better performance than higher LOD interval (LOD 100 ~ 70).

Table 2 shows experiment environment including the average numbers of vertex and faces of 3D CAD models used in the experiment, parameter values used for descriptor calculation, and average computation times for descriptor generation and comparison. The average number of vertices and faces for LOD 30 ~ 100 models and query models are 19,293 and 12,964. Shape details of 3D CAD models for 8 test cases are greatly different from each other. We generated 10,000 points from each 3D CAD model and 1,048,576 pairs of points are sampled during descriptor generation for each 3D CAD model. During descriptor generation, distance and angle interval was divided into 64 and 8 bins to construct a histogram. In average, computation time for descriptor generation from a 3D CAD model is 152.29 ms (±4.93 ms) and time required to compare two descriptor for dissimilarity calculation is 0.006 ms (±0.003 ms). Descriptor generation for 3D CAD models stored in a database can be processed off-line; generation can be done prior to retrieval. When a query model is given to retrieve a 3D CAD model from a database, descriptor generation is required only for a single model (the query model) and descriptor comparison is done very quickly (0.006 ms). Therefore, ideally 140 thousand models in a database can be compared with a query model, within 1 s.

Overall, the results of our experiment show that, in all cases, retrieving the intended model from a query model created by the user through the freehand sketch-based modeling system is possible. Therefore, we argue that the proposed method can robustly work as a 3D CAD model retrieval system. The models designed using the freehand sketch-based system generally have different shapes form the source models in the database, and our experimental results confirmed proved this. However, we expected that simplified models of source models would result in higher similarity than the source models themselves when comparing them with query models designed by the user, since query models typically have simple shapes. Experimental results show that each query model designed by the user shows the highest similarity with the LOD 30 model simplified from the corresponding source model among all test cases. Thus, we conclude that the proposed method is valid for use in 3D CAD model retrieval systems.

5 Conclusion

In this research, we proposed a 3D CAD model retrieval system using a freehand sketch-based modeling system and a 3D CAD model retrieval engine. The former system enables rapid, efficient query model generation, facilitating model search robustness; the latter engine uses multi-resolution 3D CAD models created from source models via a feature-based simplification method. For comparison of 3D CAD models, a shape distribution-based comparison method was applied in the proposed system. Shape distribution-based comparison has shortcomings in detecting partial differences of shapes, but is efficient in rapid model comparison in a large database.

Experiments were conducted to validate the performance of the proposed 3D CAD model retrieval method. Multi-resolution models were generated from source models using a feature-based simplification method and their descriptors were used in shape distribution-based comparison. From the experiments, descriptors generated from multi-resolution models with low LOD resulted in higher accuracy similarity measures than descriptors generated from the source 3D CAD model when compared with query models designed using a freehand sketch-based modeling system.

At present, the proposed method does not consider the retrieval of assembly models. Retrieval of assembly models is required in order to extend the reusability of existing 3D CAD model databases. Furthermore, partial search techniques should be investigated so that users can search 3D CAD model databases with a query model that contains only part of the intended shape.

Change history

07 September 2017

An erratum to this article has been published.

References

Cheon SU, Han S (2008) A template-based reconstruction of plane-symmetric 3D models from freehand sketches. Comp Aided Des 40(9):975–986

Cheon SU, Kim BC, Mun D, Han S (2012) A procedural method to exchange editable 3D data from a free-hand 2D sketch modeling system into 3D mechanical CAD systems. Comput Aided Des 44(2):123–131

Company P., Piquer A., Contero M., 2004, On the evolution of geometrical reconstruction as a core technology to sketch-based modeling, in the Proceedings of EUROGRAPHICS Workshop on Sketch-Based Interfaces and Modeling

El-Mehalawi M, Miller RA (2003) A database system of mechanical components based on geometric and topological similarity. Part I: representation. Comput Aided Des 35(1):83–94

Foucault G, Cuilliere JC, Francois V, Leon JC, Maranzana R (2008) Adaptation of CAD model topology for finite element analysis. Comput Aided Des 40(2):176–196

Gunn TG (1982) The mechanization of design and manufacturing. Sci Am 247(3):114–130

Hoppe H., 1996, Progressive Meshes, in the Proceedings of ACM SIGGRAPH

Horn BKP (1984) Extended Gaussian images. Proc IEEE 72(12):1671–1686

Iyer N, Jayanti S, Lou K, Kalyanaraman Y, Ramani K (2005) Three-dimensional shape searching: state-of-the-art review and future trends. Comput Aided Des 37:509–530

Kallio K., 2005, 3D6B Editor: Projective 3D sketching with line-based rendering, in the Proceedings of 2nd Eurographics Workshop on Sketch-Based Interfaces and Modeling

Kang Y, Kim BC, Mun D, Han S (2014) Method to simplify ship outfitting and offshore plant equipment three-dimensional (3-D) computer-aided design (CAD) data for construction of an equipment catalog. J Mar Sci Technol 19(2):185–196

Koo SB, Lee KW (2002) Wrap-around operation to make multi-resolution model of part and assembly. Comput Graph 26(5):687–700

Kwon S, Kim BC, Mun D, Han S (2015a) Simplification of feature-based 3D CAD assembly data of ship and offshore equipment using quantitative evaluation metrics. Comput Aided Des 59:140–154

Kwon S, Kim BC, Mun D, Han S (2015b) Graph-based simplification of feature-based 3D CAD models for preserving connectivity. J Comput Inf Sci Eng 15(3):031010–031014

Lee S.H., Lee K., 2012, Simultaneous and incremental feature-based multiresolution modeling with feature operations in part design, Comput Aided Des, 44(5), pp. 457–83

Leizerowicz W, Bilgic T, Lin J, Fox MS (1996) 1996, Collaborative design using WWW. In: the Proceedings of the WET-ICE’96

Liu Y, Luo X, Joneja A, Ma C, Fu X, Song D (2013) User-adaptive sketch-based 3-D CAD model retrieval. IEEE Trans Autom Sci Eng 10(3):783–795

Ohbuchi R, Minamitani T, Takei T (2005) Shape-similarity search of 3D models by using enhanced shape functions. Int J Comput Appl Technol 23(2–4):70–85

Osada R, Funkhouse T, Chazelle B, Dobkin D (2002) Shape distributions. ACM Trans Graph 21(4):807–832

Paquet E, Rioux M, Murching A, Naveen T, Tabatabai A (2000) Description of shape information for 2-D and 3-D objects. Signal Process Image Commun 16(1):103–122

Pu J, Lou K, Ramani K (2005) A 2D Sketch-Based User Interface for 3D CAD Model Retrieval. Comp-Aid Des Applic 2(6):717–725

Pu J., Jayanti S., Hou S., Ramani K., 2006, 3D CAD Model Retrieval Based on Multiple Levels of Detail, The 14th Pacific Conference on Computer Graphics and Applications

Ramesh M, Yip-Hoi D, Dutta D (2001) Feature based shape similarity measurement for retrieval of mechanical parts. J Comput Inf Sci Eng 1(3):245–256

Rodríguez MA, Egenhofer MJ (2003) Determining semantic similarity among entity classes from different ontologies. IEEE Trans Knowl Data Eng 15(2):442–456

Sheffer A (2001) Model simplification for meshing using face clustering. Comput Aided Des 33(13):925–934

Tangelder JW, Veltkamp RC (2008) A survey of content based 3D shape retrieval methods. Multimed Tools Appl 39(3):441–471

Yang Y, Zha Z, Gao Y, Zhu X, Chua T (2014) Exploiting Web Images for Semantic Video Indexing Via Robust Sample-Specific Loss. 16(6):1677–1689

Acknowledgment

This research was supported by the Civil-Military Technology (Project ID: 14-CM-MC-15), the Industrial Core Technology Development Program (Project ID: 10048341) funded by the Ministry of Trade, Industry and Energy, and the Plant Research Program (Project ID: 14IFIP-B091004-01) funded by the Ministry of Land, Infrastructure and Transport of the Korean government. The authors gratefully acknowledge this support.

Author information

Authors and Affiliations

Corresponding author

Additional information

An erratum to this article is available at https://doi.org/10.1007/s11042-017-5147-2.

Rights and permissions

About this article

Cite this article

Kim, H., Cha, M. & Mun, D. Shape distribution-based retrieval of 3D CAD models at different levels of detail. Multimed Tools Appl 76, 15867–15884 (2017). https://doi.org/10.1007/s11042-016-3881-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11042-016-3881-5