Abstract

An economical and proficient approach has been developed for the synthesis of chromenopyrimidines via three-component reaction of thiobarbituric acid/barbituric acid, methylarenes and dimedone/1,3-cyclohexanedione by using lemon juice as a natural, biodegradable catalyst and TBHP as an oxidant. This transformation involves metal-free C–C bond formation via C–H activation of methylarenes under mild reaction conditions.

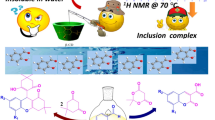

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Recently, the direct C–H bond functionalization/C–C bond formation of hydrocarbons via C–H bond activation has attracted much attention in organic synthesis [1,2,3,4,5,6]. Especially, in view of the green perspective, selective and controlled functionalization without using metal catalyst has become a challenging area for organic chemists. As a characteristic C–H bond functionalization route, the direct benzylic oxidation of alkylarenes is a vital procedure to afford the parallel carbonyl compounds [7,8,9,10] which is used as a constituent in the construction of well-designed fine chemicals and pharmaceuticals [11,12,13]. Methylarenes are the most abundant and inexpensive naturally available surrogates for carbonyl compounds, which are obtained from crude oil as a by-product in the production of gasoline and coke. A number of methods have been reported for the direct benzylic oxidation of alkylarenes using heavy metal catalysts such as stoichiometric amount of KMnO4 [14], Cr(VI) [15], excess amount of Fe [16], Ru [17], Mn [18], Bi [19], Co [20], Au [21], Rh [22], with an oxidant. These methods are non-selective, tiresome, environmentally unfavorable and operationally difficult. In view of the above, the direct selective oxidation of methylarenes to benzaldehydes is of crucial importance. Thus, there is a demand of operationally simple, high yielding, green, eco-friendly protocol using metal-free oxidants and high-atom economical pathway. The work on the controlled oxidation of methylarenes to benzaldehyde in good yield [23,24,25] provoked us to design a new process that utilizes methylarenes as a green, low-cost and readily accessible starting material for the in situ generation of benzaldehydes.

Chromenes are very important structural motif found in a variety of natural products like anthocyanins, tocopherols, alkaloids, flavonoids [26,27,28,29,30,31] and biologically active molecules like antibiotic rhodomyrtone [32] and cancer cell apoptosis inducer BENC-511 [33]. Chromenes also exhibit an extensive range of biological activities such as anti-anaphylactic [34], antimicrobial [35], antitumor [36], spasmolytic [37], anticoagulant [38] and diuretic activities [39]. Therefore, the development of synthetic procedures that facilitate the synthesis of these compounds has attracted considerable attention. Pyrimidine derivatives are of extensive curiosity due to their potential biological activity [40] and also their versatility as synthones in organic synthesis [41, 42].

Recent developments in the utilization of benzylic C–H bonds inspired us to look into the C–H bond activation of easily available and inexpensive methylarenes to achieve the synthesis of biologically active chromenopyrimidines. In past decades, the use of a natural catalysts in organic synthesis has also attracted considerable attention due to their eco-friendly and environmentally acceptable nature. Lemon juice is a biodegradable and natural catalyst. The existence of citric and ascorbic acid makes the lemon juice as an acidic catalyst in organic synthesis [43,44,45,46].

Previously, chromenopyrimidines have been produced by multicomponent reaction of barbituric acid, 1,3-cyclohexanedione/dimedone and aromatic aldehyde using various catalysts [47,48,49]. In spite of these efforts, a metal-free and mild approach for the synthesis of chromenopyrimidine derivatives using accessible, inexpensive, naturally available and sustainable surrogates is still in high demand.

By considering all the above facts and as a part of our contemporary research on the design and construction of biologically active compounds [50], we herein report a lemon juice catalyzed, metal-free, one-pot synthesis of chromenopyrimidine derivatives via C–H activation of methylarenes by using tert-butyl hydroperoxide (TBHP, 70% in H2O) as an oxidant (Scheme 1).

Results and discussion

The work initiated by taking thiobarbituric acid (1.0 mmol), toluene (2.0 mmol) and dimedone (1.0 mmol) as a model reaction. The desired product (4h) could not be obtained in sufficient yield when 10 mol% of sulfamic acid, benzoic acid, formic acid and acetic acid was used with 10 equiv. of TBHP (70% in H2O) (Table 1, entry 1–4). When lemon juice was used with TBHP, 40% yield of the product was obtained (Table 1, entry 5). Subsequently, screening of various solvents like benzene, CCl4, hexane, CH2Cl2, CHCl3, H2O (Table 1, entries 6–11) was done. Pleasingly, 67% yield was afforded with lemon juice (0.2 ml) and TBHP (4 equiv.) under solvent-free condition (Table 1, entry 14). Now, the amount of lemon juice and TBHP were optimized, and it was found that 0.3 ml of lemon juice with 3 equivalents of TBHP worked best, giving 85% yield of the product (Table 1, entry 17). Since lemon juice contains citric acid and ascorbic acid, their different amounts were tested under optimized condition (Table 1, entry 19–24) and it was found that lemon juice has better catalytic properties than citric acid followed by ascorbic acid. Better catalytic activity of citric acid than ascorbic acid can be attributed to the higher Ka (acid dissociation constant) value of citric acid. Encouraged by this, numerous oxidants like H2O2, oxone, K2S2O8, meta-chloroperoxybenzoic acid (m-CPBA), peracetic acid (PAA), benzyl peroxide, benzoyl peroxide, tert-butyl peroxybenzoate (TBPB) and di-tert-butyl peroxide (DTBP) were tested with lemon juice, under solvent-free condition, but unfavorable results were obtained (Table 1, entry 25–33). In the further optimization, lemon juice without TBHP (Table 1, entry 34), TBHP without lemon juice (Table 1, entry 35) and reaction without lemon juice and TBHP (Table 1, entry 36) under solvent-free condition have been done, but they did not lead to the desired product. Combination of citric and ascorbic acid has been tested under optimized condition to investigate their effect in lemon juice catalyzed reactions, and results are summarized in Table 1 (entry 37–40). Combinations have been made on the basis of amount of citric and ascorbic acid present in lemon juice [51, 52].

In order to extend the scope of this methodology, a wide range of methylarenes, i.e., both electron-donating and electron-withdrawing groups containing methylarenes, were investigated under optimal conditions. The substituted methylarenes worked efficiently with thiobarbituric/barbituric acid and dimedone/1,3-cyclohexanedione to afford the desired products in good yields (84–88%) (Figs. 1, 2).

Some control experiments were carried out to establish the reaction mechanism. By performing quenching experiment with radical scavengers like (2,2,6,6-tetramethylpiperidin-1-yl)oxidanyl (TEMPO) and butylatedhydroxytoluene (BHT), the participation of free-radical species in the reaction was established. The model reaction gave the corresponding product 4h in 17% and 10% yields in the presence of 2 equiv. of TEMPO and BHT, respectively, under standard conditions, whereas the product formation quenched completely with 5 equivalents. Thus, the involvement of radical intermediate was established by inhibitory action of TEMPO and BHT. A blank experiment was performed by taking toluene with TBHP which resulted in 87% of benzaldehyde, 9% of benzyl alcohol and trace amount of benzoic acid. The intermediacy of benzyl alcohol was confirmed by subjecting benzyl alcohol to standard conditions to deliver benzaldehyde in 96% yield. Further, the intermediacy of benzyl alcohol was confirmed by using it in the synthesis of 4h under standard reaction conditions (Scheme 2).

The plausible reaction mechanism based on reported literature, isolated product and controlled experiment is given in Scheme 3. Oxidation of methylarenes (2) by TBHP leads to corresponding aromatic aldehyde (2Y) through radical pathway. Now Knoevenagel condensation takes place between (1) and (2Y) to produce (A). Ultimately, Michael addition between (A) and (3) followed by removal of H2O produced the final product (4/5).

Experimental

Thiobarbituric acid/barbituric acid, methylarenes, 1,3-diketones and TBHP (70% in H2O) were purchased from E. Merck, Germany and Sigma–Aldrich Chemicals, USA and were used as received. All the reactions were monitored by thin-layer chromatography (TLC) and visualized using UV light. Infrared (IR) spectra were recorded on a Perkin-Elmer FT–IR spectrometer. Melting points were determined by using Stuart Melting point apparatus SPM10. Elemental analyses (C, H and N) were carried out using Perkin-Elmer microanalyzer. 1H and 13C NMR spectra were recorded using Bruker 500 MHz spectrometer in DMSO-d6, and chemical shifts were expressed in δ ppm, using TMS as an internal reference.

General procedure for extraction of lemon juice (preparation of catalyst) [53]

Fresh fruits of Citrus limon (lemon) was bought from the local shop and washed with water thoroughly. The juice was extracted by fruit juicer and then filtered with cotton to remove the solid substance and to obtain a clear portion of juice. Now, clear juice was used as an acid catalyst after measuring its pH (between 2 and 3).

General procedure for the synthesis of chromenopyrimidine derivatives (4/5)

Methylarene (2.0 mmol) and TBHP (70% in H2O, 3.0 equiv.) were stirred at room temperature for 10 min; then, thiobarbituric acid/barbituric acid (1.0 mmol), cyclic 1, 3-diketone (1.0 mmol) and extracted lemon juice (0.3 ml) were added to it. The reaction mixture was heated at 80 °C for 3 h. After the completion of reaction (monitored by TLC), the reaction mixture was cooled to room temperature and mixed with water. The mixture was extracted with ethyl acetate, dried with sodium sulfate, and organic solvent was evaporated under reduced pressure to obtain the product. Pure compounds were obtained by column chromatography.

Conclusion

In conclusion, a practical and efficient protocol for the metal-free C–C bond formation via C–H activation of inexpensive methylarenes has been developed. Juice of lemon has been exploited as a natural and biodegradable catalyst for the green and environmentally benign synthesis of Chromenopyrimidine derivatives by multicomponent reaction of barbituric/thiobarbituric acid, 1, 3-diketones and methylarenes.

References

Beccalli EM, Broggini G, Martinelli M, Sottocornola S (2007) C–C, C–O, C–N bond formation on sp 2 carbon by Pd (II)-catalyzed reactions involving oxidant agents. Chem Rev 107:5318–5365. https://doi.org/10.1021/cr068006f

Liu B, Wang W, Huang R, Yan J, Wu J, Xue W, Yang S, Jin Z, Chi YR (2017) Direct activation of β-sp3-carbons of saturated carboxylic esters as electrophilic carbons via oxidative carbene catalysis. Org Lett 20:260–263. https://doi.org/10.1021/acs.orglett.7b03650

Alberico D, Scott ME, Lautens M (2007) Aryl–aryl bond formation by transition-metal-catalyzed direct arylation. Chem Rev 107:174–238. https://doi.org/10.1021/cr0509760

Chen X, Engle KM, Wang DH, Yu JQ (2009) Palladium (II)-catalyzed C– H activation/C– C cross-coupling reactions: versatility and practicality. Angew Chem Int Ed 48:5094–5115. https://doi.org/10.1002/anie.200806273

Moselage M, Li J, Ackermann L (2015) Cobalt-catalyzed C–H activation. ACS Catal 6:498–525. https://doi.org/10.1021/acscatal.5b02344

Shang R, Ilies L, Nakamura E (2017) Iron-catalyzed C–H bond activation. Chem Rev 117:9086–9139. https://doi.org/10.1021/acs.chemrev.6b00772

Hudlicky M (1990) Oxidations in organic chemistry. American Chemical Society, Washington

Recupero F, Punta C (2007) Free radical functionalization of organic compounds catalyzed by N-hydroxyphthalimide. Chem Rev 107:3800–3842. https://doi.org/10.1021/cr040170k

Ishii Y, Sakaguchi S, Iwahama T (2001) Innovation of hydrocarbon oxidation with molecular oxygen and related reactions. Adv Synth Catal 343:393–427. https://doi.org/10.1002/1615-4169(200107)343:5%3C393:AID-ADSC393%3E3.0.CO;2-K

Guo Z, Liu B, Zhang Q, Deng W, Wang Y, Yang Y (2014) Recent advances in heterogeneous selective oxidation catalysis for sustainable chemistry. Chem Soc Rev 43:3480–3524. https://doi.org/10.1039/c3cs60282f

Romines KR, Freeman GA, Schaller LT, Cowan JR, Gonzales SS, Tidwell JH, Andrews CW, Stammers DK, Hazen RJ, Ferris RG (2006) Structure–activity relationship studies of novel benzophenones leading to the discovery of a potent, next generation HIV nonnucleoside reverse transcriptase inhibitor. J Med Chem 49:727–739. https://doi.org/10.1021/jm050670l

Masson PJ, Coup D, Millet J, Brown NL (1995) The effect of the β-D-xyloside naroparcil on circulating plasma glycosaminoglycans an explanation for its known antithrombotic activity in the rabbit. J Biol Chem 270:2662–2668. https://doi.org/10.1074/jbc.270.6.2662

Surburg H, Panten J (2016) Common fragrance and flavor materials: preparation, properties and uses. Wiley, New York

Pan J-F, Chen K (2001) A facile catalytic oxidation of activated hydrocarbons to the carbonyl functionality mediated by Mn(II) complexes. J Mol Catal A Chem 176:19–22. https://doi.org/10.1016/S1381-1169(01)00238-2

Rothenberg G, Wiener H, Sasson Y (1998) Pyridines as bifunctional co-catalysts in the CrO3-catalyzed oxygenation of olefins by t-butyl hydroperoxide. J Mol Catal A Chem 136:253–262. https://doi.org/10.1016/S1381-1169(98)00070-3

Nagano T, Kobayashi S (2008) Iron catalyst for oxidation in water: surfactant-type iron complex-catalyzed mild and efficient oxidation of aryl alkanes using aqueous TBHP as oxidant in water. Chem Lett 37:1042–1043. https://doi.org/10.1246/cl.2008.1042

Yi CS, Kwon K-H, Lee DW (2009) Aqueous phase C–H bond oxidation reaction of arylalkanes catalyzed by a water-soluble cationic Ru (III) complex [(pymox-Me2) 2RuCl2]+ BF4−. Org Lett 11:1567–1569. https://doi.org/10.1021/ol900097y

Lee NH, Lee C-S, Jung D-S (1998) Selective oxidation of benzylic hydrocarbons to carbonyl compounds catalyzed by Mn(III) salen complexes. Tetrahedron Lett 39:1385–1388. https://doi.org/10.1016/S0040-4039(98)00030-6

Bonvin Y, Callens E, Larrosa I, Henderson DA, Oldham J, Burton AJ, Barrett AG (2005) Bismuth-catalyzed benzylic oxidations with tert-butyl hydroperoxide. Org Lett 7:4549–4552. https://doi.org/10.1021/ol051765k

Jin C, Zhang L, Su W (2011) Direct benzylic oxidation with sodium hypochlorite using a new efficient catalytic system: TEMPO/Co (OAc) 2. Synlett 2011:1435–1438. https://doi.org/10.1055/s-0030-1260760

Li H, Li Z, Shi Z (2009) Gold-catalyzed benzylic oxidation to carbonyl compounds. Tetrahedron 65:1856–1858. https://doi.org/10.1016/j.tet.2008.12.055

Catino AJ, Nichols JM, Choi H, Gottipamula S, Doyle MP (2005) Benzylic oxidation catalyzed by dirhodium (II, III) caprolactamate. Org Lett 7:5167–5170. https://doi.org/10.1021/ol0520020

Sarma BB, Efremenko I, Neumann R (2015) Oxygenation of methylarenes to benzaldehyde derivatives by a polyoxometalate mediated electron transfer–oxygen transfer reaction in aqueous sulfuric acid. J Am Chem Soc 137:5916–5922. https://doi.org/10.1021/jacs.5b01745

Gaster E, Kozuch S, Pappo D (2017) Selective aerobic oxidation of methylarenes to benzaldehydes catalyzed by N-hydroxyphthalimide and cobalt (II) acetate in hexafluoropropan-2-ol. Angew Chem Int Ed 56:5912–5915. https://doi.org/10.1002/anie.201702511

Lumb JP (2017) Stopping aerobic oxidation in its tracks: chemoselective synthesis of benzaldehydes from methylarenes. Angew Chem Int Ed 56:9276–9277. https://doi.org/10.1002/anie.201704160

Veitch NC, Grayer RJ (2008) Flavonoids and their glycosides, including anthocyanins. Nat Prod Rep 25:555–611. https://doi.org/10.1039/b718040n

He F, Mu L, Yan G-L, Liang N-N, Pan Q-H, Wang J, Reeves MJ, Duan C-Q (2010) Biosynthesis of anthocyanins and their regulation in colored grapes. Molecules 15:9057–9091. https://doi.org/10.3390/molecules15129057

Mukai K, Okabe K, Hosose H (1989) Synthesis and stopped-flow investigation of antioxidant activity of tocopherols. Finding of new tocopherol derivatives having the highest antioxidant activity among phenolic antioxidants. J Org Chem 54:557–560. https://doi.org/10.1021/jo00264a011

Pratap R, Ram VJ (2014) Natural and synthetic chromenes, fused chromenes, and versatility of dihydrobenzo [h] chromenes in organic synthesis. Chem Rev 114:10476–10526. https://doi.org/10.1021/cr500075s

Nour AM, Khalid SA, Kaiser M, Brun R, Wai’l EA, Schmidt TJ (2010) The antiprotozoal activity of methylated flavonoids from Ageratum conyzoides L. J Ethnopharmacol 129:127–130. https://doi.org/10.1016/j.jep.2010.02.015

Keri RS, Budagumpi S, Pai RK, Balakrishna RG (2014) Chromones as a privileged scaffold in drug discovery: a review. Eur J Med Chem 78:340–374. https://doi.org/10.1016/j.ejmech.2014.03.047

Kaneshima T, Myoda T, Toeda K, Fujimori T, Nishizawa M (2017) Antimicrobial constituents of peel and seeds of camu-camu (Myrciaria dubia). Biosci Biotechnol Biochem 81:1461–1465. https://doi.org/10.1080/09168451.2017.1320517

Yin S-Q, Shi M, Kong T-T, Zhang C-M, Han K, Cao B, Zhang Z, Du X, Tang L-Q, Mao X (2013) Preparation of S14161 and its analogues and the discovery of 6-bromo-8-ethoxy-3-nitro-2H-chromene as a more potent antitumor agent in vitro. Bioorg Med Chem Lett 23:3314–3319. https://doi.org/10.1016/j.bmcl.2013.03.097

Rueping M, Sugiono E, Merino E (2008) Asymmetric organocatalysis: an efficient enantioselective access to benzopyranes and chromenes. Chem Eur J 14:6329–6332. https://doi.org/10.1002/chem.200800836

Shi Y, Zhou C-H (2011) Synthesis and evaluation of a class of new coumarin triazole derivatives as potential antimicrobial agents. Bioorg Med Chem Lett 21:956–960. https://doi.org/10.1016/j.bmcl.2010.12.059

Gourdeau H, Leblond L, Hamelin B, Desputeau C, Dong K, Kianicka I, Custeau D, Boudreau C, Geerts L, Cai S-X (2004) Antivascular and antitumor evaluation of 2-amino-4-(3-bromo-4, 5-dimethoxy-phenyl)-3-cyano-4H-chromenes, a novel series of anticancer agents. Mol Cancer Ther 3:1375–1384 PMID:15542776

Magar R, Thorat P, Jadhav V, Tekale S, Dake S, Patil B, Pawar R (2013) Silica gel supported polyamine: a versatile catalyst for one pot synthesis of 2-amino-4H-chromene derivatives. J Mol Catal A Chem 374:118–124. https://doi.org/10.1016/j.molcata.2013.03.022

Zghab I, Trimeche B, Mansour MB, Hassine M, Touboul D, Jannet HB (2017) Regiospecific synthesis, antibacterial and anticoagulant activities of novel isoxazoline chromene derivatives. Arab J Chem 10:S2651–S2658. https://doi.org/10.1016/j.arabjc.2013.10.008

Ghorbani-Vaghei R, Toghraei-Semiromi Z, Karimi-Nami R (2011) One-pot synthesis of 4H-chromene and Dihydropyrano [3, 2-c] chromene derivatives in hydroalcoholic media. J Braz Chem Soc 22:905–909. https://doi.org/10.1590/S0103-50532011000500013

Mobinikhaledi A, Foroughifar N, Mosleh T, Hamta A (2014) Synthesis of some novel chromenopyrimidine derivatives and evaluation of their biological activities. Iran J Pharm Res 13:873–879

Lagoja IM (2005) Pyrimidine as constituent of natural biologically active compounds. Chem Biodivers 2:1–50. https://doi.org/10.1002/cbdv.200490173

Achelle S, Plé N (2012) Pyrimidine ring as building block for the synthesis of functionalized π-conjugated materials. Curr Org Synth 9:163–187. https://doi.org/10.2174/157017912799829067

Deshmukh M, Patil SS, Jadhav S, Pawar P (2012) Green approach for Knoevenagel condensation of aromatic aldehydes with active methylene group. Synth Commun 42:1177–1183. https://doi.org/10.1080/00397911.2010.537423

Patil S, Jadhav S, Patil U (2012) Natural acid catalyzed synthesis of Schiff base under solvent-free condition: as a green approach. Arch Appl Sci Res 4:1074–1078

Pal R, Khasnobis S, Sarkar T (2013) First application of fruit juice of Citrus limon for facile and green synthesis of bis-and tris (indolyl) methanes in water. Chem J 3:7–12

Patil S, Jadhav SD, Deshmukh M (2011) Natural acid catalyzed multi-component reactions as a green approach. Arch Appl Sci Res 3:203–208

Ghahremanzadeh R, Fereshtehnejad F, Bazgir A (2010) Chromeno [2, 3-d] pyrimidine-triones synthesis by a three-component coupling reaction. Chem Pharm Bull 58:516–520. https://doi.org/10.1248/cpb.58.516

Kumar R, Raghuvanshi K, Verma RK, Singh MS (2010) Application of cyclic-1, 3-diketones in domino and multicomponent reactions: facile route to highly functionalized chromeno [2, 3-d] pyrimidinones and diazabenzo [b] fluorenones under solvent-free conditions. Tetrahedron Lett 51:5933–5936. https://doi.org/10.1016/j.tetlet.2010.09.017

Bhattacharjee D, Sutradhar D, Chandra AK, Myrboh B (2017) L-proline as an efficient asymmetric induction catalyst in the synthesis of chromeno [2, 3-d] pyrimidine-triones, xanthenes in water. Tetrahedron 73:3497–3504. https://doi.org/10.1016/j.tet.2017.05.025

Kumari S, Kumar D, Gajaganti S, Srivastava V, Singh S (2019) Sc (OTf) 3 catalysed multicomponent synthesis of chromeno [2, 3-d] pyrimidinetriones under solvent-free condition. Synth Commun 49:431–443. https://doi.org/10.1080/00397911.2018.1560471

Shrestha N, Shrestha S, Bhattarai A (2016) Determination of ascorbic acid in different citrus fruits of Kathmandu Valley. J Med Biol Sci Res (JMBSR) 2:9–14

Liu Y, Heying E, Tanumihardjo SA (2012) History, global distribution, and nutritional importance of citrus fruits. Compr Rev Food Sci Food Saf 11:530–545. https://doi.org/10.1111/j.1541-4337.2012.00201.x

Alikhani A, Foroughifar N, Pasdar H (2018) Lemon juice as a natural catalyse for synthesis of Shiff’s base: a green chemistry approach. Int J Adv Eng Res Sci (IJAERS) 5:61–65. https://doi.org/10.22161/ijaers.5.2.7

Acknowledgements

Authors are grateful to IIT (BHU) for financial assistance in the form of institute fellowship and CIFC, IIT (BHU) for instrumentation facilities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kumari, S., Singh, S. & Srivastava, V. Lemon juice catalyzed C–C bond formation via C–H activation of methylarene: a sustainable synthesis of chromenopyrimidines. Mol Divers 24, 717–725 (2020). https://doi.org/10.1007/s11030-019-09980-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11030-019-09980-1