Abstract

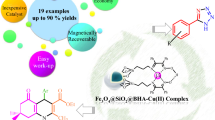

The development of heterogenization of copper nanoparticles on conductive supports is very challenging and has received much attention. Here, we synthesize a practical, efficient, and inexpensive heterogeneous catalyst to grow stable metallic copper(II) nanoparticles on the surface of magnetic carbon nanotube (Fe3O4–CNT) catalyst support physically functionalized with triethanolamine (TEA) that acts as a low-cost and non-toxic ligand to capture the copper nanoparticles [Fe3O4–CNT–TEA–Cu(II)]. The as-prepared heterogeneous catalyst was characterized by different techniques, such as Fourier transform infrared spectroscopy, energy-dispersive X-ray spectroscopy, thermogravimetric analysis, vibrating sample magnetometer, X-ray diffraction patterns, field-emission scanning electron microscopy, and atomic absorption spectroscopy analysis. The catalytic behavior of Fe3O4–CNT–TEA–Cu(II) was investigated in the preparation of 5-substituted 1H-tetrazole derivatives via one-pot, three-component reaction between aromatic aldehydes, hydroxylamine, and sodium azide. The low catalyst loading, wide substrate scope, use of inexpensive materials, simple separation of the catalyst from the reaction mixture by an external magnet, short reaction times, easy workup, affordability, and superb yield are some advantages of this protocol.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Life revolves around carbon, which is a fundamental natural abundant element obtained from biomass to biofuel. Nanostructured carbon materials, particularly carbon nanotubes (CNTs), are ideal candidates for a wide range of applications including hydrogen storage, electronic devices, sensor devices, solar cells, energy storage, and structural components as well as compatible catalyst supports [1,2,3,4,5] due to their good surface area, high chemical, thermal, and mechanical stability, low cost, inertness, tunable carbon framework, and porous structure [6, 7]. The tubular structure of CNTs makes them unique among diverse types of carbon such that they can be applied as an alternative material for catalytic support in heterogeneous catalysis [8]. Particularly, CNTs have rich surface functional groups (mostly hydroxyl and carboxyl), which make them an appropriate support material for metal nanoparticles [9, 10]. In recent years, the heterogenization of transition metals on support has received much attention in the development of sustainable organometallic chemistry [11]. In this regard, CNTs are one of the important selections for the synthesis of multi-task heterogeneous metallic-based catalysts, which are a new class of catalytic systems. There are different procedures for supporting metals on carbon nanostructures: deposition from solution, self-assembly methods, electro- and electrophoretic deposition, and deposition from the gas phase. It can be emphasized that the method adopted for the preparation of these systems greatly affects the final properties and morphology of nanoparticles [12]. In this connection, deposition from solutions is the most common method, which includes the saturation of carbon materials with metal solutions. Among various metal nanoparticles, copper nanoparticles display unique catalytic reactivity in a wide range of organic synthesis and catalysis because of the high conductivity, commercial availability, abundance, inexpensive, and the tremendous potential of copper for replacing valuable metals such as platinum, gold, and silver [13, 14]. Nevertheless, previous studies have indicated that perspective developments in the preparation of copper nanoparticles are challenging because Cu metal can undergo rapid oxidation, forming aggregates [15,16,17]. This drawback can be overcome by diverse protecting agents such as polymers and organic ligands [18, 19]. Immobilization of copper(II) onto organic ligand is one of the best protocols to produce heterogeneous catalysts with high stability, high loading, and high activity. In the past few years, various organic ligands have been used as linkers for immobilization of copper(II) [20,21,22]. The ligands used for this purpose must be stable to high temperature, air, moisture, and aqueous solutions [23, 24]. Triethanolamine (TEA) is a class of organic molecules including amine and alcohol groups. TEA is a set of versatile ligands that easily form coordination compounds with almost all metal ions because of its low cost, non-toxic, environmentally friendly and commercially availability [25, 26]. It behaves as N and O-donor ligands and usually acts as a bi- or tridentate ligand [27]. Numerous effective TEA ligand-based catalytic systems have been developed in the past few years. However, despite these remarkable achievements, up to now, there are only limited examples of reports on the use of TEA ligand on solid supports as heterogeneous catalysts [28, 29]. Most of the ligand-based catalyst systems require a centrifugation or filtration step to retrieve the catalyst. One of the best techniques for retrieving a catalyst is the immobilization of magnetic nanoparticles on common nanosolid supports creating a magnetic heterogeneous catalytic system. Till now, magnetic nanocatalysts have received a significant consideration of organic chemists because of their easy separation and recycling using a simple external magnetic, which is not time-consuming and prevents loss of catalyst during the separation process [30]. Over the last recent years, considerable attention has been paid to combination of carbon nanotubes and magnetic nanoparticles to create carbon magnetic nanostructures [31]. These composites have the properties of both carbon nanotubes and magnetic nanoparticles which not only have the advantages of simple separation and retrieval but also a high surface area for dispersion of active sites of the catalysts.

Multicomponent reactions (MCRs) [32] have recently gained increasing consideration owing to the vast range of applications in the preparation of biologically active heterocyclic compounds with high atom economy and bond-forming efficiency. Compared to conventional stepwise synthesis, MCRs are useful in being intrinsic convergent nature and in requiring minimum reaction time and effort to achieve structural complexity. For these reasons, MCRs are especially well suited for diversity-oriented synthesis. Thus, multicomponent reactions are accepted as green chemistry criteria for sustainable organic synthesis [33, 34].

Recently, tetrazoles have received significant interest due to their wide usages in medicinal chemistry, material sciences, information recording systems, explosives, coordination chemistry, catalysis technology, and possible application in high-energy chemistry [35, 36]. Tetrazoles and its derivatives are applied for biological activities including antiviral, antibacterial, anti-nociceptive, antifungal, anti-inflammatory, and anticancer activities [37, 38]. For these reasons, numerous procedures have been reported for their preparation. Ordinary preparation of 5-substituted 1H–tetrazoles is by [3 + 2] cycloaddition of azides to the corresponding nitriles [39, 40]. Nevertheless, many of these methods have some demerits such as the use of expensive and toxic reagents, hardness in obtaining and/or synthesis of the starting materials, unsatisfactory yields, long reaction time, tedious workup, and difficulty in separation and retrieval of catalysts. Because of easy approachability and less toxicity of aldehydes in comparison with nitriles and great performance of Cu catalysts in [3 + 2] cycloaddition reactions, using Cu catalysts for preparation of 5-substituted 1H-tetrazoles via one-pot, three-component reaction between aromatic aldehydes, hydroxylamine (or oximes) and sodium azide have been attracted considerable attention of organic chemists in last recent years. To the best of our knowledge, only few papers have been reported for the preparation of tetrazoles from the aldehyde. These studies have been done using catalysts such as Bi(OTf)3 [41], Cu–MCM-41 [42], P2O5 [43], [bmim]N3/Cu(OAc)2 [44], Fe3O4@SiO2-dendrimer-encapsulated Cu(Π) [45], (NH4)4Ce(SO4)4–2H2O [46], nanosized Cu2O on melamine–formaldehyde resin [47]. Cu(OAc)2 [48] and InCl3 [49] have been used for the synthesis of 5-substituted 1H-tetrazoles from oxime. So, these areas remain largely unexplored.

Considering the importance of tetrazoles and continuing with our interest in the synthesis and application of new eco-friendly heterogeneous catalysts in organic reactions [50,51,52,53,54,55], in the present study, we report for the first time, the synthesis and characterization of a novel, recoverable, and durable magnetic heterogeneous catalyst that contains complex of triethanolamine ligand that is bound covalently to magnetic carbon nanotube. This catalyst has been successfully investigated for the synthesis of tetrazoles via multicomponent reaction between aromatic aldehydes, hydroxylamine, and sodium azide. In our surveys, this is the first report of using magnetic carbon nanotube as a catalyst support for the preparation of tetrazoles. Ambient reaction conditions, excellent yields, short reaction times, and operational simplicity with retrievability of the catalysts are the outstanding features of the catalyst.

Experimental

Materials and instruments

All the chemicals in this work were purchased from Merck and Sigma-Aldrich and used without any further purification. The formation of products was checked through TLC on Merck silica gel 60 F254 plates. Melting points of all products were obtained on a Thermo Scientific 9100 apparatus. Fourier transform infrared (FT-IR) spectra were measured in the range of 4000–400 cm−1 using Shimadzu 8400 spectrometer. X-ray powder diffraction (XRD) was conducted using a Philips with Cu-Ka radiation of wavelength 1.54 Å. Field-emission scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopic (EDX) analysis were acquired with a TESCAN MIRA II digital scanning microscope. Magnetic measurements were obtained on a vibrating sample magnetometry (VSM; Lakeshore 7407) at room temperature. Thermogravimetric analysis (TGA) was performed using a DuPont 2000 thermal analysis apparatus at a heating rate of 10 °C min−1 under air atmosphere. The copper determination was determined by an Agilent model 240 AA Shimadzu (USA) flame atomic adsorption spectrometer. All measurements were performed in an air/acetylene flame, and the Cu hollow cathode lamps were used as the radiation sources. NMR spectra were recorded in DMSO on a Bruker Advance 400 MHz instrument spectrometer.

Preparation of Fe3O4–CNT nanocomposite

Magnetic carbon nanotubes were synthesized by suspending 0.1 g of CNT–COOH in 150 mL aqueous solution containing 0.429 g of FeCl2.4H2O and 1.165 g FeCl3·6H2O under N2 atmosphere at 80 °C. Then, ammonium hydroxide aqueous solution (≥ 25%) was added dropwise to the initial mixture, while the solution was under constant mechanical stirring. The pH of the final mixture should be in the range of 10–11, and the reaction was continued for about 120 min. The obtained precipitate was separated with an external magnet, washed with water and dried at 80 °C under vacuum [56].

Preparation of Fe3O4–CNT–TEA nanocomposite

For the preparation of Fe3O4–CNT–TEA, the acquired Fe3O4–CNT was dispersed in ethanol (50 mL) for 20 min. Next, triethanolamine (2 mmol) was added to the uniform mixture of Fe3O4–CNT and the mixture was stirred under reflux condition for 24 h. After cooling down to room temperature, the resulted product was collected by a permanent magnet, washed three times with ethanol and dried under vacuum at 60 °C.

Synthesis of Fe3O4–CNT–TEA–Cu(II) nanocomposite

Fe3O4–CNT–TEA was dispersed in deionized water (30 mL) for 30 min. Next, a yellow solution of Cu(OAc)2 (20 mg in 30 mL deionized water) was added to the uniform mixture of Fe3O4–CNT–TEA solution and the mixture was stirred for 8 h at 90 °C. Then, Fe3O4–CNT–TEA–Cu(II) was filtered magnetically and washed by water and dried at 80 °C under vacuum.

Typical procedure for the synthesis of tetrazole derivatives

A mixture of aromatic aldehyde (1 mmol), hydroxylamine (1.2 mmol), sodium azide (1.5 mmol), and Fe3O4–CNT–TEA–Cu(II) nanocomposite (0.005 g) in DMF (3 mL) was magnetically stirred at 70 °C for a specified time (see Table 2). The reaction progress was monitored by TLC. Upon completion of the reaction, the mixture was cooled to ambient temperature and the catalyst was separated by an outer magnet. The solvent was removed under reduced pressure, and the residue was dissolved in water (5 mL). Then 15 mL of 2 N HCl was added and allowed to be stirred to afford the tetrazole in the powder form. The precipitate was filtered and crystallized from a mixture of ethanol and water. Further purification with column chromatography was unnecessary.

Spectroscopic data of synthesized compounds

5-Phenyl-1H-tetrazole (Table 2 entry 1)

Powder. 1H NMR (400 MHz, DMSO-d6): δ = 7.59–7.63 (m, 3H), 8.04–8.07 (m, 2H), 17.01 (brs, 1H) ppm. 13C NMR (100 MHz, DMSO-d6): δ = 124.59, 127.44, 129.89, 131.72, 155.68 ppm.

5-(4-Chlorophenyl)-1H-tetrazole (Table 2 entry 2)

Powder. 1H NMR (400 MHz, DMSO-d6): δ = 7.68 (d, J = 8.8 Hz, 2H), 8.05 (d, J = 8.4 Hz, 2H) ppm. 13C NMR (100 MHz, DMSO-d6): δ = 123.82, 129.15, 130.00, 136.27, 155.45 ppm.

5-p-Tolyl-1H-tetrazole (Table 2 entry 6)

Powder. 1H NMR (400 MHz, DMSO-d6): δ = 2.39 (s, 3H), 7.41 (d, J = 8.0 Hz, 2H), 7.93 (d, J = 8.0 Hz, 2H), 16.64 (brs, 1H) ppm. 13C NMR (100 MHz, DMSO-d6): δ = 21.50, 121.98, 127.31, 130.40, 141.54, 155.74 ppm.

5-(4-Methoxyphenyl)-1H-tetrazole (Table 2 entry 7)

Powder. 1H NMR (400 MHz, DMSO-d6): δ = 3.84 (s, 3H), 7.16 (d, J = 8.8 Hz, 2H), 7.98 (d, J = 8.8 Hz, 2H) ppm. 13C NMR (100 MHz, DMSO-d6): δ = 55.91, 115.30, 116.84, 129.07, 155.23, 161.88 ppm.

4-(1H-Tetrazol-5-yl) phenol (Table 2 entry 8)

Powder. 1H NMR (400 MHz, DMSO-d6): δ = 6.95 (d, J = 8.8 Hz, 2H), 7.86 (d, J = 8.8 Hz, 2H), 10.23 (brs, 1H) ppm. 13C NMR (100 MHz, DMSO-d6): δ = 115.04, 116.59, 129.20, 155.01, 160.54 ppm.

5-(4-Fluorophenyl)-1H-tetrazole (Table 2 entry 12)

Powder. 1H NMR (400 MHz, DMSO-d6): δ = 7.45–7.49 (m, 2H), 8.08–8.11 (m, 2H) ppm. 13C NMR (100 MHz, DMSO-d6): δ = 115.64 (d, J = 21.2 Hz), 127.68, 127.96 (d, J = 7.9 Hz), 160.30, 161.82 (d, J = 241.2 Hz) ppm.

2-(1H-Tetrazol-5-yl) pyridine (Table 2 entry 13)

Powder. 1H NMR (400 MHz, DMSO-d6): δ = 7.64 (ddd, J = 7.6, 7.6, 1.2 Hz, 1H), 8.09 (dt, J = 7.8, 1.7 Hz, 1H), 8.23 (dt, J = 8.0, 1.0 Hz, 1H), 8.80 (ddd, J = 4.8, 1.6, 0.8 Hz, 1H), 17.19 (brs, 1H) ppm. 13C NMR (100 MHz, DMSO-d6): δ = 123.08, 126.60, 138.74, 144.14, 150.55, 155.25 ppm.

5-Benzyl-1H-tetrazole (Table 2 entry 17)

Powder. 1H NMR (400 MHz, DMSO-d6): δ = 4.29 (s, 2H), 7.19–7.28 (m, 2H), 7.31–7.37 (m, 2H), 7.51–7.54 (m, 1H), 16.24 (brs, 1H) ppm.

Results and discussion

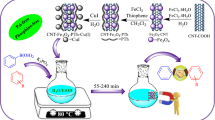

Due to the significant necessity to simple and green recycling of the heterogeneous catalyst, we synthesized Fe3O4–CNT–TEA–Cu(II) as a new heterogeneous magnetic nanocatalyst. Scheme 1 indicates the synthesis of the magnetic nanocomposite. Initially, Fe3O4–CNT nanocomposite was prepared according to a chemical co-precipitation procedure of FeCl2.4H2O and FeCl3·6H2O in ammonia solution. The reaction of magnetic carbon nanotube with triethanolamine (TEA) in ethanol under reflux conditions for 24 h produced the TEA-functionalized Fe3O4–CNT nanoparticles (Fe3O4–CNT–TEA). Next, Cu(II) nanoparticles were loaded on Fe3O4–CNT–TEA by dispersion in an aqueous solution of Cu(OAc)2. Finally, the catalyst was separated using a permanent magnet and dried under vacuum. The amount of copper loading was measured using AAS analysis which was found to be 0.53 mmol g−1. The prepared magnetic nanocatalyst was authenticated by FT-IR, SEM, EDX, TGA, XRD, and VSM.

Characterization of the catalyst

Firstly, the FT-IR spectra of CNT–COOH, Fe3O4–CNT, and Fe3O4–CNT–TEA–Cu(II) were employed to examine the surface functionality of the nanoparticles (Fig. 1). In Fig. 1a, the characteristic absorption bands observed at 3457 and 1728 cm−1 are related to the OH and C=O bonds in CNT–COOH. Additionally, the signal located around 1400–1600 cm−1 can be attributed to the structure of graphite in CNTs. As visible in the curve 1b rather than 1a, the existence of the distinctive Fe–O peak at 580 cm−1 is direct evidence to verify the presence of magnetite nanoparticles on the CNTs. A number of characteristic peaks of TEA molecules at 1006, 1490, 1656, 2986, and 3448 cm−1 are indicated in Fig. 1c. The bands around 3448 and 1656 cm−1 are attributed to the stretching and bending vibration of –OH, respectively. The peak at 2986 cm−1 is belonged to the stretching vibration of –CH2 group. The bands at around 1490 and 1006 cm−1 are attributed to the C–OH group of TEA bound to the particle surface. These results confirm that the TEA-coated Fe3O4–CNT has been successfully formed.

The particle size and surface morphology of the synthesized nanocatalyst were recorded using SEM technique which is presented in Fig. 2. It can be seen that Fe3O4–CNT–TEA–Cu(II) nanocatalyst has nearly spherical shape and uniform size with a mean size of 31 nm, indicating good agreement with the calculated result from the Debye–Scherrer equation.

TGA analysis was used to investigate the thermal durability and indium content of the functionalized CNTs, between 25 and 800 °C in air conditions at ramp 5 °C/min (Fig. 3). The TGA curves indicated the initial weight loss up to 150 °C due to adsorbed water onto samples surface. As a result of the decomposition of CNT–COOH, a significant weight reduction can be seen at 600 °C. However, after supporting of Fe3O4 nanoparticles, the stability of Fe3O4–CNT is dropped in respect to CNT–COOH. As observed, the sample of Fe3O4–CNT began to decompose at 495 °C. This can be related to the catalytic role of metal oxide nanoparticles in the oxidation process of carbon materials [57]. However, the Fe3O4–CNT–TEA–Cu(II) particles showed a noticeable weight loss in the temperature range of 200–450 °C, which is attributed to the loss of covalently bonded organics.

EDX is one of the powerful tools to determine catalyst purity and survey the type of elements of the catalyst. The EDX spectrum of the synthesized catalyst is depicted in Fig. 4 and reveals the presence of C, Fe, O, N, and Cu elements of Fe3O4–CNT–TEA–Cu(II) nanocatalyst structure. FT-IR, TGA, and EDX analyses are in good harmony with each other and successfully indicate immobilization and stability of TEA–Cu complex onto magnetic carbon nanotube.

The magnetic measurements of Fe3O4–CNT and Fe3O4–CNT–TEA–Cu(II) were evaluated using vibrating sample magnetometer (VSM) at room temperature. It has been reported that saturation magnetization (Ms) value of bare Fe3O4 nanoparticles is 61.06 emu g−1 [58]. As indicated in Fig. 5, the saturation magnetization of Fe3O4–CNT and Fe3O4–CNT–TEA–Cu(II) is found to be 40.04 and 25.89 emu g−1, respectively. This decrease in Ms confirms successful chemical immobilization of the Cu–TEA complex present on the surface of the nanoparticles. Nevertheless, the catalyst could be fleetly and easily magnetically separated from the reaction system.

The phase structure of the new catalyst was identified with XRD. XRD patterns of CNT–COOH, Fe3O4–CNT, and Fe3O4–CNT–TEA–Cu(II) are exhibited in Fig. 6. The characteristic peaks at 26.3° and 42.6° are assigned to (0 0 2) and (1 0 0) planes of hexagonal graphite structure of CNT that appeared in all the patterns. XRD patterns of CNT–Fe3O4 show diffraction peaks around 26.31, 30.51, 35.91, 43.61, 54.01, 57.51, and 63.11 which attributed to (220), (311), (400), (511), and (440) planes of the cubic magnetite with spinel structures, respectively (JCPDS 65–3107) [59]. An almost identical XRD pattern was detected after immobilization of TEA–Cu on Fe3O4–CNT (Fig. 6c). These results indicate that the crystal structure of Fe3O4–CNT nanoparticles is not changed after modification with TEA–Cu which means that the Cu sites are in their Cu(II) status.

Catalytic application of Fe3O4–CNT–TEA–Cu(II) in the synthesis of tetrazole derivatives

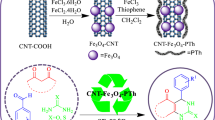

To demonstrate the efficacy of the Fe3O4–CNT–TEA–Cu(II) magnetic nanocomposite, its applicability was evaluated in a one-pot synthesis of tetrazoles derivatives (Scheme 2).

For this purpose, benzaldehyde, hydroxylamine, and sodium azide were selected as the model starting materials to optimize the reaction conditions including the effect of catalyst, amount of sodium azide, solvent, and temperature. Initially, the sample reaction was carried out in different levels of the catalyst in DMF at 70 °C. It was realized that 0.005 g of the catalyst was efficient in providing high yield and increasing the catalyst loading did not ameliorate the product efficiency or reaction time while the lower catalyst loading has lessened the reaction yield even after longer reaction time. Also, when the sample reaction was performed without catalyst, as well as in the presence of Fe3O4 NPs and Cu(OAc)2 at 70 °C, the demanded product was synthesized in the low yield (Table 1, entries 1–6). In order to obtain an optimal temperature, the model reaction was done at different temperatures (Table 1, entries 3, 7–9). A temperature of 70 °C had the best result. The influence of the amount of the NaN3 on the reaction was also explored, and it was found that 1.5 mmol NaN3 was enough to gain excellent product yield (Table 1, entries 10–11). We next made a study on the effect of solvents in the reaction. An effort to catalyze the reaction in the absence of solvent resulted in very low yield. Afterward, the reaction was fulfilled in different solvents and DMF as solvent provided higher yields than those using other common solvents, including DMSO, H2O, EtOH, MeOH, and toluene (Table 1, entries 12–17). Therefore, the best result was obtained at 70 °C with 0.005 g Fe3O4–CNT–TEA–Cu(II) and 1.5 mmol of NaN3 in DMF after 1.5 h.

As indicated in Table 2, the reaction was performed in the presence of both aldehydes containing electron-releasing and electron-withdrawing substituents. All the substrates produced the corresponding products in high yields (Table 2, entries 2–12), but the aldehydes with electron-donating substituents needed longer reaction time (Table 2, entries 6–11) due to fewer electrophile properties of their carbonyl group. Furthermore, the efficacy of steric effects was clearly seen in this procedure. For instance, 2-chlorobenzaldehyde was converted to the desired product in lower yield after longer time in comparison with 4-chlorobenzaldehyde (Table 2, entries 2 and 3). Heteroaromatic aldehydes, including 2-pyridinecarboxaldehye, 3-indolecarboxaldehyde, and 2-thiophenecarboxaldehyde, synthesized the corresponding tetrazoles in good yields (Table 2, entries 13–15). This catalyst was used also well for aliphatic aldehydes such as 2-phenylacetaldehyde and 3-phenylpropanal (Table 2, entry 17–18). These observations illustrated the premiere performance of Fe3O4–CNT–TEA–Cu(II) as a new magnetic heterogeneous catalyst for the preparation of tetrazoles.

Reaction mechanism

A plausible mechanism for the synthesis of tetrazoles is illustrated in Scheme 3. Initially, the activation of the carbonyl group of the aldehyde A by the catalyst and the nucleophilic attack of the nitrogen atom of hydroxylamine to it produces oxime. Thereafter, coordination of the oxygen atom of the oxime with Fe3O4–CNT–TEA–Cu(II) nanocatalyst activates it toward the attack of the azide ion on the electron-deficient carbon atom. The [3 + 2] cycloaddition reaction between the imine group of oxime and sodium azide gives the intermediate C. Then water elimination produces the tetrazoles salt D. Finally, the addition of hydrochloric acid produces the tetrazole derivatives E.

Comparison of the catalytic behavior of the Fe3O4–CNT–TEA–Cu(II) nanocomposite with the precedents in Literature

In order to indicate the advantage of this procedure, we compared the results of this method with previously reported procedures for preparation of 5-phenyl-1H-tetrazole (Table 2, entry 1) from benzaldehyde, hydroxylamine, and sodium azide. The results are collected in Table 3, which show that these methods are beneficial, but some of them have several drawbacks such as high temperature (Table 3, entries 1, 2, 3, 4, 5) and long reaction time (Table 3, entry 1, 2, 5, 6), while preparation of tetrazoles using Fe3O4–CNT–TEA–Cu(II) nanocatalyst has been performed with shorter reaction time, lower temperature, and high product yield.

Reusability of the catalyst

The retrievability and reusability of the catalyst in large-scale synthesis are crucial parameters for commercial and industrial utilization of any catalytic activity. In order to investigate the stability of the catalyst, after the first cycle, Fe3O4–CNT–TEA–Cu(II) was separated from the reaction mixture using a permanent magnet and washed with hot ethanol and dried at 80 °C under vacuum. Afterward, the recycled catalyst was added to another vessel including the starting materials. The consecutive reaction was carried out under the same conditions as discussed before. As noted in Fig. 7, the catalyst was reused leastwise eight cycles without considerable loss in its activity. Changes in the elemental composition of Fe3O4–CNT–TEA–Cu(II) nanocomposite were evaluated by EDX technique. Figure 8 depicts the EDX analysis of Fe3O4–CNT–TEA–Cu(II) after the catalyst was used in the synthesis of pyrazole-fused isocoumarins. As indicated in Fig. 8, EDX analysis of recycled catalyst indicated that Cu leaching to reactant mixture during the reaction was negligible.

Leaching

In another study, the leaching of copper from the Fe3O4–CNT–TEA–Cu(II) magnetic nanocatalyst was examined. To do this, the sample reaction between benzaldehyde, hydroxylamine, and sodium azide was down in the presence of the catalyst. Then, after about half the reaction progress, the reaction was stopped and the catalyst was separated from the reaction mixture using an outer magnet. Residual mixture was kept back to continue under optimized conditions without the catalyst. As indicated in Fig. 9, only a trace yield was observed even after 180 min. These results display the true heterogeneous nature of the catalyst.

Conclusion

We have successfully synthesized for the first time a novel, inexpensive, and recyclable Cu(II)–TEA complex immobilized on Fe3O4–CNT with nanotube morphology decorated by the spherical nanoparticles. The new catalyst was applied for the preparation of 5-substituted 1H-tetrazoles through one-pot multicomponent reaction of aldehyde, hydroxylamine, and sodium azide with good to high yields. The simple experimental procedure, easy workup, eco-friendly nature and cost-effectiveness, using low weight percentage of the catalyst, simple recovery of the catalyst from the reaction mixture with the assistance of a permanent magnet, and retrievability of the catalyst for many times without noteworthy loss of its efficiency and stability make this method attractive for the preparation of 5-substituted 1H-tetrazoles. Additionally, purification with column chromatography was not required. As well, the overall process is green and clean. These results thus broaden the scope of this catalyst in the other organic reactions.

References

De Volde MF, Tawfick SH, Baughman RH, Hart AJ (2013) Carbon nanotubes: present and future commercial applications. Science 339:535–539. https://doi.org/10.1126/science.1222453

Tsapenko AP, Goldt AE, Shulga E, Popov ZI, Maslakov KI, Anisimov AS, Sorokin PB, Nasibulin AG (2018) Highly conductive and transparent films of HAuCl4-doped single-walled carbon nanotubes for flexible applications. Carbon 130:448–457. https://doi.org/10.1016/j.carbon.2018.01.016

Qi P, Vermesh O, Grecu M, Javey A, Wang Q, Dai H, Peng S, Cho K (2003) Toward large arrays of multiplex functionalized carbon nanotube sensors for highly sensitive and selective molecular detection. Nano Lett 3:347–351. https://doi.org/10.1021/nl034010k

Dalton AB, Collins S, Munoz E, Razal JM, Ebron VH, Ferraris JP, Coleman JN, Kim BG, Baughman RH (2003) Super-tough carbon-nanotube fibres. Nature 423:703. https://doi.org/10.1038/423703a

Zhang Q, Huang JQ, Qian WZ, Zhang YY, Wei F (2013) The road for nanomaterials industry: a review of carbon nanotube production, post-treatment, and bulk applications for composites and energy storage. Small 9:1237–1265. https://doi.org/10.1002/smll.201203252

Kour G, Gupta M, Vishwanathan B, Thirunavukkarasu K (2016) (Cu/NCNTs): a new high temperature technique to prepare a recyclable nanocatalyst for four component pyridine derivative synthesis and nitroarenes reduction. New J Chem 40:8535–8542. https://doi.org/10.1039/C6NJ01464J

Zhai Y, Dou Y, Zhao D, Fulvio PF, Mayes RT, Dai S (2011) Carbon materials for chemical capacitive energy storage. Adv Mater 23:4828–4850. https://doi.org/10.1002/adma.201100984

Guo DJ, Li HL (2006) Electrocatalytic oxidation of methanol on Pt modified single-walled carbon nanotubes. J Power Sources 160:44–49. https://doi.org/10.1016/j.jpowsour.2006.01.026

Kim E, Jeong HS, Kim BM (2014) Studies on the functionalization of MWNTs and their application as a recyclable catalyst for CC bond coupling reactions. Catal Commun 46:71–74. https://doi.org/10.1016/j.catcom.2013.11.028

Karousis N, Tagmatarchis N, Tasis D (2010) Current progress on the chemical modification of carbon nanotubes. Chem Rev 110:5366–5397. https://doi.org/10.1021/cr100018g

Shaabani A, Afshari R, Hooshmand SE, Tabatabaei AT, Hajishaabanha F (2016) Copper supported on MWCNT-guanidine acetic acid@Fe3O4: synthesis, characterization and application as a novel multi-task nanocatalyst for preparation of triazoles and bis (indolyl) methanes in water. RSC Adv 6:18113–18125. https://doi.org/10.1039/C5RA23294E

Bacsa RR, Serp P (2011) Decorated (coated) carbon nanotubes: (X/CNTs). In: Carbon meta-nanotubes: synthesis, properties and applications, pp 163–221. https://doi.org/10.1002/9781119954743.ch4

Khanna P, Gaikwad S, Adhyapak P, Singh N, Marimuthu R (2007) Synthesis and characterization of copper nanoparticles. Mater Lett 61:4711–4714. https://doi.org/10.1016/j.matlet.2007.03.014

Seo JY, Kang HW, Jung DS, Lee HM, Park SB (2013) One-step synthesis of copper nanoparticles embedded in carbon composites. Mater Res Bull 48:1484–1489. https://doi.org/10.1021/acs.langmuir.7b02900

Xia X, Xie C, Cai S, Yang Z, Yang X (2006) Corrosion characteristics of copper microparticles and copper nanoparticles in distilled water. Corros Sci 48:3924–3932. https://doi.org/10.1016/j.corsci.2006.04.007

Yanase A, Komiyama H (1991) Real-time optical observation of morphological change of small supported copper particles during redox treatments. Surf Sci 248:20–26. https://doi.org/10.1016/0039-6028(91)90057-Y

Hafez IH, Berber MR, Fujigaya T, Nakashima N (2017) High electronic conductivity and air stability of ultrasmall copper–metal nanoparticles supported on pyridine-based polybenzimidazole carbon nanotube composite. ChemCatChem 9:4282–4286. https://doi.org/10.1002/cctc.201700921

Zhang HX, Siegert U, Liu R, Cai WB (2009) Facile fabrication of ultrafine copper nanoparticles in organic solvent. Nanoscale Res Lett 4:705. https://doi.org/10.1007/s11671-009-9301-2

Cioffi N, Torsi L, Ditaranto N, Sabbatini L, Zambonin PG, Tantillo G, Ghibelli L, D’Alessio M, Bleve-Zacheo T, Traversa E (2004) Antifungal activity of polymer-based copper nanocomposite coatings. Appl Phys Lett 85:2417–2419. https://doi.org/10.1063/1.1794381

Shaabani A, Afshari R (2018) Magnetic Ugi-functionalized graphene oxide complexed with copper nanoparticles: efficient catalyst toward Ullman coupling reaction in deep eutectic solvents. J Colloid Interface Sci 510:384–394. https://doi.org/10.1016/j.jcis.2017.09.089

Elhamifar D, Ardeshirfard H (2017) Phenyl and ionic liquid based bifunctional periodic mesoporous organosilica supported copper: an efficient nanocatalyst for clean production of polyhydroquinolines. J Colloid Interface Sci 505:1177–1184. https://doi.org/10.1016/j.jcis.2017.07.010

Agrahari B, Layek S, Ganguly R, Pathak DD (2018) Synthesis and crystal structures of salen-type Cu(ii) and Ni(ii) Schiff base complexes: application in [3+2]-cycloaddition and A3-coupling reactions. New J Chem 42:13754–13762. https://doi.org/10.1039/C8NJ01718B

Feng J, He Y, Liu Y, Du Y, Li D (2015) Supported catalysts based on layered double hydroxides for catalytic oxidation and hydrogenation: general functionality and promising application prospects. Chem Soc Rev 44:5291–5319. https://doi.org/10.1039/C5CS00268K

Zou Y, Wang P, Yao W, Wang X, Liu Y, Yang D, Wang L, Hou J, Alsaedi A, Hayat T (2017) Synergistic immobilization of UO22+ by novel graphitic carbon nitride@ layered double hydroxide nanocomposites from wastewater. Chem Eng J 330:573–584. https://doi.org/10.1016/j.cej.2017.07.135

Wattanathana W, Nootsuwan N, Veranitisagul C, Koonsaeng N, Laosiripojana N, Laobuthee A (2015) Simple cerium-triethanolamine complex: synthesis, characterization, thermal decomposition and its application to prepare ceria support for platinum catalysts used in methane steam reforming. J Mol Struct 1089:9–15. https://doi.org/10.1016/j.molstruc.2015.02.010

Lommens P, Tack P, Vander Elst L, Van Driessche I, Vincze L, Sinnaeve D (2018) Spectroscopy as a tool to detect multinuclear Cu(II)–triethanolamine complexes in aqueous solution. Dalton Trans 47:3755–3763. https://doi.org/10.1039/C7DT04146B

Karadag A, Yilmaz VT, Thoene C (2001) Thoene, Di-and triethanolamine complexes of Co(II), Ni(II), Cu(II) and Zn(II) with thiocyanate: synthesis, spectral and thermal studies. Crystal structure of dimeric Cu(II) complex with deprotonated diethanolamine, [Cu2(μ-dea)2(NCS)2]. Polyhedron 20:635–641. https://doi.org/10.1016/S0277-5387(01)00720-3

Shiri L, Zarei S, Kazemi M, Sheikh D (2018) Sulfuric acid heterogenized on magnetic Fe3O4 nanoparticles: a new and efficient magnetically reusable catalyst for condensation reactions. Appl Organomet Chem 32:e3938. https://doi.org/10.1002/aoc.3938

Veisi H, Pirhayati M, Kakanejadifard A (2017) Immobilization of palladium nanoparticles on ionic liquid-triethylammonium chloride functionalized magnetic nanoparticles: as a magnetically separable, stable and recyclable catalyst for Suzuki–Miyaura cross-coupling reactions. Tetrahedron Lett 58:4269–4276. https://doi.org/10.1016/j.tetlet.2017.09.078

Mohammadinezhad A, Akhlaghinia B (2017) Fe3O4@Boehmite-NH2-CoII NPs: an inexpensive and highly efficient heterogeneous magnetic nanocatalyst for the Suzuki-Miyaura and Heck-Mizoroki cross-coupling reactions. Green Chem 19:5625–5641. https://doi.org/10.1039/C7GC02647A

Fan GY, Huang WJ (2015) Solvent-free hydrogenation of nitrobenzene catalyzed by magnetically recoverable Pt deposited on multiwalled carbon nanotubes. Synth React Inorg Met-Org Nano-Met Chem 45:819–1825. https://doi.org/10.1080/15533174.2013.872139

Kappe C, Zhu J (2005) Multicomponent reactions. Wiley-VCH, Weinheim

Cioc RC, Ruijter E, Orru RV (2014) Multicomponent reactions: advanced tools for sustainable organic synthesis. Green Chem 16:2958–2975. https://doi.org/10.1039/C4GC00013G

Brauch S, Van Berkel SS, Westermann B (2013) Higher-order multicomponent reactions: beyond four reactants. Chem Soc Rev 42:4948–4962. https://doi.org/10.1039/C3CS35505E

Tahmasbi B, Ghorbani-Choghamarani A (2017) First report of the direct supporting of palladium–arginine complex on boehmite nanoparticles and application in the synthesis of 5-substituted tetrazoles. Appl Organometal Chem 31:e3644. https://doi.org/10.1002/aoc.3644

Taghavi F, Gholizadeh M, Saljooghi AS, Ramezani M (2017) Cu(ii) immobilized on Fe3O4@APTMS-DFX nanoparticles: an efficient catalyst for the synthesis of 5-substituted 1H-tetrazoles with cytotoxic activity. MedChemComm 8:1953–1964. https://doi.org/10.1039/C7MD00302A

Prajapti SK, Nagarsenkar A, Babu BN (2014) An efficient synthesis of 5-substituted 1H-tetrazoles via B(C6F5)3 catalyzed [3 + 2] cycloaddition of nitriles and sodium azide. Tetrahedron Lett 55:3507–3510. https://doi.org/10.1016/j.tetlet.2014.04.089

Abrishami F, Ebrahimikia M, Rafiee F (2015) Synthesis of 5-substituted 1H-tetrazoles using a recyclable heterogeneous nanonickel ferrite catalyst. Appl Organometal Chem 29:730–735. https://doi.org/10.1002/aoc.3358

Gutmann B, Roduit JP, Roberge D, Kappe CO (2010) Synthesis of 5-substituted 1H-tetrazoles from nitriles and hydrazoic acid by using a safe and scalable high-temperature microreactor approach. Angew Chem 122:7255–7259. https://doi.org/10.1002/anie.201003733

Joshi SM, Mane RB, Pulagam KR, Gomez-Vallejo V, Llop J, Rode C (2017) The microwave-assisted synthesis of 5-substituted 1H-tetrazoles via [3 + 2] cycloaddition over a heterogeneous Cu-based catalyst: application to the preparation of 13N-labelled tetrazoles. New J Chem 41:8084–8091. https://doi.org/10.1039/C7NJ00568G

Sridhar M, Mallu KKR, Jillella R, Godala KR, Beeram CR, Chinthala N (2013) One-step synthesis of 5-substituted 1H-tetrazoles from an aldehyde by reaction with acetohydroxamic acid and sodium azide under Bi(OTf)3 catalysis. Synthesis 45:507–510. https://doi.org/10.1055/s-0032-1318108

Abdollahi-Alibeik M, Moaddeli A (2015) Multi-component one-pot reaction of aldehyde, hydroxylamine and sodium azide catalyzed by Cu–MCM-41 nanoparticles: a novel method for the synthesis of 5-substituted 1H-tetrazole derivatives. New J Chem 39:2116–2122. https://doi.org/10.1039/C4NJ01042F

Khan KM, Fatima I, Saad SM, Taha M, Voelter W (2016) An efficient one-pot protocol for the conversion of benzaldehydes into tetrazole analogs. Tetrahedron Lett 57:523–524. https://doi.org/10.1016/j.tetlet.2015.12.067

Heravi MM, Fazeli A, Oskooie HA, Beheshtiha YS, Valizadeh H (2012) Click synthesis of 5-substituted 1H-tetrazoles from aldehydes, hydroxylamine, and [bmim]N3 via one-pot, three-component reaction. Synlett 23:2927–2930. https://doi.org/10.1055/s-0032-1317671

Esmaeilpour M, Sardarian AR, Firouzabadi H (2018) Dendrimer-encapsulated Cu(II) nanoparticles immobilized on superparamagnetic Fe3O4@SiO2 nanoparticles as a novel recyclable catalyst for N-arylation of nitrogen heterocycles and green synthesis of 5-substituted 1H-tetrazoles. Appl Organometal Chem 32:e4300. https://doi.org/10.1002/aoc.4300

Mitra B, Mukherjee S, Pariyar GC, Ghosh P (2018) One pot three-component synthesis of 5-substituted 1H-tetrazole from aldehyde. Tetrahedron Lett 14:1385–1389. https://doi.org/10.1016/j.tetlet.2018.02.067

Behrouz S (2017) Highly efficient three-component synthesis of 5-substituted-1H-tetrazoles from aldehydes, hydroxylamine, and tetrabutylammonium azide using doped nano-sized copper(I) oxide (Cu2O) on melamine–formaldehyde resin. J Saudi Chem Soc 21:220–228. https://doi.org/10.1002/anie.200701045

Patil UB, Kumthekar KR, Nagarkar JM (2012) A novel method for the synthesis of 5-substituted 1H-tetrazole from oxime and sodium azide. Tetrahedron Lett 53:3706–3709. https://doi.org/10.1016/j.tetlet.2012.04.093

Guggilapu SD, Prajapti SK, Nagarsenkar A, Gupta KK, Babu BN (2016) Indium(III) chloride catalyzed synthesis of 5-substituted 1H-tetrazoles from oximes and sodium azide. Synlett 27:1241–1244. https://doi.org/10.1055/s-0035-1561559

Arghan M, Koukabi N, Kolvari E (2018) Mizoroki-Heck and Suzuki-Miyaura reactions mediated by poly (2-acrylamido-2-methyl-1-propanesulfonic acid)-stabilized magnetically separable palladium catalyst. Appl Organometal Chem 32:e4346. https://doi.org/10.1002/aoc.4346

Koukabi N, Kolvari E, Zolfigol MA, Khazaei A, Shaghasemi BS, Fasahati B (2012) A magnetic particle-supported sulfonic acid catalyst: tuning catalytic activity between homogeneous and heterogeneous catalysis. Adv Synth Catal 354:2001–2008. https://doi.org/10.1002/adsc.201100352

Koukabi N, Kolvari E, Khazaei A, Zolfigol MA, Shirmardi-Shaghasemi B, Khavasi HR (2011) Hantzsch reaction on free nano-Fe2O3 catalyst: excellent reactivity combined with facile catalyst recovery and recyclability. Chem Comm 47:9230–9232. https://doi.org/10.1039/C1CC12693H

Kolvari E, Koukabi N, Hosseini MM (2015) Perlite: a cheap natural support for immobilization of sulfonic acid as a heterogeneous solid acid catalyst for the heterocyclic multicomponent reaction. J Mol Catal Chem 397:68–75. https://doi.org/10.1016/j.molcata.2014.10.026

Kolvari E, Koukabi N, Hosseini MM, Vahidian M, Ghobadi E (2016) Nano-ZrO2 sulfuric acid: a heterogeneous solid acid nano catalyst for Biginelli reaction under solvent free conditions. RSC Adv 6:7419–7425. https://doi.org/10.1039/C5RA19350H

Akbarzadeh P, Koukabi N, Kolvari E (2019) Three-component solvent-free synthesis of 5-substituted-1H-tetrazoles catalyzed by unmodified nanomagnetite with microwave irradiation or conventional heating. Res Chem Intermed 45:1009–1024. https://doi.org/10.1007/s11164-018-3657-9

Lotfi Z, Mousavi HZ, Sajjadi SM (2017) Magnetic carbon nanotubes modified with 1,4-diazabicyclo [2.2.2] octane are a viable sorbent for extraction of selective serotonin reuptake inhibitors. Microchim Acta 184:1427–1436. https://doi.org/10.1007/s00604-017-2150-2

Li J, Tang S, Lu L, Zeng HC (2007) Preparation of nanocomposites of metals, metal oxides, and carbon nanotubes via self-assembly. J Am Chem Soc 129:9401–9409. https://doi.org/10.1021/ja071122v

Sabaqian S, Nemati F, Nahzomi HT, Heravi MM (2018) Silver(I) dithiocarbamate on modified magnetic cellulose: synthesis, density functional theory study and application. Carbohydr Polym 184:221–230. https://doi.org/10.1016/j.carbpol.2017.12.045

Chidambaram S, Pari B, Kasi N, Muthusamy S (2016) ZnO/Ag heterostructures embedded in Fe3O4 nanoparticles for magnetically recoverable photocatalysis. J Alloys Compd 665:404–410. https://doi.org/10.1016/j.jallcom.2015.11.011

Acknowledgements

The authors gratefully acknowledge the Semnan University Research Council for the financial support of this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Akbarzadeh, P., Koukabi, N. & Kolvari, E. Anchoring of triethanolamine–Cu(II) complex on magnetic carbon nanotube as a promising recyclable catalyst for the synthesis of 5-substituted 1H-tetrazoles from aldehydes. Mol Divers 24, 319–333 (2020). https://doi.org/10.1007/s11030-019-09951-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11030-019-09951-6