Abstract

Triacetone triperoxide (TATP) is an organic peroxide that is sensitive and can be readily synthesized, and is thus used as an explosive. In this study, three sulfuric acid (H2SO4) concentrations (1, 9, and 18 M) were used to synthesize TATP. The higher concentrations of H2SO4 resulted in higher concentrations and swift production of TATP. Each combination was compounded with different thermal hazard characteristics. The thermal decomposition of TATP was studied through differential scanning calorimetry (DSC) to obtain exothermic onset temperature (T0), heat of decomposition (ΔHd), and maximum temperature during the overall reaction (Tmax). The apparent activation energy (Ea) was calculated using the Kissinger method and the Ozawa method. Gas chromatography and mass spectrometry were employed to confirm the synthesized TATP. This study used DSC to evaluate the thermal decomposition and analyze the efficiency of fire-extinguishing reagents. Results showed that different inhibiting reagents had different efficiency levels for TATP. Thus, inhibiting reagents can be expected to diminish the damage caused by TATP explosions. In this study, the mechanism of TATP synthesis was investigated.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Triacetone triperoxide (TATP) was originally discovered in 1895 by Wolffenstein [1]. TATP can be synthesized by mixing sulfuric acid (H2SO4) with acetone and hydrogen peroxide (H2O2) [2]. TATP has been recognized as an easily accessible explosive. Because of its sensitivity, TATP is not suitable for use as a commercial or military explosive. TATP has become popular with covert manufacturers of explosives. Recent high-profile examples of the use of organic peroxides, such as TATP, include the attempted attack on American Airlines Flight AA63 in 2001 as well as the London transport system bombings in July 2005 [3].

In this study, we assessed the reactive scheme and thermal hazards of TATP. Differential scanning calorimetry (DSC) was used to determine the exothermic reaction of TATP as a catalyst under three H2SO4 concentrations (1, 9, and 18 M) [4]. Gas chromatography and mass spectrometry (GC/MS) was applied to analyze the elements for the mixture of H2O2, CH3COCH3, and H2SO4.

On the basis of the thermal analysis of TATP, some safety measures are recommended for school laboratories, families, and industrial plants. All waste liquids should be stored and released carefully to avoid the risk of explosion. Furthermore, TATP was mixed with four fire-extinguishing powders to determine the best fire-extinguishing reagent to provide safer infraction for firemen and school laboratories.

Experimental

A standard TATP sample (0.1 mg of TATP dissolved in 1.0 mL of CH3CN) was purchased from AccuStandard Co., New Haven, Connecticut, USA (M-8330-ADD-24, CAS No. 17088-37-8). The other experimental materials used were acetone (99.5 mass%), H2O2 (65 mass%), H2SO4 (1, 9, and 18 M), and CH3CN, purchased from local suppliers.

Four fire-extinguishing powders, namely ABC powder (70 mass% NH4H2PO4), XBC powder (70 mass% KCl), BC powder (90 mass% NaHCO3), and KBC powder (85 mass% KHCO3), were used; in each experimental trial, 0.1 mL of H2SO4 (1, 9, and 18 M) was added to a mixture comprising 1 mL of H2O2 (65 mass%) and 1 mL of CH3COCH3 (99.5 mass%) at 4 °C.

Dynamic scanning experiments were performed using a Mettler TA8000 system coupled with a DSC821e measuring test crucible (Mettler ME-26732). The heating rates selected in this study were 1, 2, 4, and 10 °C min−1. The selected heating rates were based on DSC standard calibration heating rate which is 4 °C min−1. Therefore, the heating rates we chose in this study can clearly perform the difference from multi-heating rates. The scope of heating stage was from 30 to 300 °C. The samples (TATP and TATP mixture samples) and reference samples were heated in the same furnace. When the temperature was rise, the release heat during decomposition of target samples can be detected and recorded as electronic signal.

Kinetic analysis of the crucible test was performed using multi-heating rates methods based on the equations of Kissinger [5,6,7,8] and Ozawa [9,10,11,12,13,14,15,16,17]. The kinetic analysis can be expressed as follows:

where Tmax is the temperature corresponding to the maximum in the DSC exothermic process at a specific heating rate (β). From the slope of the linear value drawing of log (βT −2max ) versus T −1max , Ea can be calculated if the reaction follows n-th order scheme.

Ea is obtained from the slope of the plot of log β against T −1max .

Results and discussion

Reaction analysis of synthesized TATP

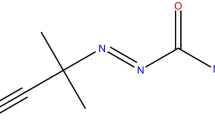

TATP is a highly sensitive explosive material and can be readily synthesized. Acetone, H2O2, and H2SO4 were used to manufacture TATP. These three materials are easy to obtain in homes, in laboratories, and at businesses. The predicted reaction mechanism is shown in Scheme 1 [18]. The quantity of the pure TATP sample was too small to perform an experiment; therefore, it was only used for comparison with artificially synthesized TATP at GC/MS for peak 222 AMS existence, as shown in Fig. 1. TATP is potentially hazardous, regardless of whether it is manufactured intentionally or accidentally. Therefore, this study recommends that H2O2, CH3COCH3, and H2SO4 should not be put together in a wastewater drum or any other container. The Kissinger and Ozawa methods demonstrated that the low Ea of TATP was very dangerous, indicating that TATP is prone to decompose rapidly. The TATP samples in this study decomposed around 40–60 °C and released more than 2500 J g−1 of ΔHd.

Predicted reaction mechanism to synthesize TATP [12]

DSC results at various heating rates (1, 2, 4, and 10 °C min−1)

The aim was to detect the thermal hazards of TATP with three concentrations of H2SO4 as a catalyst. In practice, a higher acid concentration can produce a higher concentration of TATP. This study indicated an important result that when H2O2 and acetone are mixed with H2SO4 with an excessive concentration, TATP is manufactured in the solution. In practice, H2O2, acetone, and H2SO4 are prohibited from being together in a wastewater drum or any containers.

TATP manufacturing process by 1 M H2SO4 as a catalyst

Figure 2 indicates that TATP with 1 M H2SO4 as a catalyst decomposed at approximately 95 °C through DSC at four heating rates (1, 2, 4, and 10 °C min−1). According to the thermal curves, TATP with 1 M H2SO4 catalyst decomposed rapidly and possessed two exothermic peaks. However, at 10 °C min−1, it only exhibited one exothermic peak.

TATP manufacturing process by 9 M H2SO4 as a catalyst

Figure 3 indicates that TATP with 9 M H2SO4 catalyst decomposed at approximately 50–60 °C through DSC at four heating rates (1, 2, 4, and 10 °C min−1). According to the thermal curves, TATP with 9 M H2SO4 catalyst decomposed unevenly and the final decomposition occurred at less than 141 °C. Heat of decomposition (ΔHd) of TATP with 9 M H2SO4 catalyst was measured to be approximately 2500 J g−1.

TATP manufacturing process by 18 M H2SO4 as a catalyst

The thermal decomposition reaction of TATP with 18 M catalyst is depicted in Fig. 4. TATP (18 M H2SO4 catalyst) decomposed at 40–80 °C, and the final decomposition occurred at less than 128 °C. ΔHd of TATP with 18 M H2SO4 catalyst was measured at approximately 2600 J g−1.

TATP mixed with 40 mass% of ABC powder

The thermal decomposition reaction of TATP mixed with 40 mass% of ABC powder is shown in Fig. 5. The mixture decomposed partially at 130–150 °C, and the final decomposition occurred at 210 °C.

E a calculation

Because the TATP was decomposed with 1 M H2SO4 catalyst exhibits two exothermic peaks (Fig. 6), Tmax is not easy to determine. Accordingly, this study cannot calculate the Ea of TATP with 1 M H2SO4 catalyst.

Ea of TATP with 9 M H2SO4 catalyst was determined to be 46 kJ mol−1 using the Kissinger kinetic equation, as shown in Table 1. Similarly, Ea of TATP with 18 M H2SO4 catalyst was decided to be 44 kJ mol−1, as given in Table 2. The Ea of TATP with 9 M H2SO4 was determined to be 49 kJ mol−1 using the Ozawa kinetic equation (Table 1). Similarly, Ea of TATP with 18 M H2SO4 was calculated to be 47 kJ mol−1 (Table 2).

Linear regression of TATP and TATP mixed with ABC powder at various heating rates by the Kissinger and Ozawa methods

The linear regressions of TATP synthesized using 9 M H2SO4 at 1, 2, 4, and 10 °C min−1 heating rates through DSC (Kissinger method) are shown in Fig. 6. The linear regressions of TATP synthesized using 18 M H2SO4 at 1, 2, 4, and 10 °C min−1 heating rates through DSC (Kissinger method) are illustrated in Fig. 7. The linear regressions of TATP mixed with ABC powder at 1, 2, 4, and 10 °C min−1 heating rates through DSC (Kissinger method) are shown in Fig. 8.

The linear regressions of TATP synthesized using 9 M H2SO4 at 1, 2, 4, and 10 °C min−1 heating rates through DSC (Ozawa method) are illustrated in Fig. 9. The linear regressions of TATP synthesized using 18 M H2SO4 at 1, 2, 4, and 10 °C min−1 heating rates through DSC (Ozawa method) are disclosed in Fig. 10. The linear regressions of TATP mixed with ABC powder at 1, 2, 4, and 10 °C min−1 heating rates through DSC (Ozawa method) are shown in Fig. 11. GC/MS was applied to prove the existence of TATP. The mass spectrum of TATP showed a peak at 222 amu.

Mixed with fire-extinguishing reagents to reckon TATP mixed with ABC powder

The Ea was obtained through the Kissinger and Ozawa methods, and the samples were 60 mass% of TATP and 40 mass% of ABC powder. The Ea of TATP mixed with ABC powder was 196 kJ mol−1 (Kissinger method) and 195 kJ mol−1 (Ozawa method). Both Ea were larger than those for TATP without mixing with ABC powder. The T0 of TATP mixed with ABC powder was approximately 130–150 °C, which was greater than that for TATP without adding the ABC powder. However, the ΔHd for TATP mixed with ABC powder was nearly the same as that for TATP without ABC powder.

Comparison of TATP mixed with various fire-extinguishing reagents

When TATP was mixed with ABC powder, the T0 of that mixture was evaluated to be approximately 150 °C and the Tmax of TATP was 200 °C. The ΔHd of the mixture was considerably reduced to 1300 J g−1. Ea of TATP mixed with ABC powder was calculated to be approximately 172 kJ mol−1 using DSC software.

The T0 of TATP mixed with BC powder was analyzed to be 160 °C, the Tmax was 190 °C, and the ΔHd was 2460 J g−1. The T0 of TATP mixed with KBC powder was assessed to be 160 °C, the Tmax was 180 °C, and the ΔHd was 2752 J g−1. The T0 of TATP mixed with XBC powder was appraised to be 120 °C, the Tmax was 170 °C, and the ΔHd was 1833 J g−1.

Conclusions

This study used three concentrations of H2SO4 to synthesize TATP and to realize the behaviors of thermal explosions and runaway reactions. DSC was employed to obtain T0, ΔHd, and Tmax, and the heating rates selected for the temperature-programmed ramp were 1, 2, 4, and 10 °C min−1. Kinetic analysis of the step was performed using the preceding heating rate methods based on the equations of the Kissinger and Ozawa methods, and Ea was thus derived.

Through DSC testing, it was found that TATP decomposed at 50 °C and the Tmax of TATP was 140 °C. Table 2 presents that ABC, XBC, KBC, and BC powders are useful fire-extinguishing reagents that can increase T0 and Ea. Moreover, ABC and XBC powders can reduce ΔHd. When TATP was mixed with ABC powder, the T0 of the mixture was determined to be approximately 150 °C and ΔHd of the mixture was significantly decreased to 1300 J g−1. The Ea of TATP mixed with ABC powder was calculated to be approximately 172 kJ mol−1 using DSC software. Among the four fire-extinguishing reagents, this study found ABC powder to be the best choice to reduce the thermal hazards of TATP. Thus, these findings are useful for future selection of fire-extinguishing reagents.

References

Dubnikova F, Kosloff R, Almog J, Zeiri Y, Boese R, Itzhaky H, Alt A, Keinan E. Decomposition of triacetone triperoxide is an entropic explosion. J Am Chem Soc. 2005;127:1146–59.

Laine DF, Roske CW, Cheng IF. Electrochemical detection of triacetone triperoxide employing the electrocatalytic reaction of iron (II/III) ethylenediaminetetraacetate and hydrogen peroxide. Anal Chim Acta. 2008;608:56–60.

Armitt D, Zimmermann P, Steinborner S. Gas chromatography/mass spectrometry analysis of triacetone triperoxide (TATP) degradation products. Rapid Commun Mass Spectrom. 2008;22:950–8.

Mullen C, Huestis D, Coggiola M, Oser H. Laser photoionization of triacetone triperoxide (TATP) by femtosecond and nanosecond laser pulses. Int J Mass Spectrum. 2006;252:69–72.

Chen WC, Lin JR, Liao MS, Wang YW, Shu CM. Green approach to evaluating the thermal hazard reaction of peracetic acid through various kinetic methods. J Therm Anal Calorim. 2016;127(1):1019–26.

Deng J, Zhao JY, Huang AC, Zhang YN, Wang CP, Shu CM. Thermal behavior and microcharacterization analysis of second-oxidized coal. J Therm Anal Calorim. 2017;127(1):439–48.

Huang AC, Chen WC, Huang CF, Zhao JY, Deng J, Shu CM. Thermal stability simulations of 1,1-bis(tert-butylperoxy)-3,3,5 trimethylcyclohexane mixed with metal ions. J Therm Anal Calorim. 2017;130(2):949–57.

Kissinger HE. Variation of peak temperature with heating rate in differential thermal analysis. J Res Natl Bur Stand US. 1956;57:217–21.

Liu SH, Chen YC, Hou HY. Thermal runaway hazard studies for ABVN mixed with acids or alkalines by DSC, TAM III, and VSP2. J Therm Anal Calorim. 2015;122:1107–16.

Liu SH, Lin CP, Shu CM. Thermokinetic parameters and thermal hazard evaluation for three organic peroxides by DSC and TAM III. J Therm Anal Calorim. 2011;106:165–72.

Liu SH, Yu YP, Lin YC, Weng SY, Hsieh TF, Hou HY. Complex thermal evaluation for 2,2′-azobis(isobutyronitrile) by non-isothermal and isothermal kinetic analysis methods. J Therm Anal Calorim. 2014;116:1361–7.

Ozawa T. A modified method for kinetic analysis of thermoanalytical data. J Therm Anal Calorim. 1976;9:369–73.

Ozawa T. Critical investigation of methods for kinetic analysis of thermoanalytical data. J Therm Anal Calorim. 1974;7:601–17.

Ozawa T. Kinetic analysis of derivative curves in thermal analysis. J Therm Anal Calorim. 1970;2:301–24.

Tong JW, Chen WC, Tsai YT, Cao Y, Chen JR, Shu CM. Incompatible reaction for (3-4-epoxycyclohexane) methyl-3′-4′-epoxycyclohexyl-carboxylate (EEC) by calorimetric technology and theoretical kinetic model. J Therm Anal Calorim. 2014;116:1445–52.

Tsai LC, Tsai YT, Lin CP, Liu SH, Wu TC, Shu CM. Isothermal versus non-isothermal calorimetric technique to evaluate thermokinetic parameters and thermal hazard of tert-butyl peroxy-2-ethyl hexanoate. J Therm Anal Calorim. 2012;52:8206–15.

Wang C, Yang Y, Tsai YT, Deng J, Shu CM. Spontaneous combustion in six types of coal by using the simultaneous thermal analysis-Fourier transform infrared spectroscopy technique. J Therm Anal Calorim. 2016;126:1591–602.

Matyas R, Pachman J, Ang HG. Study of TATP: spontaneous transformation of TATP to DADP. Propellants Explos Pyrotech. 2008;33(2):89–91.

Acknowledgements

The authors thank Prof. Mei-Li You for his assistance in solving the problems presented by thermokinetic analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shiue, GY., Huang, AC. & Chen, JR. Thermal decomposition of triacetone triperoxide by differential scanning calorimetry. J Therm Anal Calorim 133, 745–751 (2018). https://doi.org/10.1007/s10973-018-7021-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7021-5