Abstract

Using simultaneous thermal analysis-Fourier transform infrared spectroscopy, we analyzed the oxidation and exothermic behaviors of six types of coal based on various factors, such as characteristic temperature, heat release, and gas release, to establish a foundation for prevention and control of spontaneous combustion in six types of coal in China. According to the experimental results, a decrease in the metamorphic grade of coal causes an increase in the amount of volatile matter, the heat release rate, and the total heat released. The apparent exothermic onset temperature and initial temperature for the release of H2O, CO2, CO, and CH4 during the nonisothermal oxidation process of coal took place earlier, indicating that the oxidation reaction occurred more easily in lower-grade coal, increasing the hazards of spontaneous combustion. Moreover, when decomposing, coal releases large amounts of CH4, which may cause gas explosions in coal mines. Therefore, technology facilitating the detection of CH4 and prevention of explosions should be developed for use in the coal industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In China, spontaneous combustion of coal has caused numerous accidents, resulting in economic loss and human casualties. On June 23, 2014, the spontaneous combustion of coal triggered a gas explosion in a mining area that killed 22 people in Chongqing, China [1]. In the same year (November 26, 2014), 24 people perished in Liaoning Province [2]. Undoubtedly, feasible control of spontaneous combustion of coal is still a crucial problem that has yet to be solved [3–8].

Spontaneous combustion of coal is a self-accelerating, nonlinear, and physical and chemical reaction process. In general, coal–oxygen compound theory has been applied broadly and developed completely for studying the coal spontaneous combustion [3]. The theory holds that when coal comes into contact with oxygen, it can generate an exothermic reaction because of physical adsorption, causing the coal’s surface temperature to increase. During this process, certain functional groups that are easily oxidized on the coal’s surface may undergo an oxidation reaction and release heat, resulting in the accumulation of thermal energy. If ventilation in the coal mine (i.e., heat removal) is less than the heat generated, the temperature rise may reach the ignition point of coal [9–13]. A spontaneous combustion of coal reaction may occur, resulting in fire, explosion, or the release of toxic gases [14–18].

In this study, six types of coal with different metamorphic grades, anthracite, lean coal, coking coal, gas coal, nonstick coal, and lignite, were tested to determine the characteristics of oxidation reaction, mass loss, and heat release, as well as which functional groups of gases were released by simultaneous thermal analysis-Fourier transform infrared spectroscopy (STA-FTIR). Therefore, the characteristics of spontaneous combustion of coal could be effectively identified and used for developing preventative technology, to help mitigate the risk of disaster and unpredictable environmental pollution [19, 20].

Experimental

Samples

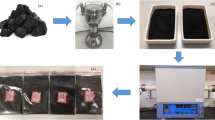

The six types of coal used and listed from high to low metamorphic grades are anthracite (Yah-Ma-Zhuang, Henan, China), lean coal (Sang-Shu-Ping, Shaanxi, China), coking coal (Shi-Hao-Cun, Henan, China), gas coal (Nantun, Shandong, China), nonstick coal (Shi-Cao-Cun, Ningxia, China), and lignite (Jungar Banner, Inner Mongolia). All samples were pretreated. First, the oxidation layer on the coal surface was peeled to retain the central part. Second, the retained coal was broken under N2 to prevent oxidation. Finally, the broken coal was collected and dried at low temperature to yield the experimental sample. Each type of coal underwent industrial and element analysis prior to the experiments, and the results are presented in Table 1. According to the industrial analysis results, an increase in the metamorphic grade corresponded with a decrease in the fixed carbon content (FCad) but an increase in the volatile contents (V ad). Coking coal had the largest ash content (A ad), and the largest moisture content (M ad) appeared in lignite. From the element analysis results, a decrease in the metamorphic grade corresponded with lower carbon content and higher hydrogen and oxygen content. These results correspond to the basic properties of coal with differing metamorphic grades.

Simultaneous thermal analysis-Fourier transform infrared spectroscopy

The characteristic temperature of different oxidation stages for six types of coal was investigated by using STA-449-F3 (NETZSCH, Bavaria, Germany), which consists of thermogravimetry (TG) and differential scanning calorimetry (DSC) techniques. Furthermore, the change in the functional groups of released gases with increasing temperature was observed through VERTEX70v FTIR (Bruker Corporation, MA, USA). The related experimental data, including the mass loss, mass loss rate, exothermic onset temperature of oxidation, and heat of oxidation reaction, as well as which functional groups of gases were released with heating, could be started, measured, and recorded simultaneously by using STA-FTIR. The size of the sample and reference crucible used in STA was 10.0 mL. The temperature ranges of TG, FTIR, and DSC were set from 20.0 to 800.0 °C with a heating rate of 10.0 °C min−1. Based on the structure of coal, the scanning range of infrared spectroscopy was from 4000 to 650 cm−1, and the resolution was 4 cm−1. The scanning times for each test were 32.0. The experiment was conducted in a 1:4 of oxygen/nitrogen environment with a flow rate of 50.0 mL min−1.

Element analysis and industrial analysis

Element analysis of samples was investigated by using elemental analyzer EA 2400 II (PerkinElmer, USA). The mass of the sample was 50.0 mg. The furnace temperature was from 100.0 to 1100.0 °C. The related experimental data included C, H, O, N, and S contents.

Industrial analysis of samples was by industrial analyzer WBGF-6000 (Wanbo Instrument Co., Ltd., PR China). The mass of the sample was 800.0 mg. Oxygen pressure and nitrogen pressure were set at 0.2 MPa. The temperature was set from 20.0 to 800.0 °C. The experimental data included moisture content (M ad), ash content (A ad), volatile contents (V ad), and fixed carbon content (FCad).

Results and discussion

TG results

TG was used to observe the mass loss of samples to determine properties of composition, thermal stability, and oxidation or degradation behaviors. Figure 1 shows the TG and differential thermogravimetry (DTG) results for six types of coal, and the characteristic temperature of oxidation reaction for coal could be classified by five features: characteristic temperature of maximum evaporation of water and desorption of gases, characteristic temperature of maximum oxidization mass gain, characteristic temperature of ignition point, characteristic temperature of maximum mass loss rate, and characteristic temperature of terminal residual, identified as T 1 to T 5, respectively. According to the results, the T 2 values of six types of coal—from high to low metamorphic grades—were 401.0, 363.0, 335.0, 300.0, 288.0, and 234.0 °C, indicating a declining trend. Because the metamorphic grade was lower, there was more volatile content in the coal, causing the oxidation rate to increase, so that the T 2 took place earlier. For the same reasons, T 3–T 5 for six types of coal also showed a similar trend. The T 3 values were 523.0, 470.0, 446.0, 442.0, 429.0, and 357.0 °C after the metamorphic grade was decreased. The T 4 values were 563.0, 522.0, 519.0, 492.0, 458.0, and 397.0 °C, and the T 5 values were 655.0, 639.0, 617.0, 603.0, 549.0, and 611.0 °C after the metamorphic grade was decreased. Therefore, the metamorphic grade of coal is a crucial factor in determining spontaneous combustion. During exploitation, storage, or disposal, coal of a lower metamorphic grade should be cautiously handled and subject to prevention and control measures, to mitigate the risk of the spontaneous combustion of coal. However, in the current study, nonstick coal had a maximum DTG of −20.54 % min−1, and lignite had a minimum DTG of −5.62 % min−1. Therefore, when coal reached the combustion stage, the degree of violence of the combustion reaction for coal bores no relationship with the metamorphic grade, but was correlated with other factors, including composition of rock of coal, molecular structure, minerals content and distribution, and ash content. Various characteristic temperatures tested by applying TG for six types of coal are displayed in Table 2.

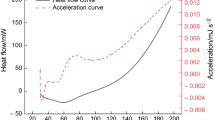

DSC results

Figure 2 shows the DSC experimental results for six types of coal. There were two thermal stages from the DSC curves. The first stage was an endothermic reaction caused by the evaporation of water and desorption of gases, which could correspond to the T 1 of the TG results. The second stage was an exothermic reaction corresponding to the TG results from oxidation mass gain to combustion (from T 2 to T 4). All DSC curves were defined according to four characteristic temperatures. T D1 was the temperature of maximum endothermic reaction with evaporation of water and desorption of gases, T D2 was the exothermic onset temperature of oxidation reaction, T D3 was the maximum heat release rate, and T D4 was the end of the combustion reaction. We found that T D1 occurred earlier with a lower metamorphic grade of coal; thus, the evaporation of water and the desorption of gases depended on the metamorphic grade of the coal. At the second stage, there was more than one exothermic peak during the heat release process for all coals, except for anthracite, which had only a single exothermic peak. This is because anthracite has a higher metamorphic grade, meaning that it has pure coal composition and a simple molecular structure. Moreover, gas coal showed the largest total heat of exothermic reaction, which is inconsistent with its metamorphic grade. This phenomenon could indicate that when the oxidation reaction of coal occurred, the intensity of the reaction depended on the physical or chemical properties of coal itself. In addition, because the total heat of exothermic reaction can be used to evaluate the severity of spontaneous combustion of coal, the heat generated by gas coal during the oxidation process must be immediately removed, leading to excessive heat accumulation in the coal seam. Related characteristic temperatures obtained from the DSC test are listed in Table 3.

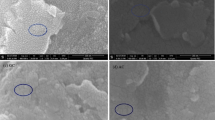

FTIR results

Because of the inherent complexity of coal, FTIR is utilized to analyze the time, characteristics, and concentration of gases released during the oxidation process. Figure 3 presents a 3D diagram (temperature–wave number–absorbance) of FTIR compared with the TG thermal curve for six types of coal. We observed that the temperature of gases released reasonably matched the characteristic temperature of the TG test, and the temperature of maximum gases released was also close to the maximum mass loss temperature. Therefore, the composition analysis for these released gases could be applied for further analysis of the oxidation process and evaluation of spontaneous combustion of coal. Figures 4, 5, 6 and 7 show the absorbance versus temperature for four index gases: CH4, H2O, CO, and CO2, respectively. According to the literature, the wave numbers of 2650–2200 cm−1 and 850–400 cm−1 that are simultaneously present indicate CO2 stretching; the wave numbers of 3100–2800 cm−1 combined with 1400–1100 cm−1 indicate CH4 stretching; the wave numbers of 3700–3625 cm−1 indicate –OH stretching under dissociated conditions; the wave numbers of 1650–1350 cm−1 indicate –OH stretching of an in-of-plane ring bend, which could confirm the presence of H2O; and the wave numbers of 2200–1900 cm−1 indicate CO stretching [21, 22]. H2O stretching appeared in nonstick coal and lignite at ca. 170.0 °C because they contained more free and bound water than other types of coal. Moreover, the initial temperature of H2O, CO, or CO2 released took place earlier with lower metamorphic grades of coal. These results demonstrate the combustion reaction of higher metamorphic grades coal, which are difficult to process and are the same as the TG results. Another cause of spontaneous combustion of coal is CH4, because high CH4 and oxygen concentrations could cause a gas explosion. CH4 is produced because of the oxidation of coal and CH4 adsorption by coal in nature. According to the FTIR results, CH4 was released from 450.0 to 600.0 °C, and lean coal released the most CH4 during the combustion process. Anthracite released the least. Therefore, reinforced control technology for CH4 release should be developed for various types of coal, mitigating the risk of a gas explosion. The characteristic parameters of the release of CO, H2O, and CO2 coal are presented in Table 4.

Conclusions

Our study confirmed the behaviors of spontaneous combustion of coal for six different metamorphic grades of coal, and various characteristic temperatures and index gases for coal spontaneous combustion were also determined by using the STA-FTIR technique. The main findings of this study are as follows:

-

1.

From the industrial and element analysis results, six types of coal were defined completely. In addition, according to the TG results, coal with a lower metamorphic grade can readily trigger coal spontaneous combustion. However, when a combustion reaction occurs, the vigor of spontaneous combustion of coal has no relationship with the metamorphic grade, but is rather related to inherent physical and chemical properties of coal itself.

-

2.

When the metamorphic grade of coal is lower, the temperature of maximum endothermic reaction with evaporation of water and desorption of gases also happens earlier. Gas coal has the maximum heat of combustion reaction when oxidation reaction occurs; therefore, heat removal in a gas coal mine should be strictly governed to mitigate the risk of spontaneous combustion of coal.

-

3.

With a decrease in the metamorphic grade of coal, the initial temperature of H2O, CO, or CO2 release takes place earlier, indicating that the combustion reaction proceeds easily. Moreover, when decomposing, coal can release great amounts of CH4, which may cause a gas explosion in a coal mine. Therefore, CH4 detection technology should be implemented for coal use, storage, mining, transportation, and disposal.

Abbreviations

- A ad :

-

Ash content (%)

- FCad :

-

Fixed carbon content (%)

- M ad :

-

Moisture content (%)

- T 1 :

-

Characteristic temperature of maximum evaporation of water and desorption of gases (°C)

- T 2 :

-

Characteristic temperature of maximum oxidization mass gain (°C)

- T 3 :

-

Characteristic temperature of ignition point (°C)

- T 4 :

-

Characteristic temperature of maximum mass loss rate (°C)

- T 5 :

-

Characteristic temperature of terminal residual (°C)

- T D1 :

-

Temperature at the maximum endothermic reaction with evaporation of water and desorption of gases (°C)

- T D2 :

-

Exothermic onset temperature of oxidation reaction (°C)

- T D3 :

-

Temperature at the maximum heat release rate (°C)

- T D4 :

-

Temperature at the end of the combustion reaction (°C)

- V ad :

-

Volatile contents (%)

References

Web of The Central People’s Government of the People’s Republic of China. (2014). http://www.gov.cn/xinwen/2014-10/10/content_2762334.htm.

Web of The Central People’s Government of the People’s Republic of China. (2014). http://www.gov.cn/xinwen/2014-11/26/content_2783534.htm.

Wen H, Zhang F, Jin Y, Liu W. Experiment research on effect of sulfur on characteristic parameters of coal spontaneous combustion. Coal Saf. 2011;42:5–7 (in Chinese).

Pandey J, Mohalik NK, Mishra RK, Khalkho A, Kumar D, Singh VK. Investigation of the role of fire retardants in preventing spontaneous heating of coal and controlling coal mine fires. Fire Technol. 2015;51:227–45.

Qi X, Wei C, Li Q, Zhang L. Controlled-release inhibitor for preventing the spontaneous combustion of coal. Nat Hazards. 2016;82:891–901.

Zhou F, Wang D, Zhang Y, Zhang Y, Li X. Practice of fighting fire and suppressing explosion for a super-large and highly gassy mine. J China Univ Ming Technol. 2007;17:459–63.

Xie Z, Li X, Liu M. Application of three-phase foam technology for spontaneous combustion prevention in Longdong coal mine. Proc Eng. 2011;26:63–9.

Mao Z, Zhu H, Zhao X, Sun J, Wang Q. Experimental study on characteristic parameters of coal spontaneous combustion. Proc Eng. 2013;62:1081–6.

Deng J, Xu J, Zhang X, Wen H, Li L. Investigation on the relation of coal low temperature oxidation and the size of coal sample. Coal. 1999;8:13–5.

Baris K, Kizgut S, Didari V. Low-temperature oxidation of some Turkish coals. Fuel. 2012;93:423–32.

Xin H, Wang D, Qi X, Qi G, Dou G. Structural characteristics of coal functional groups using quantum chemistry for quantification of infrared spectra. Fuel Process Technol. 2014;118:287–95.

Wang H, Dlugogorski BZ, Kennedy EM. Theoretical analysis of reaction regimes in low-temperature oxidation of coal. Fuel. 1999;78:1073–81.

Méndez LB, Borrego AG, Martinez-Tarazona MR, Menéndez R. Influence of petrographic and mineral matter composition of coal particles on the combustion reactivity. Fuel. 2003;82:1875–82.

Tahmasebi A, Yu J, Han Y, Li X. A study of chemical structure changes of Chinese lignite during fluidized-bed drying in nitrogen and air. Fuel Process Technol. 2012;101:85–93.

Li B, Chen G, Zhang H, Sheng C. Development of non-isothermal TGA-DSC for kinetics analysis of low temperature coal oxidation prior to ignition. Fuel. 2014;118:385–91.

Xie J, Xue S, Cheng W, Wang G. Early detection of spontaneous combustion of coal in underground coal mines with development of an ethylene enriching system. Int J Coal Geol. 2011;85:123–7.

Ozbas KE, Kök MV, Hicyilmaz C. DSC study of the combustion properties of Turkish coals. J Therm Anal Calorim. 2003;71:849–56.

Li L, Jiang D, Beamish BB. Calculation of ignition times under adiabatic conditions by activation energy. J China Coal Soc. 2010;35:802–5.

Beamish BB, Barakat MA, George JDS. Spontaneous-combustion propensity of New Zealand coals under adiabatic conditions. Int J Coal Geol. 2001;45:217–24.

Guo Z, Bai Z, Bai J, Wang Z, Li W. Synergistic effects during co-pyrolysis and liquefaction of biomass and lignite under syngas. Prog Energy Combust Sci. 2015;119:2133–40.

Deng J, Wang K, Zhang Y, Yang H. Study on the kinetics and reactivity at the ignition temperature of Jurassic coal in North Shaanxi. J Therm Anal Calorim. 2014;118:417–24.

Meriste T, Yörük CR, Trikkel A. TG–FTIR analysis of oxidation kinetics of some solid fuels under oxy-fuel conditions. J Therm Anal Calorim. 2013;114:483–9.

Acknowledgements

Financial support for this work was provided by two key projects of the National Natural Science Foundation of China (Nos. 51134019 and 5150418), and the Natural Science Foundation of Shaanxi Province (CN) (No. 2014JM7276) is also gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, C., Yang, Y., Tsai, YT. et al. Spontaneous combustion in six types of coal by using the simultaneous thermal analysis-Fourier transform infrared spectroscopy technique. J Therm Anal Calorim 126, 1591–1602 (2016). https://doi.org/10.1007/s10973-016-5685-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5685-2