Abstract

The paper deals with the thermally stimulated discharge current (TSD or TSDC) method; exclusively with the short circuited one. Because of its low effective frequency, TSD has excellent resolving power. Problems both of measurement and of the evaluation are analyzed. The effects of experimental circumstances and theoretical considerations are demonstrated by results on different polymers and model calculations as well. In order to get reliable results, the sample preparation must be performed carefully. It is particularly valid in case of solution cast samples. The depolarization curve of a real polymer is always complex, consisting of superimposed relaxation processes. This fact causes unexpected problems in the evaluation. Heating rate slightly affects the peak separation; however, high heating rate might produce thermal inhomogeneity in the sample.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The behavior of polymers is determined by relaxation processes; therefore, investigation and understanding these processes are essential. Reversed behavior of polymers makes possible the determination of these processes.

Even in homopolymers of simple structure, different relaxation processes running simultaneously making the analysis of experimental results difficult. For example, α relaxation (glass transition) assigned to main-chain segmental motion, the β relaxation assigned to side-chain motion and further short-distance conformational motions. The picture is much more complicated if the material is complex; e.g., a copolymer, a polymer blend or plasticized one. The components might influence each others mobility.

These processes can be investigated in mechanical field; thermo-mechanical analysis (TMA), dynamic mechanical analysis (DMA), thermally stimulated creep (TSC); in electric field, dielectric thermal analysis (DETA), thermally stimulated discharge (TSD) and by thermal properties, differential scanning calorimetry (DSC).

Brief description of the experimental technique and evaluation

Keeping a polymer sample (or any insulating material) in an electric field it causes its particles to become oriented into the direction of field. This process accumulates electric charge. The higher is the field the greater is the probability of this orientation. Therefore, the polarization and the depolarization current are proportional to the polarizing field up to very high fields [1, 2].

Removing the field, e.g., by short circuiting, the particles re-orient; the charges generate current. Hindering the re-orientation by cooling the sample in the field, the polarization remains. Such a permanently polarized material is called electret. One of the first descriptions of permanent polarization is related to Eguchi [3, 4] who produced electret from rosin and carnauba wax mixture in 1919.

The method was first used for inorganic materials. Cowell and Woods [5] investigated CdS crystals and described the depolarization process. These equations are valid for polymers, too.

Comprehensive work of van Turnhout [6] is one of the most known descriptions of the theory of the TSD method.

Heating up the sample, the particles get reoriented; because of the short circuit, the external field is zero. The accumulated charges generate the depolarization current acquired as a function of temperature or time. The depolarization process gives information about the mobility of particles, molecular groups and structural units.

The schematic arrangement of the instrument is shown in Fig. 1; the time-run of the process in Fig. 2 [7] explains the steps of the experiment.

Scheme of a short-circuit TSD experiment (t time, T temperature, E electric field, I current). The sample is polarized under E field at T p polarizing temperature for a certain t p period then cooled down. #1 is the conductive, #2 is the polarization current. Reaching the T 0 initial temperature the electric field is turned off, the sample is short circuited and heated by a b heating rate, while the #3 depolarization current is acquired

Both the polarization and the depolarization are controlled by the relaxation processes characterized by the τ relaxation time. The relaxation time is temperature-dependent and can be described well by the Arrhenius law (Eq. 1) in a not too broad temperature range.

where τ 0 is a pre-exponential factor (formally the relaxation time at infinite temperature), A is the energy of activation, R is the gas constant.

The time function of the polarization at T temperature is:

where P 0 is the equilibrium polarization at E field and T temperature.

If P polarization exists in the material placing it into zero field (short circuited), the polarization decays by

P 0 is here the polarization at t = 0.

The depolarization current density (Eq. 4) is the first derivative of Eq. (3).

Because the temperature is a linear function of time during the depolarization experiment

the remaining polarization at t time is:

the depolarization current:

or considering Eq. (5), as function of temperature:

Differentiating Eq. (8), the condition of current maximum is:

In case of Arrhenius type relaxation time temperature function (Eq. 1), the relaxation time at the temperature of current maximum is:

τ 0 can also be easily calculated by Eq. (11)

In order to describe the depolarization process, the value of energy of activation is needed.

From Eqs. (8) and (1), the current of an individual relaxation process is:

Substituting A/RT ≡ s and integrating, the following convergent series is obtained:

Because the external field is zero during depolarization, the obtained current is algebraic sum of currents originating from overlapping processes.

Determination of relaxation strength

The relaxation strength (Δε) represents the relative permittivity difference from the beginning, and the end of a transition can be calculated from the surface charge density. It is independent of the sample geometry, the polarizing field and the heating rate; therefore, it is suitable for characterization of the intensity of the process.

The surface charge density is:

where \(\mathcal{A}\) is the electrode area; Q is the full charge of a transition and can be determined by integration of current by time.

ε 0 is the permittivity of vacuum.

More detailed deduction can be found in [7, 8].

Determination of energy of activation

Initial rise method

Because, at starting of depolarization, the value of the integral is zero, the initial part of the process, up to about 10% of maximum theoretically, can be described as:

where c is a constant and the A energy of activation can be determined from the slope of the ln(j) − 1/T.

Heating rate method

Testing the same sample at different b heating rates the current maxima shifts to higher temperature if the b is higher. Energy of activation can be calculated as [9]:

Although the procedure is exact, at least three measurements are necessary using different heating rates. As it is demonstrated in the following paragraphs, this method is extremely sensitive to errors during the determination of peak positions.

Peak width methods

A current peak of a transition having single relaxation time is demonstrated in Fig. 3. From the half width of the peak, the energy of activation can be calculated with the equation below [9]:

where ΔT is T u – T l. The practical problem is that the transitions of overlapping processes make impossible the determination of half widths. Because the shape of the depolarization current peaks in Arrhenius representation depends on the energy of activation only as shown in Fig. 4, both the upper half and the lower half are suitable for determination of it. Using the equations below, the energy of activation can be determined [7].

From the full peak:

from the lower half:

and from the upper half:

Determination of effective frequency

The TSD is a quasi-static method but can be characterized by so-called effective (or equivalent) frequency [7].

The effective frequency is usually below 10−3 Hz (see Table 1).

Experimental

Apparatus

Two instruments were used for polymer tests in this paper.

Instrument 1 The older measurements were taken with the DDS unit of Unirelax built by Műanyagipari Kutató Intézet (Research Institute of Plastics, Budapest) [10] and using a polarizing supply designed and assembled by the author.

Electrometer | 0.1 pA to 1 mA |

Temperature range | −150 to 250 °C |

Sample size | 53-mm diameter, |

0.05–1-mm thickness | |

Electrode size | 38-mm diameter (11.3 cm2) |

Heat transfer | metal block |

Cooling | liquid nitrogen |

Cooling and heating rate | 1 K min−1 fixed |

Polarizing voltage | 60 V to 3 kV |

Instrument 2 The new instrument is a Setaram TSC II with a home made sample holder of 4 times larger area than the standard accessory.

Electrometer | 0.1 fA to 20 mA |

Temperature range | −150 to 350 °C |

Sample size | 26-mm diameter |

Electrode size | 18-mm diameter (2.545 cm2) |

0.02–1-mm thickness | |

Heat transfer | helium |

Cooling | liquid nitrogen |

Cooling and heating rate | 0.1–20 K min−1 |

Polarizing voltage | 0–500 V |

Representation of TSD curves (spectra)

Because the result of a TSD measurement is a function of current against temperature, it is the usual representation. In order to make comparable results, normalization is suggested, i.e., transforming the raw curves to equal electrode area and electric field. Choosing these data is arbitrary. In this paper, all results were transformed to a field of 1 kV mm−1 and 30 cm2 electrode area by a computer program compiled for evaluation of TSD results [7]. The model calculations were also made with this program. Although the program is capable for different graphical representation of results (e.g., logarithmic, Arrhenius), figures are plotted from its listed outputs by a standard graphical software.

Electrode area and field independent representation are also possible. Calculating

the result is formally conductivity therefore called dielectric conductivity. Its unit is S m−1. Although this depends on the heating rate only, because of very small numbers (in range of 10−18–10−12 S m−1) is inconvenient.

Materials

Several polymers were studied; all of them are in form of thin film of 0.1–1-mm thickness. The materials and the preparation methods are described as figure legends.

Effects of experimental conditions

The depolarization process may be affected by unknown or unexpected circumstances, such as thermal irregularities, contaminations, the electrode material and contact; moreover, the evaluation methods might be sensitive to minor measuring errors. These effects are analyzed in the followings.

Effect of thermal irregularity

Measuring material properties as a function of temperature, the uniformity of temperature is always a question; one must consider the irregular thermal distribution within the specimen.

Let us assume that the temperature sensor is placed at the midpoint of the sample and the temperature differs between the sensor and rim of the sample; additionally, the temperature profile is linear. In this case, Eq. (25) is valid, so the depolarization current for disk shaped sample is:

where \(T^{{\prime }}\) is the temperature at r radius.

Figure 5 shows in solid line the depolarization peak of a transition calculated with peak position 20 °C, peak current 100 pA, energy of activation 100 kJ mol−1, and in dashed line the numerical solution for the following conditions: Electrode diameter is 18 mm; the temperature difference between the sensor and the rim is 5 °C. So \(T^{{\prime }}\) = T + 5/9r gave the result shown in dashed line.

Effect of heating rate

The depolarization current can be described by Eq. (13) equation only if the heating rate is rigorously fixed.

The higher is the heating rate, the higher is the depolarization current because the stored charge is the same. It makes the measurement and the evaluation easier; the depolarization curve is less noisy. However, keeping the linear ramp is more difficult at higher rates; there is a danger of thermal inhomogeneity in the sample and the heating rate also affects the resolving power.

As the energy of activation can be determined from the shift of peak position using different heating rates (Eq. 18), the peak position can also be calculated at different heating rates if the energy of activation is known.

Two depolarization processes, i.e., transitions were taken for model calculations demonstrating the effect of heating rate:

#1 | Relaxation strength: 2; |

|---|---|

Energy of activation: 100 kJ mol−1; | |

Peak at 1 °C min−1: 40 °C; |

#2 | Relaxation strength: 3; |

|---|---|

Energy of activation: 200 kJ mol−1; | |

Peak at 1 °C min−1: 50 °C; |

The calculations were run with 0.1, 1 and 10 °C min−1 heating rate, respectively. The data of the transitions are summarized in Table 1.

Increasing the heating rate, the temperature of the maximum also increases. The higher is the energy of activation, the lower is the shift.

The sums of the individual current peaks, i.e., the calculated curves are plotted in Fig. 6. For sake of ease of comparison, current values are divided by the heating rate. In case of 0.1 °C min−1, the result shows undoubtedly two peaks. In case of 10 K min−1, the difference between the maxima is 1.1 °C; only, the peaks are completely overlapped.

Calculated depolarization current curve of two simultaneous processes divided by the heating rate. Thin lines show the relaxation times. #1 100 kJ mol−1, relaxation strength 2; #2 200 kJ mol−1, relaxation strength 3; solid line 0.1 K min−1; long dashed line 1 K min−1; short dashed line 10 K min−1. Detailed data are summarized in Table 1

The two thin lines in Fig. 6 show the relaxation time versus temperature functions for each transition. It must be independent of the heating rate.

The depolarization current almost proportionally increases by the heating rate; however, it increases the chance of higher thermal gradient in the sample.

Low heating rate apparently increases the resolving power; according to Eq. (23), the effective frequency is low. However, in peculiar case, the effect could be even reversed; overlapped peaks split at higher heating rate.

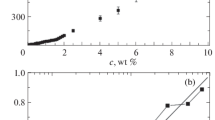

Determination the energy of activation by heating rate method

Equation 18 is theoretically suitable for determination of energy of activation. Unfortunately, it is very sensitive to uncertainty of peak position. Figure 7 shows the test result on rigid PVC with different heating rates; Fig. 8 the peak positions. Let us suppose that the peak position of high peak is exactly 92 °C at 1 °C min−1 heating rate. Calculating the energy of activation from read value at 5 °C min−1, we obtain 330 kJ mol−1. Considering the uncertainty, the readout is about ±0.5 °C; the energy of activation was calculated varying the peak position. The result is shown in Fig. 9. Even a few tenth of centigrade caused significant deviation.

Peak positions of PVC transitions at different heating rates from Fig. 7

It must be mentioned that pyroelectric effect can also occur in case of PVC as demonstrated by Broadhurst et al. [11] and might cause shift in peak position.

Effect of solvent residuals

Polymer film test specimens are often prepared by solution casting [12]. The standard method for removal of solvent is drying the film until constant mass. The drying is usually continued in vacuum. Unfortunately, solvent traces always remain in the polymer and modify the relaxation process. Figure 10 shows the results on unmodified rigid PVC. It must be mentioned that the gold electrodes were sputtered in vacuum of 0.05 hPa; the solvent residuals still not liberated and did not degraded the vacuum. One must reckon with the effect of solvent and a decreased transition temperature. Split transitions might merge because of the mutual solvent interaction.

Depolarization current curve of PVC K = 58. Heating rate 5 K min−1, polarizing field 500 V mm−1 (instrument 2). A roll-milled at 180 °C; B powder, compression molded at 175 °C; C cast film from 5 g 100 mL−1 THF solution, dried and vacuum dried at room temperature; D THF cast film after 2 days extraction with methanol

Effect of electrode contact

The short-circuit TSD method supposes the external field is zero; the whole electrode is in metallic contact with the specimen. In case of rigid materials at the surface, small surface roughness might form local air gaps. For modeling purposes, air gaps of 6.2 µm were made by spacers on the 1/3 area of the electrode. The result is increased noise as shown in Fig. 11. The noisy curve can be obtained not only as consequence of incorrect electrode contact but because of the coarse inhomogeneous structure of the specimen.

Effect of electrode material

Best solution of making electrodes is metalizing either by high temperature evaporation or by sputter coating. According to my experience, gold and silver can be used with equal result. Conductive paints can also be used, but the solvents of these paints must be considered. For nonpolar materials, aqueous graphite is useful and cheap. For water soluble materials (e.g., polysaccharides), the silver-based Leitsilber paint is preferable.

Limits of the initial rise method

The initial rise method seems to be the simplest procedure to determine the activation energy of a relaxation transition. Plotting the depolarization current in Arrhenius plot, i.e., plotting the natural logarithm of current against inverse temperature, the initial part of a transition is linearized according to Eq. (17). It is valid only if there are no other processes in the temperature range tested. This condition is fulfilled in case of thermally stimulated luminescence [13], but TSD curves contain several simultaneous processes.

One of our most regular TSD measurements is the test on nitrile rubber, a random copolymer of butadiene with 33% acrylonitrile. The curve contains three processes signed by 1, 2 and 3 in Fig. 12. One and 2 are regular relaxation processes; process 3 has no maximum in the tested temperature range. Energy of activation was determined from the half widths by Eq. (21) for process 1 and by Eq. (22) for process 2.

Depolarization current curve of 33% acrylonitrile containing nitrile rubber. Instrument 1; 1 K min−1. Electrode: silver paint; polarization temperature: 100 °C thin dotted lines: resolved peaks (Data in Table 2)

The Arrhenius plot in Fig. 13 shows that only process 3 can be considered as initial rise, the fitting of linear is precise. The initial rise method can be used for the calculated transitions of 1 and 2; the obtained values are reproduced within acceptable error. The question mark indicates that fitting a linear function to the initial part of the transition on measured curve is questionable.

Arrhenius plot of the depolarization current in Fig. 12 measured: solid line; resolved peaks: dashed lines; fitted initial rise: thin dotted lines

Effect of polarizing temperature

The polarization in the material at T p temperature depends on the polarization time and on the relaxation time according to Eq. (2). To approach the P 0 equilibrium polarization by 1% accuracy, the polarization time must be at least 5 times longer than the relaxation time at T p temperature. Therefore, proper selecting the polarization temperature and time is essential for the evaluation of TSD curves. It is particularly important in case of multiple transitions near to each other. Unfortunately, there are several publications using low polarizing temperature making conclusion about the process well over the polarizing temperature [2]. Figure 14 shows the result on rigid PVC using different polarizing temperatures. PVC has two well separable transitions in the glass transition range. Lowering the polarizing temperature to 100 °C ,the higher peak becomes indiscernible because of lowered intensity. At 80 °C polarizing temperature, this peak completely disappeared but the peak of lower temperature seems still unchanged. At 60 °C, polarizing temperature even the lower peak is severely distorted and is not suitable for determination of parameters any more.

Application examples

The method is suitable for investigation of copolymers and polymer blends [12]. The separation of segmental motion in block copolymers is much better than using DMA [8].

Impact modified plastics are multiphase systems; both the phase structure and the interfacial layer are sensitive to the processing history. The structural changes during processing can be followed by TSD; the results allow assessing the impact properties [14, 15].

Because of the excellent resolving power fine structural changes can be studied. Even plasticized PVC proved to be inhomogeneous materiel, the distribution of plasticizer depends on the thermal history of material [16]. These irregularities can not be detected by DMA.

Natural polymers, e.g., pectin, guar gum, gelatin [17], leaf powder containing biocomposites [18] can also be tested. Natural-based polymer, namely ethyl cellulose, was tested by Gaur et al. using corona charging [19] as polarization method.

Chebli et al. [20] tested unsaturated resins, and curing kinetics was determined from the TSD results. For research of polymer nanocomposites, the method proved to be also useful. Polycarbonate-based nanocomposites were studied by Rathore et al. [21] and PVDF barium titanate systems by Gaur [22].

Conclusions

TSD is an excellent tool for studying the relaxation processes in polar polymers. In order to make the most of the method, the experimental conditions must be carefully designed.

In order to get comparable curves, normalization of current values to constant area and electric field are suggested. For comparing peak intensities, relaxation strength is a useful value.

Using solution cast samples, the residual solvent must be considered. Drying to constant mass is not enough in most cases. Likewise, using solvent-containing electrode material (conductive paint) might interact with the sample.

Some polymers are heat sensitive, but the polarizing temperature must be high enough to build up the equilibrium polarization of the process, higher than the descending part of the current peak. Otherwise, the evaluation leads to incorrect results. Simply, it is not worth measuring over the polarizing temperature.

The method has inherently excellent resolving power. In case of suspected overlapped peaks, repeating the measurement with different heating rate is recommended.

High heating rate makes the method more “productive”; however, the high heating rate might cause thermal inhomogeneity in the sample. The applicable heating rate depends on the instrument, in particular on the specimen holder assembly. To low heating rate, worsen the signal-to-noise ratio.

The initial rise and heating rate methods are applicable only in case of “clean” transitions; complex TSD curves usually consist of several superimposed processes.

Abbreviations

- A :

-

Energy of activation (J mol−1; kJ mol−1; eV mol−1)

- \(\mathcal{A}\) :

-

Area (m2; cm2)

- b :

-

Heating rate (K min−1; K s−1)

- B :

-

Constant (–)

- C :

-

Constant (–)

- c :

-

Constant (–)

- G d :

-

Dielectric conductivity (Ω−1m−1; S m−1)

- E :

-

Electric field (Vm−1; kV mm−1)

- f :

-

Frequency (Hz)

- I :

-

Current (in general) (A)

- I d :

-

Depolarization current (pA)

- I m :

-

Peak current (pA)

- I r :

-

Reduced depolarization current (1 kV mm−130 cm2) pA

- g :

-

Thickness of air gap (m; mm)

- j :

-

Current density (A m−2)

- k :

-

Boltzman constant (1.3806 × 10−23 J K−1)

- l :

-

Thickness of the sample (m; mm)

- Q :

-

Eclectic charge (As; pAs)

- Q 0 :

-

Charge of a transition (pAs)

- P :

-

Polarization (As m−2)

- R :

-

Gas constant (8.314 J mol−1 K−1; 5.189 × 10−19 eV mol−1 K−1)

- s :

-

Assisting variable (–)

- t :

-

Time (s)

- T :

-

Absolute temperature (K)

- T 0 :

-

Initial temperature (K)

- T l :

-

Temperature of lower half (K)

- T m :

-

Temperature of the current peak (K)

- T p :

-

Polarizing temperature (K)

- T u :

-

Temperature of upper half (K)

- U :

-

Voltage (V)

- U p :

-

Polarizing voltage (V)

- x :

-

Distance (m; mm)

- ε :

-

Dielectric constant (F m−1)

- ε 0 :

-

Dielectric constant of vacuum (8.854 × 10−12 F m−1)

- ε r :

-

Relative dielectric constant (–)

- Δε :

-

Relaxation strength (ε r0 − ε r∞) here (σ/Eε 0) (–)

- ν :

-

Frequency (Hz)

- σ :

-

Charge density (As m−2)

- τ :

-

Relaxation time (s)

- τ 0 :

-

Pre-exponential factor (s)

- \(\vartheta\) :

-

Temperature in centigrades (subscripts are the same as in case of T) (°C)

- ω :

-

Angular frequency (rad s−1)

References

Dudognon E, Bernès A, Lacabanne C. Study by thermostimulated currents of dielectric relaxation through the glass transition in an amorphous polymer: poly(n-butyl methacrilate). Macromolecules. 2001;34:3988–92.

Mahrous SJ. Thermally stimulated current study of relaxation in pvc stabilized with zinc carboxilate. J Macromol Sci B. 1995;34(4):369–78.

Eguchi M. On dielectric polarization. Proc Phys Math Soc Jpn Ser. 1919;3:326–31.

Eguchi M. Further researches on permanently polarized dielectric. Proc Phys Math Soc Jpn Ser. 1920;3(2):169–76.

Cowell TAT, Woods J. The evaluation of thermally stimulated current curves. Br J Appl Phys. 1967;. doi:10.1088/0508-3443/18/8/302.

van Turnhout J. Thermally stimulated discharge of polymer electrets. Amsterdam: Elsevier; 1975.

Marossy K. Assessment of activation energies of transitions by thermally stimulated discharge current (TSD) experiments. Polym Bull. 1989;. doi:10.1007/BF00255214.

Marossy K, Deák G, Kéki S, Zsuga M. Thermally stimulated discharge (TSD) current and dynamic mechanical investigation of polyisobuthylene-polybuthylene terephtalate thermoplastic multiblock copolymers. Macromolecules. 1999;. doi:10.1021/ma981511x.

Hedvig P. Dielectric spectroscopy of polymers. Bristol: Hilger; 1977.

Yalof SA, Hedvig P. The combined electrical, thermal, mechanical analysis of the behavior of materials with unirelax. Thermochim Acta. 1976;17(3):301–18.

Broadhurst MG, Malmberg FI, Mopsik FI, Harris WP. Piezo- and pyro-electricity in polymer electrets; in annual report. In: Conference on electrical insulation and dielectric phenomena. 1972. p. 398–404 (ISBN 0309-02112-x)

Ahmed MT, Fahmy T. Distributed relaxations in PVC/PEMA polymer blends as revealed by thermostimulated depolarization current. Polym Test. 1999;18:589–99.

Karmakar M. On the initial rise method for kinetic analysis in thermally stimulated luminescence. Ind J Sci Technol. 2012;5(11):3674–7.

Marossy K. Thermally stimulated discharge current (TSD) study on PVC–CPE blends. Polym Bull. 1991;. doi:10.1007/BF00316910.

You F, Chen G, Zou J, Yang Z, Guo S. The experimental results and simulation of temperature dependence of brittle-ductile transitions in PVC/CPE blends and PVC/CPE/nano-CaCO3 composites. J Appl Polym Sci. 2012;. doi:10.1002/app.34662.

Marossy K. Thermally stimulated depolarization (TSD) current study of plasticized PVC. Polym Bull. 1998;. doi:10.1007/s002890050425.

Szóda K, Zsoldos G, Kollár M. Preparation and evaluation biofoil materials. In: Proceedings of XXX- microCAD conference miskolc. 2016. ISBN 978-963-358-113-1

Patel AK. Structural mechanical and electrical study of some polymer biocomposite film. Indian ETD repository. 2013. p. 101–83. http://hdl.handle.net/10603/10198. Accessed 28 Oct 2014.

Gaur MS, Singh R, Singh PK, Indolia AP, Singh R. The effect of annealing time on thermally stimulated discharge current of corona-charged ethyl cellulose. J Therm Anal Calorim. 2011;103:679. doi:10.1007/s10973-010-1010-7.

Chebli K, Marais S, Saiter JM, Pardo E, Grenet J, Metayer M. Relaxation in unsaturated polyester resins studied by thermally stimulated depolarization currents. J Therm Anal Calorim. 2000;62:657. doi:10.1023/A:1012065122936.

Rathore BS, Gaur MS, Singh KS. Investigation of thermally stimulated charge relaxation mechanism in SiO2 filled polycarbonate nanocomposites. J Therm Anal Calorim. 2012;107:675. doi:10.1007/s10973-011-1624-4.

Gaur MS, Singh PK, Ali A, Singh R. Thermally stimulated discharge current (TSDC) characteristics in β-phase PVDF–BaTiO3 nanocomposites. J Therm Anal Calorim. 2014;117:1407. doi:10.1007/s10973-014-3908-y.

Acknowledgements

The research was supported by the TÁMOP 4.2.1.B-10/2/KONV-2010-0001 Grant.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Marossy, K. Practical approach to thermally stimulated discharge (TSD) method on polymers. J Therm Anal Calorim 129, 161–170 (2017). https://doi.org/10.1007/s10973-017-6098-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6098-6