Abstract

The research on development of nanodielectric material is the requirement of capacitor industry. The polymeric material could not have a high dielectric constant due to limitation of structure and physical properties. However, combination of suitable nanofiller can increase the dielectric constant several times. We have reported the dielectric properties of polysulfone + ZnO nanodielectric system. The dielectric properties are observed to be governed by dipolar polarization fully and interfacial polarization partially. The relaxation time of dipoles is quite high: It means that nanodipoles have sufficient relaxation time to orient in the direction of field. Interface provides additional trapping level for storage of charge carriers energetically. The permittivity of new material increases many times of base material even at lower concentration of fillers.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

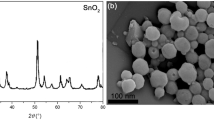

Introduction

Dielectric spectroscopic studies are very useful to understand the concept of intermolecular solute–solute interaction and solute–solvent interactions along with their molecular conformations [1]. Every day demand of insulating material is increasing which are highly efficient electric machine, electric insulation systems are subjected to electric, mechanical with greater intensity and higher recitation rate [2]. Therefore, the insulation materials with super electrical insulating properties, good mechanical properties, and high-temperature durability are required in high-tech electrical machines [3]. Organic–inorganic nanocomposites have attracted much attention because they combine the flexibility and processability of organic components and the durability and thermal stability of inorganic components [4–11]. In addition to the enhancement of the optical, structural, and mechanical properties and thermal stability [8–11], a remarkable improvement is also observed by the researcher in dielectric constant or relative permittivity after incorporation of different types of nanofillers in polymer matrix [12]. A polymer nanocomposite (PNC) provides more advantages than micron-sized filled polymer nanocomposites because it provides resistance to degradation. Polymer nanocomposites with better electrical and dielectric properties are slowly emerging as an excellent functional material for dielectric and electrical insulation properties. Although the technology of addition of nanofillers in polymers to enhance a particular dielectric property has been in existence from several decades [13, 14], polymer nanodielectrics, designed with high permittivities and low dissipation factors, will find applications as dielectrics in capacitors and transmission lines to be used in communications equipment, computers, and space power systems [15, 16]. The amount of charge stored in polymer nanodielectric capacitors is controlled by the dielectric properties of the films employed. The total energy density that can be stored in a capacitor is directly proportional to the dielectric constant so as much higher dielectric constant will be, the material will have a good amount of application in industries. Polysulfone (PSF) is a high-performance polymer with excellent chemical and thermal stabilities [17]. It is one of the thermoplastic polymers. These thermoplastic, amorphous, and rigid polymers offer useful physical, mechanical, and electrical properties which are maintained over a broad temperature range, due to their morphological structure. It has a good thermo-oxidative stability and flame retardancy, so it is a superior replacement of polycarbonate [18, 19]; polysulfone provides a resistance to high temperature, acts as a flame retardant without compromising its strength that usually results from addition of flame retardants, and is used as a dielectric in capacitors [20]. ZnO one of the multifunctional inorganic nanoparticles has drawn increasing attention of many researchers in recent years due to its significant physical and chemical stabilities, high catalysis activity, and intensive ultraviolet and infrared adsorption [21]. Therefore, ZnO nanoparticles could improve the properties of polymer matrix. However, ZnO nanoparticles, like other nanoparticles, possess high surface energy, which could be dispersed in organic solvent and matrix. Therefore, it is necessary to prepare ZnO/polymer nanodielectric to prevent the formation of agglomerated nanoparticles. The nanocomposites can improve the dispersion stability of ZnO and increase interfacial adhesion between the polymers and ZnO nanoparticles [22–24]. To design polymer nanocomposites, the several nanomaterials such as carbon nanotubes, inorganic nanoparticles, clay minerals, and biomaterials have been used for two decades to improve mechanical, thermal, transport, optical, and electrical properties. The nanodielectrics prepared by solution method have attracted great interest since they exhibited controllable dispersion and controlled uniform thickness of thin film. By the combination of these two dissimilar materials, material scientists have long appealed to develop novel nanodielectric material for energy storage device and supercapacitor. Therefore, in this study ZnO nanofiller-filled PSF nanodielectrics were used to investigate the frequency- and temperature-dependent dielectric relaxation process over the frequency range of 500–105 Hz and temperature range from 30 to 210 °C.

Experimental

Material

Polysulfone (PSF) used in the present study was procured from Polyscience, and ZnO nanoparticle of size less than 100 nm was procured Sigma-Aldrich, New Delhi, India. The analytical-grade N,N-dimethylformamide (DMF) (Merck) was used as a solvent.

Sample preparation

All the samples of pristine polysulfone (PSF) and ZnO-filled PSF nanocomposites were prepared by using the sol–gel technique with different mass% (3, 5, and 10 mass%) of nanoparticles. The 5 g PSF was dissolved in 50 mL of N,N-dimethylformamide (DMF) and then kept for 8 h on magnetic stirrer to obtain a homogeneous and transparent solution at 40 °C. The optical glass plates are slowly drawn from solution and kept in oven at 60 °C for a period of 1 h. The solvent was then evaporated to yield circular thin film shape. The thin films were further dried at room temperature without gassing of 10−5 torr for a further period of 24 h to remove volatile residual solvent. The ZnO of certain amount was dissolved in 20 mL of N,N-dimethylformamide (DMF) and added drop by drop in solution of PSF for the preparation of PSF + ZnO nanocomposite samples of different mass%. The nanocomposite samples could be easily peeled off from glass plate following the method stated above.

Characterization

The samples were vacuum-aluminized over the central circular area of 1.4 cm diameter using high-vacuum coating unit (Vacuum Equipment Company Ltd, Noida, India) for the dielectric measurements. The dielectric relaxation measurements were made using Hioki 3532-50 LCR Hi-TESTER. It provides 42 Hz to 5 MHz, for measurements with precise ±0.08 % basic accuracy with most rapid measurement time of 5 ms. The signal level can be set over a wide range, from 10 mV to 5 Vrms and from 10 µA to 100 mA (up to 1 MHz). The sample was sandwiched between two brass-plated stainless steel electrodes. The assembly was placed in a thermostatic furnace, and the temperature was measured with digital multi-thermometer (CE Company, New Delhi, India). The different dielectric measurements (i.e., tangential loss (tan δ ), dissipation factor (D), capacitance (C p), and conductance (G) for PSF and PSF + ZnO nanocomposite samples) were taken with pristine, and different mass% (3, 5, and 10 mass%) of ZnO were carried out in the frequency range 500 to 105 Hz at different temperatures (i.e., 30, 60, 90, 120, 150, 180, and 210 °C). The experimental data have been used to evaluate the various dielectric parameters, i.e., permittivity, tangential loss, AC conductivity, dielectric relaxation, and electrical modulus. All these parameters are essential to understand the charge transport mechanism and utility of material for several industrial applications.

Results and discussion

Frequency-dependent dielectric parameters

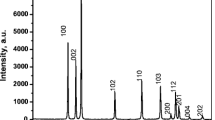

Permittivity

The variation of dielectric permittivity with frequency for the polysulfone (PSF) nanocomposites having ZnO nanofiller at different mass% is shown in Fig. 1. It shows the typical dielectric permittivity (ɛ r) of PSF/ZnO nanocomposite as a function of frequency with different mass% concentration of ZnO nanofillers at different temperatures. It has been observed that dielectric permittivity of polysulfone (PSF)/ZnO nanocomposites increases with filler concentration in polymer matrix. The increased dielectric permittivity is due to the trapping of charges at the extended interface which normally results in increased conductivity and higher loss [25]. This behavior could be explained on the basis of the Coulomb blockade effect. The Coulomb blockade effect or single-electron charging effect, which allows for the precise control of small numbers of electrons, provides an alternative operating principle for nanometer-scale devices.

Various structures have been made in which electrons are confined to small volumes. Perhaps not surprisingly, there is a deep analogy between such confined electrons and atoms [26]. Such regions with only dimensions of 1–100 nm and containing between 1000 and 1,000,000 nuclei are referred to as ‘nanoregions’, ‘artificial atoms’, or ‘solid-state atoms’ [27]. This nanoregion corresponds to the size of embedded nanoparticles in a polymer matrix. Charging of this region is equivalent to single-electron charging; therefore, development of dielectric material by this method can be very useful for embedded capacitor. It is found that the dielectric permittivity measured at a lower frequency is always greater than at higher frequency [28]. We have observed that there is a significant increment in the permittivity with increasing mass% of nanofiller in polymer. The permittivities of the pristine PSF as well as nanocomposites are rapidly decreasing up to 10 kHz, and after that permittivities are marginally reduced with increasing frequency over the range of 10–100 kHz due to the reduction in the polarization caused by the dipolar groups [29, 30]. The frequency dependence of dielectric study indicates that at 30 °C, dielectric constant of the PSF ranges from 6.2 to 9.3 at 10 mass% of ZnO nanofiller in polymer matrix. Similarly, the dielectric constant increases at 90 and 120 °C from 15.89 to 28.06 and 32.20 to 54.37, respectively. This increasing nature of the dielectric constant with ZnO nanofiller indicates that the number of polar groups increases due to the incorporation of filler in polymer, and it grows with the concentration which causes an extra polarization under electric fields. Another interesting observation is that dielectric spectra with 3 mass% are found to be lower than those of the pristine PSF in the entire frequency range as shown in Fig. 1 at 180 °C. For only 5 and 10 mass% ZnO nanocomposites, the effective dielectric spectra are higher than those of pristine PSF. A similar observation of lower permittivity in polymer nanocomposites was also reported for TiO2-filled epoxy polymer nanocomposites and other composites [31, 32].

The reduction in dielectric permittivity for 3 mass% ZnO with PSF polymer matrix may be possible because the polarization process in the nanocomposites is curtailed. The decrease in dielectric constant with frequency is the expected behavior in most of the dielectric materials [33, 34]. It could be seen that frequency-dependent permittivity is comparatively high near glass transition temperature (180 °C) because of increase in chain mobility. In general incorporation of nanoparticle significantly changes the permittivity because nanoparticles in polymer matrix distort and enhance the local electrical field due to difference in the dielectric constants or electrical conductivities between the particles and the polymer. This behavior also occurs due to dielectric relaxation which is the cause of anomalous dispersion, and this relaxation process involves the orientational polarization which in turn depends upon the molecular arrangement of the nanodielectric material. Therefore, the rotational motion of molecules of dielectric material is not sufficiently fast for the attainment of equilibrium with field at higher-frequency range. Thus, dielectric constant seems to be decreasing with increase in the frequency range as shown in the Fig. 1. The addition of nanofiller results in overall increase in dielectric constant due to both dipolar and free charge contributions. So the increase in the molecular mobility is reflected by increase in free charge mobility.

Tangential loss

Figure 2 shows the variation of tangent loss with frequency of PSF nanocomposites with different mass% of ZnO nanofiller at different temperatures (i.e., 30, 90, 120, and 180 °C). Tangential loss (tan δ) depends on the electrical conductivity of the polymer nanocomposites and electrical conductivity in turn depends on the number of charge carriers in the bulk of material, the relaxation time of the charge carriers, and the frequency of the applied field. At 30 °C the tangential loss is decreasing with increase in the mass% concentration as well as increase in the frequency, whereas tangential loss spectra at 90 and 120 °C are characterized by peaks appearing at the characteristics frequency for the PSF as well as PSF nanocomposites. These peaks suggest the presence of relaxing dipoles in the bulk of samples. The strength and frequency of relaxation depend on the characteristic properties of dipolar relaxation. The tangential loss at 120 °C shows that peak is shifting toward the higher-frequency side. The shifts of peak toward higher frequencies are due to addition of relaxing dipoles and increases in conductivity.

The tan δ marginally increased with increase in the frequency with occurrence of a peak around the 5 × 103 Hz and then slowly starts to decrease beyond it. However, at 180 °C PSF and PSF nanocomposites do not show any peak. Figure 2 shows that with ZnO-nanofilled polymer nanocomposites, the value of tan δ is less than that of unfilled polymer matrix for all filler concentrations. Usually, the introduction of inorganic fillers into polymer matrix enhances the tan δ values of the polymer nanocomposites as there is an enhancement in the sources of charge carries in the nanocomposites samples [35].

AC conductivity

Frequency dependence of AC complex conductivity is expressed by the relation \( \sigma^{*} = \sigma^{\prime } + j\sigma^{\prime \prime } \), where \( \sigma^{\prime } \) ac conductivity term which is frequency-dependent function and \( \sigma^{{\prime \prime }} \) is the dc conductivity, i.e., the conductivity which is independent from the frequency. Frequency-dependent conductivity, i.e., σ a.c. has been calculated by the relation

where ω = 2πf. Figure 3 shows the variation of AC conductivity of PSF and PSF/ZnO nanocomposites with frequency at different temperatures.

A typical universal dielectric response is that at low frequencies, the bulk ac conductivity is frequency independent, but at higher frequencies the ac conductivity increases and follows the power law behavior [36] σ(ω)αω n. The observed behavior of nanocomposites is considered to be incompatible with conventional Debye behavior, the distribution of relaxation times, and stretched exponential approach. It is important that any proposed model for the universal dielectric response must also explain its commonality, and for this reason random resistor–capacitor (R–C) networks have been recently examined in heterogeneous system [37–39]. The R–C network is developed in PSF–ZnO nanocomposites, which represent a nanostructure that contains both dielectric (the capacitor) and conductive regions (the resistor). For PSF/ZnO nanocomposites, the disorder is on a small-scale whereby mobile oxygen vacancies are distributed in the insulating PSF host.

The general trend of the conductivity is to increase according to increase in frequency. The ac conductivity spectra show increasing behavior of the ac conductivity with increase in the frequency with filler concentration at different temperatures. It is well known that electrical conductivity of polymer nanocomposites material is governed by the polymer chain dynamics and mobility of charge carriers. When the frequency is increased, mobility of polymer chains is increased and the fraction of free volume in polymer nanocomposites is also increased due to which ac conductivity of PNC’s increases. The increase in conductivity after incorporation of nanofiller accounted for the increase in the number of dipoles, due to the modification of trap structure introduced by the addition of ZnO nanofiller. Figure 4 shows variation of ac conductivity of nanocomposites with different mass% of ZnO nanofiller at 30 and 180 °C at different frequencies. It is very clear from the characteristics that at lower and higher temperatures, conductivity is gradually increasing with concentration and it does reflect a significant increment with frequency. As temperature reaches 180 °C, conductivity of nanocomposites will increases. It is found from the Fig. 4 that at 30 °C for pristine PSF at 20-kHz frequency, conductivity is 3.61 × 10−7 S m−1 and PSF with 10 mass% ZnO provides 5.55 × 10−7 S m−1. However, at 180 °C pristine PSF at 20-kHz frequency gives 1.56 × 10−5 S m−1 and PSF with 10 mass% gives 2.03 × 10−5 S m−1. It indicated that at higher temperature, number of free charge carrier increases due to incorporation of nanofiller. This enhancement in the conductivity with increasing amount of ZnO nanofiller concentration also may be possible due to the larger amount of nanofillers in polymer matrix due to which inter-particle distance are less and particles might be in contact, which enhances the probability of charge carrier’s transfer which provides a possibility at different concentrations of nanofiller that there may be an overlapping of the interfacial zones in the nanocomposites leading to the percolation of charge carries. This overlapping of the interfacial zones depends on the dispersion of nanoparticles in the polymer matrix. This increased behavior of the conductivity also justifies the good dispersion of the nanofiller in polymer matrix.

Dielectric relaxation

The dielectric relaxation is the exponential decay with time of polarization in the dielectric. The relaxation time (τ) may be defined as the time in which this polarization is reduced to 1/e times its original value, e being the natural logarithmic base [40]. Basically the relaxation time is the cause of anomalous dispersion in which the dielectric constant decreases with increase in frequency. Figure 5 shows the change in relaxation time increasing with frequency at different mass% of ZnO nanofiller. Figure 6 is clearly indicating the exponential decay with respect to frequency. It is very clear from the relaxation spectra (Fig. 5) that the relaxation time (τ) for all nanoparticle-filled polymer nanocomposites is less than that of the pristine polysulfone (PSF). It is also found from spectra that at the room temperature, i.e., 30 °C, the relaxation is of the order of 10−7, whereas at 180 °C the order of relaxation time increases to the order of 10−6. The increased value of relaxation time (τ) with temperature may be due to the intermolecular interaction of ZnO nanofiller with polysulfone (PSF) molecules as well as increase in free volume. This behavior clearly shows the good interaction of ZnO nanofiller with polysulfone (PSF) matrix.

Electrical modulus

In dielectric study, for the electrode polarization effect and to resolve the low-frequency relaxation, electrical modules formalism is used for the study of dielectric relaxation, and it is used to study electrical relaxation phenomenon in many polymers. Figures 7 and 8 show the real part M′ and imaginary part of M″ of the complex electric modulus of the PSF and ZnO-filled PSF nanocomposites with different mass% of ZnO at different temperatures (30, 90, and 120 °C) were calculated by the following relation [41].

Figure 7 shows that electrical modulus of pristine PSF and PSF nanocomposites is gradually increasing with increase in frequency at various temperatures, but spectra of M ″ of pristine and PSF nanocomposites are showing sharp peak at 90 and 120 °C, but no any peaks are observed at 30 °C. The observed sharp peaks at 90 and 120 °C indicate the relaxation at higher-frequency side and show the fast symmetric crystalline relaxation almost the same attributes were also observed with PVDF/BaTiO3 nanocomposites [42]. The M ″ peaks for both relaxation process shift toward the higher frequency with increase in the temperature from 90 to 120 °C, and these peaks start to dominate at 180 °C as shown in Fig. 8. Imaginary part of electric modulus M″ at 90 °C shows the good amount of broadening of peaks at different mass% of nanofiller, however, M ″ spectra at 120 °C show that the peak broadening decreases, and this behavior signifies the asymmetric nature of Maxwell–Wagner–Sillers (MWS) relaxation. From the M″ spectra it has been also observed that the height of the peak decreases with increase in the mass% of nanofiller.

Temperature-dependent dielectric parameters

Permittivity

Figure 9 shows the variation in permittivity with temperature at constant frequency for different mass% of ZnO nanofiller polymer nanocomposite. The figure clearly indicates the significant increment in the permittivity with temperature as well as filler concentration. From the permittivity spectra, we found the with small increment in filler concentration till 90 °C but after 90 °C, the permittivity significantly increases with higher temperature, and this significant change at higher temperature indicates the charge carries are free to move through the polymer nanocomposite material causing a polarization, and hence permittivity increases. The increase in permittivity above the room temperature may be due to the increase in molecular mobility, expansion of the lattice, and excitation of charge carriers present inside the nanocomposite at the defect sites [43]. The density of charge carriers increases with increase in the concentration of ZnO nanoparticles in polymer matrix; therefore, the resultant permittivity in nanocomposite is due to the orientation of polysulfone (PSF) as well as ZnO dipoles. This orientation of large number of dipoles together with field is also responsible for the increasing permittivity. It is very well known that dielectric permittivity of the composites material depends on the polarizibility of the molecules; the higher the polarizibility of the molecules, the higher the permittivity. At low temperature below 30–90 °C, the density of charge carriers is large, so dipoles cannot easily orient themselves and so polarization process is less, but after 90 °C, i.e., at higher temperature the dipoles become comparatively free, and they respond to the applied electric field. Thus, polarization increased, and hence dielectric permittivity is also increased with the temperature [44]. The increase in dielectric permittivity is attributed to the higher orientation polarization of the polymer at higher temperatures due to greater mobility of molecules [45]. It has been also observed that the decrease in dielectric permittivity with increasing frequency is due to the fact that the interfacial diploes do not have sufficient time to orient themselves in the electric field direction; therefore, with increase in frequency, the tendency for the interfacial polarization is expected to decrease, resulting in the decrease in dielectric permittivity [46, 47].

Relaxations in glass transition temperature region involve local molecular motion. The motion of a relatively small group of atoms is considered in the framework of frozen in structure a side group, and the side group cannot rotate freely in the polymer about the C–C bond, which links to the main chain because of the large inter- and intra-molecular forces. Because of this, the side group has different energies in different rotational positions. However, below T g the main chain is approximately rigid. When material passes through the glass transition temperature region, the free volume is frozen in or unchanged in glassy state, and this generally shows the steady nature of various dielectric parameters as observed in the present study.

Dielectric loss

Figure 10 shows the variation of tangential loss of polysulfone/ZnO nanocomposite samples with temperature at different frequencies. The tangential loss (tan δ) decreases with increase in the concentration of filler concentration and increases with temperature. In polymer and their composite, loss tangent is a function of electrical conductivity which depends on the number of charge carrier mobility. From the above loss spectra, it is clear that magnitude of the tan δ decreases with frequency may be due to the decrease in the number of charge carrier and delay in settling of the dipoles due to availability of very short time in one half cycle of alternating voltage [48]. At 5 kHz, tan δ spectra do not show any significant peak, and it is only increasing continuously with temperature; however, at 20, 50, and 95 kHz, tan δ spectra show the relaxation peak at 120 °C, and after this temperature tan δ value starts to decrease due to thermal agitation which further increases due to leakage current.

AC conductivity

Figure 11 shows the variation in ac conductivity with temperature at different frequencies for polysulfone nanocomposite.

It is very clear from the empirical relation (Eq. 2) that the conductivity depends on the number of charge carriers (n i) and the mobility of the ions species in the material. AC conductivity spectra show that as the concentration of ZnO nanofiller increases with increasing temperature, conductivity also increases. At lower temperature, conductivity slowly increases as shown by the spectra, but at higher temperature conductivity increases significantly (i.e., Fig. 11). Increased conductivity with temperature suggests that the free volume around the polymer chain causes the mobility of ions and polymer segment [49, 50]. From the conductivity spectra, it has been observed that as the temperature increases, the ac conductivity also increases, and it may also be due to decrease in viscosity which provides increased chain flexibility. The variation in ac conductivity with temperature has been also explained in terms of segmental motion that results in an increasing free volume of the samples and hence the motion of the ionic charge. The amorphous nature of the PSF samples provides a greater free volume of the system upon increasing the temperature, and thus segmental motion permits the ions to transfer from one side to another [51]. This inter-chain or intra-chain charge carrier movement and development of R–C network in PSF/ZnO nanocomposites are responsible for higher value of ac conductivity.

Dielectric relaxation

Figure 12 shows the variation of relaxation time as a function of temperature at different frequencies for different mass% of ZnO nanocomposites. Relaxation spectra show that relaxation time is increasing with temperature, but relaxation time for all nanocomposites samples is less than that of pristine PSF. The increment of relaxation time with temperature at different frequencies is also the evidence of the increase in hindrance of polymer chain dynamic. At 5-kHz frequency, there are marginal changes, but as the frequency increases, we can very easily observe the significant variation. Relaxation spectra also show interesting results at 50 and 95 kHz, and these spectra show that the relaxation time for nanocomposite samples is more than that of pristine sample.

The addition of ZnO can improve the modulus of PSF, which is obvious, because ZnO has a very weak effect on the crosslink density of PSF. It is interesting that the characteristics relaxation time are related to uncoiling/disentangling of soft segment chain network in the soft phase increased with the addition of ZnO. This suggested that characteristic relaxation time-derived from relaxation spectrum is not always related to the overall relaxation rate as suggested in the literature [52].

It is suggested that the addition of ZnO enhanced the degree of microphase separation. It means the hard segment content in the soft phase decreased, soft chain flexibility increased, and elasticity increased, thus leading to a slow stress relaxation process. We have observed that the relaxation trends are corresponding to change of nanophase separation with ZnO contents. This separation trend is consistent with the trend in the relaxation time. In some cases a sharp peak is observed, which is associated with the change in softness of chain due to incorporation of ZnO.

Electrical modulus

The electrical modulus corresponds to the relaxation of the electric field in the materials when the electric displacement remains constant. The electrical modulus is reciprocal of the dielectric constant. Physically, it is corresponding to the relaxation of the electric field in the material when the electric displacement remains constant \( M^{*} (\omega ) = \frac{1}{{\varepsilon^{*} }} \) [53]. Although it was originally introduced by Macedo to study the space charge relaxation phenomenon, M* representation is now widely used to analyze ionic conductivity. Figure 13 shows that real part of electrical modulus is decreasing with increasing temperature, and the magnitude of M′ for all nanocomposites samples at all frequencies is less than that of pristine samples. Almost the similar nature is also observed at all frequencies. It is also clear from the variation of dielectric constant with temperature with different frequency spectra that dielectric constant is increasing; therefore, dielectric electric modulus must be decreasing with temperature at different frequencies. Electric modulus spectra indicate that at higher temperature, the dielectric permittivity is very large as shown in Fig. 9.

The trends of temperature-dependent electric modulus are generally same for all samples. The electric modulus is constant at higher temperature starting from 150 °C (i.e., glass transition temperature (T g) region of PSF). The variation of electric modulus with temperature shows the thermally activated nature of interfaces.

Conclusions

It is concluded that the dielectric properties of polysulfone (PSF)-based nanodielectric are attributed to the large volume fraction of interfaces in the bulk of the polymer and the ensuing interactions between the charged nanoparticle surface and the polymer chains. ZnO nanoparticles in PSF matrix show some improved dielectric behaviors even at low concentration of nanofiller. The increase in dielectric constant and decrease in dielectric loss tangent were observed by the incorporation of ZnO nanoparticles in the temperature range of 30–210 °C. The increase in dielectric constant is due to the piling of charges at the extended interface which normally results in increased conductivity and higher loss. However, the reduced dielectric loss was observed in the high-dielectric constant materials containing ZnO nanoparticles in virtue of Coulomb blockade effect, the well-known quantum effect of nanoparticles, which reduces the electron tunneling. As such, it reduces the conduction loss part from the total dielectric loss of the dielectric composite systems. This Coulomb blockade process can be an effective approach to achieve the high dielectric constant and low dielectric loss simultaneously at low frequency. The loading level of ZnO nanoparticles in the nanocomposites has significant influence on the dielectric properties of the composite system and supplies different effects at different frequency ranges as well.

References

Kumar S, Periyasamy P, Jeevanandham P. Dielectric relaxation studies of binary liquid mixtures of a few glycols with 1, 4-dioxane. Int J ChemTech Res. 2011;3:369–75.

Oliver JA, Stone GC. Implication for the application of adjustable speed drive electronics to motor stator winding insulation. IEEE Electr Insul Mag. 1995;11:32–6.

Li H, Liu G, Liu B, Chen W, Chen S. Dielectric properties of polyimide/Al2O3 hybrids synthesized by in situ polymerization. Mater Lett. 2007;61:1507–11.

Zhong J, Zhang M, Jiang Q, Zeng S, Dong T, Cai B, Lei Q. Mater Lett. 2006;60:585–91.

Musto P, Ragosta G, Scarinzi G, Mascia L. Toughness enhancement of polyimides by in situ generation of silica particles. Polymer. 2004;45:4265–74.

Kandary AL, Ali AAM, Ahmad Z. Morphology and thermo-mechanical properties of compatibilized polyimide-silica nanocomposites. J Appl Polym Sci. 2005;98:2521–31.

Abbate M, Musto P, Ragosta G, Scarinzi G, Mascia L. Polyimide-silica hybrids: spectroscopy morphology and mechanical properties. Macromol Symp. 2004;218:211–20.

Chen BK, Su CT, Tseng MC, Tsay SY. Preparation of polyetherimide nanocomposites with improved thermal mechanical and dielectric properties. Polym Bull. 2006;57:671–81.

Althues H, Henle J, Kaskel S. Functional inorganic nanofillers for transparent polymers. Chem Soc Rev. 2007;36:1454–65.

Bourgeat-Lami EJ. Organic–inorganic nanostructured colloids. Nanosci Nanotechnol. 2002;2:1–24.

Tyan HL, Liu YC, Wei KH. Enhancement of imidization of poly(amic acid) through forming poly(amic acid)/organoclay nanocomposites. Polymer. 1999;40:4877–86.

Singha S, Thomas MJ. Permittivity and tan delta characteristics of epoxy nanocomposites in the frequency range of 1 MHz–1 GHz. IEEE Trans Dielectr Electr Insul. 2008;15:2–11.

Ueki MM, Zanin M. Influence of additives on the dielectric strength of high-density polyethylene. IEEE Trans Dielectr Electr Insul. 1999;6:876–81.

Bai Y, Cheng Z-Y, Bharti V, Xu HS, Zhang QM. High dielectric-constant ceramic-powder polymer composites. Appl Phys Lett. 2000;76:3804–6.

Dang ZM, Yuan JK, Yao SH, Liao RJ. Flexible nanodielectric materials with high permittivity for power energy storage. Adv Mater. 2013;25:6334–65.

Wempe LK, Nelson RP. Research and development technical report DELET-TR. 1984;83:0405–10.

Macocinschi D, Grigoriu A, Filip D. Aromatic polysulfones for flame retardancy. Eur Polym J. 2002;38:1025–31.

Herbert CG, Ghassemi H, Hay AS. Introduction of amino, aliphatic, and aliphatic carboxylic acid side groups onto poly (arylene ether sulfone)s via transimidization reactions. J Polym Sci Part A Polym Chem. 1997;35:1095–104.

Harris JE, Johnson RN. Mark HF, Bikales NM, Overberger UG, Menges G, editors. Encyclopedia of polymer science and engineering. 1985;13:196.

Saxena P, Gaur MS, Shukla P, Khare PK. Relaxation investigations in polysulfone: thermally stimulated discharge current and dielectric spectroscopy. J Electrostat. 2008;66:584–8.

Gaur MS, Singh PK, Chauhan RS. Optical and thermo electrical properties of ZnO nano particle filled polystyrene. J Appl Polym Sci. 2010;118:2833–40.

Tachikawa S, Noguchi A, Tsuge T, Hara M, Odawara O, Wada H. Optical properties of ZnO nanoparticles capped with polymers. Materials. 2011;4:1132–43.

Patsidis AC, Kalaitzidou K, Psarras GC. Graphite nanoplatelets/polymer nanocomposites: thermomechanical, dielectric, and functional behavior. J Therm Anal Calorim. 2014;116:41–9.

Gaur MS, Indolia AP. Thermally stimulated dielectric properties of polyvinylidenefluoride–zinc oxide nanocomposites. J Therm Anal Calorim. 2011;103:977–85.

Lu J, Moon KS, Xu J, Wong CP. Synthesis and dielectric properties of novel high-K polymer composites containing in situ formed silver nanoparticles for embedded capacitor applications. J Mater Chem. 2006;16:1543–8.

Kastner MA. The single electron transistor and artificial atoms. Ann Phys (Leipzig). 2000;9:885–94.

Gammon D. Electrons in artificial atoms. Nature. 2000;405:899–900.

Chanmal CV, Jog JP. Dielectric relaxation in PVDF/BaTiO3 nanocomposites. Express Polym Lett. 2008;2:294–301.

Brosseau C, Queffelec P, Talbot P. Microwave characterization of filled polymers. J Appl Phys. 2001;89:4532–40.

Mathioudakis GN, Patsidis AC, Psarras GC. Dynamic electrical thermal analysis on zinc oxide/epoxy resin nanodielectrics. J Therm Anal Calorim. 2014;116:27–33.

Nelson JK, Fothergill JC, Dissado LA, Peasgood W. Towards an understanding of nanometric dielectrics. In: IEEE conference on electrical insulation and dielectric phenomena (CEIDP). 2000. p. 295–298.

Imai T, Hirano Y, Hirai H, Kojima S, Shimizu T. Preparation and properties of epoxy-organically modified layered silicate nanocomposites. In: IEEE international symposium on electrical insulation (ISEI). 2002. p.379–383.

Arous M, Ben Amor I, Kallel A, Fakhfakh Z, Perrier G. Crystallinity and dielectric relaxations in semicrystalline poly(ether ether ketone). J Phys Chem Solids. 2007;68:1405–14.

Tanaka T, Montanari GC, Mülhaupt R. Polymer nanocomposites as dielectrics and electrical insulation perspectives for processing technologies, material characterization and future applications. IEEE Trans Dielectr Electr Insul. 2004;11:763–83.

Raja V, Sharma AK. Narasimha Rao VVR. Impedance spectroscopic and dielectric analysis of PMMA-CO-P4VPNO polymer films. Mater Lett. 2004;58:3242–7.

Panteny S, Stevens R, Bowen CR. The frequency dependent permittivity and ac conductivity of random electrical networks. Ferroelectrics. 2005;319:199–208.

Almond DP, Vaines BJ. The dielectric properties of random R–C networks as an explanation of the `universal’ power law dielectric response of solids. Phys Condens Matter. 1999;11:9081.

Bouamrane R, Almond DP. The ‘emergent scaling’ phenomenon and the dielectric properties of random resistor–capacitor networks. J Phys Condens Matter. 2003;15:4089.

Vainas B, Almond DP, Luo J, Stevens R. An evaluation of random RC networks for modelling the bulk ac electrical response of ionic conductors. Solid State Ionics. 1999;126:65–80.

Debye P. Polar molecules. New York: Chemical Catlog; 1929 Chap 5.

Tsangaris GM, Psarras GC, Kouloumbi N. Electric modulus and interfacial polarization in composite polymeric systems. J Mater Sci. 1998;33:2027–37.

Chanmal CV, Jog JP. Dielectric relaxations in PVDF/BaTiO3 nanocomposites. Express Polym Lett. 2008;2:294–301.

Bhimasankaram T, Suryanarayana SV, Prasad G. Piezoelectric polymer composite materials. Curr Sci. 1998;74:967–76.

Tiwari DC, Sen V, Sharma R. Temperature dependent studies of electric and dielectric properties of polythiophene based nanocomposites. Indian J Pure Appl Phys. 2012;50:49–56.

Raju GG. Dielectrics in electric field. New York: Marcel Dekker Inc; 2003.

Nakamura K, Wada Y. Piezoelectricity, pyro-electricity and the electrostriction constant of poly vinylidene fluoride. J Polym Sci. 1971;9:161–73.

Bunget I, Popescu M. Physics of solid dielectrics. Amsterdam: Elsevier; 1984.

Khare PK, Gaur MS, Singh R. Dielectric properties of pure and malachite green doped polymethyl methacrylate films. Indian J. Phys. 1994;68:545–52.

Tripathi SK, Gupta A, Kumari M. Studies on electrical conductivity and dielectric behavior of PVDF-HFA-PMMA_NaI polymer blend electrolyte. Bull Mater Sci. 2012;35:969–75.

Takahashi Y, Miyaji K. Long-range order parameters of form II of poly (vinylidene fluoride) and molecular motion in the α relaxation. Macromolecules. 1983;16:1789–92.

Tsunemi K, Ohno H, Tsuchida E. Electrochim Acta. 1983;28:833.

Xia H, Song M, Zhang Z, Richardson M. Microphase separation, stress relaxation, and creep behavior of polyurethane nanocomposite. J Appl Polym Sci. 2007;103:2992–3002.

Harun MH, Saion E, Kassim A, Mahmud E, Husain MY, Mustafa IS. Dielectric properties of poly (vinyalalcohal)/polypyrrole composite polymer films. J adv Sci Arts. 2009;1:9–16.

Acknowledgements

This research study was supported by a Grant from Department of Science and Technology, New Delhi (SERB Vide Letter No. SR/S2/CMP-0091/2010), New Delhi (India). We are highly thankful to Director, HCST, Farah, Mathura (U.P.) who provided all possible facilities related to this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, P.K., Gaur, M.S. & Chauhan, R.S. Dielectric properties of sol–gel synthesized polysulfone–ZnO nanocomposites. J Therm Anal Calorim 122, 725–740 (2015). https://doi.org/10.1007/s10973-015-4807-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4807-6