Abstract

Innovative pharmaceutical development in an attempt to enhance the bioavailability of poorly water-soluble drugs is supporting the increase in solid dispersion (SD) technology by using different excipients and solvents. Ethinyl estradiol (EE) is an estrogen component that presents poor solubility and is commercialized at low concentrations (usually 30 or 35 μg). A full solid-state characterization of EE was conducted using differential scanning calorimetry (DSC), thermogravimetric analysis (TG/DTG), fourier transform infrared spectroscopy (FTIR), powder X-ray diffraction (PXRD), and scanning electron microscopy to examine its physicochemical properties and polymorphic state. The main aim of this work was to develop and characterize a stable SD containing EE and pharmaceutical excipients, to enhance the drug solubility. For this task, four excipients (starch, microcrystalline cellulose, lactose, and PVP) and four solvents (ethanol, acetone, dichloromethane, and chloroform) were tested. Each prepared sample was monitored by DSC and PXRD to evaluate the SD formation. Stability tests were performed with the successful SD that was stored under three different conditions [75 % relative humidity (RH)/40 °C; 90 % RH/25 °C; and 0 % RH/25 °C] and analyzed after 15 and 30 days by DSC and PXRD. The results showed that polyvinylpyrrolidone combined with any solvents was able to consistently produce a stable solid dispersion with EE.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

An important step in the development of new pharmaceutical formulations is the improvement of the dissolution and oral bioavailability of poorly soluble drugs in water [1] The preparation of solid dispersions (SD) as a feasible method to enhance bioavailability bypasses the limitations of other approaches, such as salt formation, solubilization, and reduction of particle size [1, 2].

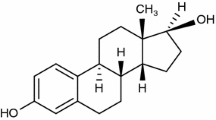

Ethinyl estradiol (EE), (17α)-19-norpregna-1,3,5-(10)-trien-20-yne-3,17-diol is the most widely used estrogenic component in oral contraceptives and hormone replacement therapy [3]. EE is a crystalline white or yellowish powder, insoluble in water but soluble in ethanol, ether, acetone, dioxane, and chloroform. EE is also soluble in vegetable oils and diluted alkaline solutions [4–6]. It is sold in small dosages (between 30 and 35 μg), alone or in combination with other substances [5]. EE can exist as various pseudopolymorphs [3]; thus, the selection of solvents and stability studies that evaluate polymorphs are essential for the development of formulations containing this active pharmaceutical ingredient (API).

Solid dispersions (SD) are mixtures containing two or more components, typically a hydrophilic matrix and a hydrophobic API, and they have advantages such as increased solubility, bioavailability, and stability [2, 7, 8]. Solid dispersions have applications in drug formulation because, when exposed to an aqueous medium, the hydrophilic matrix dissolves and releases the API as fine colloidal particles, producing a higher dissolution rate and consequently increasing the oral bioavailability [2]. However, in the preparation of SD with a polymorphic API, it is important to emphasize that changes to the properties of its crystals can affect the solubility and stability of the API in the final product [7]. The amorphization of the API is one of the most common polymorphic transitions. API amorphous forms often exhibit desirable physicochemical properties such as higher rates of dissolution and better solubility compared with their crystalline counterparts [9].

Analytical and physicochemical techniques such as thermal analysis (differential scanning calorimetry—DSC and thermogravimetry—TG), powder X-ray diffraction—PXRD, fourier transform infrared—FTIR spectroscopy, and scanning electron microscopy—SEM have been used to characterize APIs and obtain information on the polymorphic state, particle size, powder morphology, melting point, crystallinity, and stability/degradation [10–13]. However, no studies on EE solid-state characterization were found in the literature.

The main aim of this work was first to characterize EE using techniques such as thermal analysis (TG and DSC), PXRD, FTIR, and SEM, and next to develop a stable SD containing EE and pharmaceutical excipients, to enhance the drug solubility. DSC and PXRD were used to monitoring the SD formation and studding its stability.

Materials and methods

Materials

The raw materials used were pharmaceutical grade (99 % purity): ethinyl estradiol (EE) (Zhejiang, China), pre-gelatinized starch (STA), microcrystalline cellulose (MCL), anhydrous lactose (LAC) and polyvinylpyrrolidone K25 (PVP). These excipients were provided by the Eurofarma Laboratory, Brazil. Absolute ethanol, acetone, chloroform, and dichloromethane (analytical grade, JTBaker, USA) were used.

Solid dispersion preparation

The SD was prepared according to solvent method. In this method, the excipient and the API are solubilized in a solvent that is, in sequence, evaporated for 12 h at 50 °C. Some different method can be used to remove the solvent like evaporation at low pressure, freeze-drying, and spray-drying [14]. Four homogeneous EE solutions were prepared using ethanol, acetone, dichloromethane, and chloroform. Each solution was fractionated into four aliquots that were sprayed with starch, microcrystalline cellulose, lactose, and PVP, resulting in 16 different samples. The EE–excipient ratio was 1:4 (m/m) in each sample. The prepared samples were dried at 50 °C for 12 h.

Control samples

To ensure that polymorphic transition observed in the SD was due to the solvent–excipient–API interaction, the effects of solvents and excipients were evaluated separately and compared to the first ones.

To evaluate the solvent effect in EE polymorphic transitions, four homogeneous EE solutions (EE–solvent control) were prepared using ethanol, acetone, dichloromethane, and chloroform, and dried at 50 °C for 12 h.

EE–excipient control samples were prepared by the physical mixture of EE powder with each excipient, without the previous solubilization of EE in the solvent. The mixtures were prepared at a 1:4 (m/m) ratio in a polyethylene container (3 cm height × 2 cm diameter) and homogenized by vortexing for 1 min using stainless steel balls (2 mm diameter) to mix. These samples were used to evaluate the effect of each excipient alone in the amorphization process.

Characterization of EE

Thermal analysis (TG and DSC)

TG curves were obtained using a thermobalance (model Q600, TA Instruments, USA) with 12 mg of sample packed into an aluminum crucible and heated from 30 to 600 °C under a dynamic nitrogen atmosphere (50 mL min−1) with a heat flow of 10 °C min−1. The DSC curves were obtained using a DSC calorimeter (model DSC7020, SII Nano Technology, Japan). Samples (3.3 mg) were placed in a hermetic aluminum pan with a pinhole in the lid and heated from 25 to 230 °C under a dynamic nitrogen atmosphere (50 mL min−1) with a heat flow of 10 °C min−1. The DSC cell was cleaned prior to use and calibrated daily with an indium standard (purity 99.99 %; T onset = 156.4 °C; ΔH fusion = 28.7 J g−1).

Powder X-ray diffraction (PXRD)

PXRD was performed using a diffractometer (model Ultima IV, Rigaku, Japan) with measurements of 2θ ranging from 5° to 55° at 40 kV and 30 mA. The samples were prepared according to USP 32 instructions (procedure 941) [6].

Fourier transform infrared spectroscopy (FTIR)

The infrared analyses were performed using a FTIR spectrometer (model IRPrestige, Shimadzu, Japan) with potassium bromide disks in the range from 4,000 to 400 cm−1. The spectra were recorded at room temperature using 20 scans and a resolution of 4 cm−1.

Scanning electron microscopy (SEM)

SEM micrographs were obtained using a field-emission scanning electron microscope (model JSM-6340F, JEOL, Japan) after vacuum-coating with gold and using direct analysis by SEM (×500/×10,000).

Evaluation of SD formation

Sixteen samples and eight control samples were analyzed by DSC and PXRD to determine whether SD formation occurred under the same characterization analysis conditions described in “Characterization of EE” section.

Stability studies of SD

Samples that resulted in successful SD were subjected to stability studies. For these studies, the samples were stored under three different stress conditions: 75 % relative humidity (RH)/40 °C; 90 % RH/25 °C; and 0 % RH/25 °C. After 15 and 30 days, they were evaluated using DSC, TG, PXRD, and FTIR under the same analysis conditions described in “Characterization of EE” section.

Results and discussion

Characterization of EE

The DSC curve of EE (Fig. 1a) showed three well-defined events: an endothermic event at 103.6 °C (T onset = 97.3 °C|ΔH fusion = 22.8 J g−1) corresponding to dehydration; an endothermic peak indicative of melting at 184.1 °C (T onset = 181.9 °C|ΔH fusion = 88.6 J g−1); and a decomposition event under an inert atmosphere after 205 °C.

TG/DTG curves showed a mass loss of 0.8 % at 103 °C, confirming the dehydration peak shown by DSC. Then, the curves presented thermal stability up to 206 °C. The thermal decomposition of EE occurred in two steps: the first step occurred at a temperature range from 206.5 to 409.3 °C (T peak DTG = 352.7 °C) with a mass loss of 72.1 %, and the second step was observed at a temperature range from 409.3 to 525.6 °C (T peak DTG = 463.5 °C) with a mass loss of 24.5 %, as shown in Fig. 1.

EE can be found in different pseudopolymorphic forms due to its flexibility in forming distinct types of H bonds with solvent molecules or between EE molecules, which allow the formation of different stable solvates [3]. Guguta et al. [3] determined the crystalline structure of four new solvates using dioxane, nitromethane, ethanolate, and N,N-dimethylformamide (DMF) and re-examined the structure of methanol and acetonitrile solvates and hemihydrates by single-crystal X-ray diffraction.

The PXRD pattern of EE (Fig. 1b) showed more intense peaks at 2θ at 11, 13.18, 13.94, 15.76, 16.86, 17.24, 18.34, 19.66, 21.42, and 22.5, characteristic of the crystallinity of two different polymorphic forms of EE. By comparison with data from the ICSD database [15], it is possible to identify the presence of hemihydrate polymorphic forms.

The SEM image of EE is presented in Fig. 2a. According to USP32 classification [6], irregularly shaped particles, including aggregates of flakes, were visualized in the sample. Furthermore, prismatic crystals could be observed, confirming the presence of two polymorphic forms as demonstrated by PXRD and confirmed by comparison with the ICSD database [15].

Figure 2b shows the EE infrared spectrum with characteristic bands from the API functional groups: a large band from 3.436 to 3.227 cm−1 due to OH stretching from intermolecular H bonds; intense bands at 2.970, 2.935, and 2.866 cm−1 from CH3 and CH2 asymmetric stretching, and CH2 symmetric stretching, respectively; medium-intense bands from C=C stretching of the aromatic ring at 1.616, 1.581, 1.500, and 1.469 cm−1; and a band at 1.253 cm−1 from phenolic C–O stretching [16].

Evaluation of SD formation

Control assay: EE–solvent interaction study

Ethanol and acetone induced the formation of a different polymorphic form (melting near 147 °C) that recrystallized when it was heated (Fig. 3a). These results were confirmed by PXRD (Fig. 3b). Chloroform and dichloromethane DSC curves did not present changes in EE peak fusion, and PXRD patterns presented the same diffraction profile of EE, indicating that these solvents do not contribute to the polymorphic change of EE under these study conditions.

It is important to note that, despite chloroform and dichloromethane being largely used in SD preparations, they are toxic (class II, according to ICH). Thus, they should be used with caution, and their presence in the final product must be reduced to residual concentrations [17].

Control assay: EE–excipient interaction study

The DSC curves obtained for EE and excipients are shown in Fig. 4a. In this figure, the melting temperature range of EE does not overlap with thermal events from the excipients, indicating that the event is specific to EE. Therefore, any change in shape, T onset or ΔH fus, is indicative of some interaction between EE and the excipients [12, 13, 18]. In the DSC curve for the physical mixture containing PVP, it was observed that the endothermic melting peak disappeared completely, indicating that there was a chemical (decomposition) or physical (solubilization of EE) interaction. Physical mixtures containing other excipients did not present with such changes in DSC curves. The PXRD pattern of EE, which indicates its crystallinity, did not change with any of the physical mixtures of drug–excipient evaluated (Fig. 4b). Data were also compared with the correlation value.

Prepared sample characterization: evaluation of SD formation

The thermal characterization of the prepared samples was useful for monitoring changes in EE fusion parameters, observing the disappearance or formation of new thermal events to evaluate the efficiency of excipients or solvents on EE polymorphic transition and aiding the development of a SD. The EE fusion event (184 °C, showed in Fig. 1) disappeared in the DSC curves from several samples (Fig. 5c, g), indicating that the methodology adopted was effective in obtaining amorphous EE. Additionally, in most of the samples, the EE fusion peak enthalpy values were very low (Table 1), possibly due to partial amorphization of EE in these samples. The results by PXRD (Fig. 5h) also confirmed the non-crystallinity of EE.

The EE/STA/ethanol sample had a fusion event at approximately 147 °C (Fig. 5a) that was characteristic of a second polymorphic form of EE. In X-ray analysis (Fig. 5b), this material had a different diffraction pattern from EE, confirming the polymorphic transition of API.

The diffraction pattern of EE (15.76°, 18.34°, 19.66° 2θ) was present in the samples involving the combination of EE/STA with acetone, chloroform, and dichloromethane (Fig. 5b). These starch-containing materials did not show changes in the melting point of EE. Thus, the use of the combination EE/starch/solvent was not effective in developing an EE SD.

The DSC curves and PXRD patterns from microcrystalline cellulose-containing samples are shown in Fig. 5c, d, respectively. The resulting mixture of EE/MCL with chloroform and dichloromethane did not change the melting point of EE, and the PXRD patterns of these samples were similar to the pattern exhibited by EE and physical mixtures of these components. The sample of EE/MCL with acetone had no EE fusion event, but characteristic peaks of EE were detected by PXRD analysis, indicating the presence of crystal of EE. However, the PXRD pattern of the sample of EE/MCL with ethanol had no detectable diffraction peak, demonstrating the amorphization of the API. Thus, the use of ethanol combined with MCL was efficient for the development of an EE SD.

The sample of EE/LAC with ethanol exhibited a new fusion event at approximately 147 °C, which corresponds to a second polymorphic form of EE (Fig. 5e). The X-ray analysis indicated that this material has a diffraction pattern different from EE, confirming its polymorphic transition (Fig. 5f). The mixture of EE/LAC with acetone did not change the melting point of EE, and the PXRD pattern was similar to EE and physical mixtures of these components, showing intense diffraction peaks of EE (i.e., 13.94°,16.86°, 18.34° 2θ). The chloroform and dichloromethane EE/LAC samples did not change the melting point of EE, and the PXRD patterns showed the same diffraction peaks of EE. Therefore, lactose has no effective molecular interactions with EE or solvents for the generation of an EE SD.

The sample of EE with PVP showed disappearance of the EE melting point in all solvents tested (Fig. 5g). Furthermore, no detectable diffraction pattern was observed for these samples, confirming that the mixture was efficient for the amorphization of the API and the development of an EE SD (Fig. 5h).

The amorphous characteristic is common to most polymeric excipients used in the pharmaceutical industry, including the pre-gelatinized starch, microcrystalline cellulose, and PVP that were used this study. The presence of an amorphous API can favor the interaction between the components of the formulation and thus enhance the stability of the final product [10].

The intermolecular interaction between EE and PVP may slow or inhibit API crystallization and, consequently, favor amorphization. Several studies [1, 2, 7, 8] show that polymers used in SD preparations, such as PVP, induce this effect. The inhibition of API crystallization by PVP is due to specific interactions, specifically hydrogen bonds, between the drug and excipient. The extent of crystallization inhibition is dependent on the drug–excipient ratio, where a greater inhibition of crystallization is achieved at higher proportions [1, 2, 7, 8].

Stability studies

PVP was selected to stability studies, because it demonstrated be an appropriate excipient to produce an EE SD, independent of the solvent used. However, samples prepared with chloroform and dichloromethane were discarded due to their toxicity. Therefore, only the PVP-containing samples prepared with ethanol and acetone were used for stability studies.

Initial time

The DSC curve for PVP (Fig. 6a) shows that this excipient lacks a crystalline structure because it does not have a fusion peak. The endothermic event that occurs from 30 to 100 °C in each PVP-containing sample corresponds to its moisture. The physical mixture had a ΔH fus smaller than expected value (8.65 J g−1 rather than 17.7 J g−1). This finding can be explained by the solubilization of the API in an excipient that is characterized by an elastic state due to heating. The DSC curves for SDs showed no EE melting point, which is indicative of API amorphization that was later confirmed by PXRD.

SD samples and physical mixtures have the same thermal stability, presenting overlap events in their TG curves, according to Fig. 6b. The same PXRD pattern of EE was observed in the physical mixture, but it could not be observed from either the ethanol or acetone SD (Fig. 6c). The results of FTIR analysis are available in Fig. 6d. The EE spectrum has the following bands: a 3,607 cm−1 band corresponding to O–H stretching from free hydroxyls; a 3,436 to 3,227 cm−1 band due to O–H stretching from intermolecular hydrogen bonds; strong bands at 2,970, 2,935, and 2,866 cm−1 from CH3 and CH2 asymmetric stretching and CH2 symmetric stretching, respectively; four intermediate intensity bands at 1,616, 1,581, 1,500, and 1,469 cm−1 corresponding to C=C stretching of the aromatic ring; and a 1,253 cm−1 band from C–O stretching of phenolic groups. The PVP spectrum has bands at 3,431 and 1,654 cm−1, which correspond to OH vibration and C=O from the pyrrolyl ring, respectively. The spectrum of the physical mixture has bands representative of both PVP and EE, seen as an overlap of the PVP and EE spectra. However, spectra of the SD samples have changes in their absorption bands. The band at 3,607 cm−1 that corresponds to the O–H stretching from free hydroxyls disappears, indicating the formation of hydrogen bonds between EE and PVP. The bands corresponding to CH3 and CH2 vibrations appear to be less intense in the SD spectrum.

After storage

The same samples were analyzed again after storage (15 and 30 days under three different conditions: 75 % RH/40 °C; 90 % RH/25 °C and 0 % RH/25 °C) by DSC, PXRD and FTIR. The results were similar to the initial study results. The absence of an EE melting peak in DSC, the absence of a PXRD pattern, and the maintenance of absorption bands from SDs samples after 15 (data not shown) and 30 days of storage in three different stress conditions demonstrated that these samples were stable in these storage conditions (Fig. 7).

Conclusions

Based on the results of this study, the characteristics of the excipients and solvents can affect the polymorphic stability of API in the formulation. Therefore, selection of the proper parameters during formulation preparation was very important to ensure a stable product. Thermal analysis combined with PXRD demonstrated to be helpful to characterize of polymorphic transitions, monitoring the SD formation, and to perform SD stability studies of successful SD. Stability studies (75 % RH/40 °C) were also performed to evaluate the SD developed. PVP is an appropriate excipient to produce a stable SD with EE independent of the solvent used. To improve the quality and efficiency of a SD of EE–excipient, pharmaceutical developments should also evaluate the different EE–excipient ratios and clarify the effect of mixing ratio on the characteristics and stability of samples. Other important step of this work will be conducting dissolution tests, to compare SD solubility with traditional formulations solubility.

References

Yu M, Sun L, Li W, Lan Z, Li B, Tan L, et al. Investigation of structure and dissolution properties of a solid dispersion of lansoprazole in polyvinylpyrrolidone. J Mol Struct. 2011;1005(1–3):70–7. doi:10.1016/j.molstruc.2011.08.019.

Rahul Panditraj Ghaste DDC, Shah RR, Ghodake DS. Solid dispersions: an overview. Pharm Inf. 2009;7(5).

Guguta C, Eeuwijk I, Smits JMM, de Gelder R. Structural diversity of ethinyl estradiol solvates. Cryst Growth Des. 2008;8(3):823–31. doi:10.1021/cg0702277.

O’Neil MJ. The Merck index an encyclopedia of chemicals, drugs, and biologicals. Merck, Whitehouse Station, N.J. 2006. http://app.knovel.com/web/toc.v/cid:kpTMIAECD1.

Sweetman SC. Martindale : the complete drug reference. 35th ed. London; Chicago: Pharmaceutical Press; 2009.

United States Pharmacopeial Convention. United States Pharmacopeia 32; National Formulary 27. Rockville, Md.: United States Pharmacopeial Convention. 2008.

Nair R, Gonen S, Hoag SW. Influence of polyethylene glycol and povidone on the polymorphic transformation and solubility of carbamazepine. Int J Pharm. 2002;240(1–2):11–22. doi:10.1016/s0378-5173(02)00083-2.

Sharma A, Jain CP. Solid dispersion: a promising technique to enhance solubility of poorly water soluble drug. Int J Drug Delivery. 2011;3:149–70. http://www.arjournals.org/index.php/ijdd/article/view/211.

Bruni G, Milanese C, Bellazzi G, Berbenni V, Cofrancesco P, Marini A, et al. Quantification of drug amorphous fraction by DSC. J Therm Anal Calorim. 2007;89(3):761–6. doi:10.1007/s10973-006-7943-1.

Karabas I, Orkoula MG, Kontoyannis CG. Analysis and stability of polymorphs in tablets: the case of risperidone. Talanta. 2007;71(3):1382–6. doi:10.1016/j.talanta.2006.07.009.

Maximiano FP, Novack KM, Bahia MT, de Sa-Barreto LL. Soares da Cunha-Filho MS. Polymorphic screen and drug-excipient compatibility studies of the antichagasic benznidazole. J Therm Anal Calorim. 2011;106(3):819–24. doi:10.1007/s10973-011-1371-6.

Daniel JSP, Veronez IP, Rodrigues LL, Trevisan MG, Garcia JS. Risperidone—Solid-state characterization and pharmaceutical compatibility using thermal and non-thermal techniques. Thermochim Acta. 2013;568:148–55. doi:10.1016/j.tca.2013.06.032.

Veronez I, Daniel JP, Garcia J, Trevisan M. Characterization and compatibility study of desloratadine. J Therm Anal Calorim. 2013;115(3):2407–2414. doi:10.1007/s10973-013-3271-4.

Leuner C, Dressman J. Improving drug solubility for oral delivery using solid dispersions. Eur J Pharm Biopharm. 2000;50(1):47–60. doi:10.1016/s0939-6411(00)00076-x.

Bergerhoff G. Brown ID. In: Allen FH, et al., editors. Crystallographic databases. Chester: International Union of Crystallography; 1987.

Silverstein RM, Webster FX. Identificação espectrométrica de compostos orgânicos. Rio de Janeiro: LTC; 2006.

International Conference on Harmonisation. Impurities: guideline for residual solvents Q3C. vol 01 Jul. Rockville, MD: U.S. Dept. of Health and Human Services, Food and Drug Administration, Center for Drug Evaluation and Research: Center for Biologics Evaluation and Research; 2009.

Julio TA, Zamara IF, Garcia JS, Trevisan MG. Compatibility of sildenafil citrate and pharmaceutical excipients by thermal analysis and LC-UV. J Therm Anal Calorim. 2013;111(3):2037–44. doi:10.1007/s10973-012-2292-8.

Acknowledgements

The authors thank FAPEMIG (Processo APQ-0975-12), Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES), Instituto Nacional de Ciência e Tecnologia de Bioanalítica (INCTBio), Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) and Laboratório de Cristalografia/UNIFAL-MG for PXRD analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Veronez, I.P., Daniel, J.S.P., Júnior, C.E.C. et al. Development, characterization, and stability studies of ethinyl estradiol solid dispersion. J Therm Anal Calorim 120, 573–581 (2015). https://doi.org/10.1007/s10973-015-4508-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4508-1