Abstract

The thermal characterisation of binary mixture formed from hydrogen-bonded supramolecular liquid crystals 4-hexylbenzoic acid (6BA) and 4-octyloxybenzoic acid (8OBA) was investigated by differential scanning calorimetry (DSC) and phases identified by polarised optic microscopy (POM). The phase diagram of the mixture was obtained from theoretical calculations, and binary mixture with a maximum nematic range according to the phase diagram was produced. The DSC and POM results clearly indicate that the produced liquid crystal mixture displays liquid crystalline properties, and the nematic range of 6BA/8OBA eutectic mixture is wider than the nematic ranges of both liquid crystals 6BA and 8OBA. Also with increasing the heating rate from 5 to 20 °C min−1, the phase transitions occur in a shorter time. As a result, the 6BA/8OBA mixture does not loss its liquid crystalline properties against sudden temperature changes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

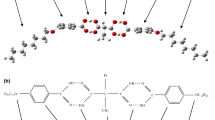

Liquid crystals (LCs) are fascinating materials that have both conventional liquid and solid crystal properties [1, 2] and are important in the field of advance materials such as liquid crystal display (LCD) devices. With the development of LCD technology, there is a growing interest in the synthesis and investigation of liquid crystal mixtures. Lots of liquid crystals used in LCD technology are the eutectic mixtures developed by mixing two or more mesogenic substances [3]. Hydrogen-bonded liquid crystals (HBLCs) and their complex mixtures [4–8] have recently attracted a great deal of attention because of their interesting physical properties in accordance with the intermolecular hydrogen bonds [9, 10]. Hydrogen bonds enable the variety of mesogenic and non-mesogenic formations in order to develop complexes showing rich phase polymorphism. Typical representation of liquid crystal materials that are formed via hydrogen bonds inside the dimer molecules is 4,n-alkylbenzoic acid (nBA) and 4,n-alkyloxybenzoic acid (nOBA). Here, the constant of n is the carbon number in the alkyl chain of the liquid crystal.

Phase transition behaviours, optical properties, and electro-optic effects provide the basis for liquid crystal display technology. Therefore, this disquisition about thermo-optical properties of nematic liquid crystal mixtures has substantial significance in technological applications [11]. In order to diversify the electro-optic and thermal properties of nematic liquid crystals used for imaging technology in potential applications, studies have been carried on some of the supramolecular liquid crystal [12] mixtures. In this study, we present the experimental results on thermal and optical properties for binary mixtures of 4-hexylbenzoic acid (6BA) and 4-(octyloxy)benzoic acid (8OBA), which display mesomorphic behaviour due to the presence of sufficient dimer concentration and are shaped with hydrogen bonds. 6BA and 8OBA, as well as other members of nBA and nOBA homologous series, are important for the technological applications due to the possession of a good chemical stability.

Experimental

Materials

4-hexylbenzoic acid (6BA) and 4-(octyloxy) benzoic acid (8OBA), which were hydrogen-bonded pure liquid crystal materials used in this study, were purchased from Sigma-Aldrich company. Since the purity ratios of the purchased chemical materials were relatively high (99.9 %) and their phase transition temperatures were in accordance with the values given in the Sigma-Aldrich catalogue, they were not subject to further purification process. Figure 1 illustrates the chemical structures of the purchased pure liquid crystals.

Preparation of LC mixture samples

The mixture samples to be used in the DSC measurements were weighed at ratio of 52 % 8OBA and 48 % 6BA pure liquid crystals, and they were subject to heat treatment on the magnetic stirrer after they were mixed at room temperature. The heated samples were mixed for 30 min before and after nematic–isotropic phase transformation by using mechanical stirring methods. After the formation of a homogenous mixture, the samples were left to cool at room temperature. In order to prevent oxidation, the contract of the sample with air is hindered as much as possible. In order for all the samples to have a completely homogenous mixture, heating and mixing processes were repeated with 30-min interval. The homogenous mixtures were placed in DSC (PerkinElmer DSC 8000) on an aluminium pan, and after the measurements were taken, the analyses were performed.

As shown in Fig. 2, primarily sandwich-shaped liquid crystal cells were prepared for polarised optical microscope studies. The glasses to be used in cell formation were sensitively cleaned in an ultrasonic bath and dried in a sterile oven. After the glasses were dried, both sides were coated with a spacer; a sandwich structure was formed by superimposing the lamellas by leaving a short space. As explained above, liquid crystal samples formed by mechanical stirring methods were placed in the space of the cell in sandwich form. When the cell was heated on a heating plate, liquid crystal sample was placed between the lamellas by the effect of the surface tension forces. In order to prevent the degradation of the material by melting the spacer at high temperatures, the edges and end parts of the cell were affixed with a heating-resistant adhesive.

After placing the said liquid crystal cell on the heating plate of the polarised optical microscope, a current of about 0.7 A was applied to the heating plate, and a temperature increase at 10 °C min−1 heating ratio was provided for the samples. After the nematic–isotropic phase transformation was completely finished, the sample was left to cool at room temperature. Different images of liquid crystal samples were taken by using a Leica 180 DM LP polarisation microscope with a thermal table and a CCD camera for every phase during heating and cooling. According to these images, the phase analyses of the samples were performed.

Results and discussion

Phase diagram of 6BA/8OBA mixture

The phase diagram of 6BA/8OBA mixture was constructed from the theoretical [13–15] calculations. The calculations were done on a computer using a program written according to the Schroder-Van Laar equation [13–15] in FORTRAN language. The data to build the phase diagram of 6BA/8OBA mixture were obtained by using the phase transition temperatures and enthalpy values [16] of pure components 6BA and 8OBA in this program. The program was run three times because there are three different mesogenic ranges (Smectic A, Smectic C, Nematic) of liquid crystal 8OBA. Then, the phase diagram was plotted by combining the data obtained. Figure 3 shows the phase diagram of the liquid crystal 6BA/8OBA mixture system. As shown in Fig. 3, homogeneous nematic phase can be observed for the whole concentration range of 6BA. Five distinct regions crystalline (Cr), smectic A (SmA), smectic C (SmC), nematic (N), and isotropic (I) are clearly identified in this diagram. In the upper region, a single phase is obtained, where the 6BA/8OBA mixture forms an isotropic solution. The nematic–isotropic temperature (T NI) of the blends increases with the decrease in 6BA concentration. The smectic phase is clearly observed below 32 % 6BA on the phase diagram corresponding to a LC mixture of 100 mass%. The diagram, calculated with Schröder Van Laar equation, exhibits a eutectic temperature at 64.9 °C. It is clear that the largest nematic range is obtained in the mixture ratio of 52 % 8OBA and 48 % 6BA according to the phase diagram. The phase diagram constructed for the 6BA/8OBA binary mixture system is found to agree with that reported literatures [15, 17–19] recently for a similar experiment.

DSC studies of HBLCs

Phase transition temperatures and enthalpies of a liquid crystal sample can be calculated from a single data run, and DSC is an analytical tool that is widely used in technology and that can easily provide wide range of thermodynamic data. Invaluable qualitative and quantitative information about the liquid crystalline phases can be derived from the thermodynamic data at and in the vicinity of their phase transitions. Transition temperatures, enthalpies, and entropies are important quantities characterising the materials. The difference in transition temperature between the melting and clearing points gives the range of stability of the liquid crystalline phases. Phase transition enthalpies and entropies are concerned to the level of the adjustment parameter of the molecules in the system.

DSC curves for the pure 6BA, 8OBA, and their mixture are recorded in both the heating and cooling scans. The phase transition temperatures are identified as the temperatures at which peaks appear in cooling or heating curves. The area under the peak which is automatically measured by the DSC represents the associated heat of transition, ΔH, or enthalpy. Since the entropy jump is related to the heat of transition, i.e., ΔH = TΔS, where T is the transition temperature and ΔS is the entropic change, the calorimetric measurements determine the order of each phase transition. Figure 4 illustrates the DSC curves obtained via continuous heating of the pure 6BA, 8OBA liquid crystals, and 6BA/8OBA mixture. As for pure 8OBA [20], the stable mesophase sequence on heating from room temperature is crystalline (Cr)-smectic A (SmA)-smectic C (SmC)-nematic (N)-isotropic (I), whereas for pure 6BA [21], the SmA and SmC mesophases are absent being the mesophase sequence: Cr–N–I. The DSC curves for 6BA/8OBA mixture obtained on heating across the crystalline-to-nematic and the nematic-to-isotropic phase transitions are also shown in Fig. 4. As shown in Fig. 4, the mesophase properties of 6BA/8OBA mixture are similar to pure 6BA, and also the nematic range of 6BA/8OBA mixture is wider than the nematic ranges of both liquid crystals 6BA and 8OBA. Figure 4 illustrates that the produced 6BA/8OBA liquid crystal mixture displayed pure liquid crystal properties.

The data of transition temperatures (T) and enthalpies (∆H) obtained from Fig. 4 of the transition involving LC phases in 6BA/8OBA mixture and entropies (∆S) calculated for each phase transitions are presented in Table 1. As shown in Table 1, the phase transition temperatures and the phase transition enthalpy changes obtained during cooling were lower than the transition temperatures and the enthalpy changes obtained during heating. ΔH and ΔS values obtained in our experiments were in accordance with the values reported in the literatures [21–23].

The heating rate is an important parameter because it introduces a controllable time scale [24]. Figure 5 shows the DSC curves obtained by heating at different heating rates of 6BA/8OBA liquid crystal mixture. As shown in Fig. 5 and Table 2, the heating rate increases from 5 to 20 °C min−1, the phase transitions occur in a shorter time, because of more heat energy. For example, as seen Table 2, while the nematic phase passes to the liquid state in about 14.39 min under heating rate 5 °C min−1, the same phase transition passes to isotropic phase in about 3.46 min under heating rate 20 °C min−1. Therefore, solid phase changes from crystal–nematic to nematic–isotropic phase in a shorter period at higher heating rates. The phase transition peak heights have also increased by increasing the heating rate. These features of the sample against sudden temperature changes show abrupt phase transition, and thus imply that these samples do not loss their liquid crystalline properties against sudden temperature changes for technological applications.

Thermal stability factor

The phase transition temperatures are affected from chain length of liquid crystal molecules. It is reported [25, 26] that when the liquid crystal molecules have two end chains, the phase transition temperatures are higher for the systems with equal chain length. The chain with different lengths also affects the phase transition temperatures in an asymmetric system as well as the temperature ranges of various phases. The liquid crystals used in technology are materials which show nematic phase at room temperature. For this reason, the chain length of liquid crystal molecules must be short, or the molecules with short and long chains must be mixed. Thermal phase stability factor is an important parameter to determine the benefits of the mesogen that exhibits nematic phase [26]. In the present work, the nematic phase stability factor is discussed because 6BA/8OBA mixture only exhibits nematic phase. The nematic phase stability factor can be attributed to nematic to isotropic transition temperature as well as to the temperature range of nematic phase. It is reasonable to define a parameter called thermal stability factor (S). The nematic stability factor, S N, is given by S N = T mid∗∆T N, where T mid is the mid nematic temperature and ∆T N the nematic thermal range. In this manner, the thermal stability of nematic of 6BA/8OBA mixture is calculated and tabulated in Table 1. From Table 1, it can be seen that the stability calculated for nematic phase obtained during heating is smaller than the stability calculated for nematic phase obtained during cooling, and it also has high mesophase stability because of long alkyloxy chain of 8OBA. The liquid crystal mixtures with alkyloxy chain generally exhibited high mesophase stability. Hence, the phase transition peaks were not difficult to detect accurately by DSC.

Order parameter

Phase transition may be identified by two common types, first order and second order which depend on how the order changes during the phase transition. The order of transition can be estimated thanks to many theories such as Landau theory and mean field theory [27]. A phase transition is noted by a continuous or discontinuous change in the equilibrium value of the order parameter. A first-order transition is one which has a discontinuity in the order parameter itself, while a second-order transition is one which has a discontinuity in the first derivative of the order parameter [26]. In this study, we estimate the order of phase transitions via Navard and Cox parameter [28] that is an experimental method in determining the order of phase transition. According to Cox theory [28], the first-order or second-order transitions can be identified basing on the ratio (N X) of the measured phase transition peak heights. If the ratio is 1 < N X ≥ √2, it is called a first-order transition, and if the ratio is N X = 2, it is called a second-order transition. The magnitude nearing 1.8 and above can be considered as weak first-order transition. One can see how the Nx ratio of the individual phases is calculated in the literatures [26, 28, 29]. Corresponding to the DSC curves with scan rates of 10 and 5 °C min−1, the ratio N X was calculated and listed in Table 1. As shown in Table 1, while the crystal-to-nematic transition was first order, the nematic-to-isotropic transition was second order according to ratio N X.

POM studies of HBLCs

The morphological structure of the 6BA/8OBA liquid crystal mixture was examined by POM. The phase transitions of 6BA/8OB liquid crystal mixture observed during the heating by DSC are also observed with POM experiments. Nomenclature of phase transition is made according to the results of POM analysis and the standard textures reported in the literature [30]. For example, Fig. 6 shows the nematic phase of 6BA/8OB liquid crystal mixture observed at 110 °C during the heating by POM. Moreover, it is observed that the phase transition temperatures observed during the POM experiments are in line with the phase transition temperatures obtained in the DSC experiments. The DSC and POM results obtained for the 6BA/8OBA liquid crystal mixture are in good agreement with the results found in the literature [20, 31, 32], which conducted similar studies.

Conclusions

It was observed that phase transitions showing liquid crystal properties were present in 6BA/8OBA liquid crystal mixture during continuous heating and cooling via DSC, and the nematic range of 6BA/8OBA mixture was wider than the nematic ranges of 6BA and 8OBA, and the phase transition temperature values obtained in the DSC experiments were in good agreement with the phase transition temperature values observed in the POM experiments. Moreover, while the crystal-to-nematic transition was first order, the nematic-to-isotropic transition was second order. It was also seen that the phase transition temperatures and enthalpy values of 6BA/8OBA mixture obtained during continuous heating were higher than the phase transition temperature and enthalpy values obtained during continuous cooling. However, the entropy change and thermal stability values obtained during heating were lower than the entropy change and thermal stability values obtained during cooling. Besides all, it was observed that whether there was any reaction in the mixture when the 6BA/8OBA mixture was heated at different heating rates. The obtained DSC data showed that the 6BA/8OBA mixture does not loss its liquid crystalline properties against sudden temperature changes.

References

Priestley EB, Wojtowicz PJ, Sheng P. Introduction to liquid crystals. 1st ed. London: Plenum Press; 1974.

Demus D, Goodby J, Gray GW, Spiess HW, Vill V. Handbook of liquid crystals. 1–3 ed. VCH: Wiley; 1998.

Ahmed HA, Naoum MM. Mesophase behavior of binary and ternary mixtures of benzoic acids bearing terminal substituents of different polarity and chain-lengths. Thermochim Acta. 2014;575:122–8.

Gray GW. Molecular structure and properties of liquid crystals. London: Academic press; 1962.

Vijayakumar VN, Murugadass K, Madhu Mohan MLN. Study of intermolecular hydrogen bonding in p–n-alkoxybenzoic acids and alkyl aniline homologous series: part I. Mol Cryst Liq Cryst. 2009;515:39–48.

Vijayakumar VN, Madhu Mohan MLN. Optical, thermal and dielectric studies in linear hydrogen bonded liquid crystal homologous series. J Mol Struct. 2011;1000:69–76.

Vijayakumar VN, Madhu Mohan MLN. Study of thermal and electrical properties exhibited by two ferroelectric self-assembly systems. J Mol Struct. 2011;991:60–7.

Pongali Sathya Prabu N, Vijayakumar VN, Madhu Mohan MLN. Thermal and dielectric studies of selfassembly systems formed by hydroquinone and alkyloxy benzoic acids. Phys B. 2011;406:1106–13.

Katranchev B, Naradikian H, Petrov M. The role of hydrogen bonding for initiation of chirality, dendrites and physical gel in nematics with short range smectic C order. J Optoelectron Adv Mater. 2005;7:273–6.

Sreehari Sastry S, Lakshmi Sarada K, Mallika K, Nageswara Rao C, Lakhminarayana S, Sie Tiong H. Eigen value analysis studies on hydrogen-bonded mesogens. Liq Cryst. 2014;41:1483–94.

Özgan Ş, Okumuş M. Thermal and spectrophotometric analysis of liquid crystal 8CB/8OCB mixtures. Br J Phys. 2011;41:118–22.

Paleos CM, Tsiourvas D. Supramolecular hydrogen-bonded liquid crystals. Liq Cryst. 2001;28:1127–61.

Schröder I. Űber die Abhängigkeit der Löslichkeit eines festen Körpers von seiner Schmelztemperatur. Z Phys Chem. 1893;11:449–65.

Van Laar JJZ. The melting or freezing curves in binary systems, where the solid phase is a mixture of (amorphous solid solution or solid solutions) of the two components. Z Phys Chem. 1908;64:257–97.

Blinov LM, Chigrinov VG. Electrooptic effects in liquid crystal materials. New York: Springer; 1994.

Okumus M. Phase transitions of alkyl and alkyloxy cyanobiphenyl-benzoic acid liquid crystals and their mixtures. Ph.D. Thesis: Kahramanmaras Sutcu Imam University, 2012.

Oweimreen GA, Hwang JS. Evidence of tilt angle in an 8CB–10CB mixture. Chem Phys Lett. 2001;334:83–8.

Bouchaour T, Benmouna F, Roussel F, Buisine JM, Coqueret X, Benmouna M, Maschke U. Equilibrium phase diagram of poly(2-phenoxyethylacrylate) and 5CB. Polymer. 2001;42:1663–7.

Okumuş M, Özgan Ş. Investigation of the phase transition and absorption properties of liquid crystal hexylcyanobiphenyl/octylcyanobiphenyl mixtures. Asian J Chem. 2013;25(7):3879–83.

Chen LG. Thermo-optical properties of polymer dispersed liquid crystals. Ph.D. Thesis: RMIT University, 2007.

Monte MJS, Almeida ARRP, Almeida ARRP, Ribeiro da Silva MAV. Thermodynamic study of the sublimation of eight 4-n-alkylbenzoic acids. J Chem Thermodyn. 2004;36:385–92.

Naoum MM, Fahmi AA, Alaasar MA, Salem RA. Supramolecular liquid crystals in binary and ternary systems. Thermochim Acta. 2011;517:63–73.

Muniprasad M, Srinivasulu M, Chalapathi PV, Potukuchi DM. Influence of chemical moieties and the flexible chain for the tilted smectic phases in linear hydrogen bonded liquid crystals with schiff based pyridine derivatives. J Mol Struct. 2012;1015:181–91.

Okumuş M, Özgan Ş, Yılmaz S. Thermal and optical properties of some hydrogen-bonded liquid crystal mixtures. Br J Phys. 2014;44:326–33.

Smith GW, Gardlund ZG. Liquid crystalline phases in a doubly homologous series of benzylideneanilines-textures and scanning calorimetry. J Chem Phys. 1973;59(6):3214–28.

Rajanandkumar R, Pongali Sathya Prabu N, Madhu Mohan MLN. Characterization of hydrogen bonded liquid crystals formed by suberic acid and alkyl benzoic acids. Mol Cryst Liq Cryst. 2013;587:60–79.

Chandrasekhar S. Liquid crystals. New York: Cambridge University Press; 1977.

Navard P, Cox R. Study of the smectic a nematic transition in octyl and nonyl cyanobiphenyls. Mol Cryst Liq Cryst. 1984;102:261–4.

Pongali Sathya Prabu N, Madhu Mohan MLN. Thermal analysis of hydrogen bonded benzoic acid liquid crystals. J Therm Anal Calorim. 2013;113(2):811–20.

Gray GW, Goodby JW. Smectic liquid crystals: textures and structures. London: Leonard Hill; 1984.

Vijayakumar VN, Madhu Mohan MLN. Design and characterization of hydrogen bonded ferroelectric liquid crystals: a study of light modulation in nematic and smectic orderings. Opt Int J Light Opt. 2012;123:1044–50.

Okumuş M, Özgan Ş. Thermal and mesomorphic properties of ternary mixtures of some hydrogen-bonded liquid crystals. Liq Cryst. 2014;41(9):1293–302.

Acknowledgements

I would like to thank the Batman University Scientific Research Projects Coordination for its financial support, Project No. BTUBAP-2013-MMF-9, and Prof. Dr. Süleyman Yılmaz for his technical assistance with POM measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Okumuş, M. Thermal characterisation of binary mixture of some supramolecular liquid crystals. J Therm Anal Calorim 120, 1603–1608 (2015). https://doi.org/10.1007/s10973-015-4488-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4488-1