Abstract

Since carbon nanotubes (CNTs) are unstable in different polar solvents such as water, using surfactants can open a new gateway for solving the challenge by attaching non-covalent hydrophilic bonds. Here, the influence of different surfactants including gum arabic (GA), cetyl trimethylammonium bromide (CTAB) and sodium dodecyl sulfate (SDS) on stability and thermophysical properties of multi-walled carbon nanotubes (MWCNTs) in aqueous media is experimentally investigated. To reach this purpose, aqueous suspension of surfactant–MWCNT was synthesized in the ratios 0.5–1, 1–1 and 2–1. Zeta potential was used to determine stability of above-mentioned suspensions as a common method. Dynamic light scattering analysis was also employed to determine particles size distribution. The results indicated relative stability of suspensions in all ratios. It was also found that the minimum particle size was obtained in the presence of the ratio 1–1 of SDS and CTAB. Thermophysical properties of above-mentioned suspensions including viscosity, shear stress, electrical conductivity, surface tension and density were also studied at the range of 20–80 °C. The results indicated an increase in the electrical conductivity, density, viscosity, shear stress and a decrease in the surface tension (except in GA) of suspensions in all concentrations relative to pure water in constant temperature. As temperature increases, the electrical conductivity increases significantly, while the viscosity, shear stress, density and surface tension decreases more or less for all concentrations.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nowadays, nanofluids open a new and promising gateway for different applications due to their desirable properties [1–6]. In 1995, Choi [7] introduced “nanofluid” in United States–Argon National Lab as a new type of fluid. Nanofluids are known as the new generation of fluids with promising potential in terms of heat transfer [8–14]. To realize more performance, one of big family of carbon allotrope, carbon nanotubes (CNTs), was introduced to enhance heat transfer rate of base fluids, which has received great attention due to the high thermal conductivity [15–17]. However, researchers faced new challenges of lack of dispersibility in polar solvents for employing CNT. Due to good non-covalent linkage between the hydrophilic chains of gum arabic (GA) and water, Shanbedi et al. [18] suggested this surfactant. Amiri et al. [19] suggested covalently functionalization of CNT by hydrophilic groups. They introduced that covalent bond leads to more stability in water. Non-covalent functionalization is quick and cost-effective in comparison with covalent functionalization.

So, thermophysical properties of nanofluids such as electrical and thermal conductivity, viscosity, shear stress, surface tension and density are the main characteristics in heat transfer systems which are worthwhile to be studied.

Ding et al. [20] measured viscosity of the CNT–water nanofluid as a function of shear rate. They observed that nanofluids viscosity increases with increasing concentration and decreasing temperature. They also studied thin shear behavior and concluded that nanofluids can yield better flow performance due to high shear rate in the walls leading to low viscosity. In a separate study, they measured viscosity of the nanofluid Al2O3–water in volume concentrations of 1–4 %. Again, they found that the viscosity increases with increasing volume concentration and the fluid retains its natural Newtonian behavior [21]. Similar works have been done by Estellé et al. [22–24] on Al2O3 and CNT at low concentration and low temperatures, which investigated the effects of temperature and shearing time on viscosity for water-based nanofluids.

Properties of electrical and thermal conductivity of the suspension including ZnO and CuO in xanthan gum were studied by Ponmani et al. [25]. The results indicated a significant improvement in both electrical conductivity and thermal conductivity of the nanofluids with increase in nanoparticles concentration. They reported 25 and 50 % improvement in electrical conductivity for the suspensions including ZnO and CuO, respectively. In another study, Ganguly et al. [26] measured electrical conductivity of the nanofluid Al2O3–water. They reported a linearly increase in the electrical conductivity with increase in concentration of nanoparticles. Also, they introduced the electrical conductivity as a function of temperature.

Surface tension is one of thermophysical properties that having great effect on the boiling heat transfer and bubble dynamic in fluids. Xue et al. [27] provided surface tension data for the oxidized CNT–water nanofluids. They reported about 14 % increase in surface tension of the nanofluid compared to the pure water in the same temperature by adding oxidized CNT. Cheng et al. [28] reported a reduce in surface tension by adding surfactants into the water. Surfactants are usually used to stabilize nanofluids so their effects on physical properties cannot be ignored. Adding surfactants into nanofluids has a great effect on their surface tension [21, 29]. Surfactants have an effect like a surface membrane between nanoparticles and base fluid and change nanofluid surface tension [30].

Among thermophysical properties, density is of a great importance in free convection heat transfer. Riehl [31] performed an experimental study on the nickel–water nanofluid and reported good increase of 3.2 and 4.7 % in the density of nanofluid at nanoparticles concentrations of 3.5 and 5 %, respectively. Syam Sunder et al. [32] estimated nanofluids densities in different temperatures and reported that as temperature increased, the density decreased. Similarly, using specific weight in the temperature range 30–90 °C and different concentrations of 1–4 %, Harkirat [33] measured the density of the aqueous suspension of Al2O3. He observed that nanofluid density increased as nanoparticles concentration increased relative to the base fluid. Nanofluid density also decreased as temperature increased.

As nanofluid science developed and different researchers confirmed their high performance in heat transfer, the discussion of their stability and thermophysical properties has been received less attention. In the present research, aqueous suspensions of MWCNT were synthesized in the presence of various surfactants GA, CTAB and SDS in different weight ratios. Above-mentioned suspensions have been stabilized by creating non-covalent bonds. Then, zeta potential, average particle size distribution, dispersion, wettability, viscosity, shear stress, electrical conductivity, surface tension and density for suspensions were measured.

Experimental

Materials and methods

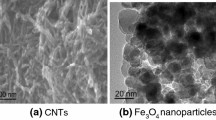

Pristine multi-walled carbon nanotubes (MWCNTs) (10–20 nm in diameter, ~30 μm in length and carbon purity >95 %) were purchased from Shenzhen Nano-Tech Port Co. Surfactants of GA, cetyl trimethylammonium bromide (CTAB) and sodium dodecyl sulfate (SDS), all analytical grade, were purchased from Merck Inc. However, Table 1 indicated property of above-mentioned surfactants.

MWCNT amount of 0.1 mass% was used for the synthesis of surfactant–MWCNT aqueous suspension. Then, above-mentioned suspensions were synthesized in the ratios of 0.5–1 (GA 0.5–1, CTAB 0.5–1, SDS 0.5–1), 1–1 (GA 1–1, CTAB 1–1, SDS 1–1) and 2–1 (GA 2–1, CTAB 2–1, SDS 2–1). For suspension stability, the ultrasonic probe with the power of 750 W and 20 kHz was used for 10 min.

Instrumentation

The stability and particle size of surfactant–MWCNT aqueous suspension were confirmed by a Malvern Zetasizer Nano ZS analyser (Malvern Instrument Inc., London, UK). The Zetasizer Nano ZS is a high-performance two-angle particles and molecular size analyzer for the enhanced detection of aggregates and measurement of small or dilute samples, and samples at very low or high concentration using dynamic light scattering (DLS) with noninvasive backscatter optics. In addition, the zeta potential analyzer uses the electrophoretic light scattering for particles, molecules and surfaces, and a molecular weight analyzer uses static light scattering. The zeta potential was recorded in the range 0–60 mV (positive or negative). Also, the Dino-Lite Premier AM7013MZT digital handheld microscope with 5 megapixel sensor was used to photograph of the droplet suspensions.

The rheological behavior of the suspensions was measured in comparison to water using a Brook field rheometer (LVDVIII Ultra Rheometer, USA) at a shear rate of 50 s−1. The rheometer was equipped with a RTD temperature probe for sample monitoring. Meanwhile, the viscosity range capability was 0.1–600 million cP (mPa s). The experiment was replicated twice to confirm the accuracy of the data measured with the rheometer. The electrical conductivity of the resulting suspension was measured using an electrical property analyzer based on the new technique. The surface tension was measured by using a Force Tensiometer K100 (KRÜSS Ltd., Germany). The principal measuring methods are based on the precise measurement of the force which occurs when wetting a measuring probe or a solid sample. In this device, the density of liquids can also be accurately measured with a special solid sample kit.

The surfactant–MWCNT aqueous suspensions were first dispersed in pure water by the ultrasonic probe with the power of 750 W and 20 kHz (Sonics & Materials, Inc., USA). Next, the above-mentioned suspensions were prepared for measurement of the stability and thermophysical properties.

Results and discussion

Stability

Zeta potential and particle size

Zeta potential indicates the extent of repulsion between two adjacent particles, attributing to the hydrodynamic level. As zeta potential increases, an electrical double layer (EDL) is formed on the particle surface, leading finer particles, implying narrower particle size distribution, which resulted in lower tendency for aggregation. When zeta falls, attraction overcomes repulsion and coagulation occurs while high zeta potential particles are stable electrically. The EDL is formed on the surface area exposed to the surrounding liquid environment.

Colloid stability and DVLO theory suggest that the stability of colloidal system is equal to the resultant of van der Waals attractive force and electric repulsion force related to EDL. The double layer is created when two particles become aggregated. According to the theory, when approaching two particles occurs, some sort of energy shield arises preventing their stick. However, if two particles are close together with enough force, overcoming the energy shield, gravity may stick them together which is irreversible. It can be considered that if repulsive force between particles is large while solving in a solvent, it prevents particles sticking. So, colloid system becomes more stable and in the absence of that force, finally sedimentation occurs and the system becomes unstable; small sediments created are stable dramatically and are not broken under Brownian motions; however, the system resumes its primary state by applying external forces.

Zeta potential of surfactant–MWCNT aqueous suspension in different concentrations is shown in Table 2. Zeta potentials are obtained for all surfactants and concentrations in the range 20.5–32 mV (negative and positive). Minimum zeta potential is for CTAB 0.5–1 and the maximum is for SDS 1–1.

Suspensions with the ratio of 1–1 have the best stability for all surfactants. The stability tendencies as a value are −32, −29.7 and 28.2 for the surfactants SDS, GA and CTAB, respectively.

Particle size distribution is of high importance by efficiency, physical stability and rheological properties of the product. Table 2 indicates average particle size distribution in suspension. In suspensions synthesized, minimum average particle size distribution belongs to the suspension CTAB 1–1 and SDS 1–1 which are 164.7 and 171.4 nm, respectively.

Dispersion

One of challenges researchers face in employing CNT in polar solvents such as water is their instability. Surfactants overcome the problem slightly by creating non-covalent bonds. Figure S1 (A, B, C) indicates samples synthesized in concentrations 0.5–1, 1–1 and 1–2. In these figures, there are foams in suspensions containing surfactants CTAB and SDS in all concentrations. This can be one of disadvantages of the two surfactants in suspensions containing CNT due to formation of foam in heat and mass transfer systems. However, some surfactants bonds may be broken in high temperatures leading to reduced suspension efficiency [34].

Foam bubbles are liquid polygon chambers surrounded by air molecules. Flat bounders and vertices intersection of bubbles form the structure of foam piping network. Flat bounders in the foam structure are continuous and connected and are crossing or foam drain channel. Excess liquids of foam structure are drained from these paths until the equilibrium is established between weight force and capillary force in layers. Foam flexibility is resulted from the presence of liquid in its structure. When liquid is drained from foam structure, round- or spherical-shaped bubbles are transformed to stiff multifaceted crystal-shaped ones (Figure S1). After elapsing 60 days, samples were again photographed to investigate the stability of above-mentioned suspensions. Figure S2 (A, B, C) shows samples synthesized in concentrations 0.5–1, 1–1, 1–2, respectively, after 60 days. The picture indicates clearly complete sedimentation of the sample CTAB 0.5–1. As mentioned in previous section, suspension CTAB 0.5–1 is of the least zeta potential value (20.5 mV).

Expansion and collision of drops and wettability are very important in nanofluids applications as improved coolants. Meanwhile, nanoparticles affect on increased base fluid wettability due to interactions of solid-particles, fluid-particles and particles–particles [35]. One of nanofluids applications is in boiling processes. Studies performed indicate that deposition of porous layers of nanoparticles as well as deposition of nanoparticles on the heater surface is the main reason of wettability improvement [36].

Figure 1a, b shows wettability of surfactant–MWCNT aqueous suspensions compared to water on the surface of stainless steel 316 at 20 and 80 °C, respectively. It is clear that low contact angle implies high surface wettability. Figure 1a, b indicates the reduction in contact angle from 20 to 80 °C. This reduction is more evident for suspensions than pure water. Wettability process is of three phases, at least two of which should be fluid. For example, here air is replaced by a liquid on a solid surface. There is no doubt that surfactant–MWCNT aqueous suspensions are a wetting factor accelerating the effect. Actually, the type of surfactant can also contribute to this.

Thermophysical properties

Viscosity and shear stress

Viscosity is a crucial factor in dynamic design of nanofluids for applications of heat transfer especially in pressure drop systems. In a moving fluid in which different layers are shifted relative to each other, the resistance of fluid layers against slide is known as fluid viscosity. The more the viscosity, the more shear stress is required for equal deformation. Nevertheless, viscosity is an inherent property of a fluid affecting heat transfer and flow. On the other hand, viscosity takes Newtonian or non-Newtonian behavior by adding nanoparticles into the base fluid depending on factors such as concentration, size and nanoparticles type, temperature and shear rate.

Viscosity and shear stress variations of surfactant–MWCNT aqueous suspensions in different concentrations and temperatures are shown in Tables 3 and 4, respectively. The results indicate reduced viscosity and shear stress in constant shear rate as temperature increases. However, this reduction is more evident for the ratios of 0.5–1 and 2–1 compared to the ratio 1–1 of surfactant–MWCNT aqueous suspensions. On the other hand, viscosity and shear stress decreased with increasing surfactant concentration (except in the ratio 1–1 at temperatures 40–80). These interactions can be attributed to aggregation of MWCNT and EDL effect [37].

Among various interactions occurred between solvent and solute, hydrophobic interaction is one of them. This can lead to formation of aggregate structures of solutes in a heterogeneous solvent. Generally, solvent molecules have high affinity to each other. Only the solutes can be solved in aqueous solution if they have destructive power of attraction between water molecules. Otherwise, water structure is closed to these solutes and forms aggregate structures. One of aggregate structures being important for surfactants in aqueous solvents is micelle structure. Surfactants are amphiphilic molecules. This implies that these molecules have a hydrophilic segment and a hydrophobic segment. When a surfactant is solved in an aqueous solution, hydrophilic segments (usually hydrophilic head of the molecule) are inclined toward water; on the contrary, hydrophobic end of molecule is driven by water molecules strongly. So, in appropriate concentrations of surfactants, hydrophilic head inclines outwardly (aqueous solution) and hydrophobic ends of the molecules direct toward each other. However, if surfactant concentration increases, it can be transformed into bar-shaped or layered. This can affect on viscosity and shear stress of aqueous suspension.

Electrical conductivity

Electrical resistance unit which is in MΩ and inverted µS is used to calculate electrical conductivity.

where R, V and I are electrical resistance, electrical potential difference and current.

Figure S3 indicates the device made for measuring electrical conductivity. Here, the power supply in a fixed voltage 10 V is used. Electrodes made of brass-copper alloy covering with chromium in 1.9 mm diameter and 15.1 mm long were used for measuring electrical conductivity. Then, output current from samples synthesized in different concentrations was recorded by Advanced Digital Multimeter TR6851. Electrical conductivity data recorded for different samples at temperatures 20–80 °C are shown in Table 5.

Increased electrical conductivity with increasing temperature is evident. It can be seen in Table 5. For example, the highest electrical conductivity was recorded about 204.6 μS cm−1 for SDS 2–1 at 80 °C, while this is 91 μS cm−1 at 20 °C. The main point is significant improvement of electrical conductivity of surfactant–MWCNT aqueous suspension relative to pure water which increases with increasing surfactant concentration. This can be due to EDL on nanotubes surfaces. On the other hand, formation of EDL affects on surface charge being able to affect on particles motions and their migration toward opposite charge. However, electrical conductivity of water affects on its corrosion rate and the degree of ionization of water salts. For example, as corrosion rate of water increases, two aqueous samples which are identical by oxygen and pH, the one with higher electrical conductivity becomes more corroded.

Surface tension

Surface phenomena and surface chemistry are very important in different industrial and non-industrial parts. For example, catalytic reactions on the surface, lubricants, corrosion, adhesives, detergents, extraction operation, biomass chemistry and electrochemical cell reactions, all are resulted from surface phenomena. Surface tension is one of surface phenomenon and is a property in liquids defined as cohesive forces between liquid molecules at the surface. Molecules on the surface are not surrounded like other molecules and are held together with a certain force; this surface creates a layer making surface molecule movement difficult.

Surface tension variation of surfactant–MWCNT aqueous suspensions in different concentrations and temperatures is shown in Table 6. The results indicate reduced surface tension as temperature increased. The main reason is higher intermolecular energy of suspension at higher temperatures and consequently increased slide ability of molecules. Nevertheless, suspensions containing surfactants CTAB and SDS reduced surface tension drastically relative to GA. This is more as surfactant concentration increases. For example, surface tension of suspensions SDS 2–1 and SDS 1–1 at 20 °C decreased 88.4 and 64.7 % and at 80 °C, 62.6 and 48.1 %.

Regarding suspension containing GA, surface tension is higher than that of pure water in all concentrations. This can be attributed to intermolecular forces which is the most important parameter in surface tension. Since surface tension is resulted from intermolecular forces, as the forces are stronger, surface tension is higher. Increased polar and ionic particles in water can increase attraction between particles because attraction between ionic particles and molecules of water is stronger than intermolecular attraction of pure water. So, surface tension in suspensions containing GA is higher than that of pure water in all concentrations.

Molecules that are present in the liquid bulk are affected by tensile forces that are equal in all directions. But the molecules at the interface of liquid–gas are naturally influenced by the unparalleled tensile forces, the result of which is molecule tension inwardly toward liquid bulk. So, most of molecules that are present in the liquid surface tend to leave the surface and to be pulled inwardly. For this reason, liquids take the forms their surface area is minimum because in this case, maximum number of molecules are in liquid bulk and the minimum on the surface.

As seen in Figure S1, suspensions containing SDS and CTAB create foams. In the layered structure between surfactants and water where some water is surrounded by surfactant layers, as soon as foam structure is drained, side surfaces become thin and surfactants layers become closer to each other. If layers become closer to each other, bubbles structures become more crystalline, multifaceted and firm. Surfactants form intersurface layers for chemical structures. Irregular space between surfactants molecules in layers and electrical charge particles indicates an event occurred in surfactants in water and contact interface. On the other hand, surface tension of water provides wall tension required for formation of thin bubbles. So, the surfactants SDS and CTAB decrease surface and intersurface tension of aqueous solvents.

Density

Density is defined as mass per unit volume which is one of thermophysical properties used for evaluating heat transfer of nanofluids. Since natural convection heat transfer is relied on buoyancy force and density difference, density effect can play a main role. However, researchers believe that increased density may lead to increased natural convection [38].

Density data obtained from surfactant–MWCNT aqueous suspensions and pure water are shown in Table 7. The results indicate that density of all samples decreased as temperature increased. However, the reduction is more for water. For example, density of pure water decreases 4.1 % at 80 °C relative to 20 °C, while density reduction for suspensions at the same temperatures was 1–1.5 %. Since density of particles is greater than that of liquids, it can be expected that by adding surfactant–MWCNT into pure water, the density of suspension increases. Generally, the density increase is increased as particle concentration increases. Here, this is not true and at the constant temperature and fixed ratio of MWCNT (0.1 mass%), adding surfactants in different concentrations does not affect on suspension density. However, surfactant–MWCNT aqueous suspensions increased density relative to pure water at all temperatures.

Conclusions

In the present study, first MWCNT aqueous suspensions containing different surfactants of GA, CTAB and SDS were synthesized in the different ratios of 0.5–1, 1–1 and 1–2 (constant value of 0.1 mass% of MWCNT). Then, their stability and thermophysical properties were studied. Regarding stability, the results are:

-

In all ratios, the stability of suspensions was appropriate relatively (except in CTAB 0.5–1).

-

The minimum particle size was obtained in the presence of SDS and CTAB in the ratio 1–1.

-

In all concentrations, suspensions containing CTAB and SDS had foam. This can be one of disadvantages of two surfactants containing MWCNT.

-

Wettability and contact angle have shown a downward trend in the temperature range of 20–80 °C. The reduction is more evident for suspensions as compared to the pure water.

Thermophysical properties of above-mentioned suspensions including viscosity and shear stress, electrical conductivity, surface tension and density were studied at temperatures 20–80 °C. The results are:

-

Increased temperature led to lower viscosity and shear stress in the constant shear rate. On the other hand, viscosity and shear stress decreased as the concentration of the surfactant increased (except in ratio 1–1 at 40–80 °C).

-

As the temperature increased, the electrical conductivity increased. Maximum electrical conductivity, 204.6 μS cm−1, was recorded for SDS 1–2 at 80 °C, while this was 91 μS cm−1 at 20 °C. However, increased surfactant concentration led to great improvement in electrical conductivity of surfactant–MWCNT aqueous suspensions than pure water.

-

Surface tension decreased as temperature increased. On the other hand, suspensions containing surfactants CTAB and SDS decreased surface tension greatly than GA. As the concentration of the surfactants increased, the surface tension decreased significantly.

-

As the temperature increased, density of all samples decreased which was more for water. On the other hand, at constant temperature and fixed ratio of MWCNT (0.1 mass%), adding surfactant in different concentrations had a poor affect on suspension density, more or less.

References

Mahian O, Kianifar A, Kalogirou SA, Pop I, Wongwises S. A review of the applications of nanofluids in solar energy. Int J Heat Mass Transf. 2013;57(2):582–94.

Yiamsawas T, Mahian O, Dalkilic AS, Kaewnai S, Wongwises S. Experimental studies on the viscosity of TiO2 and Al2O3 nanoparticles suspended in a mixture of ethylene glycol and water for high temperature applications. Appl Energy. 2013;111:40–5.

Amiri A, Shanbedi M, Amiri H, Heris SZ, Kazi S, Chew B, et al. Pool boiling heat transfer of CNT/water nanofluids. Appl Therm Eng. 2014;71(1):450–9.

Amiri A, Memarpoor-Yazdi M, Shanbedi M, Eshghi H. Influence of different amino acid groups on the free radical scavenging capability of multi walled carbon nanotubes. J Biomed Mater Res A. 2013;101A(8):2219–28.

Shanbedi M, Heris SZ, Amiri A, Adyani S, Alizadeh M, Baniadam M. Optimization of the thermal efficiency of a two-phase closed thermosyphon using active learning on the human algorithm interaction. Numer Heat Transf A Appl. 2014;66(8):947–62.

Tabari ZT, Heris SZ. Heat transfer performance of milk pasteurization plate heat exchangers using MWCNT/water nanofluid. J Dispers Sci Technol. 2014;36(2):196–204.

Choi SUS. Enhancing thermal conductivity of fluids with nanoparticles. International Mechanical Engineering Congress and Exposition; FED 231/MD 66. San Francisco: ASME; 1995. p. 99–105.

Barbés B, Páramo R, Blanco E, Pastoriza-Gallego M, Piñeiro M, Legido J, et al. Thermal conductivity and specific heat capacity measurements of Al2O3 nanofluids. J Therm Anal Calorim. 2013;111(2):1615–25.

Moreira L, Carvalho EA, Bell MJV, Anjos V, Sant’Ana AC, Alves A, et al. Thermo-optical properties of silver and gold nanofluids. J Therm Anal Calorim. 2013;114(2):557–64.

Barbés B, Páramo R, Blanco E, Casanova C. Thermal conductivity and specific heat capacity measurements of CuO nanofluids. J Therm Anal Calorim. 2014;115(2):1883–91.

Hemmat Esfe M, Saedodin S, Mahian O, Wongwises S. Thermal conductivity of Al2O3/water nanofluids. J Therm Anal Calorim. 2014;117(2):675–81.

Hosseini SM, Moghadassi AR, Henneke D, Elkamel A. The thermal conductivities enhancement of mono ethylene glycol and paraffin fluids by adding β-SiC nanoparticles. J Therm Anal Calorim. 2010;101(1):113–8.

Shanbedi M, Zeinali Heris S, Baniadam M, Amiri A, Maghrebi M. Investigation of heat-transfer characterization of EDA-MWCNT/DI-water nanofluid in a two-phase closed thermosyphon. Ind Eng Chem Res. 2012;51(3):1423–8.

Zeinali Heris S, Etemad SG, Nasr Esfahany M. Experimental investigation of oxide nanofluids laminar flow convective heat transfer. Int Commun Heat Mass Transf. 2006;33(4):529–35.

Beheshti A, Shanbedi M, Zeinali Heris S. Heat transfer and rheological properties of transformer oil-oxidized MWCNT nanofluid. J Therm Anal Calorim. 2014;118(3):1451–60.

Hong J, Lee J, Hong C, Shim S. Improvement of thermal conductivity of poly(dimethyl siloxane) using silica-coated multi-walled carbon nanotube. J Therm Anal Calorim. 2010;101(1):297–302.

Sparavigna A. Lattice specific heat of carbon nanotubes. J Therm Anal Calorim. 2008;93(3):983–6.

Shanbedi M, Zeinali Heris S, Baniadam M, Amiri A. The effect of multi-walled carbon nanotube/water nanofluid on thermal performance of a two-phase closed thermosyphon. Exp Heat Transf. 2013;26(1):26–40.

Amiri A, Shanbedi M, Eshghi H, Zeinali Heris S, Baniadam M. Highly dispersed multiwalled carbon nanotubes decorated with Ag nanoparticles in water and experimental investigation of the thermophysical properties. J Phys Chem C. 2012;116(5):3369–75.

Ding Y, Alias H, Wen D, Williams RA. Heat transfer of aqueous suspensions of carbon nanotubes (CNT nanofluids). Int J Heat Mass Transf. 2006;49(1):240–50.

Das SK, Putra N, Roetzel W. Pool boiling characteristics of nano-fluids. Int J Heat Mass Transf. 2003;46(5):851–62.

Aladag B, Halelfadl S, Doner N, Maré T, Duret S, Estellé P. Experimental investigations of the viscosity of nanofluids at low temperatures. Appl Energy. 2012;97:876–80.

Halelfadl S, Estellé P, Aladag B, Doner N, Maré T. Viscosity of carbon nanotubes water-based nanofluids: influence of concentration and temperature. Int J Therm Sci. 2013;71:111–7.

Halelfadl S, Maré T, Estellé P. Efficiency of carbon nanotubes water based nanofluids as coolants. Exp Therm Fluid Sci. 2014;53:104–10.

Ponmani S, William JKM, Samuel R, Nagarajan R, Sangwai JS. Formation and characterization of thermal and electrical properties of CuO and ZnO nanofluids in xanthan gum. Colloids Surf A. 2014;443:37–43.

Ganguly S, Sikdar S, Basu S. Experimental investigation of the effective electrical conductivity of aluminum oxide nanofluids. Powder Technol. 2009;196(3):326–30.

Xue H, Fan J, Hu Y, Hong R, Cen K. The interface effect of carbon nanotube suspension on the thermal performance of a two-phase closed thermosyphon. J Appl Phys. 2006;100(10):104909–14.

Cheng L, Mewes D, Luke A. Boiling phenomena with surfactants and polymeric additives: a state-of-the-art review. Int J Heat Mass Transf. 2007;50(13):2744–71.

Pantzali M, Kanaris A, Antoniadis K, Mouza A, Paras S. Effect of nanofluids on the performance of a miniature plate heat exchanger with modulated surface. Int J Heat Fluid Flow. 2009;30(4):691–9.

Kathiravan R, Kumar R, Gupta A, Chandra R. Characterization and pool boiling heat transfer studies of nanofluids. J Heat Transf. 2009;131(8):081902–9.

Riehl RR, editor. Analysis of loop heat pipe behaviour using nanofluid. In: Proceedings of heat powered cycles international conference (HPC), New Castle, UK; 2006.

Syam Sundar L, Ramanathan S, Sharma K, Babu PS. Temperature dependent flow characteristics of Al2O3 nanofluid. Int J Nanotechnol Appl. 2007;1(2):35–44.

Harkirat. Preparation and characterization of nanofluids and some investigation in biological applications. Thesis report. Patiala: Thapar University; 2010.

Shanbedi M, Zeinali Heris S, Amiri A, Baniadam M. Improvement in heat transfer of a two-phased closed thermosyphon using silver-decorated MWCNT/water. J Dispers Sci Technol. 2013;35(8):1086–96.

Sefiane K, Skilling J, MacGillivray J. Contact line motion and dynamic wetting of nanofluid solutions. Adv Colloid Interface Sci. 2008;138(2):101–20.

Kim S, Bang I, Buongiorno J, Hu L. Surface wettability change during pool boiling of nanofluids and its effect on critical heat flux. Int J Heat Mass Transf. 2007;50(19):4105–16.

Anoop K, Kabelac S, Sundararajan T, Das SK. Rheological and flow characteristics of nanofluids: influence of electroviscous effects and particle agglomeration. J Appl Phys. 2009;106(3):034909–15.

Trisaksri V, Wongwises S. Critical review of heat transfer characteristics of nanofluids. Renew Sustain Energy Rev. 2007;11(3):512–23.

Acknowledgements

The authors are grateful to Iran Nanotechnology Initiative Council for financial support and the Khorasan Research Institute for Food Science and Technology for performing the characterization analysis.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Shanbedi, M., Zeinali Heris, S. & Maskooki, A. Experimental investigation of stability and thermophysical properties of carbon nanotubes suspension in the presence of different surfactants. J Therm Anal Calorim 120, 1193–1201 (2015). https://doi.org/10.1007/s10973-015-4404-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4404-8