Abstract

Changes in the thermal conductivities of paraffin and mono ethylene glycol (MEG) as a function of β-SiC nanoparticle concentration and size was studied. An enhancement in the effective thermal conductivity was found for both fluids (i.e., both paraffin and MEG) upon the addition of nanoparticles. Although an enhancement in thermal conductivity was found, the degree of enhancement depended on the nanoparticle concentration in a complex way. An increase in particle-to-particle interactions is thought to be the cause of the enhancement. However, the enhancement became muted at higher particle concentrations compared to lower ones. This phenomenon can be related to nanoparticles interactions. An improvement in the thermal conductivities for both fluids was also found as the nanoparticle size shrank. It is believed that the larger Brownian motion for smaller particles causes more particle-to-particle interactions, which, in turn, improves the thermal conductivity. The role that the base-fluid plays in the enhancement is complex. Lower fluid viscosities are believed to contribute to greater enhancement, but a second effect, the interaction of the fluid with the nanoparticle surface, can be even more important. Nanoparticle-liquid suspensions generate a shell of organized liquid molecules on the particle surface. These organized molecules more efficiently transmit energy, via phonons, to the bulk of the fluid. The efficient energy transmission results in enhanced thermal conductivity. The experimentally measured thermal conductivities of the suspensions were compared to a variety of models. None of the models proved to adequately predict the thermal conductivities of the nanoparticle suspensions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Conventional heat-transfer fluids (e.g., water, ethylene glycol, engine oil, etc.) are found everywhere. Power generation, chemical production, manufacturing, transportation—these and many other facets of modern life require heat-transfer fluids. More efficient systems could be designed and built by an enhancement in the thermal properties of these fluids. Over several decades, studies of heat-transfer fluids augmented by adding particles of various materials have been done [1, 2]. Augmentation of the thermal properties of suspensions, containing particles from micrometers to millimeters in size, has been demonstrated. Unfortunately, suspensions of large particles are unstable and tend to clog systems having small channels [3–6].

Nanofluids, suspensions of particles with diameters less than 100 nm, are becoming more common thanks to advances in nanotechnology. For heat-transfer applications, the base of nanofluid suspension has a lower thermal conductivity than the particles. These suspensions are known to have high thermal conductivities relative to the pure base fluid. Unlike suspensions with large particles, nanofluids will not clog even micron-sized channels and are stable. Enhanced thermal conductivities have been shown for nanofluids containing small amounts of metal or nonmetal nanoparticles, such as Cu [1], Ag [2], Au [2], CuO [3], Al2O3 [4, 5], TiO2 [6], or carbon nanotubes [7]. However, more data is needed to determine the underlying enhancement mechanism.

In this study, the factors governing the enhancement in thermal conductivity of β-SiC nanofluids are analyzed.

Experimental

Materials

-

β-SiC nanoparticles powder, average size of nanoparticle: 20 nm (From Alfa Aesar co.).

-

β-SiC nanoparticles powder, average size of nanoparticle: 30 nm (From Alfa Aesar co.).

-

Pure liquid paraffin as base fluid.

-

Mono-ethylene glycol (MEG) as base fluid (have preparated than petrochemical company of Arak-Iran).

-

Oleic acid as dispersant.

Preparation of nanofluids

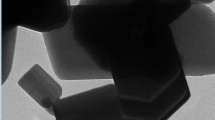

Suspensions were made by mixing β-SiC nanoparticle powders with one of the base fluids (i.e., MEG or paraffin). The reagents were used as received from the manufacturer. For paraffin based suspensions, 15% by weight of oleic acid relative to the solid powder was added to help stabilize the suspensions. No dispersant was added to MEG based suspensions. A Fritsch satellite-mill, shown in Fig. 1a, was used to ensure that the nanoparticles were well dispersed in the base fluid. The sample container and balls used in the milling process were made of agate, is shown in Fig. 1b. Suspensions were made by setting the mill to a velocity of 150 rpm for 30 min. Upon removal from the mill, the suspensions appeared completely homogeneous. Nevertheless, to ensure that the nanoparticles within the suspensions were not flocculated, the samples were placed into an ultrasonic bath (FRITSCH Ultrasonic, laborette 17). Stable nanoparticle suspensions were obtained after 1 h of intense sonication.

A photo of an unstable paraffin suspension, one that lacks oleic acid, is shown in Fig. 2a. A stable paraffin suspension, one utilizing oleic acid as a dispersant, is shown in Fig. 2b. Without the oleic acid, the paraffin suspensions are not stable. If oleic acid was added as previously described, the suspensions demonstrated good stability for the duration of the analysis.

Measuring nanofluids thermal conductivity

The thermal conductivity of nanofluids was measured by the transient hot wire method [8]. A 200 μm diameter, nickel–chromium alloy wire was used in the hot wire system. In order to prevent electrical short-circuits, a very thin Teflon coating was used to insulate the wire. The wire was put into a sample of the suspension to be measured and current was applied.

The thermal conductivity of the test fluid, k, was calculated according to Fourier’s law:

where q is power applied to the wire, T 1 and T 2 is the measured temperature at time t 1 and t 2, respectively. All measurements were performed at an ambient temperature of 25 °C. The accuracy of the system was ensured by measuring the thermal conductivity of distilled water and comparing to the previously published literature value of 0.59 W/m K [5].

Results and discussion

In general, these experiments show a striking enhancement in the thermal conductivity when β-SiC nanoparticles are added to the base fluid. This effect is shown in Fig. 3a, b. In these figures, the thermal conductivity of the suspension is shown versus particle concentration for two particle sizes. It should be noted that the particle concentration is expressed as the mass fraction of nanoparticles in the base fluid. For both MEG and paraffin based fluids, the greatest enhancement in thermal conductivity was found for smaller particles at higher concentrations. When no nanoparticles were added to the base fluids (i.e., pure MEG and paraffin), the thermal conductivity of MEG was found to be 0.27 W/m K, while paraffin was found to be 0.21 W/m K.

Next, we will discuss the effects of various factors (e.g., nanoparticle concentration, nanoparticle size, type of base fluid) on effective thermal conductivity of these nanofluids.

Effect of nanoparticle concentration

As shown in Fig. 3a, b, the effective thermal conductivity increases when the nanoparticles are added. The degree of enhancement diminishes above ~3% mass fraction. As particle concentrations increase, there will be an increase in particle-to-particle interactions because the distance between nanoparticles decreases. It is clear that additional modes of heat transfer are present when the nanoparticles are added to the fluid.

Effect of nanoparticle size

Figure 3a, b also show that the effective thermal conductivity increases as particle size is reduced. Brownian motion is the most likely cause of this factor, which has been shown to be an important factor in the thermal conductivities of nanofluids [9]. As particle size is reduced, Brownian motion increases. As a result, smaller particles exhibit more particle-to-particle interactions, which leads to an inverse relationship between particle size and thermal conductivity [9]. Smaller particles exhibit greater Brownian motion, which leads to greater thermal conductivity.

Effect of nanoparticles interactions

The rate and kind of nanoparticles interactions is different for different nanomaterials. For β-SiC nanofluids in this research, it occurred at concentrations above 3% mass. This range indicates the transition between the low concentration and high concentration regimes, which originates from the effectiveness of the particle interaction potential [10]. Specifically, the increasing of thermal conductivity is relatively independent of particle interaction for low concentrations, while it is strongly dependent on the particle interaction for high concentrations. The star and end points of the transition depend on the properties of both particles and base fluid. After this range, the nanofluid thermal conductivity may find again the rising path.

Effect of base fluid

Figure 4a, b shows the enhancement in thermal conductivity expressed as a percent versus nanoparticle concentration. When expressed as a percent, the enhancement in the thermal conductivities for SiC–paraffin nanofluids was found to be greater than that for SiC–MEG nanofluids. Table 1 list the effective thermal conductivity and enhancement in thermal conductivity expressed as a percent for both nanofluids at 1 and 5% mass fractions.

a Enhancement percent of effective thermal conductivity of β-SiC–MEG nanofluids with mass fraction for 20 and 30 nm diameters of β-SiC nanoparticles. b Enhancement percent of effective thermal conductivity of β-SiC–Paraffin nanofluids with mass fraction for 20 and 30 nm diameters of β-SiC nanoparticles

The improvement in thermal conductivity of SiC–MEG nanofluids was found to be greater than that of SiC–paraffin nanofluids. The difference in viscosity between the two fluids may account for this result. Higher viscosity fluids impede particle-to-particle interactions. This, in turn, leads to fewer interactions for a given period of time. As a result, heat is more readily transferred from MEG to the particles, than from paraffin to the particles.

Another possible cause of the enhancement could be attributed to the interfacial properties of the particle and base fluid. Interfacial effects have been shown to enhance the thermal conductivity of nanofluids. For example, the thermal conductivity of a nanofluid is influenced by molecular level layering of the fluid at solid interface [11]. The atomic structure of the liquid at the nanoparticle surface is much more ordered than liquid in the bulk. It is the ordered nature of this layer that permits for higher thermal conductivity when compared to the randomly oriented fluid in the bulk. The ordered layer of fluid molecules may be represented as an interfacial shell. Within this shell, energy is efficiently transferred by phonons. As the thickness of this shell increases, there is a corresponding increase in the volume of the interface, which results in greater heat conduction [12]. The viscosity of the fluid and the interfacial properties of the particle fluid interface both have an effect on the thermal conductivity of a nanofluid.

By keeping the previously described mechanisms in mind, a few conclusions can be drawn: the thermal conductivity and/or thickness of the interfacial shell in the SiC–paraffin system is larger than that for SiC–MEG. Consequently, the effect that SiC nanoparticles have on thermal conductivity enhancement is greater for paraffin suspensions than for those with a base of MEG.

Comparison of experimental results to existing models

Various models have been developed to predict the thermal conductivity of nanofluids. The basis of these models was developed by Maxwell [13]. Maxwell’s model accurately predicts the thermal conductivity of dilute suspensions of large, spherical particles. Maxwell’s model predicts the effective thermal conductivity, k eff, as follows:

where k m is the thermal conductivity of base fluid, α is the ratio of thermal conductivity of the particle to that of the base fluid, and ν denotes the volume fraction or concentration of the dispersed particles. The Hamilton–Crosser (H–C model) is a modification of Maxwell’s original model. It can be used to predict the thermal conductivities of suspensions containing large, non-spherical particles [14].

The H–C model is given by:

where n is the shape factor of particle (n = 3 for a spherical particles). Recently, models to account for the enhanced thermal conductivities shown by nanofluids have been developed. One such model, developed by Xue and Wen, is given by [14]:

where k e is the effective thermal conductivity of the nanofluid, k m is the thermal conductivity of the suspending fluid, k 1 is the thermal conductivity of a particle having a radius of r, k 2 is the thermal conductivity of the interfacial shell having a thickness of t, and α = r 3/(r + t)3. Figure 5a, b compare the values of the effective thermal conductivity determined experimentally to those predicted by the previously described theoretical models. The comparison for SiC–MEG is shown in Fig. 5a, while that of SiC–paraffin can be seen in Fig. 5b. In the models, a value of 340 W/m K was used for the thermal conductivity of the β-SiC nanoparticles.

By looking at Fig. 5a, b, it becomes immediately clear that none of the models accurately predicted the experimentally determined values of the thermal conductivity. The thermal conductivities predicted by the Maxwell and H–C models are linear with and are much lower than the experimentally determined values. The Maxwell and H–C models neglect affects associated with the nanoparticle-fluid interface (i.e., they only consider the thermal conductivities of the particle and the base fluid). The value of the thermal conductivity predicted by the Xue and Wen model is nearly linear with volume fraction in this regime, under these conditions. Of the models, Xue and Wen best predicts the thermal conductivities, but it fails to capture the diminishment that is shown at concentrations above 3% mass fraction. The Xue and Wen model tries to account for the enhanced thermal conductivities caused by nanoparticles in suspension. The model takes the particles size and properties of the particle–fluid interfacial shell into consideration. Previous studies estimated the thickness of the MEG interface to be t = 3 nm, while the thermal conductivity of the shell was taken to be k e = 10 W/m K [15]. In this study, we also used these values for the interface thickness and thermal conductivity. For the case of β-SiC–paraffin, values of t = 5 nm and k e = 20 W/m K were used.

Conclusions

In this study, the thermal conductivities of β-SiC–MEG and CuO–paraffin suspensions of nanoparticles were found. Initially, the effective thermal conductivity of the nanofluid increases as nanoparticles are added, however, the enhancement begins to diminish above ~3% mass fraction. This phenomenon can be related to particles interactions. Additional modes of heat transfer are present when the nanoparticles are added to the fluid, but the enhancement becomes muted as the particle concentration increases. Also, smaller particles showed more enhancement than larger particles. An increase in the Brownian motion of smaller particles is believed to be the mechanism behind this observation. It is also believed that the viscosity of the suspending fluid is an important factor. The results of this study support this supposition, but do not prove it. Finally, there seems to be a complex, inadequate description of the nanoparticle-suspending fluid interface. There does not appear to be a model that accurately describes the enhanced thermal conductivity properties of nanofluids.

References

Zhou DW. Heat transfer enhancement of copper nanofluid with acoustic cavitation. Heat Mass Transf. 2004;47:3109–17.

Patel HE, Das SK, Sundararajan T, Nair AS, George B, Pradeep T. Thermal conductivities of naked and monolayer protected metal nanoparticle based nanofluids: manifestation of anomalous enhancement and chemical effects. Appl Phys Lett. 2003;83:2931–3.

Lee S, Choi SUS, Li S, Eastman JA. Measuring thermal conductivity of fluids containing oxide nanoparticles. ASME J Heat Transf. 1999;121:280–9.

Beck MP, Sun T, Teja AS. The thermal conductivity of alumina nanoparticles dispersed in ethylene glycol. Fluid Phase Equilibria. 2007;260:275–8.

Oh DW, Jain A, Eaton JK, Goodson KE, Lee JS. Thermal conductivity measurement and sedimentation detection of aluminum oxide nanofluids by using the 3x method. Int J Heat Fluid Flow 2008;29(5):1456–61.

Murshed SMS, Leong KC, Yang C. Enhanced thermal conductivity of TiO2—water based nanofluids. Therm Sci. 2005;44:367–73.

Liu MS, Ching-Cheng Lin M, Huang I-T, Wang CC. Enhancement of thermal conductivity with carbon nanotube for nanofluids. Heat Mass Transf. 2005;32:1202–10.

Jwo CS, Teng TP, Hung CJ, Guo YT. Research and development of measurement device for thermal conductivity of nanofluids. J Phys. Conference Series 13, 7th international symposium on measurement technology and intelligent instruments; 2005. p. 55–58.

Li J, Porter L, Yip S. Atomistic modeling of finite-temperature properties of crystalline β-SiC; Thermal conductivity and effects of point defects. Nucl Mater. 1998;255:139–52.

Koo J, Kleinstreuer C. Impact analysis of nanoparticle motion mechanisms on the thermal conductivity of nanofluids. Heat Mass Transf. 2005;32:1111–8.

Keblinski P, Phillpot SR, Choi SUS, Eastman JA. Mechanisms of heat flow in suspensions of nano-sized particles (nanofluids). Heat Mass Transf. 2002;45:855–63.

Xue QZ. Model for effective thermal conductivity of nanofluids. Phys Lett A. 2003;307:313–7.

Maxwell JC. A treatise on electricity and magnetism, vol. 1. II ed. Oxford, UK: Clarendon press; 1881. p. 435.

Hamilton RL, Crosser OK. Thermal conductivity of heterogeneous two component systems. I&EC Fundam. 1962;1(3):187.

Xue Q, Xu WM. A model of thermal conductivity of nanofluids with interfacial shells. Mater Chem Phys. 2005;90:298–301.

Acknowledgements

The authors would like to acknowledge financial support from Arak University, research support from the Institute for Colorants, Paint and Coating (ICPC), Tehran-Iran and the Arak Petrochemical Company, Arak-Iran.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hosseini, S.M., Moghadassi, A.R., Henneke, D. et al. The thermal conductivities enhancement of mono ethylene glycol and paraffin fluids by adding β-SiC nanoparticles. J Therm Anal Calorim 101, 113–118 (2010). https://doi.org/10.1007/s10973-009-0498-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-009-0498-1