Abstract

Biofuel production is acquiring an important role as an energy alternative. Several research groups have proposed the use of heterogeneous catalysts in order to replace homogeneous catalysts. A new group of basic catalysts has been prepared with the aim of being used as heterogeneous catalysts in biodiesel production. The catalysts KNO3/Al2O3 have been characterized and evaluated in the transesterification processes. They were characterized by X-ray diffraction and Scanning electron micrographs. The catalytic activity was evaluated in the transesterification of sunflower oil in biodiesel. The thermal stability of the biodiesel and the percentage of esters were evaluated. Through the TG curves, the samples of 2 and 4 % of KNO3/Al2O3 have presented two mass loss and partial conversion of triglycerides in esters. Thus, the sample that contains 4 % KNO3/Al2O3 has shown better catalytic activity in the transesterification reaction of sunflower oil, with a conversion rate of 60 % ethyl esters. On the other hand, the samples of 6 and 8 % of KNO3/Al2O3 have revealed only mass loss.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

As the fossil fuels are depleting day by day, there is a necessity to find an alternative fuel to fulfill the world’s energy demand. Biodiesel fuel has been receiving a recent growing interest and has been strongly recommended as a substitute for petroleum diesel [1].

Biodiesel is an alkyl ester fatty acid obtained through transesterification of vegetable oils or animal fats using short-chain alcohols (methanol or ethanol) catalyzed by an acid or a base [2]. Compared with conventional diesel, biodiesel has the advantages of being biodegradable, renewable, non-toxic and has low pollutant emissions (especially SOx). Brazil has been highlighted in the world scene as a future potential biodiesel producer, due to its diversity of oilseeds (soybeans, canola, sunflower, cotton, palm, etc.) [3, 4].

Sunflower (Helianthus annuus L.) is an important oilseed that offers the highest potential yield of, approximately, 45–50 % oil (hulled seed mass basis). The sunflower is between the five biggest oilseeds in world production [5]. This could be attributed to some agronomic features, such as, a greater tolerance to cold and heat when compared to most oilseed crops grown in Brazil, besides having a growing demand in the industrial and commercial sunflower cultivation, which is forming an important economic alternative. Among the vegetable oils, sunflower oil is what gives one of the highest percentages of polyunsaturated fatty acids [6].

Biodiesel may be produced by a transesterification reaction in which vegetable oil or animal fat feedstocks are reacted with an alcohol (methanol or ethanol) in the presence of a catalyst. Actually, biodiesel is usually prepared in the presence of homogeneous base or acid catalysts. However, the removal of the homogeneous catalysts from the generated product is technically difficult and requires a large quantity of water, high production cost due to the high presence of free fatty acids in the raw material, could produce soap and may form soap and in turn the generation of a large amount of effluent. Hence, the required purification steps are costly and technically difficult.

The use of heterogeneous catalysts in methanolysis has been proposed by different research groups worldwide; there is a tendency to replace the homogeneous catalysts for heterogeneous [7, 8]. However, the majority of the heterogeneous catalysts developed are quite expensive. Heterogeneous base catalysts, able to catalyze the transesterification of alkyl esters, could eliminate several drawbacks of the homogeneous process: They can be easily separated from the reaction mixture without requiring the use of a solvent, they are easily regenerated, and have a less corrosive character, leading to safer, selective and more environmentally friendly operations.

The KNO3/Al2O3 catalyst has high catalytic activity related to the basicity of the catalyst [9]. It should be noted that the type of base catalyst has a significant effect on the conversion of biodiesel. In this case, the catalysts were prepared by impregnation method of alumina with an aqueous solution of 35 mass%. KNO3 by Vyas et al. [10]. A moderate conversion (84 %) has been achieved after calcining the catalyst for 4 h at 500 °C and undergoing transesterification reaction with a methanol to oil molar ratio of 12:1 and 6 % catalyst for 6 h reaction time at 70 °C and 600 rpm agitation. Kinetic studies of the experiments were carried out and activation energy (E) was determined to be 26.96 kcal, which was low enough to make the reaction insensitive to temperature. Attempts to reuse the catalyst after drying and calcination gave reduced conversion of methyl esters of 75 and 72 % in the second and third runs, respectively. The catalyst owing to its moderate conversion efficiency may not find application at industrial level of production [10, 11].

According to Souza et al. [12] studies, thermogravimetry has been applied in many areas of science by enabling a rapid evaluation of transformations occurred when different materials are subjected to temperature variations for some time. Thermogravimetric analysis (TG) was used for study of the volatilization and degradation of the samples of sunflower biodiesel.

This paper aims to synthesize, characterize, and evaluate the thermal stability of biodiesel and the catalytic activity in the transesterification reaction of sunflower oil at different reaction conditions, depending on the concentrations of the catalyst KNO3/Al2O3 by thermogravimetric analysis.

Materials and methods

Synthesis catalyst

The catalyst KNO3/Al2O3 was synthesized by method impregnation, according to Amish et al. [13], using an aqueous solution of potassium nitrate 99 % (VETEC) and alumina support ALCOA Inc. Initially, 30 mL of potassium nitrate (35 %) was added onto 10 g of alumina by the impregnation method and dried at 50 °C. The sample was then transferred to a crucible and dried in an oven at 120 °C for 20 h. The sample was cooled at room temperature in a desiccator for 24 h. The catalyst was calcined at 500 °C for 4 h in a heating rate of 10 °C min−1 and flow of 100 mL min−1 of synthetic air. The synthesis was used of the type amorphous alumina.

Characterization catalyst

The structural properties of the samples were analyzed by X-ray diffraction (XRD) on SHIMADZU diffractometer equipment, model XRD 6000, using CuKα radiation (30 kV, 30 mA) with a 2θ range of 10–70° in a scan speed of 2 °C min−1 and a step scan size of 0.02°.

Scanning electron micrographs (SEM) were obtained on Phillips equipment; model XL30-ESEM to observe the morphology of the particles.

Catalytic activity

The catalytic activity was evaluated by reaction transesterification, using the molar ratio of 15:1 (ethanol/sunflower oil). The reflux system reaction occurred using catalyst (KNO3/Al2O3) in concentration of 2, 4, 6 e 8 % w/w, for 8 h.

Then, the mixture was transferred to a separation funnel for phase separation. Two phases were observed: the ethyl ester and the glycerin. After 24 h, the glycerin was removed. The remaining material was submitted to a washing process in order to purify the esters. The washing was followed by the evaporation step at 100 °C.

The samples of biodiesel were named of 2, 4, 6 and 8 % KNO3/Al2O3.

Physicochemical characterization of the biodiesel

The physicochemical characterization of the samples of oils and biodiesel were performed according to the Standards of American Society of Testing and Materials (ASTM), Associação Brasileira de Normas Técnicas (ABNT) and the Resolution N°7/2008 of the Brazilian National Agency of Petroleum, Natural Gas, and Biofuels (ANP) [14].

The specific mass analyses were determined through an automatic densimeter, based on ASTM D 4052 [15]. Acid values were, respectively, determined by Automatic Potentiometric Titrator, AT-500 N–KEM, followed by NBR 14448, EN 14111 [16, 17]. The kinematic viscosity was determined according to NBR 10441. The analysis was used to mark the ISL viscometer, model TVB445 [18].

Thermal study of biodiesel

The thermogravimetric (TG) experiments were carried out using a Thermobalance SHIMADZU –DTG-60 model, in the temperature range of 30–600 °C, under nitrogen atmosphere flowing at a rate of 100 mL min−1, using alumina crucible of 70 μL and heating rates 10 °C min−1.

Results and discussion

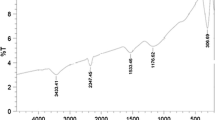

X-ray diffraction patterns of KNO3/Al2O3 sample calcined, is given in Fig. 1. As can be seen, only diffraction peaks (2θ = 14°, 28°, 38°, 49° and 67°) assigned to the amorphous support structure of Al2O3 were registered on the XRD patterns (Fig. 1a), which can be seen from the crystallographic reference PDF-(16-0384), analyzed by the JCPDS data (ICDD-2002) database of the X’Pert HighScore program. Figure 1b shows the characteristic XRD peaks of KNO3 appeared on the patterns the XRD KNO3/Al2O3, implying that a residual phase of KNO3 remained on the composite. Based on the diffractogram XRD results, the spontaneous dispersion capacity of KNO3 on the alumina structure was observed. The undetectable XRD phase of KNO3 may have dispersed onto the surface of alumina as a monolayer. For those loaded with potassium nitrate at more than the spontaneous dispersion capacity on alumina, the residual bulk phase of KNO3 remained on the composite. Accordingly, it is reasonable to imagine that only a part of the loaded KNO3could be decomposed under the activation conditions. Moreover, on the patterns of 35 mass% KNO3/Al2O3 sample calcined at 500 °C, the appearance of new diffraction of K2O species at 2θ = 52° and 55° emerged. Probably, the high basicity together with the high activity of the catalyst may be partially due to this K2O phase since a relationship was observed between the K2O species and the basicity or the catalytic activity. Studies indicate that the KNO3/Al2O3 catalyst has high catalytic activity after of the calcination, which presents a greater amount of basic sites, which serve as active sites for the transesterification reaction of vegetables oil with methanol or ethanol [9, 10].

The scanning electron micrograph (SEM) of KNO3/Al2O3 sample is presented in Fig. 2. Evidently, as shown in Fig. 2, a formation of agglomerates present in the amorphous structure can be observed, with particles of irregular size from approximately 1–60 mm. After impregnation with KNO3, the structure showed a high dispersion on the support surface, showing more homogeneity.

Evangelista [19] observed that the micrographs showed crystalline Al2O3 present in a crystalline structure, with particles of irregular size between about 1–10 mm. It also presents a main hexagonal structure with secondary structures, and when the support is impregnated with a nitrate salt, the crystalline Al2O3 has a higher packing, compared to amorphous Al2O3, which gives additional free spaces (vacancies) for impregnation.

Table 1 shows the physical–chemical characterization of the samples of sunflower biodiesel. It may be observed that due to conversion loss, all the sample of biodiesel is not in accordance with the specifications of the existing Resolution ANP Nº14/2012.

It was observed that after the transesterification reaction the kinematic viscosity and specific mass of the samples 2 and 4 % KNO3/Al2O3 was decreased; however, this was not observed in samples of 6 and 8 % KNO3/Al2O3. This viscosity and specific mass reduction is related to the catalytic conversion efficiency of triglycerides in ethyl esters. Therefore, the best catalytic conversion was observed to 4 % KNO3/Al2O3 with relation to the oil.

It was found that the biodiesel samples had values lower than 0.5 % acidity, presented according to resolution ANP Nº14/2012, except to the sample 2 % KNO3/Al2O3. The high acidity can damage the fuel filter, reducing its durability, and corroding various parts of the fuel system.

The TG/DTG allowed the determination of the thermal behavior of the ethyl biodiesel samples, as shown in Figs. 3, 4.

The TG curve of the sunflower biodiesel showed different behaviors in the thermogravimetric profile, which is related to activity of the catalyst in the transesterification reaction. TG curves of the samples of BIO-2 % KNO3/Al2O3 and BIO-4 %KNO3/Al2O3 showed two mass loss attributed to the ethyl ester volatilization and decomposition of unconverted triglycerides, in accordance with the DTG curves of biodiesel (Figs. 3, 4). This event approaching the profile shown in the thermal decomposition of the vegetable oil indicates the presence of non-reacted triglycerides [20]. The values of the ranges of temperature and percentage of mass loss for each step are shown in Table 2.

The TG curve of the cotton biodiesel, ethanol route, presented different behaviors in the thermogravimetric profile, which is related to activity of the catalyst in the transesterification reaction. TG curves of the samples of BIO-2 % KNO3/Al2O3 and BIO-4 %KNO3/Al2O3 showed two mass loss attributed to the ethyl esters volatilization and decomposition of unconverted triglycerides, in accordance with the DTG curves of biodiesel (Figs. 3, 4). This event approaching the profile shown in the thermal decomposition of the vegetal oil indicates the presence of non-reacted triglycerides [20]. The values of the ranges of temperature and percentage of mass loss for each step are shown in Table 2.

Quantitative analysis carried out by thermogravimetry demonstrated that in the samples BIO-2 %KNO3/Al2O3 and BIO-4 %KNO3/Al2O3, there was an increasing variation in the rate of conversion of the conversion of triglycerides into ethyl esters; however, it cannot be observed for BIO-6 %KNO3/Al2O3 and BIO-8 %KNO3/Al2O3 samples.

It was found that the sample BIO-4 %KNO3/Al2O3 resulted in a better conversion rate of triglycerides into ethyl esters (biodiesel) of approximately 60 %. This is attributed to the low catalytic activity due to the presence of few active basic sites and does not contribute significantly in the transesterification reaction, according to the results of XRD, since there was little contact between these sites and the triglycerides molecules during the reaction.

The sample BIO-6 %KNO3/Al2O3 and BIO-8 %KNO3/Al2O3 did not present significant conversion. However, increasing the amount of catalyst 6–8 % does not lead to improved results. The uses of large quantities of catalyst are disadvantageous because they may make the reaction mixture more viscous and increased resistance to mass transfer in multi-phase system.

Conclusions

Alumina loaded with potassium nitrate showed high catalytic activities for the transesterification reaction. The activities of the catalysts can be correlated with their corresponding basic properties. Through thermogravimetric curves, it was observed that it is possible to show, qualitatively, the thermal behavior of samples of biodiesel and sunflower oil. The 4 % KNO3/Al2O3 catalyst showed better catalytic activity in the transesterification reaction of sunflower oil under the conditions adopted, having a conversion of 60 % ethyl esters. Therefore, it is necessary to optimize the reaction conditions toward increasing this conversion of triglyceride to ethyl esters. Furthermore, it is possible to monitor the influence of the concentration of the catalyst in the transesterification reaction.

References

Koh MY, Mohd TI. A review of biodiesel production from Jatropha Curcas L. oil. Renew Sustain Energy Rev. 2011; 15: 2240–2251. doi:10.1016/j.rser.2011.02.013

Cammenga HK, Epple M. Basic principles of Thermoanalytical Techniques and their Applications in preparative Chemistry. Angew Chem-Int Ed Engl. 1995;34:1171–87. doi:10.1002/anie.199511711.

Alptekin E, Canakci M. Determination of the density and the viscosities of biodiesel–diesel fuel blends. Renew Energy. 2008;33:2623–30. doi:10.1016/j.renene.2008.02.020.

Yin X, Ma H, You Q, Wanga Z, Chang J. Comparison of four different enhancing methods for preparing biodiesel through transesterification of sunflower oil. Appl Energy. 2012;91:320–5. doi:10.1016/j.apenergy.2011.09.016.

Anwar F, Rashid U, Moser BR, Ashraf S. Production of sunflower oil methyl esters by optimized alkali-catalysed methanolysis. Biomass Bioenergy. 2008;32:1202–5. doi:10.1016/j.biombioe.2008.03.001.

Oliveira MJ, Vieira OV. Extração de óleo de girassol utilizando miniprensa. Londrina - PR: Embrapa documento 237 2004.

Crabbe E, Nolasco-Hipolito C, Kobayashi G, Sakamoto K, Ishizaki A. Biodiesel production from crude palm oil and evaluation of butanol extraction and fuel properties. Proc Biochem. 2001;37:65–71. doi:10.1016/S0032-9592(01)00178-9.

Júnior NM, Souza PHG, Pereira RE, Carvalho, LM, Faria WLS, Sales AS, Bom EPS, Aranda DAG. In:Anais do 12º Congresso Brasileiro de Catálise, Angra dos Reis. 2003.

Xie W, Peng H, Chen L. Transesterification of soybean oil catalyzed by potassium loaded on alumina as a solid-base catalyst. Appl Catal A Gen. 2006;300:67–74. doi:10.1016/j.apcata.2005.10.048.

Vyas AP, Subrahmanyam N, Patel PA. Production of biodiesel through transesterification of Jatropha oil using KNO3/Al2O3 solid catalyst. Fuel. 2008;. doi:10.1016/j.fuel.2008.10.033.

Yogesh C, Sharma A., Bhaskar Singh A., John Korstad B. Latest developments on application of heterogenous basic catalysts for an efficient and eco friendly synthesis of biodiesel: a review. Fuel. 2001;. doi: 10.1016/j.fuel.2010.10.015.

Santos AGD, Araujo AS, Caldeira VPS, Fernandes VJ, Souza LD, Barros AK. Model-free kinetics applied to volatilization of Brazilian sunflower oil, and its respective biodiesel. Thermochim Acta. 2010;506:57–61. doi:10.1016/j.tca.2010.04.015.

Amish PV, Subrahmanyam N, Payal AP. Production of biodiesel through transesterification of jatropha oil using KNO3/Al2O3 solid catalyst. Fuel. 2009;88:625–8. doi:10.1016/j.fuel.2008.10.033.

ANP, Agência Nacional de Petróleo. Resolution ANP Nº14, of 11.05.2012–18.05.2012. Available at http://nxt.anp.gov.br/NXT/gateway.dll?f=templates&fn=default.htm&vid=anp:10.1048/enu. Accessed 14 JAN 2014.

American Society for Testing and Materials. ASTM D 4052: density and relative density of liquids by digital density meter. West Conshohocken. 1996.

Associação Brasileira de Normas Técnicas. Nbr 14448: Óleos lubrificantes e fluidos hidráulicos-determinação do índice de acidez pelo método de titulação potenciométrica. Rio de Janeiro, 2005.

En Standards. EN 14111: Fat and oil derivatives. Fatty acid methyl esters (FAME). Determination of iodine value. 2003.

American Society for Testing and Materials. ASTM D 445: standard test method for kinematic viscosity of transparent and opaque liquids (and the calculation of dynamic viscosity). West Conshohocken. 2004.

Evangelista JPC. Obtenção de biodiesel através da transesterificação do óleo de farelo de arroz utilizando KI/Al2O3. 2011. 133 f. Dissertação (Mestrado em Química) – Pós-Graduação em Química, Universidade federal do Rio Grande do Norte, Natal, 2011. Available at http://bdtd.bczm.ufrn.br/tde_arquivos/35/TDE-2011-12-29T010322Z-3710/Publico/JoaoPCE_DISSERT.pdf. Accessed 20 Jan 2014.

Evangelista JPC, Chellappa T, Coriolano ACF, Fernandes VJ Jr, Souza LD, Araujo AS. Synthesis of alumina impregnated with potassium iodide catalyst for biodiesel production from rice bran oil. Fuel Proc Technol. 2012;104:90–5. doi:10.1016/j.fuproc.2012.04.028.

Acknowledgements

The authors acknowledge the ANP (Agência Nacional do Petróleo, Gás Natural e Biocombustíveis) and CAPES for financial support and Fuels and Lubricants Laboratory UFRN for the aid in accomplishing the analyses.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

da Silva, J.C.T., Gondim, A.D., Galvão, L.P.F.C. et al. Thermal stability evaluation of biodiesel derived from sunflower oil obtained through heterogeneous catalysis (KNO3/Al2O3) by thermogravimetry. J Therm Anal Calorim 119, 715–720 (2015). https://doi.org/10.1007/s10973-014-4145-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-014-4145-0

) KNO3; (x) K2O

) KNO3; (x) K2O