Abstract

Sulfur and polyphosphoric acid (PPA) were used to improve the thermal stability and high-temperature property of styrene–butadiene rubber (SBR)-modified asphalt before and after short-term and long-term aging. The physical, rheological properties, and thermal behavior of asphalt binders were studied. The study showed that the addition of PPA improved the thermal stability and high-temperature property of SBR-modified asphalt evidently, and the improved property caused by the gelation effect of PPA was not influenced by aging further. Though sulfur also improved thermal stability and high-temperature property of SBR-modified asphalt before aging, the improved properties declined evidently with further aging, due to the susceptibility of SBR/sulfur-modified asphalt to aging. It is reasonable to assume that the SBR-modified asphalt could be improved further only by the addition of PPA. In the study of polymer-modified asphalts, thermodynamic analysis can reflect the structural characteristics of asphalt binders before and after aging efficiently and confirms the conclusions of physical and rheological testings to some extent.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Research background

Asphalt is an organic mixture that is widely used in road pavement because of its good viscoelastic properties [1]. Unfortunately, asphalt becomes brittle at lower temperature and is a liquid at higher temperature, which results in low-temperature cracking of pavement and high-temperature rutting. This temperature susceptibility limits its application. Therefore, in order to enhance the aggregate performance of asphalts, it is necessary to modify asphalts by adding polymer modifiers [2–6].

Among the polymer modifiers of asphalt, SBR has been found to be one of the most effective modifiers for paving asphalt. An Engineering Brief from 1987 available at the US Federal Aviation Administration website [5] describes the benefits of SBR-modified asphalt in improving the properties of bituminous concrete pavement and seal coats. Low-temperature ductility is improved, viscosity is increased, elastic recovery is improved, and adhesive and cohesive properties of the pavement are improved. According to Becker et al., SBR latex polymers increase the ductility of asphalt pavement, which allows the pavement to become more flexible and crack resistant at low temperatures, as found by the Florida Department of Transportation [7]. Unfortunately, some main drawbacks are also found in practice. The high-temperature property of SBR-modified asphalt is not satisfactory, and the track on SBR-modified asphalt pavement is easier to be formed under heavy traffic loading, which limits the use of SBR-modified asphalt in hot areas. Furthermore, the storage stability of SBR-modified asphalt is also needed to be considered in practice. Because of the poor compatibility between SBR and asphalt, phase separation will occur during storage. For these reasons, many measures have been taken, including addition of various types of clays such as montmorillonite, organobentonite, organic palygorskite, weathered coal, and carbon black [8–11]. Compared with these measures, the most effective way is found to be one involving the addition of sulfur or PPA.

Research for SBR/PPA- and SBR/sulfur-modified asphalts

PPA and sulfur as the major modifiers in improving the high-temperature performance or storage stability of SBS- or SBR-modified asphalt have been used widely in practice. Owing to the lower cost of PPA and sulfur, the use of PPA and sulfur in the preparation of SBS- and SBR-modified asphalt reduces the SBS or SBR content to a great extent. Therefore, the cost-effective performance of PPA or sulfur has been greatly improved. Nevertheless, the published studies for the SBR/sulfur- or SBR/PPA-modified asphalts are very scarce. In the previous study, we have studied the influence of aging on the physical, rheological properties, and morphologies of SBR/sulfur- and SBR/PPA-modified asphalts partly [12, 13]; however, other important properties such as thermodynamics, dynamic viscosity, etc. have not been studied. Furthermore, although the previous study focused on the high-penetration base asphalt, the complete study on the low-penetration base asphalt is not made. However, in the most southern parts of China, the low-penetration base asphalt is more popular because of the hot climate.

Research objective and scope

The present study seeks to identify the changes in thermodynamics, dynamic viscosity and physical properties of low-penetration base asphalt (SK70), SBR-, SBR/PPA-, SBR/sulfur-modified asphalts through short-term aging test (thin film oven test, TFOT) and long-term aging test (pressurized aging vessel, PAV), to investigate the structural characteristics of asphalt binders further by thermal analysis and thermodynamics, to compare the characteristic differences among asphalt binders by aging and finally to provide a right way for further modification.

Materials and experimental

Materials

Asphalt, SK-70 paving asphalt, was obtained from the SK Petroleum Asphalt Factory, Southern Korea. The physical properties of the asphalt are as follows: softening point: 48 °C (ASTM D36); penetration: 83 dmm (25 °C, ASTM D5); viscosity: 0.35 Pa s (135 °C, ASTM D 4402). SBR was produced by the Shandong High’s trade co., LTD, China. It is very tiny powder, containing 26 mass% styrene, 0.5 mass% water soluble, 0.35 mass% volatile fraction and viscosity (ML1+4 100 °C) 48–55. Superfine sulfur powder is commercial product (industrial grade) Anqing city GuoXing chemical co., LTD. Polyphosphoric acid was purchased from Sinopharm Chemical Reagent Co Ltd. China. Polyphosphoric acid concentration calculated by P2O5 is no less than 80 %.

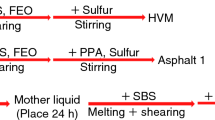

Preparation of samples

The modified asphalts were prepared using a high shear mixer (made by Weiyu Machine Co., Ltd., China). Firstly, asphalt (400 g) was heated until it became a fluid in an iron container, then upon reaching about 160 °C, the modifiers including SBR, PPA, sulfur (the amounts were based on 100 parts asphalt) were added to the asphalt, and then the blend was sheared for 40 min, the shearing temperature is 160 °C, the shearing rate is 4,000 r/min, subsequently the blend was stirred by a mechanical stirrer at 160 °C for 1 h to make sure the fully swelling of the modifiers in the asphalt. After that, the preparation has been finished. The proportion of each PMA is listed in the following:

SBR-modified asphalt: 4 mass% SBR; SBR/PPA-modified asphalt: 4 mass% SBR, 2 mass% PPA; SBR/sulfur-modified asphalt: 4 mass% SBR, 0.04 mass% sulfur.

Storage stability test

The storage stability of modified asphalts was measured as follows. The sample was transferred into an aluminum toothpaste tube (32 mm in diameter and 160 mm in height). The tube was sealed and stored vertically in an oven at 163 °C for 48 h, then taken out, cooled to room temperature, and cut horizontally into three equal sections. The samples taken from the top and bottom sections were used to evaluate the storage stability of the SBR-modified asphalts by measuring their softening points. If the difference of the softening points between the top and the bottom sections was less than 2.5 °C, the sample was considered to have good high-temperature storage stability. If the softening points differed by more than 2.5 °C, the SBS-modified asphalt was considered to be unstable.

Standard aging procedure

Two conventional tests were used to simulate the thermal oxidative aging for PMAs: thin film oven test (TFOT, standard ASTM D1754) and the pressure aging vessel (PAV, standard ASTM D6521).

Short-term aging was addressed by the TFOT Binders were aged during 5 h at 163 °C in air as described in the standard ASTM D1754. This technique has been validated for some time for unmodified asphalts for which it is considered to be more severe than actual jobsite conditions; in the case of modified asphalts, its validity is still open to doubt [14]. However, in the absence of anything better, it has been used with considerable success to compare different PMAs during laboratory studies [14, 15].

Long-term aging was addressed by the PAV. The binder after TFOT aging was aged further during 20 h at 100 °C under 2.1 MPa of air as described in the standard ASTM D6521. In the case of unmodified asphalts, the simulated aging provided is recognized to be equivalent to several years of service in a road, but how long this equivalence is depends on the asphalt recently, a study of several experimental pavements [14, 15] found this simulated aging to be equivalent to 4 years.

Dynamic mechanical analysis

Dynamic mechanical analysis (DMA) was performed using a strain-controlled rheometer (RDA II, Rheometrics). In DMA, temperature sweeps (from 30 to 100 °C) with 2 °C increments were applied at a fixed frequency (10 rad s−1) and at variable strains. Parallel plates, gap 1.0 mm for φ 25 mm, were used. In each test, about 1.0 g of sample was applied to the bottom plate, covering the entire surface, and the plate was then mounted in the rheometer. After heating to the softening point of the binder, the top plate was brought into contact with the sample, and the sample was trimmed. The final gap was adjusted to 1 mm. A sinusoidal strain was then applied by an actuator. The actual strain and torque were measured and input to a computer for calculating various viscoelastic parameters such as complex viscosity (η*) and phase angle (δ) and so on.

Thermal analysis

Thermal analysis was performed using a TA Instrument, Model SDT 2960, under argon atmosphere, mass of each sample being around 7 mg, with constant heating rates of 5, 10, and 15 K min−1, heated from room temperature to 800 °C. The argon flow during the experiments was 120 mL min−1. The TG/DTG versus temperature curves were used to evaluate the thermal stabilities of binders, respectively. All experiments were performed three times for reproducibility.

Results and discussion

Physical properties

The storage stability of PMAs is listed in Table 1. The difference between softening points is used to evaluate the storage ability of PMAs. Because the used SBR powder is too tiny and can be easily dispersed in asphalt by high-speed shearing, and therefore, the phase separation is very little. The difference in softening points is less than 2.5 °C for all PMAs. Both PPA and sulfur did not influence the storage stability of SBR-modified asphalt further.

The physical properties of PMAs before and after TFOT and TFOT + PAV aging are shown in Table 2. Usually, the influence of aging on the structures and properties of PMAs can be divided into two types. On the one hand, the changed asphalt compositions after aging lead to the improved high-temperature property, and on the other hand, the polymer degradation in aging processes leads to an opposite influence, and the final property of asphalt binder depends on the predominant role of either type.

To understand the influence of aging on the properties and structures of SBR compound-modified asphalt further, the properties of the base asphalt are also listed. Before aging, the addition of SBR improved the low-temperature property of the base asphalt greatly, and the low-temperature ductility of all PMAs is beyond 150 cm. The high-temperature property of the base asphalt is also improved to some extent by the addition of SBR, as shown by the increased softening point. Compared with the SBR-modified asphalt, the softening point of the SBR/sulfur-modified asphalt is improved further, and this is attributed to the formation of a crosslinked polymer network [12, 16]. For the SBR/PPA-modified asphalt, the improvement for high-temperature property is more obvious: the PMA possesses highest softening point. Because of the gelation effect of PPA, the hard asphalt composition increased [17], which led to the obviously improved elastic behavior. After TFOT aging, the ductility of the PMAs declines greatly because of the SBR degradation; however, the ductility difference among the aged PMAs is very little, and the ductility values meet the present standard for SBR-modified asphalt. (>20 cm after TFOT aging) [18], which means the PPA or sulfur content in the study is reasonable. The improved softening point by vulcanization disappears after aging, showing that the SBR/sulfur-modified asphalt is very susceptible to aging, and the crosslinked polymer network is destroyed. Owing to the influence of the changed asphalt composition after aging, the softening points of other binders increase. After TFOT + PAV aging treatment, the softening points of all binders increase further; however, the lower softening point of the SBR/sulfur binder shows the further degradation of the weak polymer network. For the SBR/PPA-modified asphalt, the obviously improved high-temperature property is regardless of whether after TFOT or TFOT + PAV aging shows the gelation effect caused by PPA does not influenced further by aging.

Dynamic rheological properties

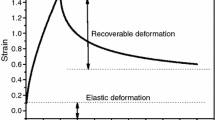

The rheological behaviors of the base asphalt, SBR-, SBR/sulfur-, SBR/PPA-modified asphalts before and after aging are shown from Fig. 1a–c. Complex viscosity η* as a fundamental rheological parameter is often used to express the contribution of asphalt binder to permanent deformation [19]. With increasing complex viscosity, the high-temperature performance of asphalt is improved. The trend of phase angle curve is used to display the susceptibility of asphalt to temperature. The higher elevated phase angle curves with increasing temperature show a serious temperature susceptibility, and the opposite conclusion also can be drawn [20].

In Fig. 1a, the susceptibility of base asphalt to temperature is improved by the addition of SBR, as shown by the lowered phase angle curve in the whole temperature range. This improvement can be attributed to the certain entanglements and interactions among polymer molecules and between polymer and asphalt components. Owing to the softening characteristics of SBR, the complex viscosity declines compared with the base asphalt. Compared with the rheological behavior of the SBR-modified asphalt, the complex viscosity of the SBR/sulfur-modified asphalt increases to some extent after 60 °C, and the varying trend of δ is slowed down further nearly in the whole temperature range, which means that the crosslinked polymer network is formed by vulcanization [19, 21]. For the SBR/PPA-modified asphalt, owing to the gelation effect of PPA, the improved complex viscosity and the lowered phase angle can be seen in the whole temperature range, which shows that the SBR/PPA-modified asphalt possesses best high-temperature rutting resistance and temperature susceptibility. After TFOT aging, as shown by Fig. 1b, the improved complex viscosity of the SBR/sulfur-modified asphalt disappears and the phase angle curve rises evidently in the whole temperature range compared with the SBR-modified asphalt, which means that the crosslinked polymer network is destroyed, and the susceptibility to temperature increases. After TFOT + PAV aging, as shown by Fig. 1c, the crosslinked polymer network in the SBR/sulfur binder is destroyed completely; the lowest complex viscosity and further elevated phase angle curve shows the increased temperature susceptibility; and the aged binder shows an obvious viscous behavior. For the SBR/PPA binder, aging does not influence the gelation effect of PPA, and the binder still possesses best rutting resistance and temperature susceptibility, as shown by the master curves of higher complex viscosity and lower phase angle.

Thermal analysis

The thermal stability of modified asphalt is an important property to be considered in the analysis for the structural characteristics of asphalt binder [22]. In this article, the thermal stabilities of the base asphalt, and the SBR-, SBR/sulfur-, SBR/PPA-modified asphalts before and after aging are studied by thermogravimetry at heating rate of 10 K min−1. Because the thermodynamic characteristic curves of all binders before and after aging are similar, the thermodynamic behaviors of all binders can be illustrated by the curves before aging, as shown from Fig. 2a–d. The TG curves show that all binders undergo the major mass loss stage 500–750 K, and the mass loss is mainly due to the volatilization of the light asphalt components such as saturates and aromatics and the decomposition of polymer [23, 24]. This is the major mass loss stage as demonstrated by the dramatic event in the DTG curve. After 750 K, the TG and DTG curves become very flat with the increasing temperature, and the mass loss in the process is mainly attributed to the further volatilization of the decayed residues of asphaltene and rubber, and the gradual carbonization of the residues [23, 24].

The onset temperature of the mass loss effect (T 0), the maximum decomposition temperature (T DTG max), the mass loss in the temperature range (500–750 K), and the residue content at 1,073 K are shown in Table 3; usually, the values of T 0 and T DTG max are used to evaluate the thermal stability of sample [23, 25]. Before aging, the base asphalt holds the lowest values. The thermal stability of the base asphalt was improved by the addition of SBR, and the thermal stability of the SBR-modified asphalt was improved further by vulcanization due to the formation of the crosslinked polymer network [26], as shown by the increased values of T 0 and T DTG max. The SBR/PPA-modified asphalt possesses the highest values of T 0 and T DTG max, which is attributed to the gelation of PPA mainly. There are also two opposite effects of aging on the thermal stability of binder. On the one hand, aging prompted the polycondensation of light components in asphalt, leading to the increased asphaltene content, which contributed to the improved thermal stability of binder; on the other hand, aging also prompted the degradation of polymer dispersed in asphalt [26]. This resulted in the lower thermal stability. The final thermal stability of binder depended on the combined effect. After TFOT aging, the T 0, T DTG max of the asphalt binders increased to some extent, showing the predominant role of the increased asphaltene. By comparing the magnitude in the increase in T 0 or T DTG max, it can be seen that the polymer degradation plays an obvious role for the SBR/sulfur-modified asphalt. After TFOT + PAV aging, because of the further increased asphaltene, the T 0, T DTG max values of the base asphalt increase further; however, the corresponding values of the modified asphalts decrease to some extent. With further aging, the polymer degradation becomes more severe, and therefore, the influence of the changed asphalt components is alleviated obviously. Compared with the other binders, the SBR/sulfur binder holds the lowest values of T 0, T DTG max after TFOT + PAV aging, which indicates the predominant role of the vulcanized polymer degradation. Owing to the gelation of PPA, the SBR/PPA still possesses a better thermal stability.

Thermal kinetic analysis

The influence of aging on the structure of PMAs also can be described further by studying the kinetic characteristics of mass loss. In the course of this research, three heating rates 5, 10, and 15 K min−1 were performed. For all binders, the thermal behaviors are similar, and there is a maximum decomposition temperature, which can be illustrated by the TG and DTG curves of the base asphalt as shown in Fig. 3a, b. An evaluation of DTG curves for each binder was done by applying Kissinger model [22, 25] as shown in Table 4. The higher the activation energy, the more difficult the decomposition reaction becomes, and the more stable the asphalt binder will be.

In Table 4, the activation energy of the base asphalt increases with further aging, because of the increase of hard asphalt compositions such as asphaltene resins; the decomposition reaction becomes more difficult. The addition of SBR increases the stability of binder, as shown by the greater activation energy compared with the base asphalt. Because of the formation of the vulcanizated polymer network, the activation energy of the SBR/sulfur-modified asphalt increases further. The SBR/PPA-modified asphalt possesses the highest activation energy, as the result of gelation. After TFOT aging, the activation energy of the polymer binders increases to some extent, showing the predominant role of the changed asphalt composition. Though the polymer dispersed in asphalt also degrades, this does not influence the stability of binders further. However, the activation energy of the polymer binders declines evidently after TFOT + PAV aging, which means the aged binders become unstable, and the degradation reaction becomes easier. The polymer degradation plays a predominant role on the thermal stability of binders after TFOT + PAV aging. The SBR/sulfur binder possesses the lowest activation energy, which confirmed its susceptibility to aging further as mentioned before—the weak polymer network degrades completely with further aging. Because of the slight effect of aging on the gelation result of PPA, the SBR/PPA binder still possesses highest energy.

Conclusions

The physical, rheological, thermodynamic tests show the structural characteristics of the SBR- SBR/PPA- or SBR/sulfur-modified asphalts before and after aging. The thermal analysis confirms the results of physical and rheological testing to some extent. For the SBR/sulfur-modified asphalt, the polymer degradation played a predominant role on the rheological and thermal behavior because of the weak polymer network, the improved properties disappeared completely with further aging. For the SBR/PPA-modified asphalt, the improved rheological and thermal behaviors were stable, because the gelation effect caused by PPA didn`t influenced further by aging. Therefore, it is more reasonable for SBR-modified asphalt to be improved further only by the addition of PPA.

References

Krishnan JM, Rajagopal KR. On the mechanical of asphalt. Mech Mater. 2005;37:1085–100.

Huang SC. Rubber concentrations on the rheology of aged asphalt binders. J Mater Civ Eng. 2008;30:221–9.

Sengoz B, Isikyakar G. Analysis of styrene–butadiene–styrene polymer modified bitumen using fluorescent microscopy and conventional test methods. J Hazard Mater. 2008;150:424–32.

Fu HY, Xie LD, Dou DY, Li LF, Yu M, Yao SD. Storage stability and compatibility of asphalt binder modified by SBS graft copolymer. Constr Build Mater. 2007;21:1528–33.

Yetkin Y. Polymer modified asphalt binders. Constr Build Mater. 2007;21:66–72.

Wang Q, Liao MY, Wang YR. Characterization of end-functionalized styrene–butadiene–styrene copolymers and their application in modified asphalt. J Appl Polym Sci. 2007;103:8–16.

Roque R, Birgisson B, Tia M, Kim B, Cui Z. Guidelines for the use of modifiers in Superpave mixtures, State Job 99052793. Tallahassee: Florida Department of Transportation; 2004.

Zhang BC, Xi M, Zhang DW, Zhang HX, Zhang BY. Properties of SBR/OMMT composite modified asphalt. Rubber Ind. 2007;54:722–5 (Chinese).

Zhang J, Wang JL, Wu YQ, Sun WX, Wang YP. Investigation on thermo-rheological properties and stability of SBR modified asphalts containing palygorskite clay. J Appl Polym Sci. 2009;113:2524–35.

Zhang J, Wu YQ, Wang JL, Wang YP, Wang YP. Improved properties of weathered coal and SBR/weathered coal compound modified asphalt. Iran Polym J. 2007;16:251–9.

Zhang J, Wang JL, Wu YQ, Wang YP. Evaluation of the improved properties of SBR/weathered coal modified bitumen containing carbon black. Constr Build Mater. 2009;23:2678–87.

Zhang F. Influence of ageing on rheology of SBR/sulfur-modified asphalts. Polym Eng Sci. 2012;52:71–9.

Zhang F. The research for SBS and SBR compound modified asphalts with polyphosphoric acid and sulfur. Constr Build Mater. 2013;43:461–8.

Durrieu F, Farcas F, Mouillet V. The influence of UV aging of a styrene/butadiene/styrene modified bitumen: comparison between laboratory and on site aging. Fuel. 2007;86:1446–51.

Mouillet V, Lamontagne J, Durrieu F, Planche JP, Lapalu L. Infrared microscopy investigation of oxidation and phase evolution in bitumen modified with polymers. Fuel. 2008;87:1270–80.

Wen GA, Zhang Y, Zhang YX, Sun K, Fan YZ. Rheological characterization of storage-stable SBS-modified asphalts. Polym Test. 2002;21:295–302.

Baumgardner GL, Masson JF, et al. Polyphosphoric acid modified asphalt: proposed mechanism. J Assoc Asphalt Paving Technol. 2005;74:283–306.

Sheng JA, Li FP, Chen J. Technical specifications for construction of highway asphalt Pavement. Beijing: Ministry of Communications of the People’s Republic of China; 2005.

Lu XH, Isacsson U. Influence of styrene–butadiene–styrene polymer modification on bitumen viscosity. Fuel. 1997;76:1353–9.

Airey GD. Rheological properties of styrene butadiene styrene polymer modified road bitumens. Fuel. 2003;82:1709–19.

Wen GA, Zhang Y, Zhang YX. Improved properties of SBS-modified asphalt with dynamic vulcanization. Polym Eng Sci. 2002;42:1070–81.

Chen JH, Li CR. Thermal analysis and application. 3rd ed. Beijing: Science Press; 1985.

Juan M, Jiménez M, Luis CQ, Carmen R. Characterization of petroleum bitumens and their fractions by thermogravimetric analysis and differential scanning calorimetry. Fuel. 1996;75:1691–700.

Radhakrishnan CK, Sujith A, Unnikrishnan G. Thermal behaviour of styrene–butadiene rubber/poly(ethylene-co-vinyl acetate) blends TG and DSC analysis. J Therm Anal Calorim. 2007;90:191–9.

Mothé MG, Leite LFM, Mothé CG. Thermal characterization of asphalt mixtures by TG/DTG, DTA and FTIR. J Therm Anal Calorim. 2008;93:105–9.

Zhang F. Influence of polyphosphoric acid and sulfur on ageing properties of polymer modified asphalt. Wuhan: Wuhan University of Technology; 2011 (Chinese).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, F., Hu, C. Influence of aging on thermal behavior and characterization of SBR compound-modified asphalt. J Therm Anal Calorim 115, 1211–1218 (2014). https://doi.org/10.1007/s10973-013-3338-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-013-3338-2