Abstract

Polyphosphoric acid (PPA) was used to improve the physical and rheological properties of high-viscosity modified (HVM) asphalt and decrease the styrene–butadiene–styrene (SBS) content. The sample preparation technique was optimized further by blending furfural extract oil and asphalt in advance. With the optimized preparation process, the major physical and rheological properties of HVM asphalt were improved further by adding the same amount of PPA comparing with other preparation processes; however, the motive viscosity, toughness and tenacity of HVM asphalt still depended on the SBS content. Various rheological tests were adopted to investigate the effect of PPA on the rheological behaviours of HVM asphalt before and after ageing. The suitable gelation accused by PPA not only improved the high-temperature rheological performances of HVM asphalt, but increased the low-temperature rheological performances. Morphology observation by using optical microscope showed the effect of vulcanization and ageing on the outline and distribution of SBS in HVM asphalt. Fourier transform infrared analysis indicated the difference of SBS content under different modifications. Thermal analysis displayed the effect of PPA on the thermodynamic behaviours of HVM asphalt and demonstrated the declined ageing susceptibility of HVM asphalt after PPA modification.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

High-viscosity modified (HVM) asphalt as the binder of draining asphalt pavement is being paid more attention. Owing to the perfect high-temperature performance, adhesion, deformation resistance, HVM asphalt also can be used widely in other pavement constructions such as bridge deck pavement, reconstruction of old cement road and so on [1, 2]. However, the application of HVM asphalt was still restricted to a great extent due to the expensive cost. SBS as the major modifier of HVM asphalt is used excessively; generally, the SBS content in HVM asphalt is about 8–10 mass/% (base on asphalt) [3]. Moreover, the rapid growth of SBS price prompted the further increase in the cost in recent years. How to reduce the cost of HVM asphalt and maintain the major properties have became a top issue in asphalt research.

Polyphosphoric acid (PPA) as a kind of additional modifier is often used in asphalt modification. The addition of PPA prompted the asphalt gelation and decreased the temperature susceptibility greatly [4]. Not only did the hard asphalt constitutes such as asphaltene and resin increase, but the molecule structure of asphaltene or resin changed correspondingly [5, 6]. With the gelation effect, PPA was often used to improve the properties of polymer-modified asphalts (PMAs) further. The suitable addition of PPA in PMAs can improve the high-temperature performances and adhesion further and decrease the temperature susceptibility without negative effects on other physical properties [7]. For this reason, PPA was usually used in the further modification for different PMAs [8,9,10], especially for styrene–butadiene–styrene (SBS)- or styrene-butadiene rubber (SBR)-modified asphalt [11,12,13,14,15,16,17]. However, for HVM asphalt as a PMA with higher SBS content, the corresponding application of PPA has not still been carried out.

In the previous work, HVM asphalt has been prepared by the addition of SBS, furfural extract oil (FEO), sulphur in asphalt under the shearing and stirring conditions [18,19,20]. The HVM asphalt owned good physical properties and can meet the corresponding standard [21]. The detailed research for the rheological properties and structural characteristics also has been explored fully [18,19,20]. However, the SBS content in the HVM asphalt was 6 mass/% and comparatively high. To decrease the SBS content and confirm the availability of PPA in HVM asphalt, PPA was adopted further in the preparation of HVM asphalt and the explicit research for the HVM asphalt including the technique conditions, the physical and rheological properties was carried out, and different analysis ways such as morphology observation, Fourier transform infrared (FTIR) and thermal analysis were used to investigate the structural characteristics of the HVM asphalt before and after ageing.

Materials and measurement

Materials

Hulian-70 road asphalt (AH-70) was bought from Xinliji Asphalt Factory, China, and the physical properties are listed in Table 1. SBS1301 as a linear thermoplastic elastomer containing 30 mass/% styrene was purchased from Baling Petrochemical Company, China. PPA was bought from Sinopharm Chemical Reagent Co. Ltd., China, and the concentration was no less than 80 mass/%. FEO is technically pure reagent, and the major constituent is arene. Superfine sulphur powder (500 mesh number) was provided by Wenhe Chemical Co., Ltd., China.

Preparation of samples

On the proportional basis of HVM asphalt [19, 20], 0.5 mass/% PPA was used to modify the properties further and decrease the SBS content. To optimize the proportion and preparation of sample, three techniques and four sample proportions were designed. The corresponding relation between preparation technique and sample is displayed in Fig. 1, and the proportion of each sample is shown in Table 2. Shearing and stirring for sample were finished by using a high-speed shear machine and a mechanical blend machine, respectively, and the preparation temperature was maintained within 180–190 °C.

HVM asphalt was prepared by technique 1 [19, 20]: SBS and FEO were added into the melting asphalt (AH-70) and the compound was sheared at 5000 r min−1 for 1 h; subsequently, sulphur was added and the compound was stirred for 2 h.

Asphalt 1 was prepared by technique 2: SBS and FEO were added into the melting asphalt and the compound was sheared at 5000 r min−1 for 1 h; subsequently, sulphur and PPA were added, and the compound was stirred for 2 h.

Asphalts 2 and 3 were prepared by technique 3: FEO was added into the melting asphalt, and the compound was stirred for 1 h and placed for 24 h at room temperature; subsequently, the compound was called as the mother liquid. After the 24-h placement, the mother liquid was heated again and became melted fully; SBS was added and the compound was sheared at 5000 r min−1 for 1 h, and then, sulphur and PPA were added further and the compound was stirred for 2 h.

Thermal ageing of asphalt

Thermal ageing of asphalt was finished by using thin film oven test (TFOT, ASTM D1754); this test was used to stimulate the short-term ageing that asphalt endured in mixing with aggregate.

Physical properties

The physical properties of asphalt were tested in the light of ASTM D36, D4402, D5, D5801-95, D113, D6084, D5976, D2171.

Rheological test

High-temperature rheological tests were performed by using dynamic shear rheometer (DSR, Anton Paar, MCR 102, Germany) under three testing modes: temperature sweep (30–118 °C, 2 °C interval, 10 rad s−1), frequency sweep (60 °C, 0.1–100 rad s−1) and repeated creep (60 °C, 30 Pa, 100 cycles, 1 s loading and 9 s recovery for one cycle), and 25-mm parallel plate and 1-mm gap were used. The major parameters such as G*, δ were used to display the rheological behaviour of sample.

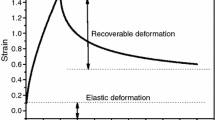

Low-temperature rheological tests were finished by adopting bending beam rheometer (TE-BBR, Cannon Instrument Company, USA) at − 20 °C. In each test, a shaped asphalt sample (125 mm long, 12.5 mm wide, 6.25 mm thick) was sustained at two ends by stainless supports and soaked in cold ethyl alcohol for 1 h. A constant loading was applied on the midpoint of sample for 240 s. The calculated parameter creeping stiffness (S) and creeping rate (m) were used to evaluate the low-temperature cracking resistance of sample.

Morphology observation

The distribution of polymer in asphalt was observed by using optical microscope (Shanghai Cai Kang optical instrument Co., Ltd) at ×400 magnification. In each test, a very little asphalt was placed on a glass slide and was heated and until it became fusion fully, and a thin cover glass was placed on the melting sample and pressed further at a nonopaque thickness.

Fourier transform infrared (FTIR) spectroscopy

The distribution and intensity of functional groups of asphalt sample and PPA were studied by using an infrared spectrometer (Thermo Nicolet Corporation, resolution 0.125 cm−1) in wave range from 400 to 4000 cm−1. A drop of asphalt solution (10 mass/% concentration, chloroform solvent) was dropped on a potassium bromide table and dried for FTIR test. PPA can be dropped on potassium bromide table and tested directly.

Thermal analysis

Thermal analysis was performed using a thermal gravimetric analyzer (Netzsch, DIL402C, Germany), under argon air atmosphere, sample mass around 7 mg, with a constant heating rate of 10 °C min−1, heated from room temperature to 800 °C. The argon air during the experiments was 120 mL min−1. The thermogravimetric (TG) curve, derivative thermogravimetry (DTG) curve and differential scanning calorimetry (DSC) curve were used to evaluate the thermal stability of binder. All experiments were performed three times for reproducibility.

Results and discussion

Physical properties

The physical properties of HVM asphalt and modified asphalts with PPA are listed in Table 3. For asphalts 1 and 2 with the same proportion, asphalt 2 owns better high- and low-temperature properties such as softening point, motive viscosity before ageing and ductility and flexibility after ageing, which means the conflict effect between PPA and FEO in technique 2 can be avoided by preblending FEO and asphalt in technique 3 and SBS can be swelled in the mother liquid fully, resulting in the improved ductility and flexibility. After the 24-h placement, the constitutes of the mother liquid became stable that not only provided enough light constitutes for the swelling of SBS but prompted the full dispersion of SBS in asphalt under the same shearing and stirring conditions. It has been demonstrated that the adhesive force between asphalt and capillary tube in motive viscosity testing depends on the outline and size of SBS in asphalt to a great extent [19], and the finer particle size and filamentous polymer outline after vulcanization often led to a stronger adhesive force and higher motive viscosity [19].

However, as for asphalt 1 made by technique 2, the lower properties mentioned above indicate the PPA addition after using FEO led to a conflict effect. Because of the similar chemical constitutes between FEO and light asphalt compositions, as confirmed previously [20], it was possible for PPA to react with FEO and decrease the role of plasticizer. Not only was the swelling of SBS restricted by this way, but the further modification of PPA on the high-temperature performance of HVM asphalt was also decreased. Therefore, it is unsuitable for HVM asphalt with PPA to be prepared by adopting technique 2.

Although the obvious modification for asphalt 2 was obtained by using technique 2, the major physical properties of asphalt 2 including softening point, motive viscosity, toughness and tenacity, elasticity recovery rate still cannot compete with those of HVM asphalt. This can be attributed to the lower SBS content in asphalt 2 to some extent. The further modification for these properties still depended on the SBS content to a great extent; therefore, it was also necessary to prepare asphalt 3 by increasing the SBS content to 5 mass/% further and adopting the technique 2 simultaneously. It can be seen that there is not obvious difference in softening point, elasticity recovery rate, toughness and tenacity, ductility and flexibility between asphalt 3 and HVM asphalt expect for motive viscosity. For HVM asphalt, higher motive viscosity and better toughness and tenacity after ageing still depend on the SBS content, so the further modification of SBS on these properties still cannot be replaced by PPA, and the predominant role of PPA was still indicated by the increased softening point before and after ageing. Even so, the motive viscosity of asphalt 3 is still far beyond 2 × 104 Pa s and meets the related standard and practical need [21]; the SBS content was also reduced by 1 mass/%. Therefore, the suitable addition of PPA in HVM asphalt is still very constructive by adopting technique 2 and asphalt 3 is the most optimized one for the further study.

Rheological properties

Temperature sweep

The rheological behaviours of HVM asphalt and asphalt 3 are shown in Fig. 2a, b, and it can be seen from Fig. 2a that there is almost no difference in G* between HVM asphalt and asphalt 3 with increasing the temperature. The minimum value and deeper turning in the phase curve of HVM asphalt indicate there was a continuous polymer network in asphalt due to the high SBS content [22]. After TFOT ageing in Fig. 2b, the minimum value and deeper turning of HVM asphalt have almost disappeared, showing the severe destruction for polymer network. The lower phase angle curve of asphalt 3 in the whole range indicates the gelation effect, and this also can be confirmed by the higher G* after 40 °C.

Frequency sweep

The dependence of rheological behaviour on frequency is shown in Fig. 3a, b. In Fig. 3a, the lower G* (after 0.25 rad s−1) and higher phase angle (after 10 rad s−1) of HVM asphalt than that of asphalt 3 show the susceptibility to dynamic shearing and HVM asphalt shows a viscous rheological behaviour with increasing the frequency. After TFOT ageing in Fig. 3b, the viscous behaviour of HVM asphalt became more obvious, as shown by the higher phase angle curve and lower G* over the whole range.

Repeated creep

The repeated creep at 60 °C is usually used to stimulate the vehicle loading on pavement, which consists of 100 cycles and each cycle contains two stages: loading (1 s, 30 Pa) and recovery (9 s, 0 Pa), and the viscous component of creep stiffness (Gv) at 51 th cycle is proposed a good index and used to evaluate the rutting resistance of sample at high temperatures according to the report [23,24,25]. The Gv of HVM asphalt and asphalt 3 is shown in Table 4, and the lower Gv of HVM asphalt before and after ageing confirmed the susceptibility to dynamic shearing.

The dynamic shearing tests showed HVM asphalt was susceptible to dynamic shearing, and asphalt 3 holds the better high-temperature rutting resistance. The addition of PPA prompted the asphalt gelation, improved the high-temperature rheological performances and decreased the susceptibility to dynamic shearing.

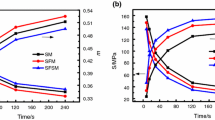

Low-temperature rheological behaviour

The low-temperature rheological behaviour of HVM asphalt and asphalt 3 before and after ageing was tested by using BBR at − 20 °C and is shown in Fig. 4. It can be seen that HVM asphalt owns higher creep stiffness (S) and lower creep rate (m) in the whole range before and after ageing, which means asphalt 3 owns better low-temperature cracking resistance. This can be attributed to the effect of PPA gelation. The suitable gelation restricted the swelling of SBS in asphalt and made SBS particles more elastic, resulting in the improved low-temperature flexibility.

Morphology

The polymer distribution in HVM asphalt and asphalt 3 before and after ageing was observed by using optical microscope and is shown from Figs. 5 to 6. In Fig. 5a, the dense filamentous polymer outlines are dispersed in asphalt for HVM asphalt. As a result of vulcanization, the outline of SBS changed greatly from coarser particles to filamentous ones and lots of filamentous polymers were entangled together to form a dense network due to the higher SBS content. Besides, there were still unvulcanized SBS particles dispersed in asphalt somewhere in Fig. 5b. For asphalt 3, the filamentous and granular polymer still can be found in asphalt, as shown in Fig. 5c, d, and the density of the vulcanized polymer network has decreased as shown in Fig. 5c due to the lower SBS content.

After TFOT ageing, the residual filamentous or granular SBS outlines still can be found in HVM asphalt and asphalt 3 after observing many samples, respectively, as shown in Fig. 6a–d. Both the amount and density of SBS network have decreased greatly than before ageing, showing the crosslinked polymer network has been degraded and dissolved in asphalt greatly. It was very difficult to find the significant morphological difference between HVM asphalt and asphalt 3 even after observing many samples.

FTIR analysis

To investigate the effect of PPA on FTIR of HVM asphalt, the FTIR spectrum of PPA is shown in Fig. 7. The FTIR spectra of base asphalt, HVM asphalt and asphalt 3 are shown in Fig. 8. Because of the similarity between unaged and aged samples, the spectrum of aged sample also can be illustrated by that of unaged one.

In the FTIR spectrum of PPA, the broad and low peak from 3405 cm−1 to 2833 cm−1 is attributed to the P–OH stretching vibration, the peak at 2320 cm−1 corresponds to P–H stretching vibration, 1646 cm−1 depends on the O–H deforming vibration, 1016 cm−1 was ascribed to the P–O–P stretching vibrations, 927 cm−1 and 721 cm−1 were the asymmetric vibrations of P–O–P, and the bending vibrations of P–O–P can observed at 493 cm−1.

In Fig. 8, the strong peak at 2851–2929 cm−1 is the C–H stretching vibration of aliphatic hydrocarbon. The peak at 1603 cm−1 is the stretching vibration of C=C of aromatic ring. The peak at 1452.2 cm−1 is the C–H asymmetric deforming of CH2 and CH3, and the peak at 1379.1 cm−1 is the symmetric deforming of CH3. The peak at 1214 cm−1 can be attributed to the frame vibration of (CH3)3 C–R. The peak at 1030.1 cm−1 depends on the stretching vibration of S=O. The small peaks from 664 cm−1 to 865.8 cm−1 are the C–H vibration of aromatic rings. Compared with PPA in Fig. 7, it can be seen that the characteristic peaks of PPA do not appear and overlapped with those of base asphalt. Compared with base asphalt, the new characteristic peak of HVM asphalt and asphalt 3 at 966.7 cm−1 corresponds to the C–H bending vibration of butadiene [26] and no new peak can be found between HVM asphalt and asphalt 3.

To investigate the effect of ageing on the spectra of HVM asphalt and asphalt 3, Eq. (1) was used to evaluate the SBS content in asphalt further [27, 28] and the calculated result is listed in Table 5.

It can be seen that the ICH=CH of asphalt 3 is lower than that of HVM asphalt because of the less SBS content. After ageing, the ICH=CH of two binders decreased to some extent due to the SBS degradation. Compared with asphalt 3, HVM asphalt holds higher ICH=CH after ageing, showing that there were more SBS residuals in HVM binder.

Thermal analysis

Thermal analysis often can be used to investigate the structural characteristics of asphalt. The thermodynamic curves of HVM asphalt and asphalt 3 before and after ageing are shown in Fig. 9a, b. Before ageing, it can be seen from Fig. 9a that the major mass loss stage that appeared in TG curve was concentrated on the temperature range from 350 to 500 °C, which is also confirmed by the corresponding major peak of DSC and DTG curves. The mass loss in the stage can be attributed to the decomposition of SBS and the volatilization of light asphalt constitutes and FEO [20, 29]. After ageing, the major mass loss still appeared in the same temperature range, as confirmed by the major peak of TG/DTG/DSC curves in Fig. 9b, and the mass loss can be attributed to the further decomposition of the residual SBS or hard asphalt constitutes such as asphaltene and the further volatilization of light asphalt constitutes [20, 29].

To evaluate the thermal stability of binder, the onset temperature of the mass loss effect (T0), the maximum decomposition temperature (Tmax), the mass loss in the temperature range (350–500 °C) of all binders are shown in Table 6, and usually, the values of T0 and Tmax are used to evaluate the thermal stability of sample [30, 31]. It can be seen that HVM asphalt holds higher T0 and Tmax and less mass loss before ageing, indicating the better thermal stability. This is because there were more SBS particles in HVM asphalt, which led to the further absorption of asphalt constitutes and resulted in the less constitutes volatilization and mass loss. After ageing, the lower T0 and Tmax of HVM binder indicate the declined thermal stability; this should be attributed to the serious SBS degradation, and HVM asphalt was more susceptible to ageing; however, the less mass loss of HVM binder also shows the extra SBS residual left.

To investigate the structural characteristics of HVM asphalt and asphalt 3 further before and after ageing, the peaks of DSC curves before and after ageing were calculated by using tangent line [29, 32], as shown in Fig. 10a, b, and the results are listed in Table 7. It can be seen that HVM asphalt holds higher area before ageing; this is because there was a higher SBS content in HVM asphalt and more SBS particles were decomposed in the stage, leading to the more energy consumption. After ageing, the declined area of HVM binder than before ageing shows there were a great SBS degradation and less energy consumed further, and the SBS decomposition played a predominant role in ageing. However, for asphalt 3, the area increased evidently after ageing and was much higher than that of HVM binder; this means there was a larger energy consumption and the asphalt constitutes after ageing were more complex, and the molecule weight distribution also became more broad. This was attributed to the PPA gelation effect to some extent. The use of PPA prompted the structural change of asphalt and increased the hard asphalt constitutes such as asphaltene or resin. In addition to the influence of ageing, not only SBS degraded partly and was dissolved in asphalt, but the hard asphalt constitutes increased further. Compared with HVM asphalt, the SBS degradation played a predominant role no longer and the complex asphalt constitutes and molecule weight distribution led to a long energy consumption process. Therefore, the susceptibility of HVM asphalt to ageing was suppressed by the addition of PPA to a great extent.

Conclusions

The preparation of mother liquid by preblending FEO and asphalt is helpful for the swelling and dispersion of SBS in asphalt. The use of PPA by preparing mother liquid can improve the softening point of HVM asphalt further at the least SBS content. Rheological tests demonstrated the further improved rheological behaviours of HVM asphalt by the suitable PPA gelation. Morphology observation displayed the formation of the crosslinked polymer network by vulcanization and confirmed the polymer decomposition after ageing. FTIR analysis indicated the difference of SBS content after modification or ageing. Thermal analysis showed the addition of PPA decreased the ageing susceptibility of HVM asphalt greatly by changing asphalt constitutes and molecule weight distribution further.

References

Liang YJ, Xu ZH. Performance evaluation of high viscosity modified asphalt. Pet Asph. 2010;24:20–2 (Chinese).

Tan YQ, Shi KL, Wang JN, Gong WQ. Research on the impact of asphalt character on stress absorbing layer performance. J Highw Transp Res Dev. 2009;26(2):13–7 (in Chinese).

Xu B. The theory and practice of porous asphalts. 1st ed. Beijing: China People Communication Press; 2011.

Mark B. Polyphosphoric acid modification of asphalt. Asphalt. 2005;20:38–40.

Bonemazzi F, Giavarini C. Shifting from sol to gel. J Pet Sci Eng. 1999;22:17–24.

Yan KZ, Zhang H, Xu HB. Effect of polyphosphoric acid on physical properties, chemical composition and morphology of bitumen. Constr Build Mater. 2013;47:92–8.

Martin JV. Polyphosphoric acid use in asphalt more than 40 years experience. Asphalt. 2006;21:14–6.

Xiao FP, Amirkhanian S, Wang HN, Hao PW. Rheological property investigations for polymer and polyphosphoric acid modified asphalt binders at high temperatures. Constr Build Mater. 2014;64:316–23.

Martin J, Hampl R, Otakar V, Dusan B, Jiri S, Ludovit Z. Rheology of conventional asphalt modified with SBS, Elvaloy and polyphosphoric acid. Fuel Process Tech. 2015;140:172–9.

Javier Y, Mahecha N, Matheus D, Inocente D, Adalberto LF. Susceptibility of low-density polyethylene and polyphosphoric acid-modified asphalt binders to rutting and fatigue cracking. Constr Build Mater. 2014;73:509–14.

Liang P, Liang M, Fan WY, Zhang YZ, Qian CD, Ren SS. Improving thermo-rheological behavior and compatibility of SBR modified asphalt by addition of polyphosphoric acid (PPA). Constr Build Mater. 2017;139:183–92.

Zhang F, Yu JY. The research for high-performance SBR compound modified asphalt. Constr Build Mater. 2010;24:410–8.

Zhang F. Studies on the modified asphalt with phosphorus compounds and its rheological properties. Master dissertation, Northwest Normal University, Lanzhou City, China, 2008.

Zhang F, Hu CB. The research for SBS and SBR compound modified asphalts with polyphosphoric acid and sulfur. Constr Build Mater. 2013;43:461–4.

Zhang F. Influence of polyphosphoric acid and sulfur on ageing properties of rubber-modified asphalts. Doctor dissertation, Wuhan University of Technology, Wuhan City, China, 2011.

Linda M. US patent 99/58600, 1998.

Willamson PO. US patent 06414056B1, 2002.

Zhang F, Hu CB. The composition and ageing of high-viscosity and elasticity asphalts. Polym Compos Online. 2017;38:2509-2517.

Zhang F, Hu CB. Preparation and properties of high viscosity modified asphalt. Polym Compos. 2017;38:936–46.

Zhang F, Hu CB, Zhuang WL. The research for low-temperature rheological properties and structural characteristics of high-viscosity modified asphalt. J Therm Anal Calorim Online. 2018;131(2):1025–35.

Liu XL. Preparation and properties of high viscosity modified asphalt. Master Thesis, Wuhan University of Technology, Wuhan City, China, 2008.

Lu X, Isacsson U. Rheological characterization of styrene-butadiene-styrene copolymer modified bitumens. Constr Build Mater. 1997;11:23–32.

Bahia HU, Hanson DI, Zeng M, Zhai H, Khatri MA, Anderson RM. Characterization of modified asphalt binders in superpave mix design. Natl Coop Highw Res Program Rep 2001;459.

Hu RY, Bahia HU, Zhai Z, Zheng M. Measuring resistance of asphalt binders to permanent deformation using the DSR device. In: TRB 80th annual meeting, Washington; 2001.

Binard C, Anderson D, Lapalu L, Planche JP. Zero shear viscosity of modified and unmodified binders. In: Proceeding of the 3rd Eurasphalt and Eurobitume congress, Vienna; 2004.

Zhang F, Hu CB. The research for high-elastic modified asphalt. J Appl Polym Sci. 2015;132:42134(1)–14).

Ouyang CF, Wang SF, Zhang Y, Zhang YX. Improving the aging resistance of styrene–butadiene–styrene tri-block copolymer modified asphalt by addition of antioxidants. Polym Degrad Stab. 2006;91:795–804.

Lamontagne J, Dumas P, Mouillet V, Kister J. Comparison by Fourier transform infrared (FTIR) spectroscopy of different ageing techniques: application to road bitumens. Fuel. 2001;80:483–8.

Zhang F, Hu CB. The research for structural characteristics and modification mechanism of crumb rubber compound modified asphalts. Constr Build Mater. 2015;76(1):330–42.

Juan M, Jiménez M, Luis CQ, Carmen R. Characterization of petroleum bitumens and their fractions by thermogravimetric analysis and differential scanning calorimetry. Fuel. 1996;75:1691–700.

Radhakrishnan CK, Sujith A, Unnikrishnan G. Thermal characterization of asphalt mixtures by TG/DTG, DTA and FTIR. J Therm Anal Calorim. 2008;93:105–9.

Gao JL. Analysis and evaluation of bitumen new index and additive index. Doctor dissertation, Southeast University, Nanjing City, China, 2005.

Acknowledgements

This research was supported by the foundation of Fujian Education Department (CN), and the fund number is JAT160060.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, F., Hu, C. & Zhang, Y. The effect of PPA on performances and structures of high-viscosity modified asphalt. J Therm Anal Calorim 134, 1729–1738 (2018). https://doi.org/10.1007/s10973-018-7740-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7740-7