Abstract

Thermal analysis is a routine method in the solution of pharmaceuticals problems such as the control of raw materials, to the determination of purity, to the qualitative and quantitative analysis of drug formulation, tests of thermal stability and compatibility, the determination of kinetic parameters, etc. The evaluation of thermal stability in the solid state is mostly made by analyzing their decomposition under isothermal and non-isothermal conditions. The present work reports the study on the thermal behavior of pentoxifylline—active substance and tablets, respectively, the determination of the kinetic parameters for the decomposition process under non-isothermal conditions and in a nitrogen atmosphere at five heating rates: 2.5, 5, 7.5, 10 and 15 °C min−1. For the determination of kinetic parameters from the TG/DTG curves, the following differential methods were utilized: Friedman isoconversional and Chang, respectively, integral methods: Flynn–Wall–Ozawa, Kissinger–Akahira–Sunose, Li–Tang, and Starink. Thermoanalytical curves showed that the active substance is thermally more stable than the tablets. The decrease in stability was attributed to the presence of excipients.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

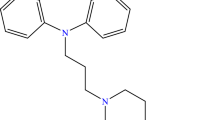

Pentoxifylline (PEX) is a tri‐substituted xanthine derivative designated chemically as 1‐(5‐oxohexyl)‐3,7‐dimethylxanthine that, unlike theophylline is a hemorrheologic agent used for the treatment of peripheral disease and intermittent claudication [1]. It improves blood flow through the peripheral circulation by decreasing blood viscosity, inhibiting platelet aggregation, enhancing erythrocyte flexibility, and diminishing fibrinogen concentration [2]. Besides this well-known hemorheological properties, PEX has also been found to exert a wide range of immunological activities [2]. It has been reported that PEX disturbs polarization and migration of human leukocytes [1, 3]. The structural formulae of the pentoxifylline is the following.

Applying the thermal methods is very important for solving pharmaceutical problems as getting the purity, qualitative and quantitative analysis of the medicine formulas, testing the stability and determining the kinetics parameters.

Thermogravimetry (TG) and differential scanning calorimetry (DSC) can be used in the pharmaceutical industry as an analytic instrument of great importance, to identify and test the purity of the active substances, with quick and efficient results. Also, DSC can be used to control the quality of the raw materials used to obtain pharmaceutical products [4–11].

The actual trend, of using the analytical techniques, consists using combination of these (thermal and of other nature: spectrophotometric first of all, gas-chromatographic, titrimetric techniques), to obtaining superior results and in the same time reducing the quantity of material studied [12–15].

Reducing of the quantity of substance analyzed can be done, with superior results, using methods based on the relation between the reaction rate and the concentration of some substances, methods known as kinetics methods.

The kinetic studies of one kind or another, some are genuine and some are not, are widely utilized in the characterization of thermally induced events in a variety of materials. Such studies provide information that may be useful for a variety of purposes particularly for comparisons within a series of similar materials, for quality control, to predict suitable process conditions, or to project an expected use lifetime [16–23].

A series of works, even recent ones, show encouraging results regarding the evaluation of the thermal behavior of pharmaceuticals products by the kinetic data obtained in non-isothermal conditions [16–23].

In our previous papers, we provided the importance and utility of the kinetic analysis in estimation on the thermal behavior of different pharmaceuticals [24–27].

The aim of a kinetic investigation is to calculate the kinetic parameters: the rate constant (k), the activation energy (E), the pre-exponential factor (A) and reaction order (n), respectively, to determine the kinetic model for the studied process.

The methods proposed for the kinetic study of thermal decomposition are commonly classified in model-fitting and model-free methods. The kinetic analysis based on an isoconversional method is frequently referred to as “model-free” because it is possible to obtain the apparent activation energy (E) as a function of the conversion degree (α) which has specific interest when the thermal decomposition occurs in more than one step. Using an isoconversional method one does not obtain directly either the reaction model or pre-exponential factor, but the effective activation energy that tends to vary with the conversion degree [28–33].

The model-free isoconversional methods are considered as the most reliable ones, especially the Friedman method [34], because of its theoretical and experimental advantages. By these methods, the overlapping reactions could be detected looking at the dependence of the activation energy on the conversion.

This paperwork studies the thermal behavior of pentoxifylline active substance (AS) and tablets, having as purpose the evaluation of its thermal stability. Also, it was effectuated the kinetic study through the thermal decomposition, under non-isothermal conditions, for the active substance.

Experimental

Materials

The substances examined by thermal analysis were: pentoxifylline—AS or PEX and pentoxifylline retard—tablet or PEXR.

The AS was obtained from Sigma-Aldrich GmbH, Germany, as pure compound, able to be used for medical purposes. The pharmaceutical was obtained from Antibiotice Iaşi, Romania, containing different (qualitative and quantitative) excipients like: lactose, talc, and magnesium stearate.

Methods

TG/DTG/DTA experiments were performed with a Netzsch-STA 449 TG/DTA instrument in the temperature range of 20–500 °C, using platinum crucibles with ≈20 mg of samples under dynamic nitrogen atmosphere (20 mL min−1) and the heating rates of 2.5, 5, 7.5, 10 and 15 °C min−1.

Results and discussion

Thermal behavior of pentoxifylline

Some of the thermal curves of the pentoxifylline—PEX and PEXR, obtained under dynamic temperature conditions at heating rate of 10 °C min−1 and a nitrogen atmosphere, are presented in Figs. 1 and 2.

The TG/DTG curves of the AS show one clear step of mass loss. The large mass loss took place in the domain range of 250–475 °C with a mass loss of 81.2 % which corresponds to the decomposition process of the PEX (T peak DTG = 390.6 °C).

The DTA curve presents a first strong event at 108.7 °C, which corresponds to the melting process of the PEX. The second peak, broad and strong, of endothermic nature, corresponds to the decomposition process with T peak DTA = 390.6 °C.

The Fig. 2 shows the thermoanalytical curves of the commercial pharmaceutical product using the same experimental conditions in relation to active substance.

The TG/DTG curves indicate the existence of a complex process of decomposition, which comprises three stages, with the following temperature ranges: 125.2–150.3 °C (Δm = 1.04 %; T peak DTG = 138.5 °C); 205.7–275.2 °C (Δm = 7.66 %; T peak DTG = 249.8 °C) and 275.2–500 °C (Δm = 70 %; T peak DTG = 368.5 °C). Practically, the thermal decomposition begins at 205 °C and the mass lost total is of 78.7 %.

The DTA curve confirms the complex nature of the thermal decomposition of PEXR by the four peaks of endothermic nature. The first peak, broad and relatively strong, in the temperature range 95.2–136.3 °C (T peak DTA = 118.3 °C) corresponds to simultaneous processes: the melting and probably one deshydratation of excipients.

The following two peaks, in the temperature range: 136.3–166.7 °C (T peak DTA = 142.2 °C) and 205.7–261.1 °C (T peak DTA = 254.8 °C), are relatively broad and of reduced intensity. The last peak, very broad and strong, in the temperature range 275.2–405.9 °C (T peak DTA = 371.6 °C), corresponds to the principal process of decomposition.

The different thermal profile of the PEXR curves in comparison with PEX, respectively, the difference between the values of the temperature intervals of decomposition and those of the endothermal peaks are due to the presence of the excipients and to the possible interactions of these ones with the AS, phenomena which happens to other drugs too.

Decreasing temperatures T onset, respectively, T peak DTG(DTA) for thermal decomposition of pentoxifylline tablets, as compared to the pentoxifylline—AS indicates a higher thermal stability of this.

Kinetic analysis

Also, the thermal stability was characterized using the kinetic parameters, on the basis of the kinetic study performed under non-isothermal conditions, which sustained the present facts.

The kinetic parameters were determined from the TG/DTG curves, using the differential method, Friedman isoconversional (Fd) [34] and Chang [35], respectively, integral methods, Flynn–Wall–Ozawa (FWO) [36, 37], Kissinger–Akahira–Sunose (KAS) [38, 39], Li–Tang (LT) [40] and Starink (St) [41].

From the equation of reaction rate:

for non-isothermal conditions dα/dt is replaced with βdα/dT:

where α is the conversion degree, t—time, f(α)—reaction model, T—temperature, β—heating rate.

The isoconversional Friedman method is based on the equation:

In order to evaluate the activation energy more precisely, the term ln (dα/dT) was obtained by numerical derivation of the curve α versus T with respect to T and subsequent taking logarithms.

For α = constant and using various heating rates, the plot ln (βdα/dT) versus (1/T) is linear (Fig. 3). The values of the activation energy as obtained from the slopes of the straight lines are listed in Table 1.

The values of the activation energy (E) obtained by the five methods are in good agreement, and the weak variation of E with α, together with the profile of thermoanalytical curves, indicates a complex process for decomposition of melt active substance, in condensed phase.

The general equation of the reaction rate for non-isothermal conditions at constant heating rate is generally written as:

where g(α)—the conversion integral, p(x)—the temperature integral, x = E/(R T).

Many approximations of the temperature integral p(x) have been suggested in the literature and as a consequence, many more or less accurate methods appeared for the activation energy analysis. All these methods involve the plot of a logarithmic function (which depends on the approximation for the temperature integral used) versus 1/T α . The general equation is:

where k is a constant depending on the approximation of the temperature integral employed, B and C are constants and the subscript α designates values related to a given extent of conversion.

Four of the linear integral isoconversional methods, considered in the literature the most accurate, were used in this article.

Flynn–Wall–Ozawa (FWO) method

The FWO method is based on Doyle’s approximation for the temperature integral, p(x) = exp(−1.052x − 5.331). For this method, k = 0 and for constant conversion α, the general linear Eq. (5) becomes:

Using the FWO method, the activation energies were calculated from the slope of the linear fitted function of ln β versus 1/T α (Fig. 4). The values of the activation energy (E α ) are included in Table 1.

Kissinger–Akahira–Sunose (KAS) method

The KAS method is based on the approximation p(x) = exp(−x/x 2) for the temperature integral. In this case, at constant conversion α, the general linear Eq. (5) leads to Eq. (7) (k = 2):

For α = constant, the activation energies were determined from the slope of the linear fitted function of ln (β/T 2 α ) versus 1/T α (Fig. 5), and the values obtained are presented in Table 1.

Li–Tang (LT) method

The approximation proposed by LT for the temperature integral is: −ln p(x) = 0.37774 + 1.89466 ln x − 1.00145x. For this method (k = 1.89466) and at constant conversion α, the general linear Eq. (5) becomes:

For α = constant, the values of E (Table 1) were determined from the slope of the linear fitted function of ln (β/T 1.89466 α ) versus 1/T α .

Starink (St) method

The approximation suggested by St for the temperature integral is: \( p(x) = { \exp }\frac{( - 1.0008x - 0.312)}{{x^{1.92} }} \). In this case, k = 1.92 and at constant conversion α, the general linear Eq. (5) becomes:

Using the Starink method, the values of E α were calculated from the slope of the linear fitted function of ln (β/T 1.92 α ) versus 1/T α and are included in Table 1.

For LT and St methods, which rely basically on the same general equation, with very few exceptions, we have not included graphical representations (practically identical to Fig. 5), only the values of E α (Table 1).

From the Eq. (1), by logarithmation it is obtained the equation corresponding to the Chang’s method:

where α is the conversion degree, t—time, f(α)—reaction model, T—temperature.

The different differential functions f(α) were substituted in Eq. (10) and the relations were linearized therefore obtaining three–parametric linear equations: z = a + bx + cy.

The use of TableCurve3D Software can determine the kinetic triplet (E, ln A, n) through the estimation of the three parameters: a, b, c.

For different f(α), the most probable to describe the kinetic model, it was calculated the regression coefficient. Based on this values and also because of the activation energy’s sign (the activation energy must have physical sense), it was chosen the function: f(α) = (1 − α)n, which represents the reaction order model, and n = 1/2 (Table 2). From the graphic representation on the experimental data (Fig. 6), the values of E, A and n were determined (Table 2).

The value of activation energy determined by Chang method is in agreement with the values presented in Table 1.

According to the values presented in Table 2 (in which the mean for n is 1.257 ± 0.064), it was not observed a significant variation of the reaction order versus temperature of reaction, and according to Sbirrazzuoli et al. [42], this denotes the presence of a process which takes place in a single step.

Regarding the physical meanings of kinetic parameters, the values of E showed a relatively lower thermal stability of the PEX, considering that ≈65 % of the values of E found in the literature are in the 100–230 kJ mol−1 range [43].

The values of n (1.257), respectively, A (≈3.6 × 107 s−1) in the range 105–1018 s−1, indicate that the kinetic model corresponds to the reaction order model, which agrees with an homogenous decomposition of purely condensed phase (the case of PEX decomposition in molten phase) [44, 45].

It is known that the thermal decomposition of drugs is a complex process which tends to proceed in several stages with different rates. Within this complex process, competitive, consecutive and parallel reactions could occur. For PEX decomposition, the competitive reactions can be excluded because the total mass lost for the five heating rates is the same.

Conclusions

There was performed a thermal study about the thermal behavior of pentoxifylline and its pharmaceutical form, respectively, the kinetic determinations under non-isothermal conditions for the pentoxiphylline active substance.

There have been observed differences between the thermal curves of the pure compound and those of the pharmaceutical product, due to the presence of the excipients in drug and to the possible interactions with the active substance.

By comparison of the thermal curves, it was revealed the complex behavior and the lower thermal stability of pentoxifylline—drug compared with the active substance, because the reason is already mentioned.

The values of the kinetic parameters, determined with differential and integral methods, are in fairly good agreement, they are situated in a narrow range (E = 152–156 kJ mol−1; ln A ≈ 17 s−1) and this fact indicates the correctness of the applied methods.

The concordance of the values for the kinetic parameters determined and the mode of dependence of the activation energy as against the conversion degree show the fact that the thermal decomposition process of the PEX is relatively complex, with simultaneous and/or successive reactions.

The kinetic study through values of kinetic parameters (especially E) can be used in the preformulation and production steps for quality control of medicines.

References

Zhang M, Xu YJ, Mengi AS, Dhala SN. Therapeutic potentials of pentoxifylline for treatment of cardiovascular diseases. J Coord Chem. 2004;58:775–85.

Kale R, Mathew D. Development of matrix diffusion controlled drug delivery system of pentoxifylline. Int J Pharm Pharm Sci. 2010;2:122–30.

Christova-Bagdassarian V, Angelov T, Atanassova M. UV-spectrometric and high performance liquid chromatographic determination of pentoxifylline in workplace air. J Univ Chem Technol Metall. 2007;42:223–7.

Kobelnik M, Lopes Cassimiro D, Ribeiro CA, Capela JMV, Dias DS, Crespi MS. Preparation and thermal study of Mg-diclofenac compound in solid state. J Therm Anal Calorim. 2012;108:213–8.

Fini A, Fasio G, Benetti L, Ghedini V. Thermal analysis of some diclofenac salts with alkyl and alkylhydroxy amines. Thermochim Acta. 2007;464:65–74.

Mora Corvi P, Cirri M, Mura P. Differential scanning calorimetry as a screening technique in compatibility studies of DHEA extended release formulations. J Pharm Biomed Anal 2006;42:3–10.

Neto HS, Barros FAP, de Sousa Carvalho FM, Matos JR. Thermal analysis of prednicarbate and characterization of thermal decomposition product. J Therm Anal Calorim. 2010;102:277–83.

Macêdo RO, Aragão CFS, do Nascimento TG, Macêdo AMC. Application of thermogravimetry in the quality control of chloramphenicol tablets. J Therm Anal Calorim. 1999;56:1323–7.

Kerch G, Glonin A, Zicans J, Merijs Meri R. A DSC study of the effect of ascorbic acid on bound water content and distribution in chitosan-enriched bread rolls during storage. J Therm Anal Calorim. 2012;108:73–8.

Giordano F, Rossi A, Pasquali I, Bettini R, Frigo E, Gazzaniga A, Sangalli ME, Miles V, Catinella S. Thermal degradation and melting point determination of diclofenac. J Therm Anal Calorim. 2003;73:509–18.

Picciochi R, Diogo HP, da Piedade MEM. Thermochemistry of paracetamol. J Therm Anal Calorim. 2010;99:391–401.

Bannach G, Cervini P, Cavalheiro ETG, Ionashiro M. Using thermal and spectroscopic data to investigate the thermal behavior of epinephrine. Thermochim Acta. 2010;499:123–5.

Iliescu T, Baia M, Miclăuş V. A Raman spectroscopic study of the diclofenac sodium-β-cyclodextrin interaction. Eur J Pharm Sci. 2004;22:487–95.

Pani NR, Nath LK, Acharya S, Bhuniya B. Application of DSC, IST, and FTIR study in the compatibility testing of nateglinide with different pharmaceutical excipients. J Therm Anal Calorim. 2012;108:219–26.

Zayed MA, Hawash MF, Fahmey MA, El-Gizouli AMM. Investigation of ibuprofen drug using mass spectrometry, thermal analyses, and semi-empirical molecular orbital calculation. J Therm Anal Calorim. 2012;108:315–22.

Li X, Wu Y, Gu D, Gan F. Thermal decomposition kinetics of nickel (II) and cobalt (II) azo barbituric acid complex. Thermochim Acta. 2009;493:85–9.

Howell BA. Utility of kinetic analysis in the determination of reaction mechanism. J Therm Anal Calorim. 2006;85:165–7.

Zhao L, Li Q, Cui Y, Wang J, Xu S, Chen X, Bi K. Thermal kinetic studies on the decompositions of cefuroxime lysine in different atmospheres and heating rates. J Therm Anal Calorim. 2012;108:269–73.

Shukla S, Mishra AP. Non-isothermal degradation-based solid state kinetics study of copper (II) Schiff base complex, at different heating rates. J Therm Anal Calorim. 2012;107:111–7.

Doyle CD. Series approximations to equation of thermogravimetric data. Nature. 1965;207:290–1.

Tiţa B, Fuliaş A, Bandur G, Rusu G, Tiţa D. Thermal stability of ibuprofen. Kinetic study under non-isothermal conditions. Rev Roum Chim. 2010;55:553–8.

Tiţa B, Fuliaş A, Rusu G, Tiţa D. Thermal behaviour of indomethacin—active substance and tablets kinetic study under non-isothermal conditions. Rev Chim (Bucureşti). 2009;60:1210–5.

Tiţa B, Fuliaş A, Tiţa D. Kinetic study of indomethacin under isothermal conditions. Rev Chim (Bucureşti). 2010;61:1037–41.

Tiţa B, Fuliaş A, Marian E, Tiţa D. Thermal behaviour of acetylsalicylic acid—active substance and tablets. Kinetic study under non-isothermal conditions. Rev Chim (Bucureşti). 2009;60:419–23.

Tiţa B, Fuliaş A, Marian E, Tiţa D. Thermal stability and decomposition kinetics under non-isothermal conditions of sodium diclofenac. Rev Chim (Bucureşti). 2009;60:524–8.

Tiţa B, Fuliaş A, Ştefănescu M, Marian E, Tiţa D. Kinetic study of decomposition of ibuprofen under isothermal conditions. Rev Chim (Bucureşti). 2011;62:216–21.

Tiţa B, Fuliaş A, Ştefănescu M, Marian E, Tiţa D. Kinetic study of sodium diclofenac under isothermal conditions. Rev Chim (Bucureşti). 2011;62:31–6.

Ortega A. A simple and precise linear integral method for isoconversional data. Thermochim Acta. 2008;474:81–6.

Chrissafis K. Kinetics of thermal degradation of polymers. Complementary use of isoconversional and model-fitting methods. J Therm Anal Calorim. 2009;95:273–83.

Saha B, Maiti AK, Ghoshal AK. Model-free method for isothermal and non-isothermal decomposition kinetics analysis of PET sample. Thermochim Acta. 2006;444:46–52.

Dickinson CF, Heal GR. A review of the ICTAC kinetics project, 2000: part 1. Isothermal results. Thermochim Acta. 2009;494:1–14.

Dickinson CF, Heal GR. A review of the ICTAC kinetics project, 2000: part 2. Non-isothermal results. Thermochim Acta. 2009;494:15–25.

Budrugeac P. Differential non-linear isoconversional procedure for evaluating the activation energy of non-isothermal reactions. J Therm Anal Calorim. 2002;68:131–9.

Friedman HL. New methods for evaluating kinetic parameters from thermal analysis data. J Polym Sci. 1965;6C:183–7.

Chang WL. Decomposition behavior of polyurethanes via mathematical simulation. J Appl Polym Sci. 1994;53:1759–69.

Flynn JH, Wall LA. A quick direct method for determination of activation energy from thermogravimetric data. J Polym Sci B. 1996;4:323–8.

Ozawa T. A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn. 1965;38:1881–6.

Kissinger HE. Reaction kinetics in differential thermal analysis. Anal Chem. 1957;29:1702–6.

Akahira T, Sunose T. Method of determining activation deterioration constant of electrical insulating materials. Res Rep Chiba Inst Technol (Sci Technol). 1971;16:22–7.

Li RC, Tang BT. A new method for analysing non-isothermal thermoanalytical data from solid state reactions. Thermochim Acta. 1999;325:43–6.

Starink MJ. The determination of activation energy from linear heating rate experiments: a comparison of the accuracy of isoconversion methods. Thermochim Acta. 2003;404:163–76.

Sbirrazzuoli N, Vincent L, Vyazovkin S. Comparison of several computational procedures for evaluating the kinetics of thermally stimulated condensed phase reactions. Chemom Intell Lab Syst. 2000;54:53–60.

Galwey KA. Magnitudes of Arrhenius parameters for decomposition reactions of solids. Thermochim Acta. 1994;242:259–64.

Genieva DS, Vlaev TL, Atanassov NA. Study of the thermooxidative degradation kinetics of poly(tetrafluoroethene) using iso-conversional calculation procedure. J Therm Anal Calorim. 2010;99:551–61.

Vlaev TL, Georgieva GV, Gospodinov GG. Kinetics of isothermal decomposition of ZnSeO3 and CdSeO3. J Therm Anal Calorim. 2005;79:163–8.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tita, B., Jurca, T. & Tita, D. Thermal stability of pentoxifylline: active substance and tablets. J Therm Anal Calorim 113, 291–299 (2013). https://doi.org/10.1007/s10973-013-3118-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-013-3118-z