Abstract

The Pracaxi oil—(Pentaclethra macroloba) contains high concentrations of fatty acids with emollient action that contribute to skin hydration. The use of this oil is supported by the utilization of natural resources thus enabling regional development and social contribution. The objective of this study was to characterize the P. macroloba oil by thermogravimetry (TG, DTG, and DTA), gas chromatography, Fourier transform infrared spectroscopy (FT-IR), and oxidation stability—Rancimat, aiming at the quality control of plant raw material. Three samples of crude oil sold by Amazon Oil Industry (Ananindeua, Pará, Brazil) were studied. The analysis of these oil samples showed different fatty acids, especially the behenic, oleic, linoleic, and lignoceric acids totalizing approximately 96 % of the grease composition and in smaller percentage arachidic, lauric, myristic, palmitic, and linolenic acids were found. The major acids have wide medicinal use. According to the TG/DTG curve, thermal stability was observed up to 220 °C, indicating a greater mass loss related to the dehydration and elimination of volatile substances. The thermal decomposition process occurred in the range of 430–450° C according to the DTG curve. The absorption spectrum in the infrared region (FT-IR) showed well-defined bands confirming the presence of functional groups present in the oil. Tests in a Rancimat have shown an induction period between 8 and 10 h demonstrating that the samples are in agreement with the standards required by ANP No. 14/2012 which requires at least 6 h of testing.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introdution

Pracaxi (Pentaclethra macroloba), Brazil nuts (Bertholletia excelsa), Andiroba (Carapa guianensis), Babassu (Orbignya oleifera), Açai (Euterpe oleracea Mart.), Buriti (Mauritia flexuosa), Cupuaçu (Theobroma grandiflorum), Murumuru (Astrocaryum murumuru), Tucuman (Astrocaryum tucuma), and Ucuúba (Virola spp.) are economically important examples of many Amazonian species due to the oil or fat extraction of their seeds which have various applications, most notably in food, pharmaceuticals, and cosmetics sectors [1–4].

The P. macroloba popularly known as “Pracaxi” is an oilseed plant distributed throughout northern Brazil, Guyana, and some parts of Central America. It belongs to the Kingdom Plantae, Phylum Magnoliophyta Class Magnoliopsida, Fabales Order, Family Mimosaceae, genus Pentaclethra and species P. macroloba [5–7].

It is a medium size plant (8–14 m), commonly found in wetlands. It has a pod-shaped fruit, 20–25 cm in length; it is curved and contains 4–8 seeds from where oil is extracted. Presents several medicinal applications, especially in the healing of ulcers, earaches, and snake bites, erysipelas, postpartum stretch marks and in addition it has insecticidal properties acting on proteases inhibition, such as trypsin and chymotrypsin of mosquito larvae, specifically against Aedes aegypti mosquito, the dengue and yellow fever vector [8, 9].

Triterpene saponins were isolated from the ethanol extract of the seeds [10]. In recent studies these compounds revealed antispasmodic, cytotoxic, and leishmanicidal activities [11–13]. The oil contains high concentrations of oleic (Omega 9), linoleic (Omega 6), and behenic acids, six times higher than their concentrations in the peanut oil (Arachis hypogea L.). These acids are used in cosmetic industry for application in makeup and hair products, due to their excellent wetting properties [14, 15].

When evaluating the options of oils from the Amazon flora, P. macroloba oil is an excellent choice because the benefits go beyond the strong marketing appeal and the opportunity to preserve the environment. This oil has a large amount of fatty acids, a class of organic compounds constituting the lipids, which are vital in the construction of the cell membrane and the epidermis and they also protect the skin preventing its dehydration [16]. The natural fatty acids esterified in lipids play important biological roles in metabolism and they can be converted into corresponding salts by alkaline hydrolysis and used as an additive in creams, soaps, and cosmetic emulsions [17]. These acids present emollient and lubricant properties able to restore natural oils in dry skin and they can act as regenerators and protectors of damage caused by sunlight. However, it is necessary to know the properties and composition of Amazonian vegetable oils and fats for the development of new products, as well as establishing control protocols to insure quality standards [18].

The quality of a therapeutic product from plant origin is represented on the set of criteria that characterize the raw material for the purpose it is intended [19]. In Latin America the majority of herbal products from the Amazon are not subjected to quality control. This situation is unacceptable at a time when the demands for safety, efficacy, and quality established by the drugs and cosmetics regulatory agencies become more rigid. The presence or entry of these products in the market are subordinated to the development of appropriate technologies for obtaining the vegetable raw material and its quality control as well as of the finished product, including clinical and analytical assessments before releasing it to the consumer.

The instrumental analytical techniques are more sensitive in research and quality control of vegetable oils, despite their high cost. Thermoanalytical assays are distinguished by a number of techniques through which the physical property of a substance and/or its reaction products is measured as a function of temperature and/or time. Gas chromatography (GC), Fourier transform infrared spectroscopy (FT-IR), and oxidative stability—Racimat [20–24] are also included as instrumental methods [20–24].

The purpose of this study was to evaluate the thermoanalytical profile [TG-DTG and differential thermal analysis (DTA)] as well as oxidative stability, gas chromatography, and infrared spectroscopy by Fourier transform of P. macroloba oil, aiming at the quality control of the vegetable raw material seeking for its feasibility for later use in cosmetic products.

Experimental

Oil of P. macroloba

The seeds of P. macroloba were harvested in the state of Pará, in the period from March to June 2010. The oil extraction was performed with the use of oil press (LDS R 135/2008, 240 kg h−1). Three samples from different lots (002/2010, 003/2010 and 006/2010) and respective analysis certificates numbers 12/2010, 28/2010, 63/2010 of crude Pracaxi oil (sample 1, 2 and 3) without addition of any preservative were provided by Amazon Oil Industry (Ananindeua, Pará, Brazil). The oil samples were stored in amber glass vials in the dark under refrigeration before being subjected to physic-chemical investigation by gas chromatography, Fourier transform infrared spectroscopy, oxidative stability by Rancimat, thermogravimetric analysis (TG-DTG), and differential thermal analysis (DTA).

Fatty acid determination by GC

The fatty acid compositions of the oils were determined by GC using an AOCS Ce 1-62 method [25]. The fatty acid methyl esters were prepared by the AOCS Ce 2-66 method [26]. Chromatographic analysis was performed with a Varian CP 3800 gas chromatograph equipped with a hydrogen flame ionization detector and a capillary column (30 m × 0.32 mm CP WAX 52 CB; 1 μm DF) (California/USA). The column temperature was programed to ramp from 80 to 250 °C at 10 °C min−1; the injector temperature was set to 200 °C, and the detector temperature was set to 250 °C. Helium was used as the carrier gas at a flow rate of 1.0 ml min−1.

FT-IR spectroscopy

The absorption spectra of the samples in the infrared Fourier transform region were obtained in an infrared spectrometer Shimadzu Corporation IR Prestige 21 Cat. No. 206-73600-36 (Kyoto-Japan) in the range 4,000–400 cm−1. The samples were dripped in tablets of potassium bromide (KBr) with scan 100 and resolution 4 cm−1 [27]. All the bands were analyzed by Origin Pro 8.0 software.

Oxidative stability—Rancimat

The evaluation of oxidative stability index (OSI) of the P. macroloba oil was obtained by Metrohm Rancimat model 743 (Herisan/Switzerland) adapted to AOCS Official Method 12b-92, 1992. The method standardized by the European Standard EN 14112, adopted in Brazil by the ANP (National Agency of Petroleum, Natural Gas and Biofuels) ANP No. 14/2012 was used, on the following conditions: 5 g of each sample, flow of 2 L h−1 of oxygen at 110 °C. The induction period (IP) was determined by measuring the conductivity. In Brazil, the limit adopted by the ANP requires at least 6 h of testing.

Thermal analysis

The samples were analyzed by TG using the thermo balance Shimadzu DTG-60H model simultaneous DTA/TG apparatus (Kyoto/Japan). The samples weighed 5 mg, ranging in temperature from room temperature to 700 °C, in dynamic nitrogen atmosphere, flow rate 50 mL min−1, heating rate 10 °C min−1, alumina crucible for TG. The curves are analyzed using Origin Pro 8.0 software.

Results and discussion

Fatty acid determination by GC

The composition of fatty acids in the three samples of crude oil analyzed was determined by gas chromatography. The results are shown in Table 1.

The analytical results showed that the P. macroloba oil presents in its chemical composition different fatty acids, especially the behenic, oleic, linoleic, and lignoceric which together account for 96 % of the grease composition calculated in terms of peak area; and in smaller percentage the following acids: arachidic (1 %), lauric (0.03 %), myristic (0.06 %), linolenic (0.12 %), and palmitic (1.8 %). The P. macroloba oil presents a significant amount of behenic acid rarely found in other Amazon vegetable oils with the percentage of 16 % of its grease composition, much higher than the concentration of the same acid found in the baru seed oil (Dipteryx alata Vog) [28], widely used by the Brazilian Midwest population eating habits and than that found in the peanut oil (A. hypogea L.), around 12 % more [29].

It has more oleic acid than that found in Brazil nuts (B. excelsa) approximately 15 % more and 30 % more than that found in Passion fruit oil; however its amount is smaller when compared to Buriti oil [30]. Oleic acid is a carboxylic acid, by having a COOH functional group. It is a long-chain fatty acid, constituted of 18 carbons and as it contains a double bond between carbons, it is called unsaturated fatty acid. It is an essential fatty acid (Omega 9), which participates in human metabolism, playing a key role in the synthesis of hormones; so its inclusion in the diet is essential. The high content of oleic acid present in most vegetable oils makes them useful in the food industry as frying oil or salad dressings. Linolenic acid (Omega 3) and linoleic acid (Omega 6) are important parts of the human diet throughout evolution. A balanced intake of both is essential to health. The clinical interventions provide additional support for beneficial effects on the use of these fatty acids for the prevention of cardiovascular diseases (blood clotting and ventricular arrhythmias) as well as hyperinsulinemia and possibly Diabetes mellitus [15].

FT-IR spectroscopy

Figure 1 shows the FT-IR spectra (overlapped) of the three samples of P. macroloba oil. It revealed a similarity in the spectrum profile characterizing that there was no mixture of Pracaxi oil with any other kind of oil. There was a prominent carbonyl stretching band at 1,746 cm−1 and vibration of the C–O bond at 1238, 1164, and 1100 cm−1, which are diagnostic for the ester linkage of the triacylglycerol similar to that found by Albuquerque [30] when working with Buriti oil. In the range near 3,000 cm−1, bands of high intensity may be observed at 2,930 and 2,855 cm−1 corresponding to the groups HC=, and –CH3, respectively [31, 32].

The low intensity band at 3,010 cm−1 is due to the stretching of unconjugated C–H double bonds, symmetrically disubstituted in the cis position. This attribution is supported by the CH out-of-plane deformation at 723 cm−1 and the stretching of the cis structure (–CH=CH–) at 1,654 cm−1. The lack of intense band derived from CH deformation at 1,000—800 cm−1 or stretching vibrations at 1,680–1,600 cm−1 can also be used to show that vibration. At 1,464 and 1,377 cm−1 approximately, a moderate intensity band of axial deformation of C–H aliphatic groups is observed. The aging process, characterized by oxidation of the sample causes changes in the matrix which are evidenced in the absorption spectrum in the infrared region of the sample. From the changes observed, the most significant one is due to the absorption band of the carbonyl group (C=O) attributed to the presence of oxidized compounds such as aldehydes, ketones, carboxylic acids, and others favored by the degradation of hydroperoxides [33, 34].

It is possible to observe from the results presented that the spectroscopic technique (FT-IR) has great potential for samples discrimination, even in situations of close composition similarity, such as oils from the same plant species, acquired at different periods of harvesting of the raw material, fact that has been confirmed in published studies involving similar matrices [35].

Rancimat measurements

The development of undesirable compounds from lipid oxidation is an important problem to be solved to obtain a shelf life extension of oils, fats, and fatty foods. To circumvent this problem oilseeds industries add external antioxidants to keep the oxidative stability of the oils. In this study no external oxidizing samples were added.

In the results presented by the Rancimat it was found that in sample 1 the IP was 8.52 h, the sample 2 had an IP of 10.32 3 h and sample 3 had an IP equal to 10.42 h. Therefore, sample 1 showed a lower oxidative stability compared to sample 2 and sample 3, which may be due to the natural oxidation of the sample. However, the three samples studied exhibited IP longer than sunflower oil free from antioxidants (1.10 h) and sunflower oil with addition of 0.5 % of the following antioxidants: butylhydroxyanisole, butylated hydroxytoluene, and tertiary butyl hydroquinone with 2.30, 3, and 6.30 h, respectively [36]. Fig. 2 shows the overlapped curves of the three samples P. macroloba oil analysed. Taking into consideration the ANP No. 14/2012, the samples have an acceptable oxidative stability because according to the standard minimum at least 6 h of testing are required.

Comparing the results of crude of P. macroloba oil with other oils described in the literature as Canola oil (7.15 h), corn (10.22 h), soybean (12.55 h), macadamia (17 h), and Pistachio (20 h) the results demonstrated that the analysis of each different oil show that the chemical composition of the vegetable oil influences its oxidative stability, and consequently on the stability of the final product made from this oil [23, 36–38].

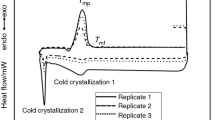

Thermal analysis

The TG–DTG and DTA shown in Figs. 3, 4 5 represent the thermal behavior of the three samples. According to the TG–DTG curve, it was observed a ramp of thermal stability of the oil to about 220 °C. Until that temperature the mass loss corresponds to the removal of water, moisture, and volatile substances probably fatty acids with 12–16 carbons in the chain; above this temperature, the thermal decomposition of the sample occurs, which, based on the DTA curve presents two to three endothermic events at 330, 440, and 540 °C, surely events such as melting, boiling, and combustion of the samples. At this range of temperature it is where the majority of mass loss occurs, around 98 %, probably long-chain fatty acids. The thermal stability of the oil was determined by the temperature range in which the mass remained unchanged. Observing the DTG curves of the three samples, the presence of a main peak of decomposition is seen, which showed temperature in the range 430–450 °C [16, 20, 21, 36].

The thermal stability of oils can be related to the unsaturation degree of their fatty acids. Typically the greater the number of unsaturations, the lower is the thermal stability. Therefore the oleic, linoleic, and linolenic fatty acids which are present in P. macroloba oil show less thermal stability when compared with lauric, myristic, palmitic, and behenic acids. This could be explained by the lower boiling point of unsaturated fatty acids in relation to their saturated equivalents [39, 40]. The mass loss values are shown in Table 2.

The graph corresponding to DTA curve shows an exothermic peak at the temperature range 400–450 °C. In this temperature range there is a clear phase transition by heat release and decomposition of saturated (C 18:0) and unsaturated (C 18:1, C 18:2 and C 18:3) fatty acids, probably due to the oxidation of the raw material. It is known that within the same species there are certain variations for different weather conditions and period of sample collection. Although the oil samples are from the same source (crude oil which has not been previously treated), these were collected at different periods, therefore, likely to show variation in the concentration of their constituents, which may contribute to increase or decrease the mass loss, showing different behaviors in the thermoanalytical profile of the samples. Therefore the thermal analysis is an important tool for the understanding of thermal stability of vegetable oils, and so aiming at a strict quality control of the raw material [20, 21, 36, 39, 40].

The DTG curve shows two peaks which correspond to the two mass losses of the TG curve. The results obtained by TG–DTG and DTA in an inert atmosphere clearly showed the thermal behavior of the analyzed oil. Using these methods it was possible to determine the stability of this material, which is a determining factor in quality control of oils and fats during processing, storage and industrial use.

Conclusions

The use of instrumental techniques such as infrared spectroscopy, gas chromatography, and thermoanalytical analysis (TG–DTG and DTA) are being widely applied in quality control of vegetable oils. These techniques are fast, efficient, and sensitive presenting many advantages over traditional methods, which sometimes take time, and are subjected to difficulties in viewing the end of the reaction by the analyst.

The techniques that were employed in this study for characterization of Pracaxi oil proved themselves as conclusive in investigating the oxidative stability of the oil composition as well as its thermal stability. Thus, these techniques may be safely used to perform quality control of this kind of oil, and so enabling their application in pharmaceutical and cosmetic industries.

References

Ferreira ES, Silveira, CS, Lucien, VG, Amaral AS. Caracterização físico-química da amêndoa, torta e compostos dos ácidos graxos majoritários do óleo bruto da Castanha do Brasil (Bertholletia excelsa HBK). Alim Nutr Araraquara. 2006;17(2):203–8.

Glória MM, Regitano-D’arce MAB. Concentrado e isolado protéico de torta de castanha do Pará: obtenção e caracterização química e funcional. Ciên Technol Aliment. 2000;20(2):240–5.

Freitas SP, Miranda IC, Coelho MAZ. Extração e fracionamento simultâneo do óleo da Castanha do Brasil com etanol. Ciênc Technol Aliment. 2007;27(suppl):14–7.

Nascimento RJS, Couri S, Antoniassi R, Freitas SP. Composição em ácidos graxos da polpa de açaí extraído com enzimas e com hexano. Rev Bras Frutifera. 2008;30(2):32–6.

Leguminosas da Amazônia-Lista Prévia-Acta bot. bras. 1989;2(1):193–237.

Raven PH, Evert RF, Eichhorn S. Biologia Vegetal. 7a ed. Rio de Janeiro:Guanabara Koogan; 2007.

Lorenzi H. Árvores Brasileiras. vol. 2, 2a edição. Nova Odessa:Instituto Plantarum; 2002.

Chun J, Goodman CL, Rice WC, McIntosh AH, Chippendale GM, Schubert KR. Pentaclethra macroloba seed effect on larval growth cell viability and miggut enzyme activity of Helicoverpa zea. J Econ Entomol. 1994;87(6):1754–60.

Rathburn, HB. Trypsin inhibitor protein from Pentaclethra macroloba having insecticidal properties. International Patent Publication Number: Wo 9719109; 1997.

Lago RCA. Chemical composition of paraocaxi and andiroba oils. Bol Tec Cent Agric Technol Agric Aliment. 1980;14:1–16.

Da Silva JO, Fernandes RS, Ticli FK, Oliveira CZ, Mazzi MV, Franco JJ, Giuliatti S, Pereira OS, Soares AM, Sampaio SV. Triterpenoid saponins, new metalloprotease snake venom inhibitors isolated from Pentaclethra macroloba. Toxicon. 2007;50(2):283–91.

Santiago GMP, Viana FA, Pessoa ODL, Santos RP, Pauliquen YBM, Arriaga AMC, Andrade-Neto M, Braz-Filho R. Avaliação da atividade larvicida de saponinas triterpênicas isoladas de Pentaclethra macroloba (Willd.) Kuntze (Fabaceae) e Cordia piauhiensis Fresen (Boraginaceae) sobre Aedes aegypti. Brazilian. J Pharmacogn. 2005;15(3):187–90.

Da Silva JO, Coppede JS, Fernandes VC, Sant’Ana CD, Ticli FK, Mazzi MV, Giglio JR, Pereira PS, Soares AM, Sampaio SV. Antihemorrhagic, antinucleolytic and other antiophidian properties of the aqueous extract from Pentaclethra macroloba. J Ethnopharmacol. 2005;100:145–52.

Freire RMM, Santos RC, Lima LM, Costa BJ, Zagonel GF. Amendoim: da mesa ao biodiesel. Embrapa Algodão—Folderes/Folhetos/Cartilhas (INFOTECA-E). Campina Grande—PB; 2010.

Novello D, Franceschini P, Quintiliano DA. A importância dos ácidos graxos omega 3 e omega 6 para a prevenção de doenças e na saúde humana. Rev Salus-Guarapuava-PR. 2008;2(1):45–54.

Baby AR, Maciel COM, Santos IMNS, Dias TCS, Kaneko TM, Consiglieri VO, Velasco MVR. Uso de extratos de plantas em produtos cosméticos. Cosmet Toilet. 2005;17(1):78–82.

Veiga-Junior VF, Pinto AC. Plantas medicinais: Cura segura? Rev Quím Nova. 2005;28(3):519–28.

Fonseca MM, Yoshida MI. Análise térmica do óleo de linhaça natural e oxidado. Vértices. 2009;11(3):61–75.

Alves TGV, Tavares EJM, Aouada FA, Negrão CAB, Oliveira MEC, Duarte Junior AP, Da Costa CEF, Silva Junior JOC, Ribeiro Costa RM. Thermal analysis characterization of PAAm-co MC hydrogels. J Therm Anal Calorim. 2011;106:717–24.

Costa RS, Negrão CAB, Camelo SRP, Ribeiro Costa RM, Barbosa WLR, Da Costa CEF, Silva Junior JOC. Investigation of thermal behavior of Heliotropium indicum L. lyophilized extract by TG and DSC. J Therm Anal Calorim. 2011;91(2):434–7.

Costa RS, Camelo SRP, Ribeiro-Costa RM, Barbosa WLR, Vasconcelos F, Silva Junior JOC. Physical, chemical and physical-chemical control of Heliotropium indicum Linn., boraginaceae, powder and tinture. IJPSR. 2011;2(8):2211–6.

Garcia CC, Franco PIBM, Zuppa TO, Antoniosi Filho NR, Leles MIG. Thermal stability studies of some Cerrado plant oils. J Therm Anal Calorim. 2007;87(3):645–8.

Ferrari RA, Souza WL. Avaliação da estabilidade oxidativa de biodiesel de óleo de girassol com antioxidantes. Rev Quím Nova. 2009;32(1):106–11.

Veiga-Junior VF, Patitucci ML, Pinto AC. Controle de autenticidade de óleos de copaíba comerciais por cromatografia gasosa de alta resolução. Rev Quím Nova. 1997;20(6):72–8.

American Oil Chemists Society. Official methods and recommended practices of the American Oil Chemists Society. 4th ed. Champaign: A.O.C.S. Official Method Ce 1-62; 1995.

American Oil Chemists Society. Official methods and recommended practices of the American Oil Chemists Society. 4th ed. Champaign: A.O.C.S. Official Method Ce 2-66; 1995.

Alves OL. Espectroscopia no Infravermelho com Transformada de Fourier: Feliz Combinação de Velhos Conhecimentos de Óptica, Matemática e Informática. Laboratório de Química do Estado Sólido (LQES). Instituto de Química. UNICAMP. Disponível em:<http:\\lqes.iqm.unicamp.br>. Acesso em: 02 Nov. 2012.

Takemoto E, Okada IA, Garbelloti ML,Tavares M, Aued-Pimentel S. Composição química da semente e do óleo de baru Dipterys olata Vog. Nativo do município de Pirenopólis, estado de Goiás. Revista Adolfo Lutz. 2001;60(2):89–97.

Organização Pan-Americana da Saúde (OPAS). Higiene dos Alimentos—Textos Básicos/Agência Nacional de Vigilância Sanitária; Food and Agriculture Organization of the United Nations: Brasília; 2006.

Albuquerque MLS, Guedes I, Alcântara P Jr, Moreira SGC. Infrared absorption spectra of Buriti (Mauritia flexuosa L.) oil. Vib Spectrosc. 2003;33:127–31.

Stuart BH. Infrared spectroscopy: fundamentals and applications. Hoboken: Wiley; 2005.

Pimentel MF, Ribeiro GMGS, Cruz RS, Stragevitch L, Pacheco Filho JGA, Teixeira LSG. Determination of biodiesel content when blended with mineral diesel fuel using infrared spectroscopy and multivariate calibration. Microchem J. 2006;82:201–6.

Oliveira JS, Montalvão R, Daher L, Suarez PAZ, Rubim JC. Determination of methyl ester contents in biodiesel blends by FTIR–ATR and FTNIR spectroscopies. Talanta. 2006;69:1278–84.

Aliske MA, Zagonel GF, Costa BJ, Veiga W, Saul CK. Measurement of biodiesel concentration in a diesel oil mixture. Fuel. 2007;86:1461–4.

Sherazi STH, Kandhro A, Mahesar AS, Bhanger MI, Talpur MY, Arain S. Application of transmission FT-IR spectroscopy for the trans fat determination in the industrially processed edible oils. Food Chem Oxf. 2009;114:323–7.

Pardauil JJR, Souza LKC, Molfetta FA, Zamian JR, Rocha Filho GN, Da Costa CEF. Determination of the oxidative stability by DSC of vegetable oils from the Amazonian area. Bioresour Technol. 2011;102:5873–7.

Arain S, Sherazi STH, Bhanger MI, Talpur FN, Mahesar SA. Oxidative stability assessment of Bauhinia purpurea seed oil in comparison to two conventional vegetable oils by differential scanning calorimetry and Rancimat methods. Thermochim Acta. 2009;484:1–3.

Souza DFS, Antoniassi R, Freitas SC, Bizzo HR. Estabilidade oxidativa dos óleos de macadâmia e de Pistache. Bol CEPPA. 2007;25(1):58–63.

Szabo M-R, Chambre D, Iditoiu C. TG/DTG/DTA for the oxidation behavior characterization of vegetable and animal fats. J Therm Anal Calorim. 2012;110:281–5. doi:10.1007/s10973-012-2253-2.

Garcia CC, Franco PIB, Zuppa TO, Antoniosi Filho, NR, Leles MIG. Thermal stability studies of some Cerrado plants oils. J Therm Anal Calorim. 2007;87(3):645–48.

Acknowledgements

The author thanks the Research Support Foundation of the State of Pará (FAPESPA), the Research and Development Foundation (FADESP) and Dean of Graduate Studies and Research (PROPESP/UFPA).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

dos Santos Costa, M.N.F., Muniz, M.A.P., Negrão, C.A.B. et al. Characterization of Pentaclethra macroloba oil. J Therm Anal Calorim 115, 2269–2275 (2014). https://doi.org/10.1007/s10973-012-2896-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-012-2896-z